Zero-gap galvanized steel sheet spliced joint laser welding method and system

A galvanized steel sheet, welding system technology, applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of unstable welding process, violent evaporation of zinc layer, spatter on welding surface, etc., to avoid welding Defects, the effect of reducing adjustment time, improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

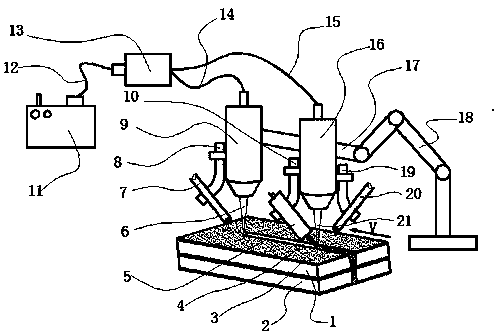

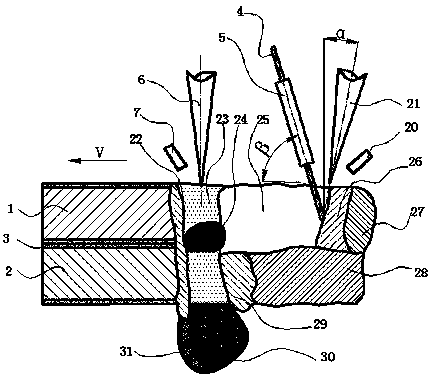

[0036] The following will be combined with figure 1 with 2 The technical solution of the present invention will be described in detail along with specific embodiments.

[0037] Such as figure 1 with 2 As shown, in the embodiment of the present invention, a zero-gap galvanized steel sheet lap joint laser welding method includes the following steps.

[0038] Step 1. Provide the first workpiece 1 and the second workpiece 2 that require lap welding. The first workpiece 1 and the second workpiece 2 are both galvanized steel sheets, which can be formed by mechanical processing. In this embodiment, the thickness of the first workpiece 1 and the second workpiece 2 is 0.8-3 mm.

[0039] Step 2. Remove impurities on the upper and lower surfaces of the first workpiece 1 and the second workpiece 2, and use a welding fixture to accurately stack and clamp the first workpiece 1 and the second workpiece 2 vertically up and down, so that the first workpiece 1 and the second workpiece 2 Cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com