Method for manufacturing holographic mother board by using electroforming imposition

A holographic and mastering technology, applied in the holographic field, can solve problems such as complex process, large influence of human factors, difficult cutting and splicing accuracy, and achieve the effect of high splicing accuracy and fast splicing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

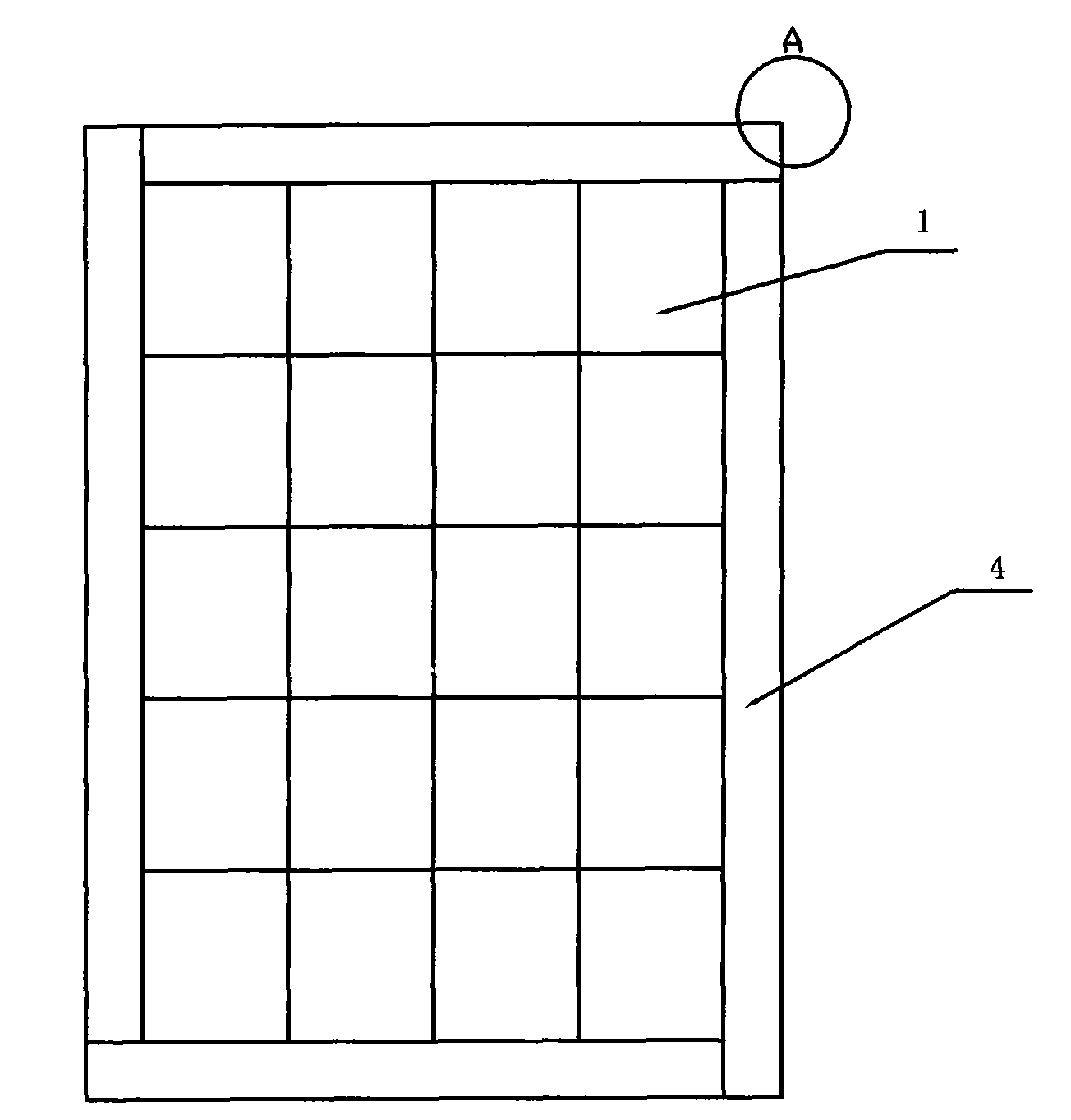

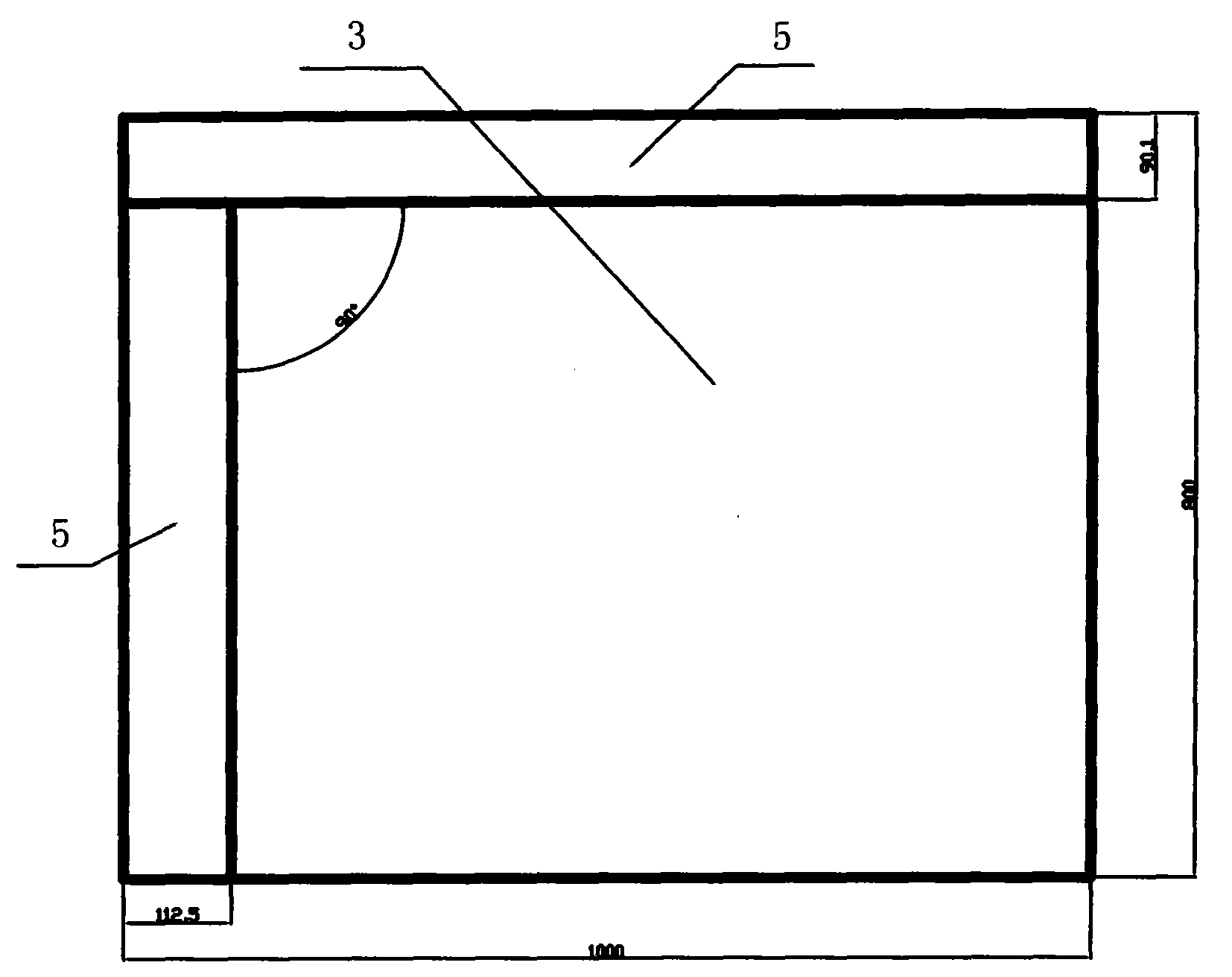

[0029] Example: Making a large-size holographic master of a hologram of a soft-packed cigarette packet

