SiC whisker synergistic silicon nitride particle toughened alumina-based ceramic cutter material and preparation process thereof

A tool material and preparation technology, applied in the field of new materials, can solve the problems of reducing the service performance of ceramic tools, alloy tools are incomparably huge, and are prone to brittle damage, and achieve superior comprehensive performance, excellent high-temperature mechanical properties, and high processing matching sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

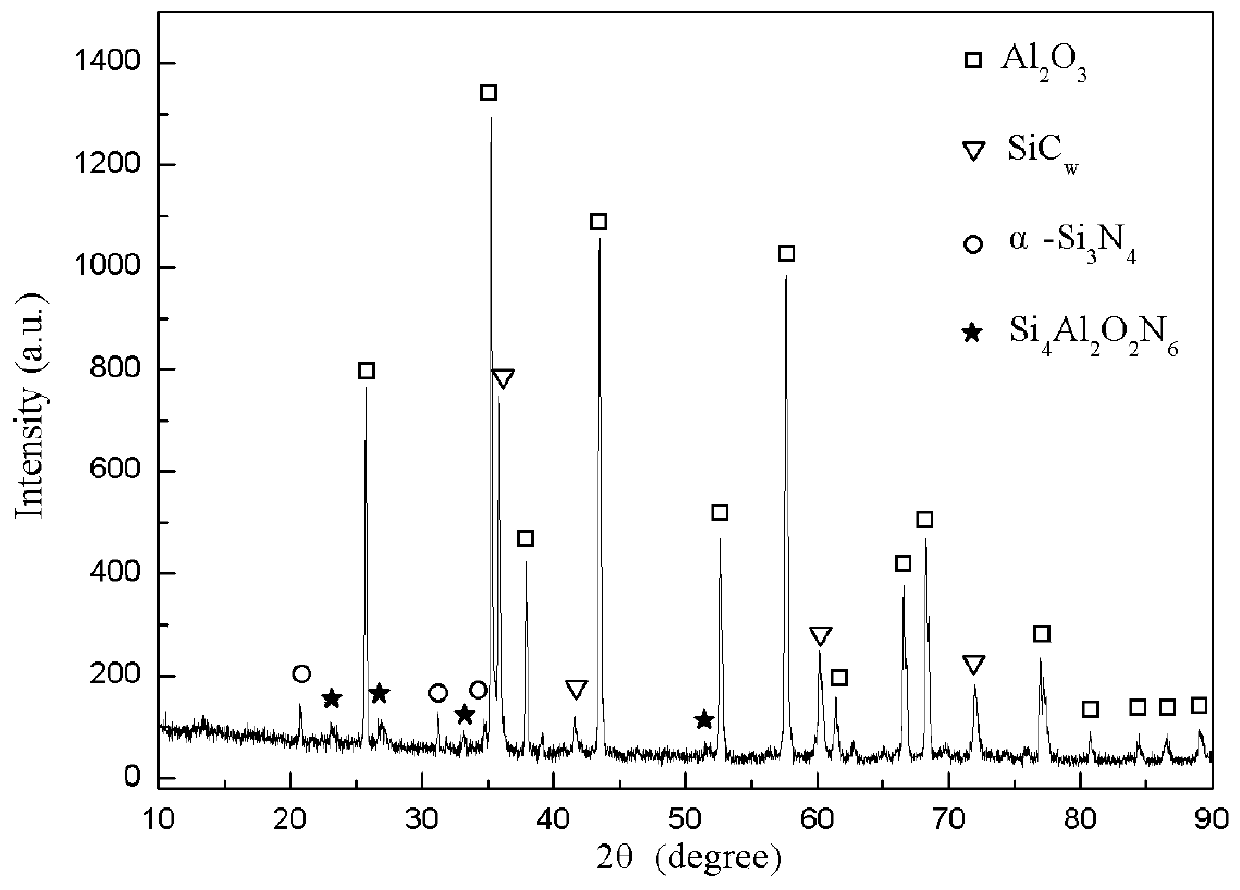

Embodiment 1

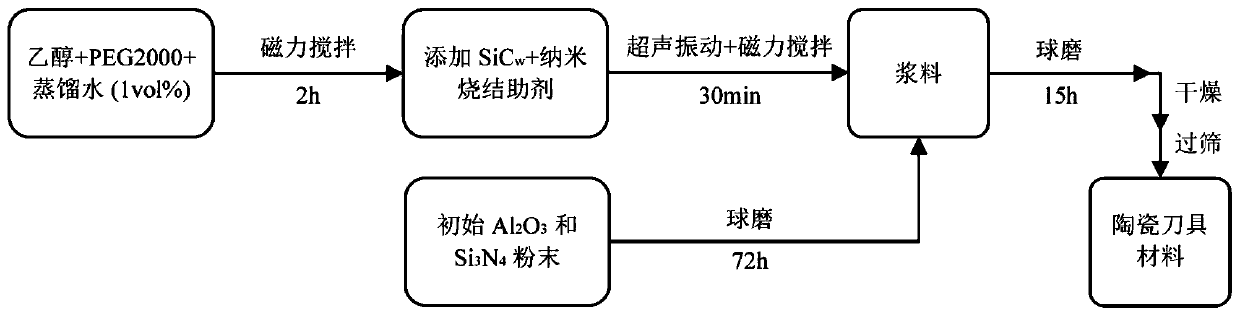

[0048] SiC whiskers synergistically with Si 3 N 4 Particle toughened Al 2 o 3 Base ceramic cutting tool material and its preparation process, the main steps are as follows:

[0049] (1) Weighing: Weigh 62.5% Al according to the volume fraction 2 o 3 powder, 20% SiC w Powder, 15% Si 3 N 4 Powder, 1.5% Y 2 o 3 powder, 1% CeO 2 and La 2 o 3 Mixed powder (CeO 2 Powder and La 2 o 3 Powder volume ratio is 1:1).

