Square steel core filling inner sleeve and opposing screw bolt splicing joint and construction method of splicing joint

A technology of piercing bolts and construction methods, which is applied in construction, building structure, and processing of building materials, etc., can solve the problems of complicated design and construction of connecting components, change of outer edge size, insufficient joint stiffness, etc., so as to avoid welding construction waste. Duration, reduction of bulge size, effect of high node stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

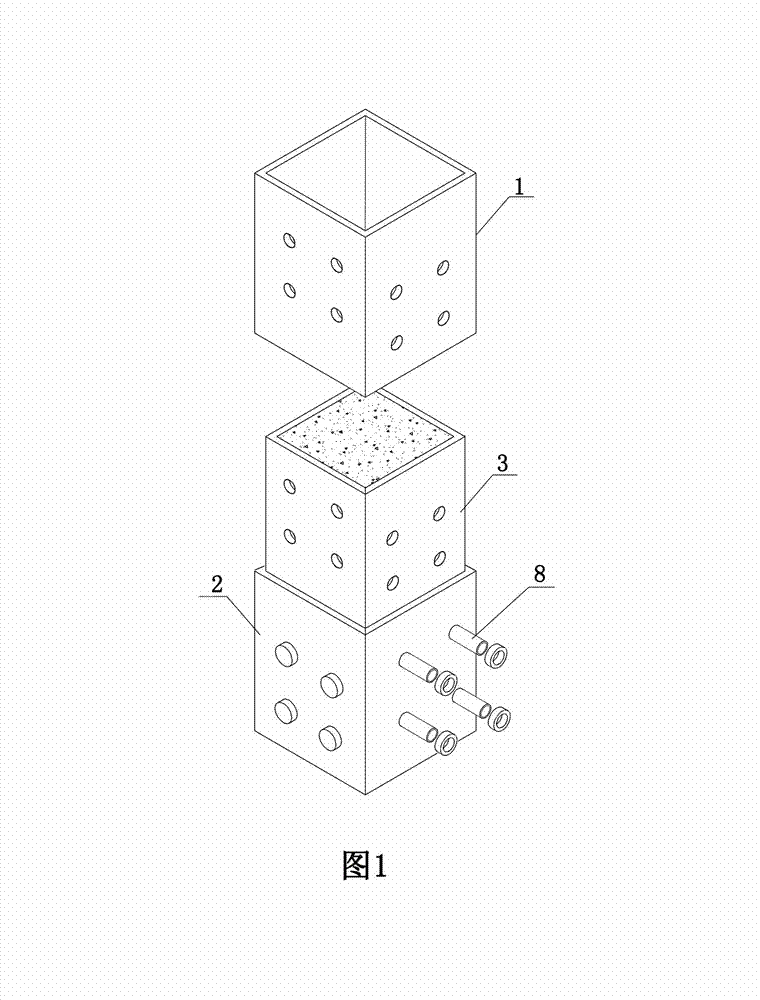

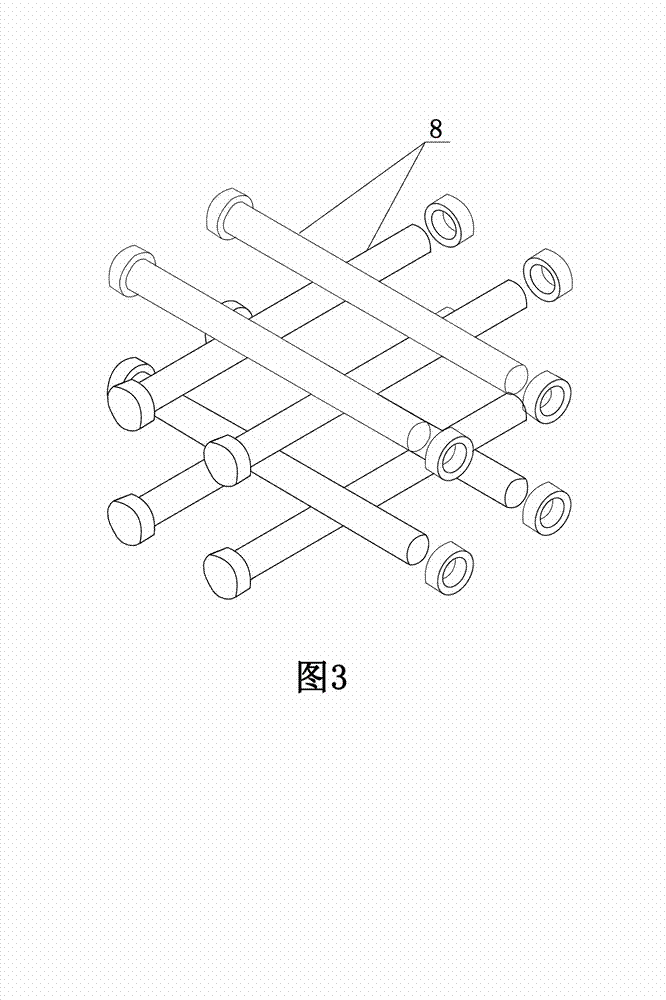

[0035] Examples see figure 1 As shown, the splicing joint of the inner sleeve of the square steel pipe filling core through the bolts includes the upper square steel pipe 1 and the lower square steel pipe 2, and