[0030] Task requirements: It is required that the effective molding area of the spliced holographic master is 775×619.8mm, the size of the unit holographic pattern (that is, the small cigarette case) is 155×103.3mm, a total of 30 unit holographic patterns, forming a 5×6 The matrix of the unit holographic graphics, plus the size of the holographic master after the frame is 1000×800mm, the purpose of the frame (trimmed nickel plate) is to meet the requirements of subsequent processes, such as electroforming or molding.

[0031] The manufacturing method is:

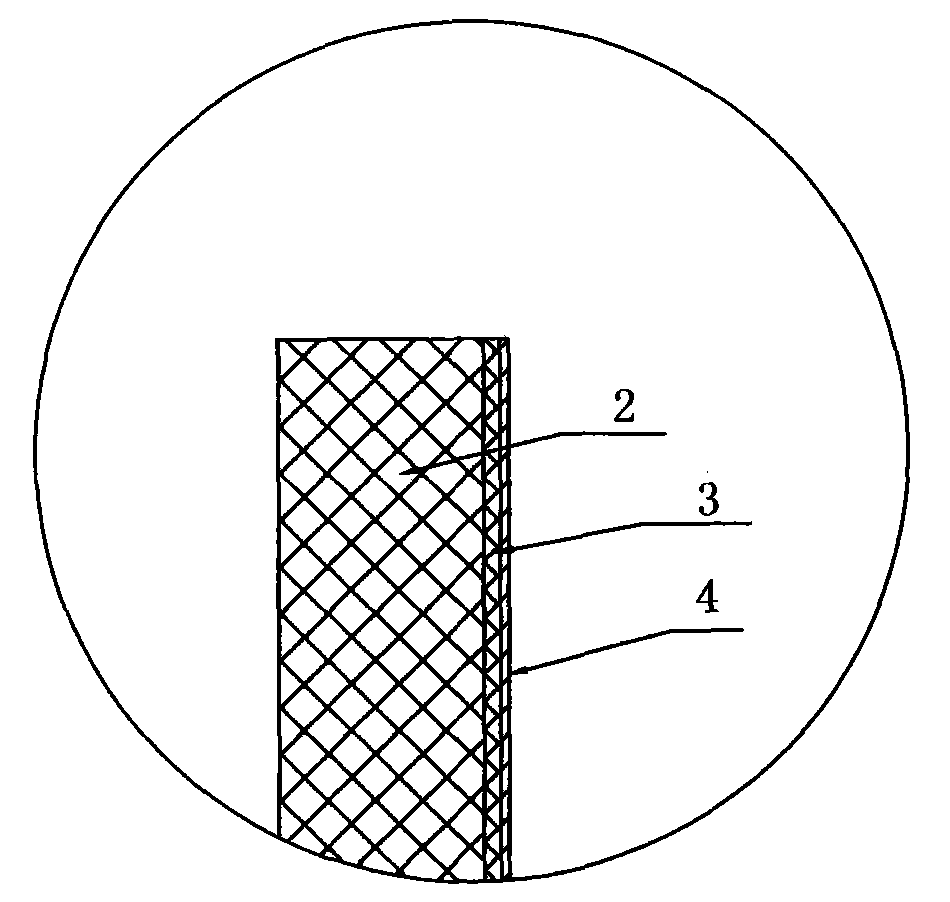

[0032] 1. Copy 30 pieces of holographic patterns (that is, unit holographic patterns) of small cigarette packs by electroforming, that is, copy 30 nickel plates with holographic patterns of small cigarette packs. The thickness of the nickel plates can be selected to be about 55 microns, but each The thickness differe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com