Storage device and beam for loom

A technology of bearing device and carrier, which is applied in the direction of bearing assembly, bearing, loom, etc., and can solve problems such as loss of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

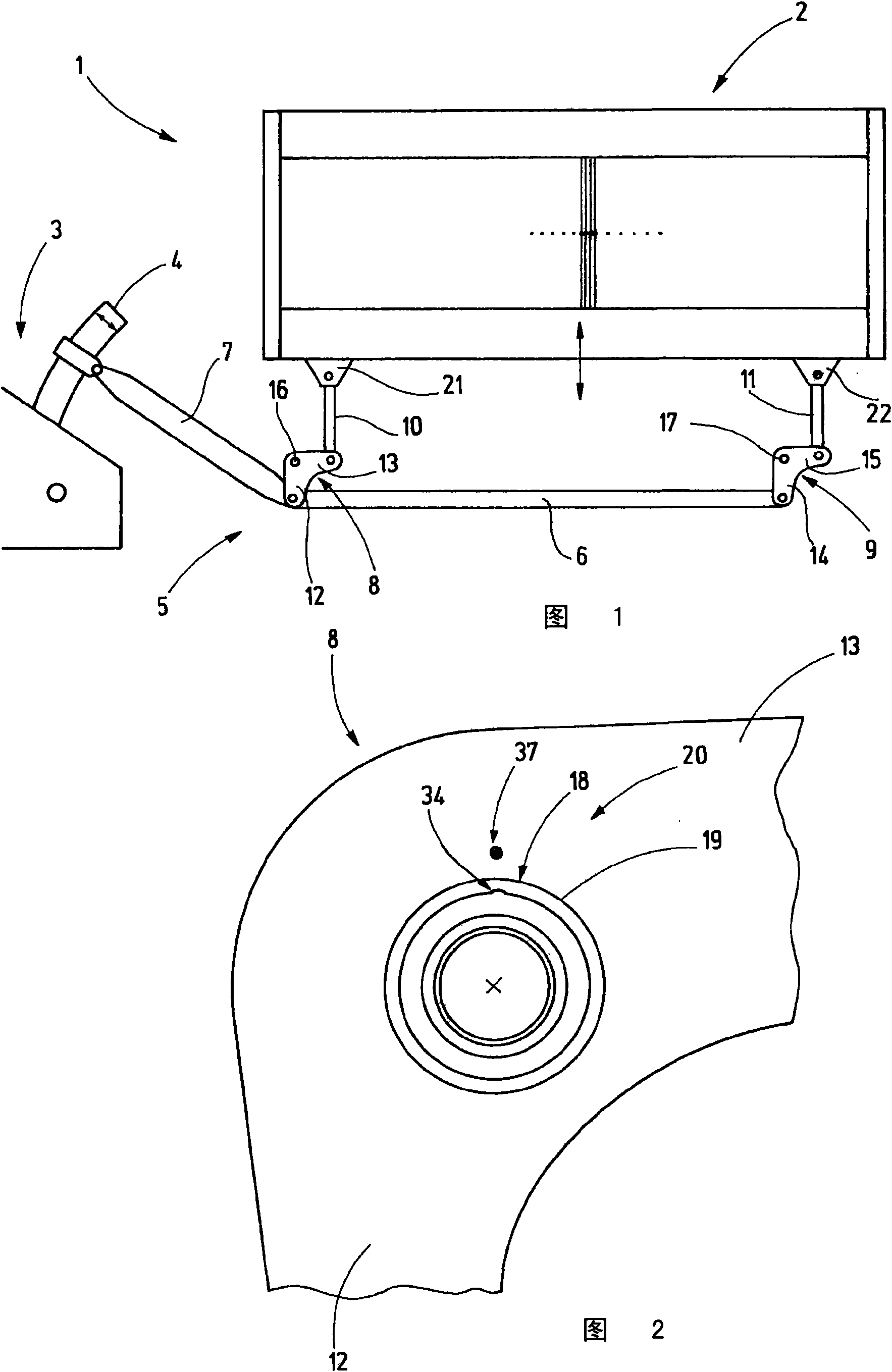

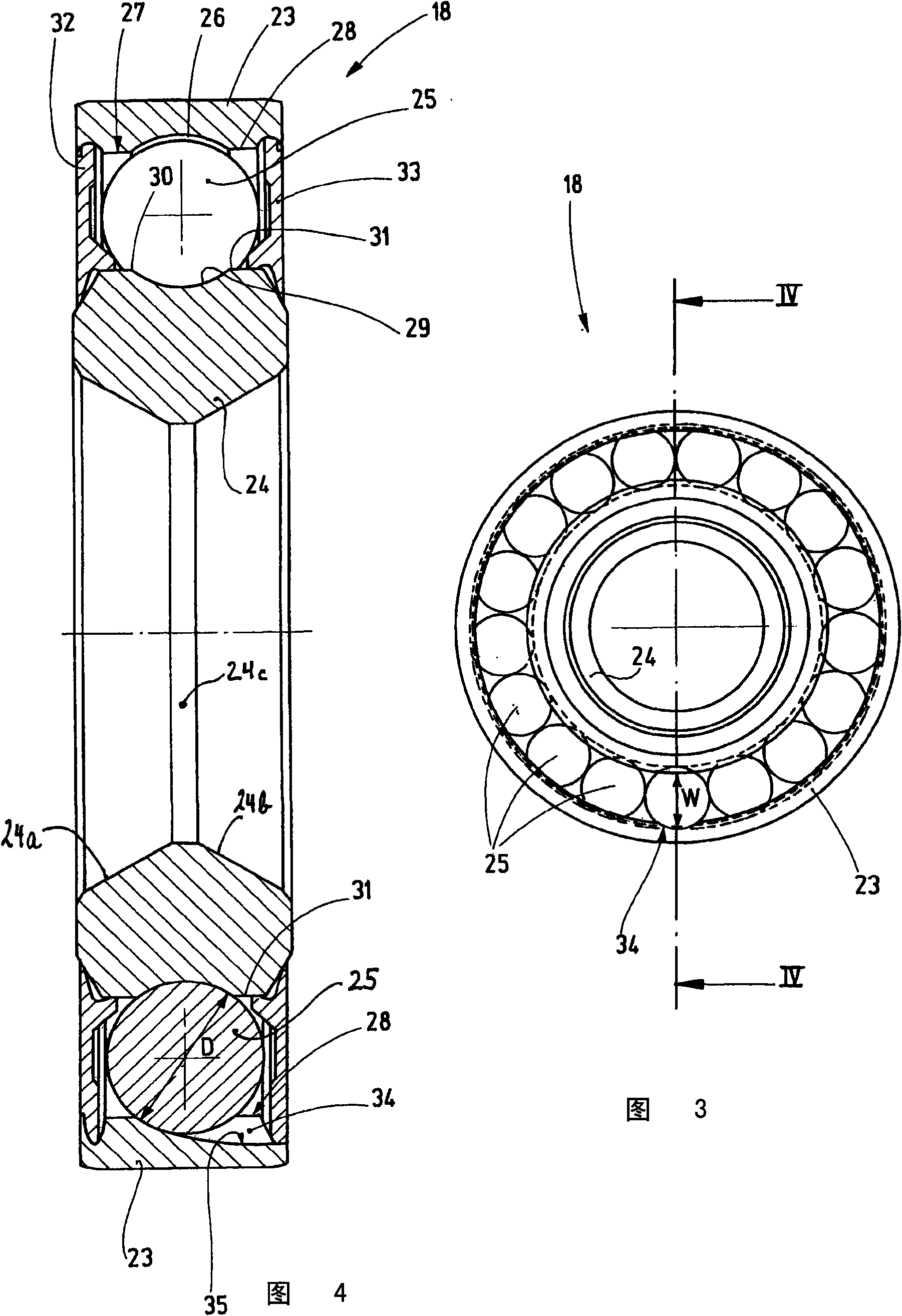

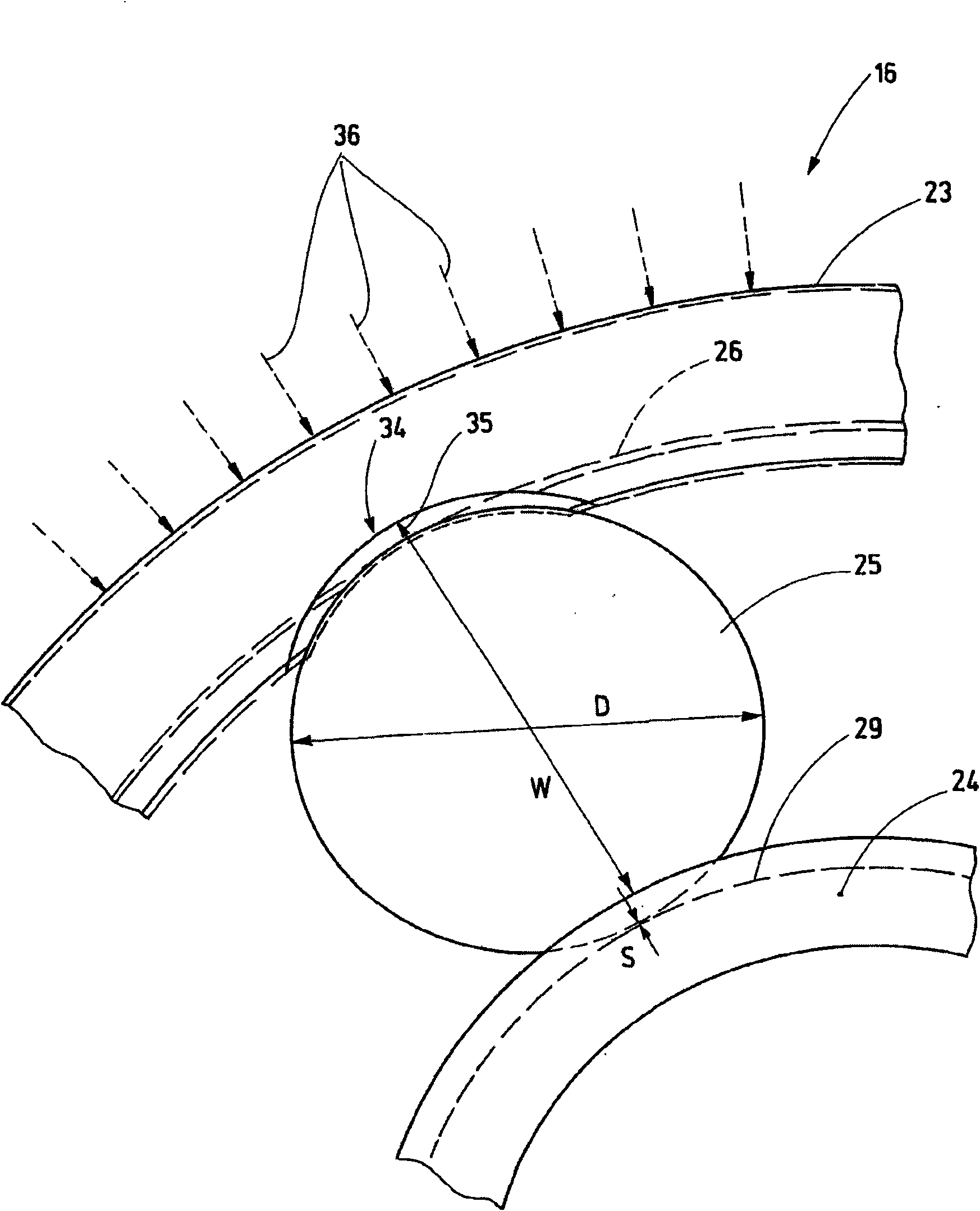

[0026] figure 1 A shedding machine 1 of a weaving machine is shown. Shedding machine 1 comprises heald frame 2, in figure 1 Only one of the heald frames is shown in . The heald frame 2 acts as a warp thread guide and moves up and down rapidly during operation, as figure 1 Indicated by double arrows. A drive machine 3 is used as the drive, the output of which is formed by a heald shaft 4 driven in an oscillating manner. Each heald frame 2 is associated with a heald frame rod 4 . The drive connection between the heald frame rod 4 and the heald frame 2 is formed by a carrier 5 representing a linkage. The carrier 5 comprises a transmission element in the form of at least one push-pull rod, also called load-bearing rod 6, at least one handle 7, at least two deflection rods 8, 9 and lifting rods 10, 11, said The shank 7 transmits the driving movement of the heald frame rod 4 to the rest of the rod assembly.

[0027] The deflection lever 8 is designed as a toggle lever. Each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com