Cable butt joint device

A cable docking and cable connector technology, applied in the direction of connecting/terminating cables, etc., can solve the problems of increasing workload and working time, unreliable connection of intermediate joints, and easy displacement of cables at both ends, and shortening the time. , The effect of reducing manpower consumption and saving material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

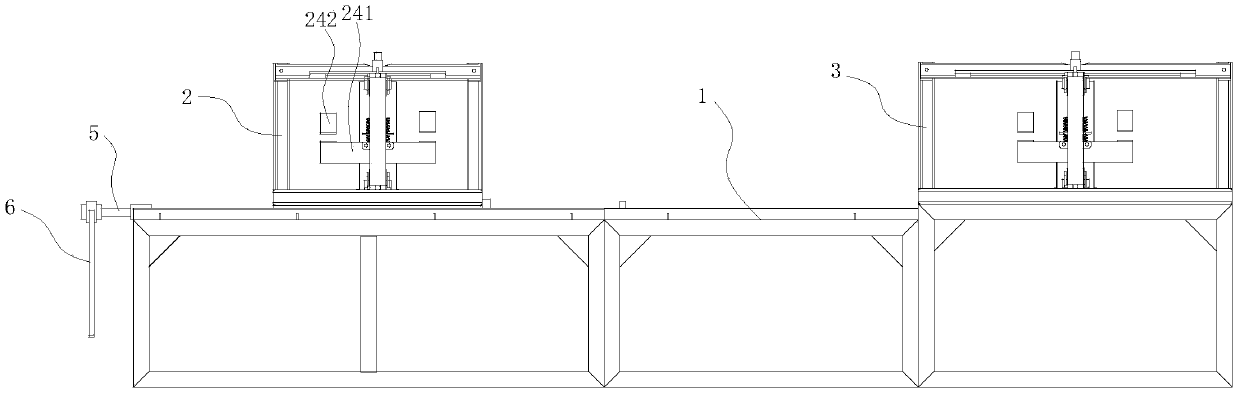

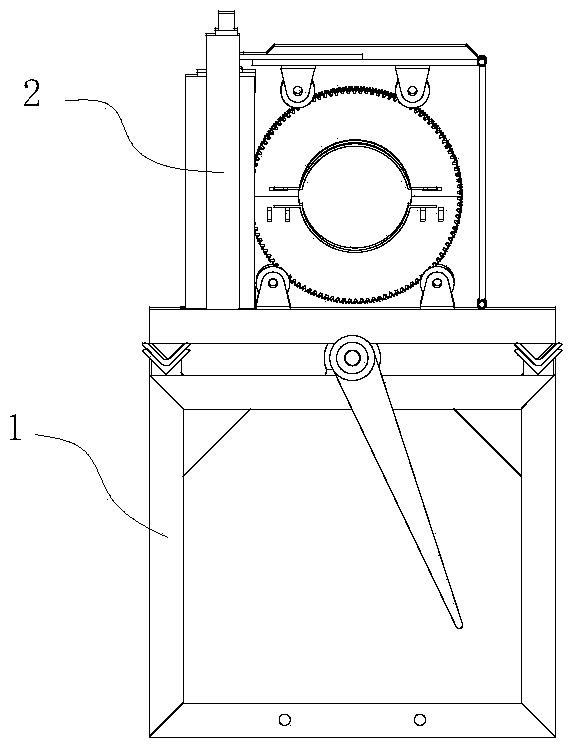

[0027] The present invention as Figure 1-7 As shown, it includes a cable connector 1 2, a cable connector 2 3 and a frame 1, the cable connector 2 is used to connect the butt end of the butt cable 1, and the cable connector 2 3 is used to connect the butt wire The docking end of the cable two, the cable connector one 2 and the cable connector two 3 are respectively arranged at the two ends of the frame 1;

