Welded joint force-corrosion coupling testing experimental method and welded joint force-corrosion coupling testing experimental device

An experimental device and testing device technology, which is applied in the direction of measuring device, applying stable tension/pressure to test material strength, weather resistance/light resistance/corrosion resistance, etc., can solve the problem that the preset deformation of weld metal and base metal cannot be obtained, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

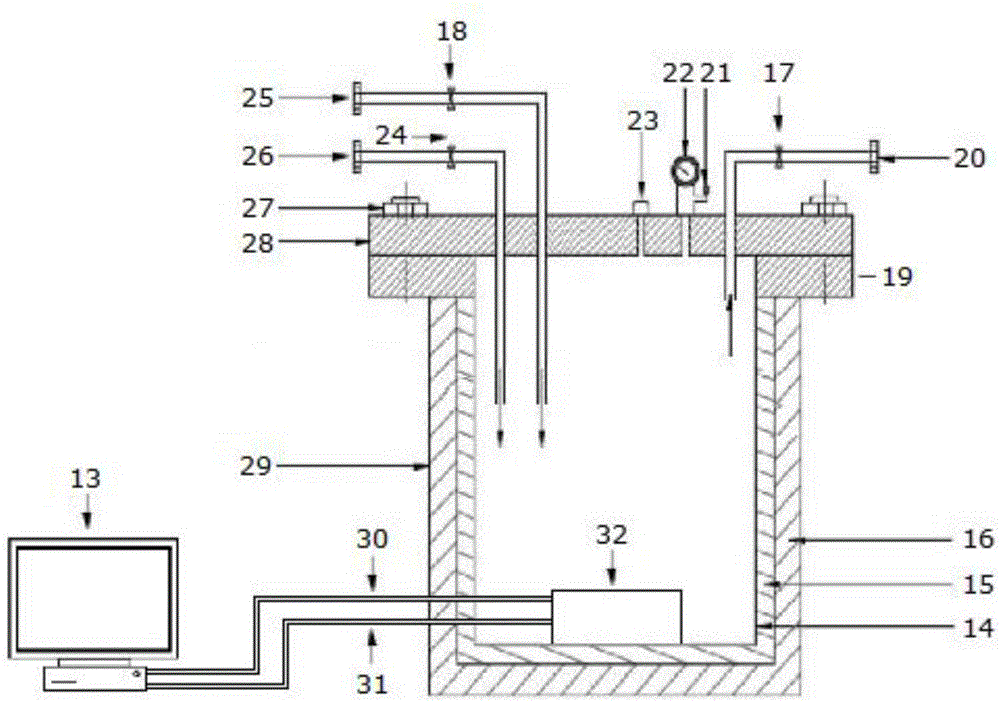

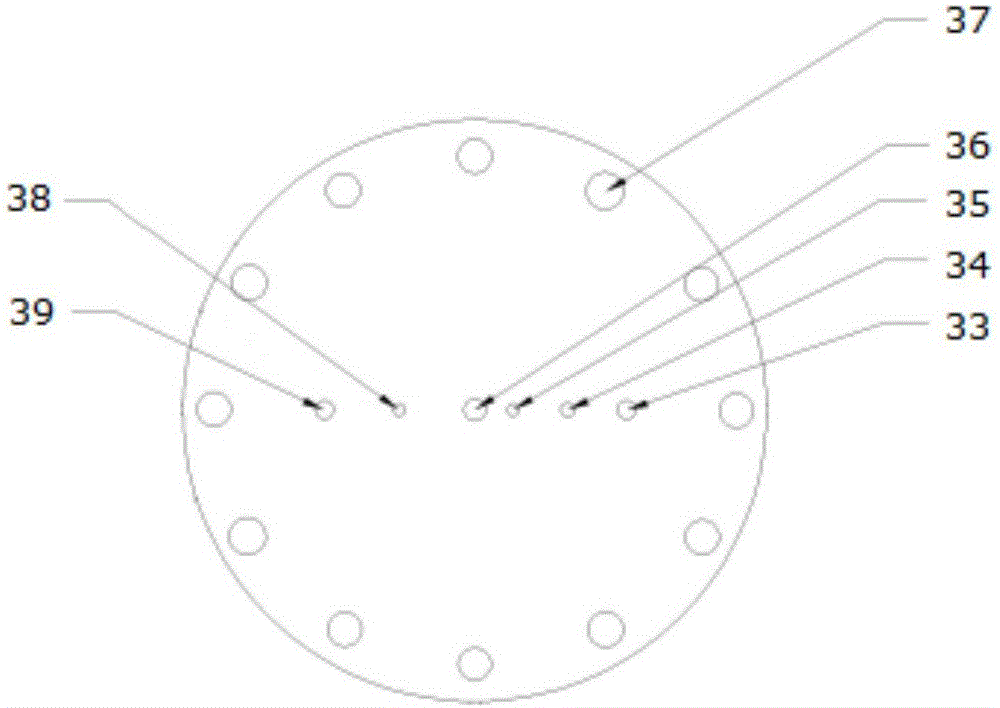

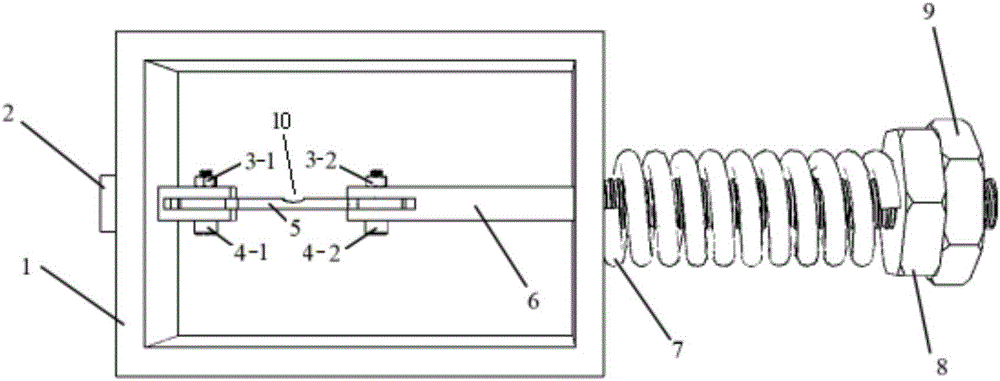

[0024] An experimental device for the coupling test of welded joint force corrosion: the autoclave body is a cylindrical container, a heating device is installed outside the autoclave body, a thermal insulation layer is arranged outside the heating device, and a heat preservation layer is installed on the upper surface of the autoclave body For the autoclave cover, the fastening bolts pass through the fixed installation holes and are connected to the connecting part of the autoclave body, so that the autoclave cover and the autoclave body are fastened into a whole and sealed, and the circular surface of the autoclave cover is arranged in turn along the diameter direction There are: the first air intake pipe hole, the second air intake pipe hole, the feeding hole, the pressure sensor hole and the air outlet pipe hole, wherein the first air intake ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Long axis | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com