Method for parallel light directly beaming parallel light or focusing light and high-energy high stream intensity device

A technology of parallel light and focused light, which is applied in solar energy concentration methods and devices, and in the field of optics. It can solve the problems of size, weight, and process that are difficult to achieve high energy, long-distance transmission, and restrictions on the large-scale and effective use of solar energy. Simple, optical surface shapes for simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

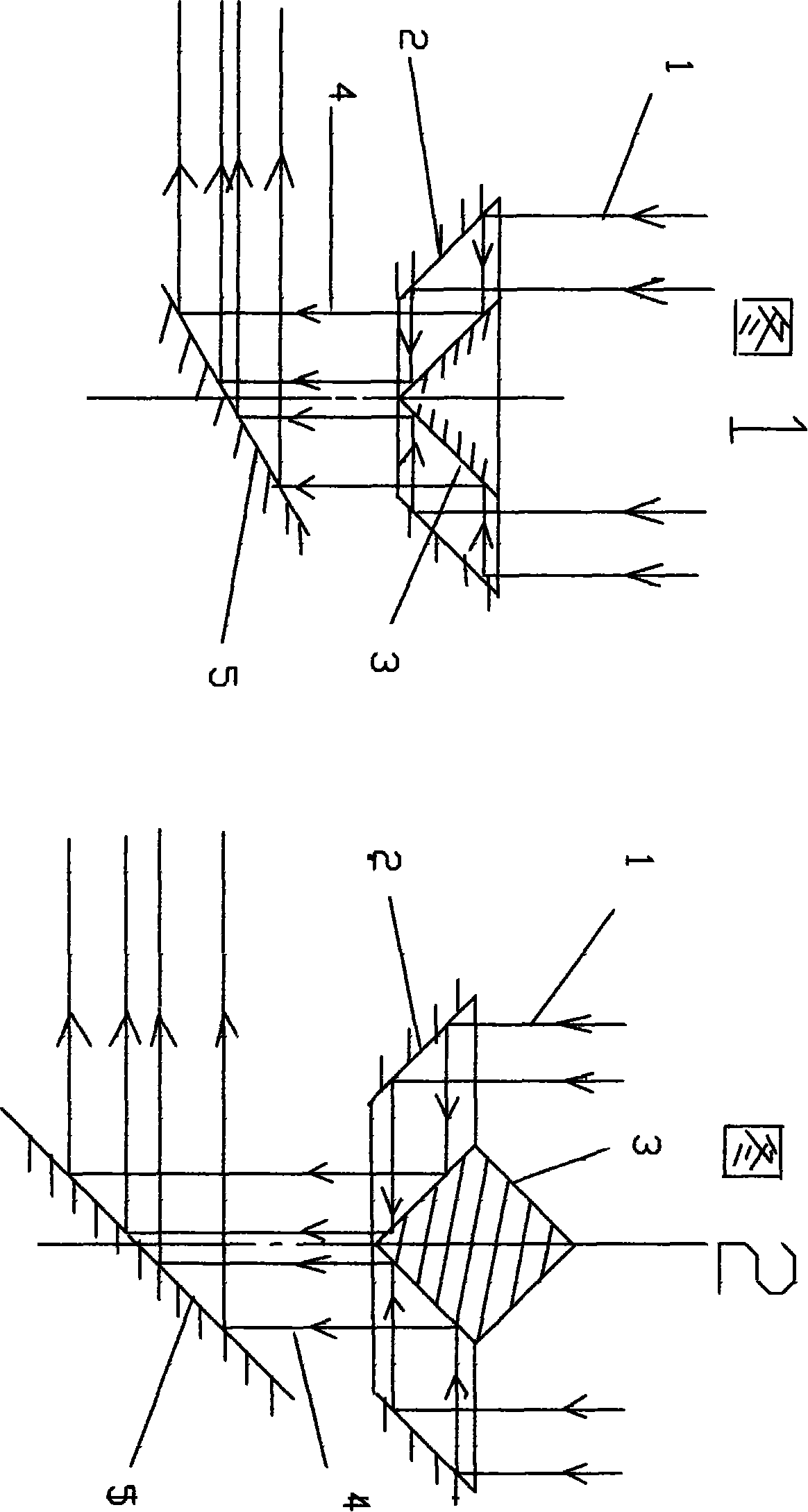

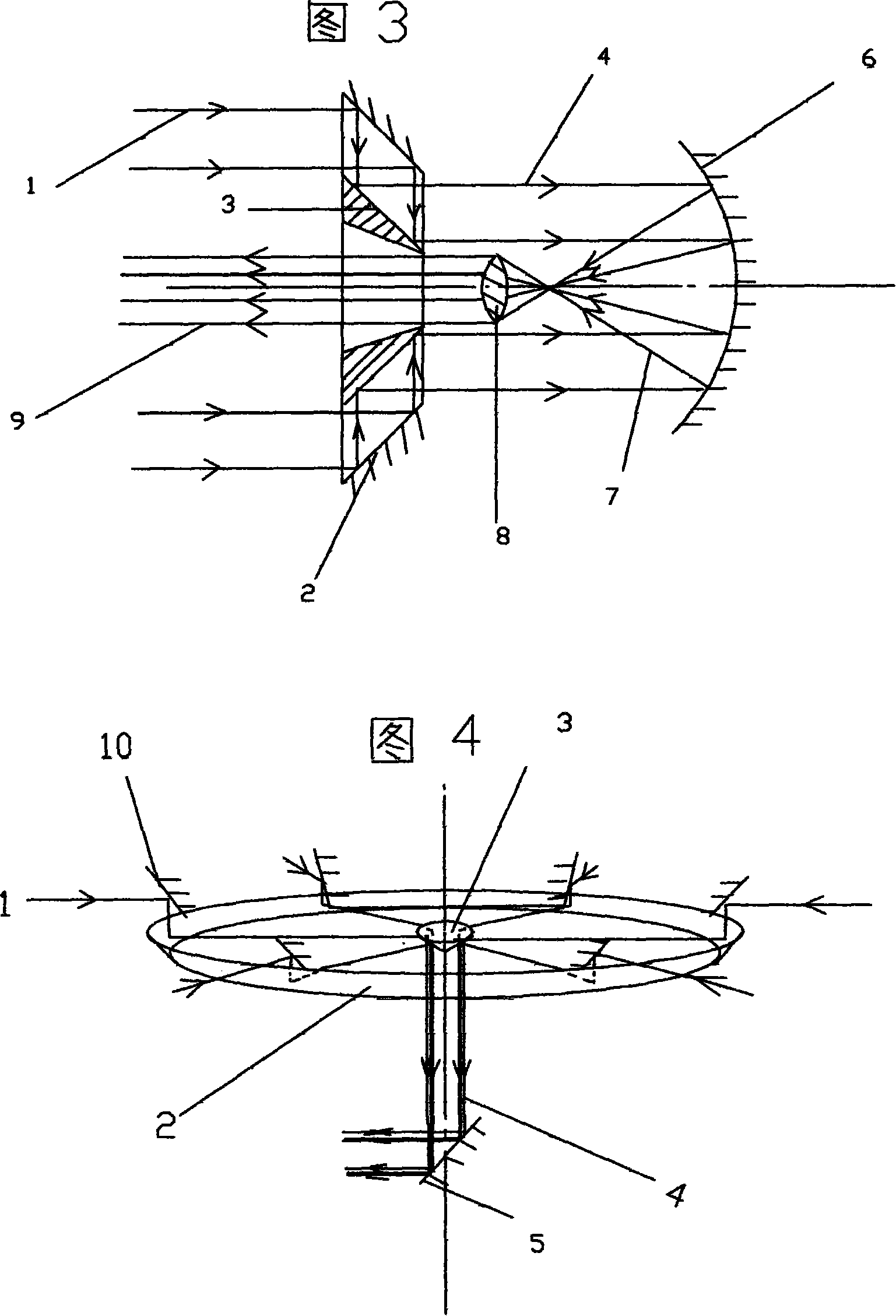

[0043] As shown in Figure 1, the present invention uses the inner surface of the outer cone 2 to reflect the sunlight 1 incident along the axis onto the outer surface of the inner cone 3, and then reflects and bundles it directly into parallel light or focused light 4 for output. The output direction is the same as the incident direction In the same way, the output and output transmission direction of the system is sent to the user through the control of the plane reflector.

Embodiment 2

[0045] As shown in Figure 1, the present invention adopts the inversion of the inner cone 3 and the other conditions remain unchanged. The sunlight 1 incident along the axis is reflected by the reflective surface of the outer cone 2 to the reflective surface of the inner cone 3 to reflect and directly gather parallel light or focused light output, and the output direction is the same as that of the focused light. The input direction is opposite, and the output transmission direction system is sent to the user through the plane reflector control system.

Embodiment 3

[0047]As shown in Figure 2, the present invention uses double cones to replace the inner cone 3 in Figure 1 to increase the system for controlling the movement of the double cones along the axis. Figure 2 At this moment, the output parallel light or focused light beam 4 of the lower cone that hits the double cone 3 is transmitted downward. When the double cone is moved downward, part of the reflective area that enters the outer cone 2 from the upper part of the double cone 3 is bundled into parallel light or focused When the light is output from the upper side, it is a two-way output. When the double cone 3 continues to move down until the lower part just moves out, there is only an upward reverse output. All output is sent to the user through the plane mirror control output transmission direction system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com