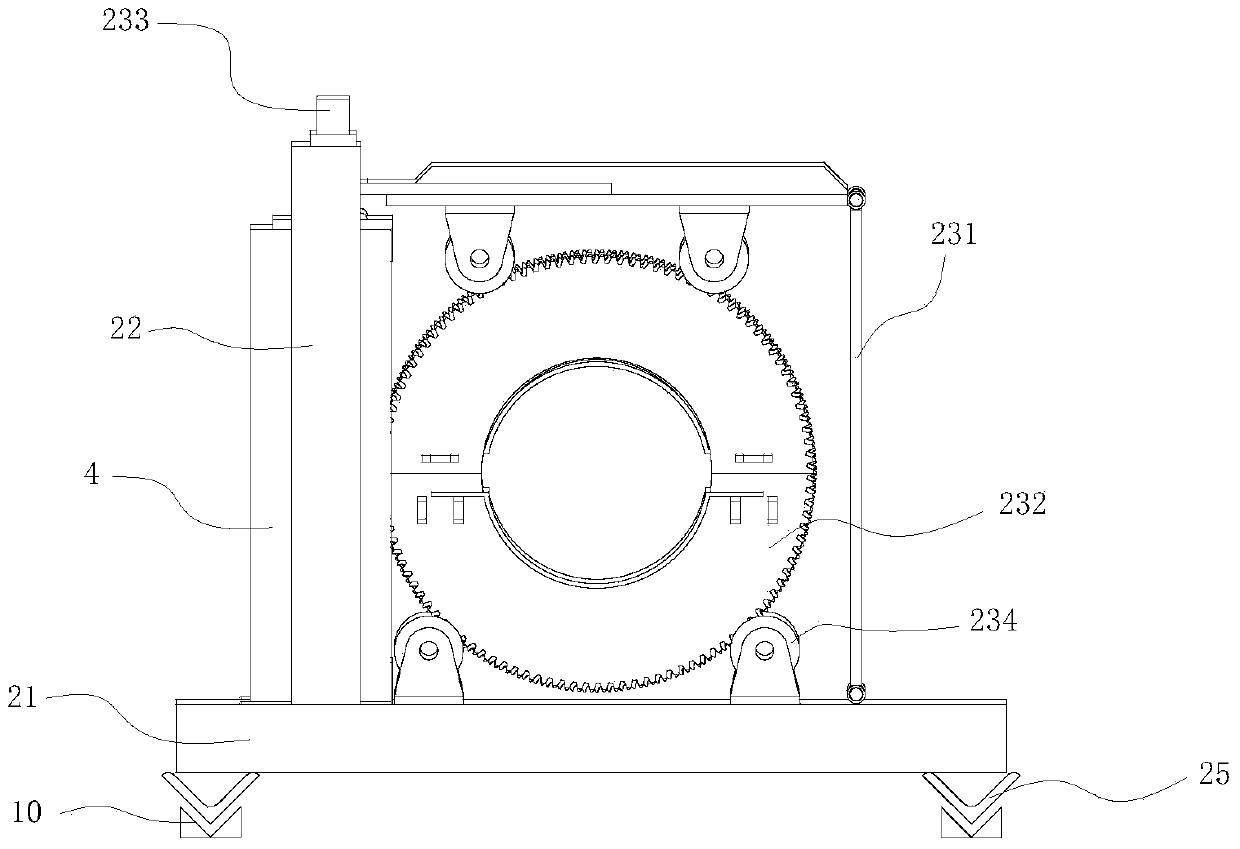

[0028] The first cable connector 2 includes a base 21, a bracket 22, a cable rotation mechanism and a cable fixing mechanism, and the bracket 22 is vertically connected to one side of the base 21,

[0029] The cable rotation mechanism includes a base frame 231, a worm wheel 232, a worm screw 233 and several rollers 234,

[0030] The pedestal 231 is L-shaped, and its two ends are respectively connected to the bottom surface of the base 21 and the top surface of the support 22, and the worm 233 is vertically connected to the base 21 and positioned on the support. 22, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com