Machining method through ceramic blades

A processing method and blade technology are applied in the accessories of tool holders, metal processing equipment, and tools for lathes, etc., to achieve the effect of saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

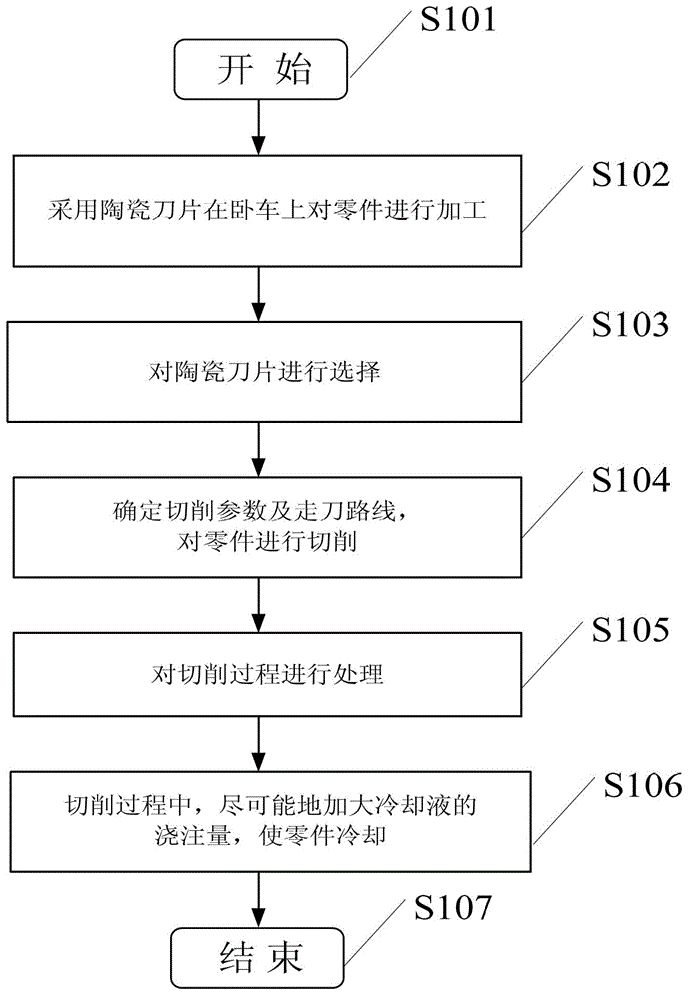

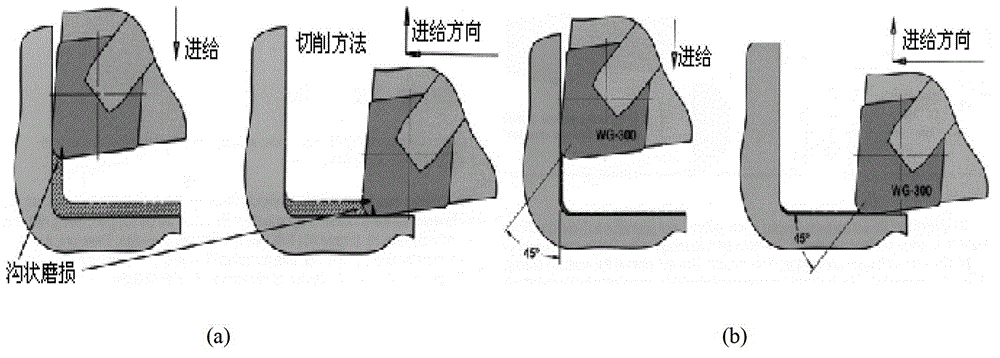

[0038] The embodiment of the present invention provides a kind of processing method that adopts ceramic blade, and its flow process is as follows figure 1 shown. The process starts at step 101 . In step 102, when the superalloy is difficult to machine, for example, when the cutting temperature is greater than or equal to 600°C, ceramic inserts are used to machine the part on a lying lathe. Materials suitable for processing ceramic blades include: high-hardness quenched steel with a hardness of Hc45-65; nickel-based and cobalt-based superalloys; high-hardness Hc45-65 cast iron materials; stainless steel, mold steel, and welds. Ceramic tools are not suitable for processing titanium alloys. Due to the low ignition point of titanium elements, if ceramic tools are used to cut titanium alloys, spontaneous combustion of waste chips may occur; in add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com