Crystallizer-oscillated eccentric mechanism without radial clearance

A crystallizer vibration and eccentric mechanism technology, which is applied in the field of continuous steel casting equipment, can solve problems such as difficult adjustment of eccentricity, and achieve the effects of eliminating radial vibration gap and wear, convenient adjustment, and easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

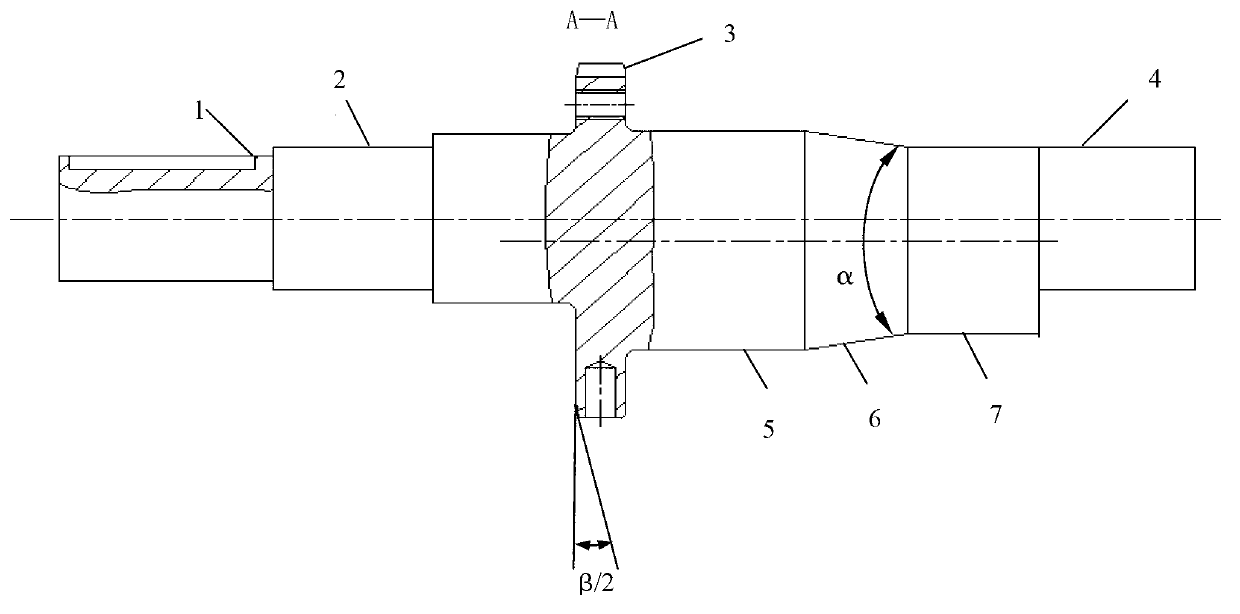

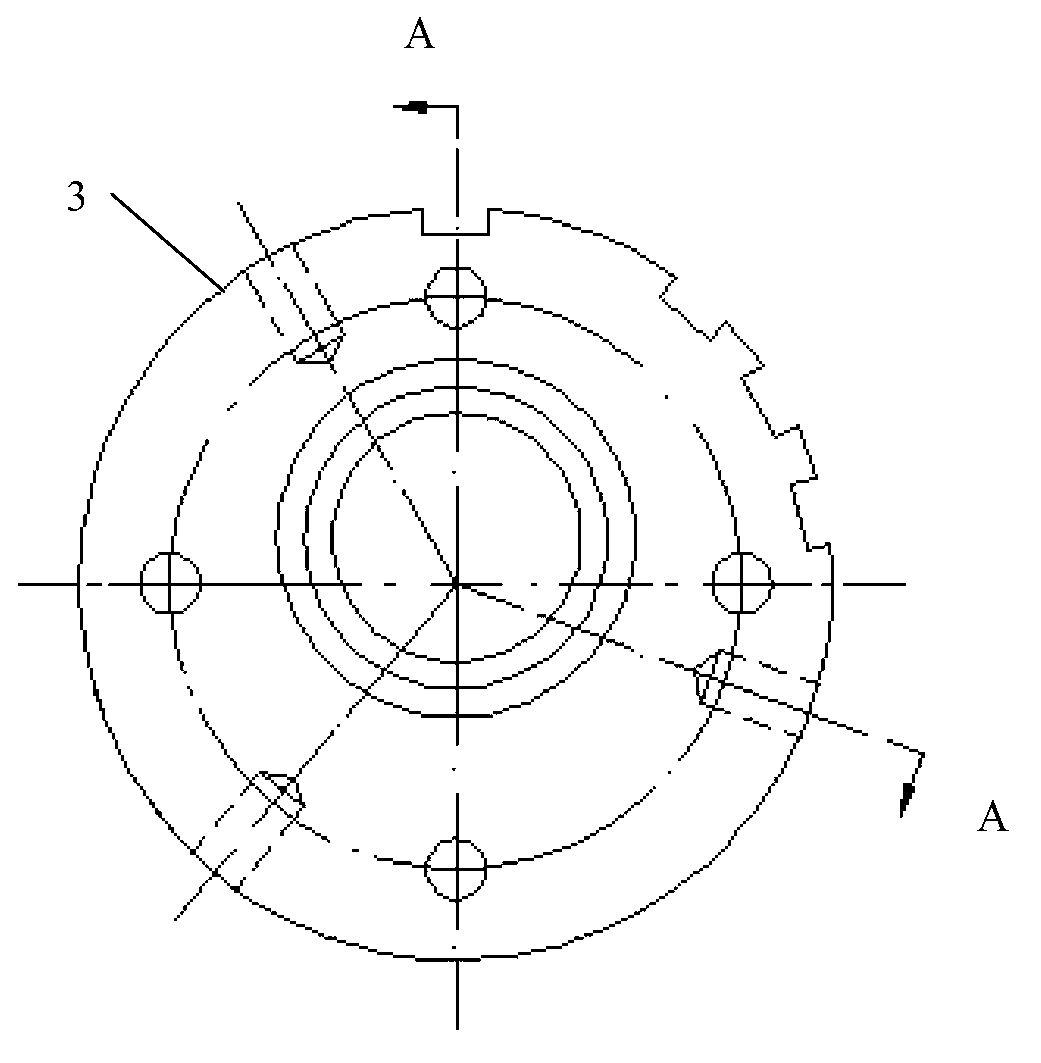

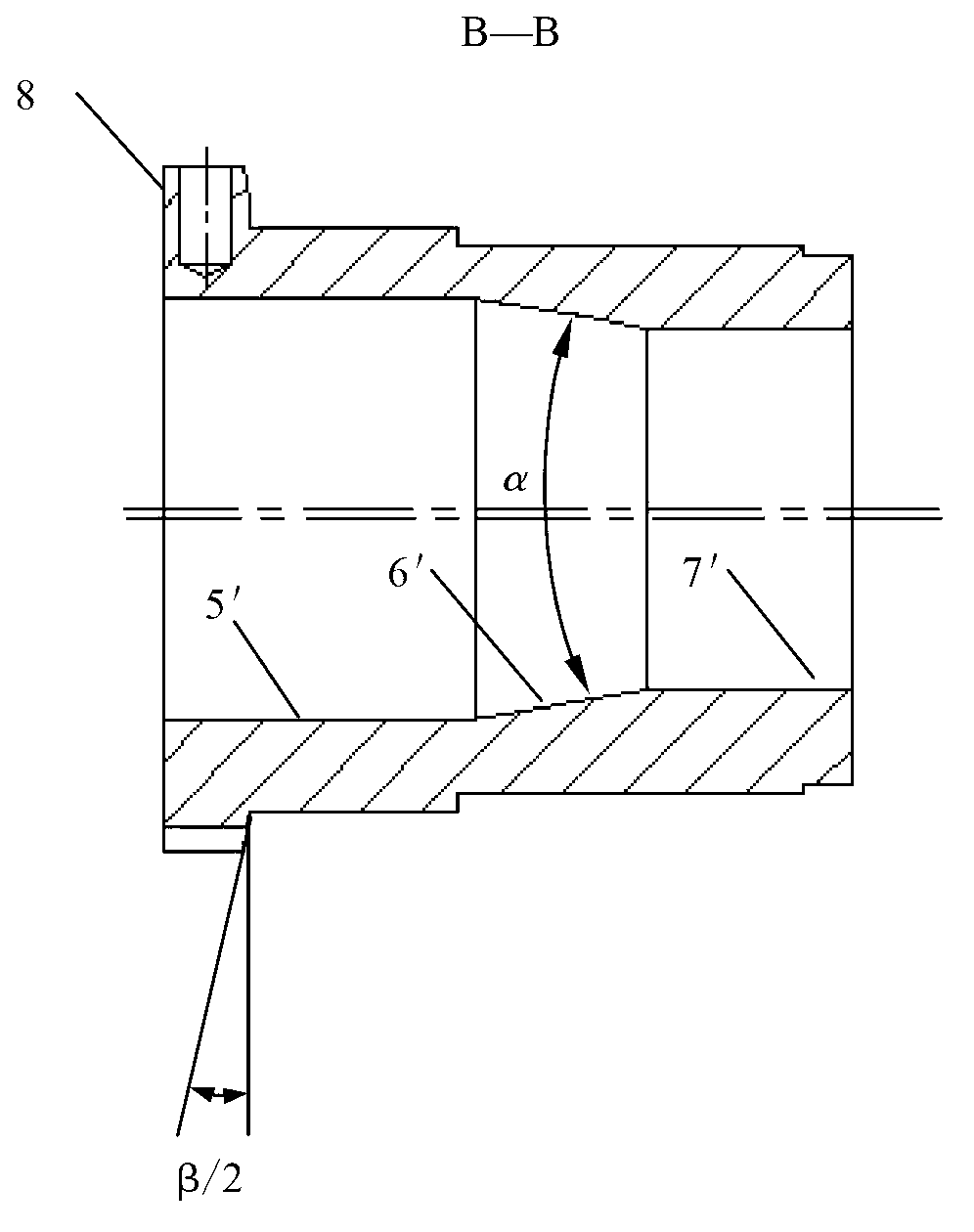

[0025] figure 1 The structure of the eccentric shaft 9 is given. The cylindrical surface 1 is connected to the reducer through a coupling. Bearings are installed on the cylindrical surfaces 2 and 4. The bearings are connected to the base to support and fix the eccentric mechanism. The matching part of the eccentric shaft 9 is composed of The large cylindrical surface 5, the circular table surface 6 and the small cylindrical surface 7 are connected in sequence. The diameters of the end faces of the convoluted surfaces at the joints are equal. The fastening and disassembly of the sleeve 12 is called the rotation axis of the eccentric shaft 9 when it is working, that is, the axis of the shaft head of the eccentric shaft 9 is the main axis, and the large cylindrical surface 5 of the eccentric shaft, the circular table surface 6, the small cylindrical surface 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com