the joint also includes the filling core connected between the upper square steel pipe 1 and the lower square steel pipe 2 Sleeve 3 and through bolt 8.

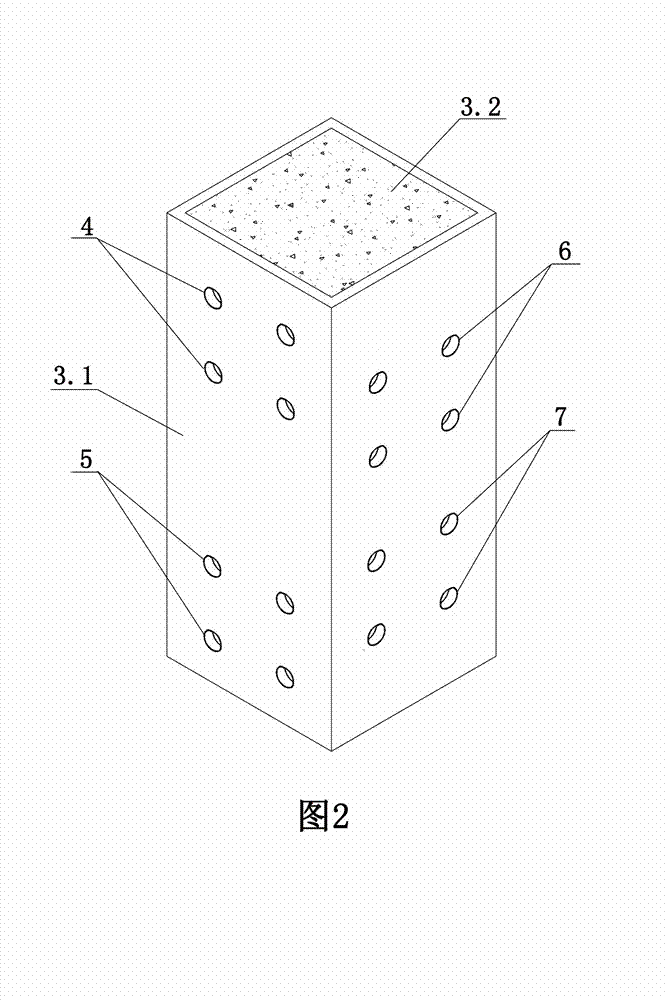

[0036] see figure 2 As shown, the core filling inner sleeve 3 is rectangular columnar, and the inside of the cylinder is poured with concrete. The upper half of the filling core inner sleeve 3 is penetrated with vertically upper bolt holes 4 and horizontally upper bolt holes 6 arranged alternately up and down. Bolt holes 5 in the lower longitudinal section and bolt holes 7 in the lower transverse section run through the lower half of the core-filling inner sleeve 3. The bolt holes 4 in the upper longitudinal section, bolt holes 5 in the lower longitudinal section, bolt holes 6 in the upper transverse section and Bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com