Laser cutting method for printed circuit board and working equipment

A printed circuit board and laser cutting technology, which is applied in laser welding equipment, metal processing equipment, printed circuit components, etc., can solve the problems of complicated process, long cycle, exhaust gas environmental pollution, etc., and achieve the goal of overcoming complicated process and easy absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

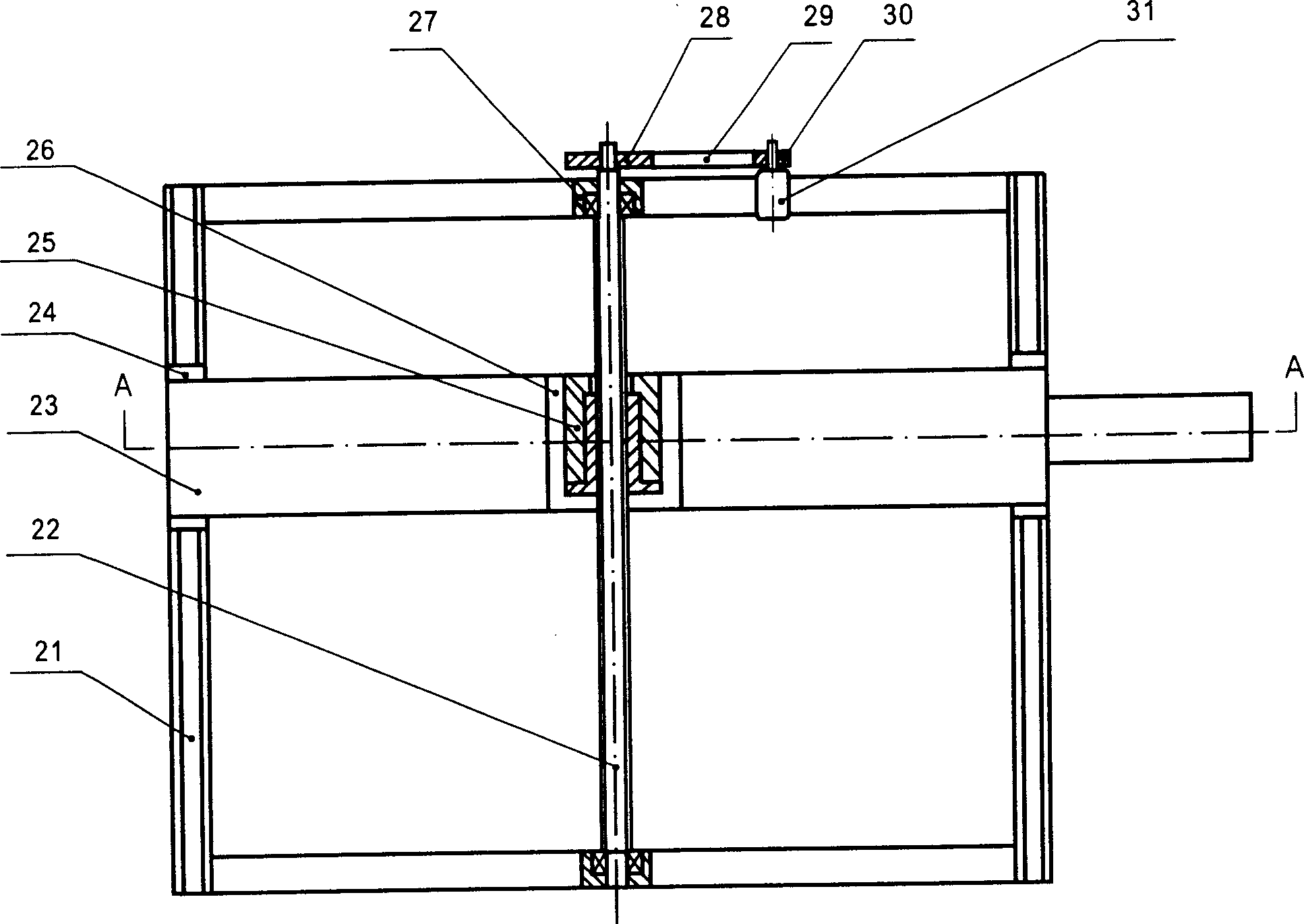

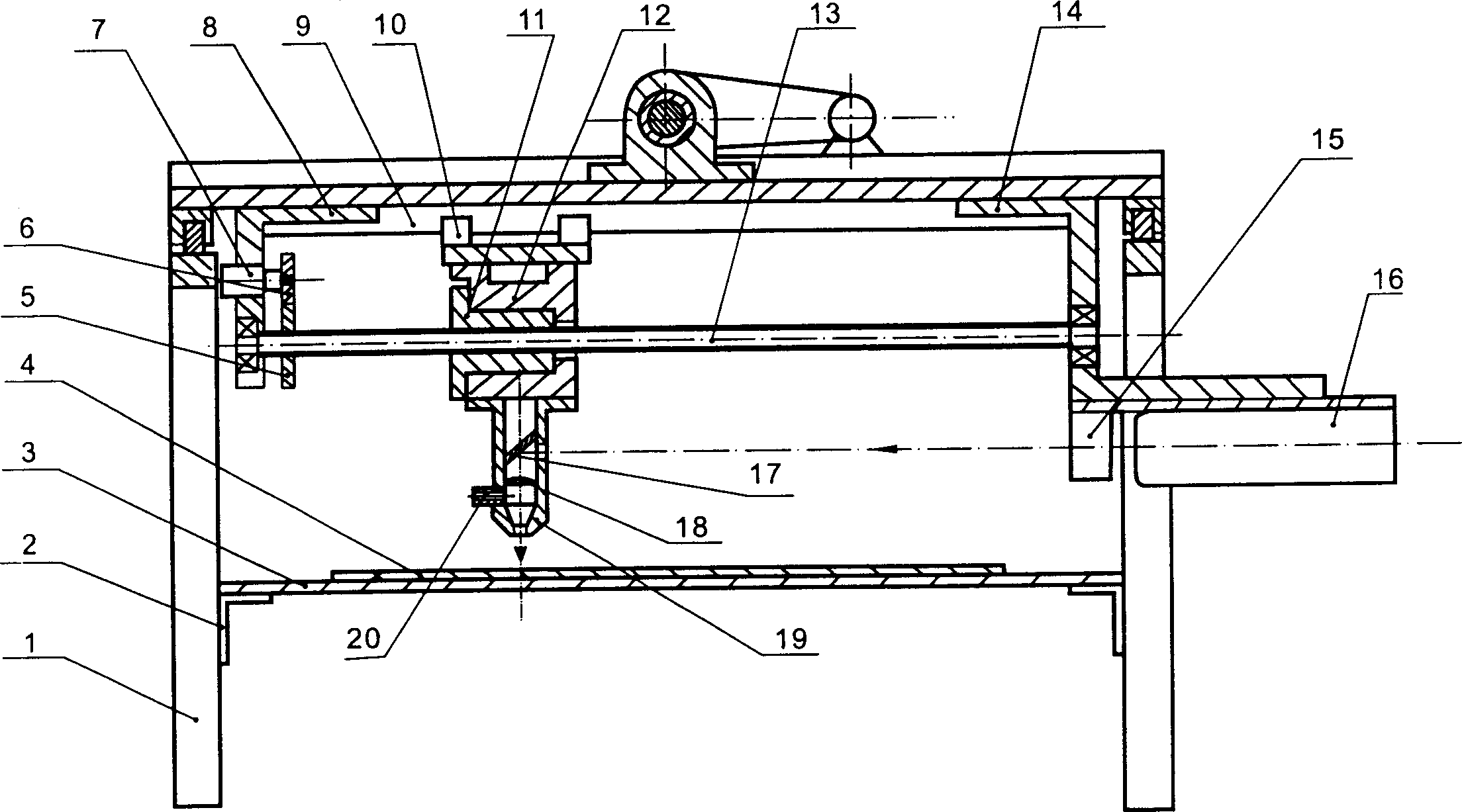

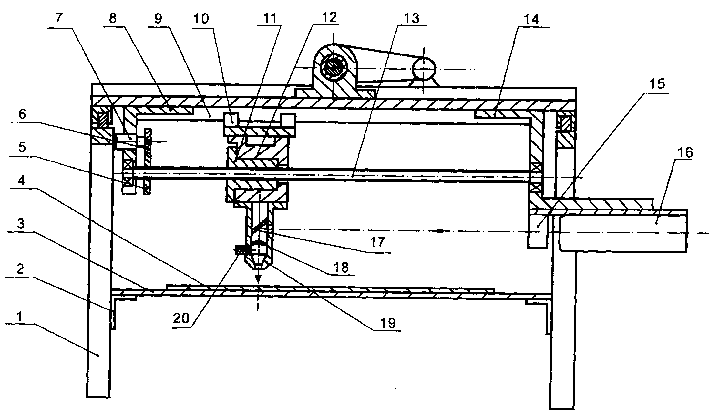

[0018] The processing equipment of the present invention is mainly composed of a frame 1, a longitudinal movement mechanism with a crossbeam 23 placed on the top of the frame 1, a transverse movement mechanism with a YG laser 16 placed on the crossbeam 23, and the like.

[0019] The longitudinal movement mechanism includes two longitudinal guide rails 21 with longitudinal sliders 24 placed on the frame 1 and longitudinal screw rods 22 with longitudinal motors 31, etc., and the crossbeam 23 is placed between the longitudinal sliders 24, and the middle part is provided with longitudinal A longitudinal nut 25 with a longitudinal nut seat 26 engaged by the threaded mandrel 22 , the longitudinal threaded mandrel 22 is rigidly connected with the frame 1 through two bearing seats 27 . Rotate the longitudinal motor 31 installed on the frame 1, through the transmission of the longitudinal driving gear 30, the synchronous belt 29, and the longitudinal passive gear 28, the longitudinal sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

| Laser wavelength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com