[0050] (2) Dispersion: 297mL of ethanol (99vol%), 3mL of distilled water (1vol%) and 0.2g of PEG2000 were prepared into a dispersion liquid, and the dispersion liquid was adjusted to an alkaline environment (pH=9) with ammonia water, and magnetically stirred for 3 hours. SiC w Powder, Y 2 o 3 Powder, CeO 2 and La 2 o 3 The mixed powder was added into the dispersion liquid, and dispersed for 2 hours with an ultrasonic cleaner and a mixer to form a uniform slurry.

[0051] (3) Ball milling: the Al obtained after slurry and ball milling for 72 hours 2 o...

Embodiment 2

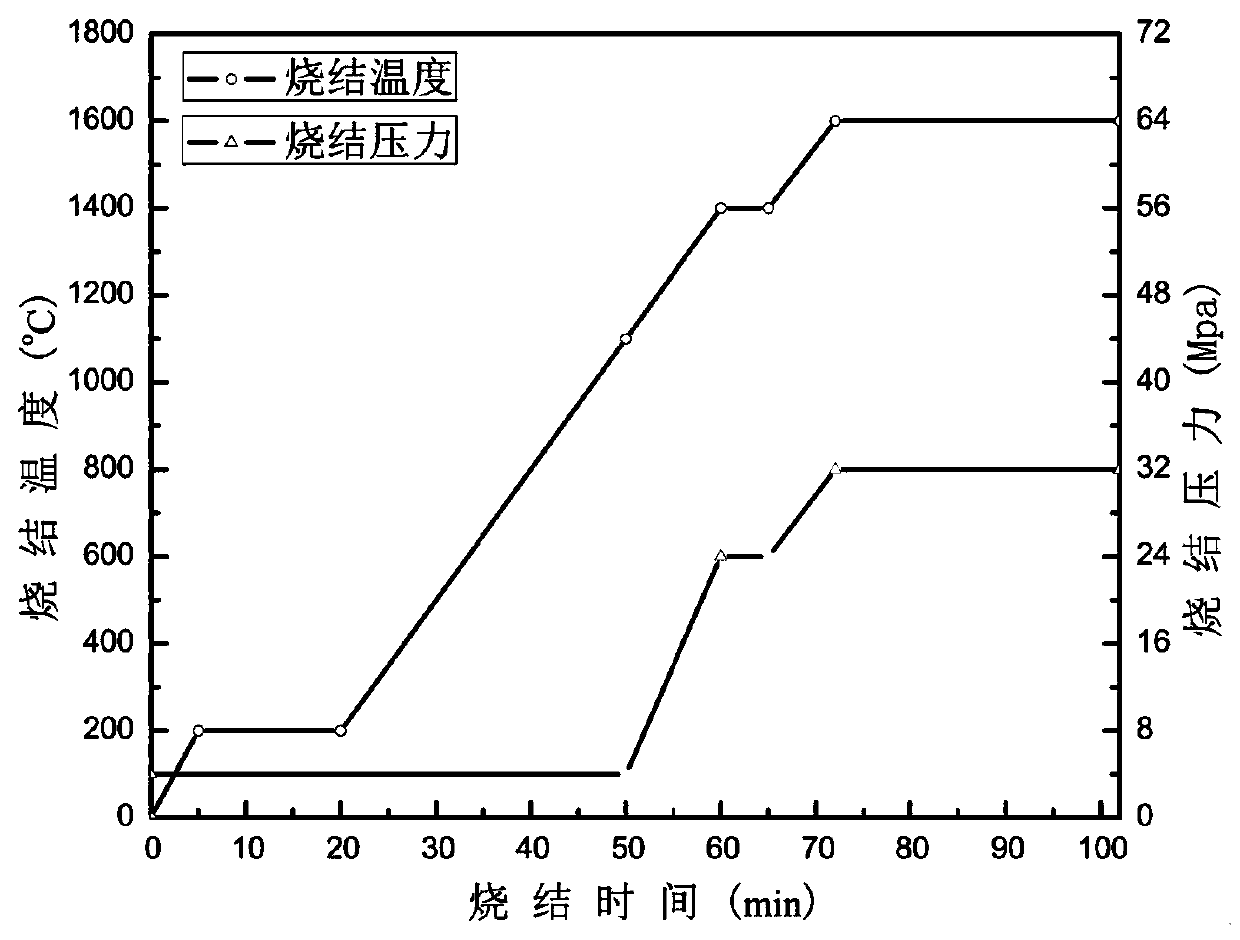

[0057] This embodiment is the same as Embodiment 1, except that the final temperature of vacuum hot pressing sintering is 1550°C.

Embodiment 3

[0059] This embodiment is the same as Embodiment 1, except that the final temperature of vacuum hot pressing sintering is 1600°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com