A type of elliptical double-suction four-channel pump impeller

A technology of elliptical and pump impellers, applied in parts, pumps, pump elements, etc. of pumping devices used for elastic fluids, can solve the problems of increased motion load, increased cost, poor symmetry of impellers, etc., to achieve stable and reliable operation, Simple structure and good passability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0035] The invention provides a non-clogging double-suction four-channel pump impeller.

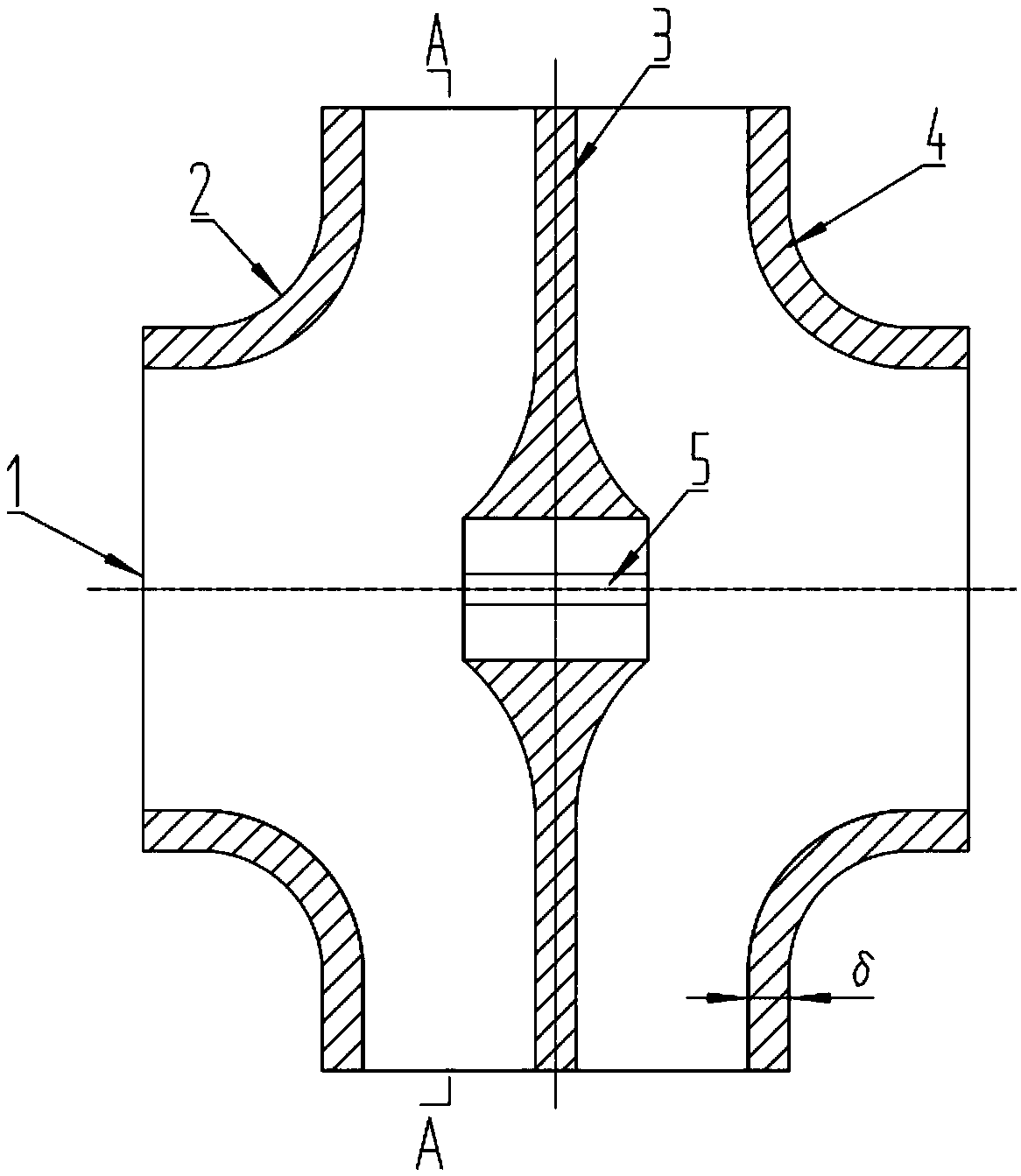

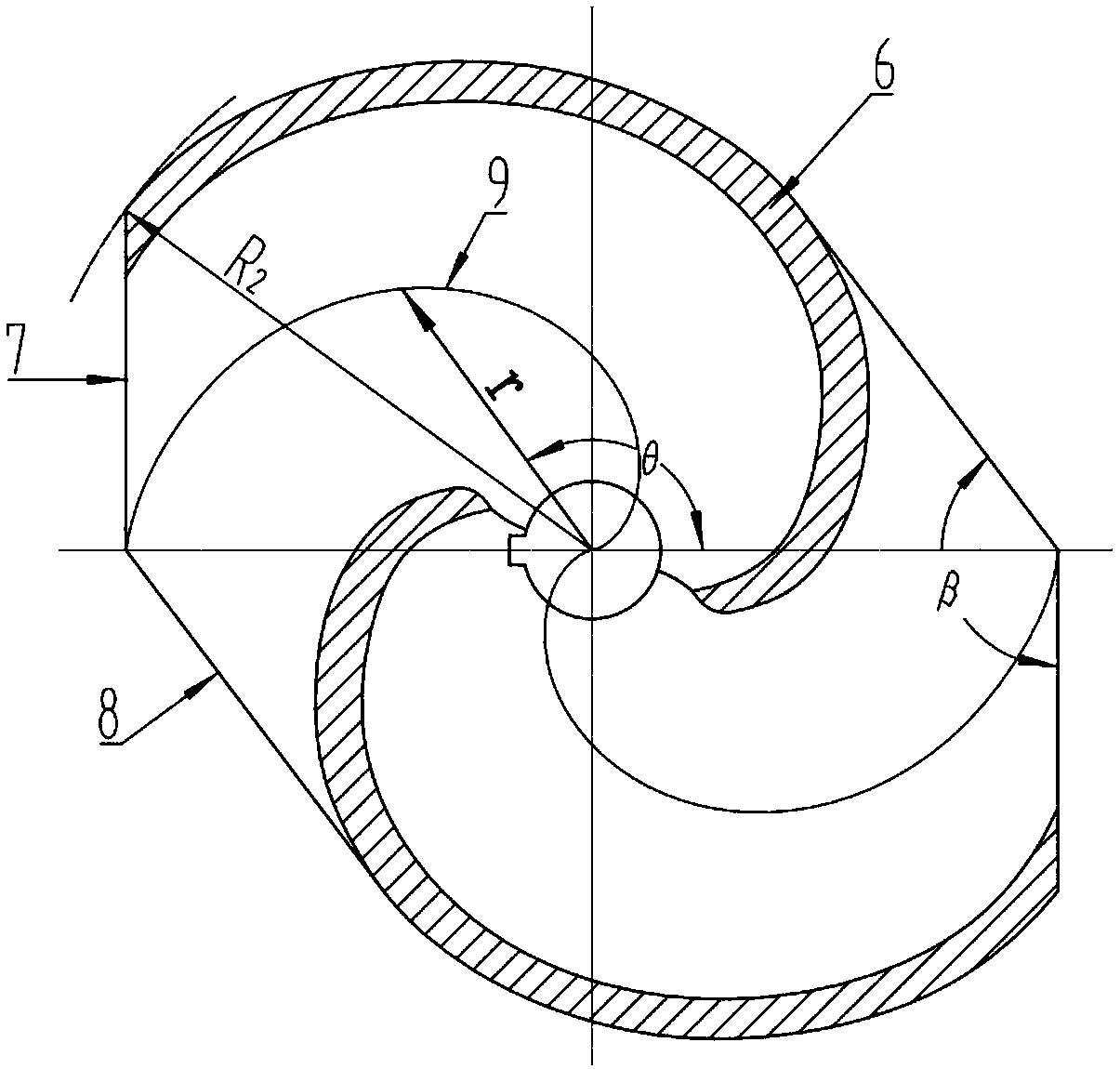

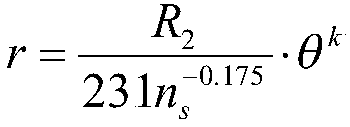

[0036] The impeller is generally oval-shaped, including an impeller front cover plate 2, an impeller rear cover plate 4, an intermediate partition plate 3, four spiral thin-walled runner blades 6, an axis 5, and both sides of the axis 5 Each has an inlet 1, wherein the impeller front cover plate 2, the impeller rear cover plate 4, the middle partition 3 and the four spiral thin-walled flow channel blades 6 together form four flow channels, which are separated by the middle partition 3 The front double flow channel and the rear double flow channel are formed. The flow channel outlet of the impeller is a double-sided wide outlet. The impeller outlet side a7 and the impeller outlet side b8 are in a large V shape, and the V-shaped apex of the outlet is on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com