Coaxial and variable-speed energy-saving wheel of train

A technology for trains and wheels, which is applied to railway car body components, transportation and packaging, etc. It can solve the problems of different wheel wear, noise, energy consumption, etc. on both sides, and achieve the effect of avoiding energy consumption by sliding friction and harsh noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

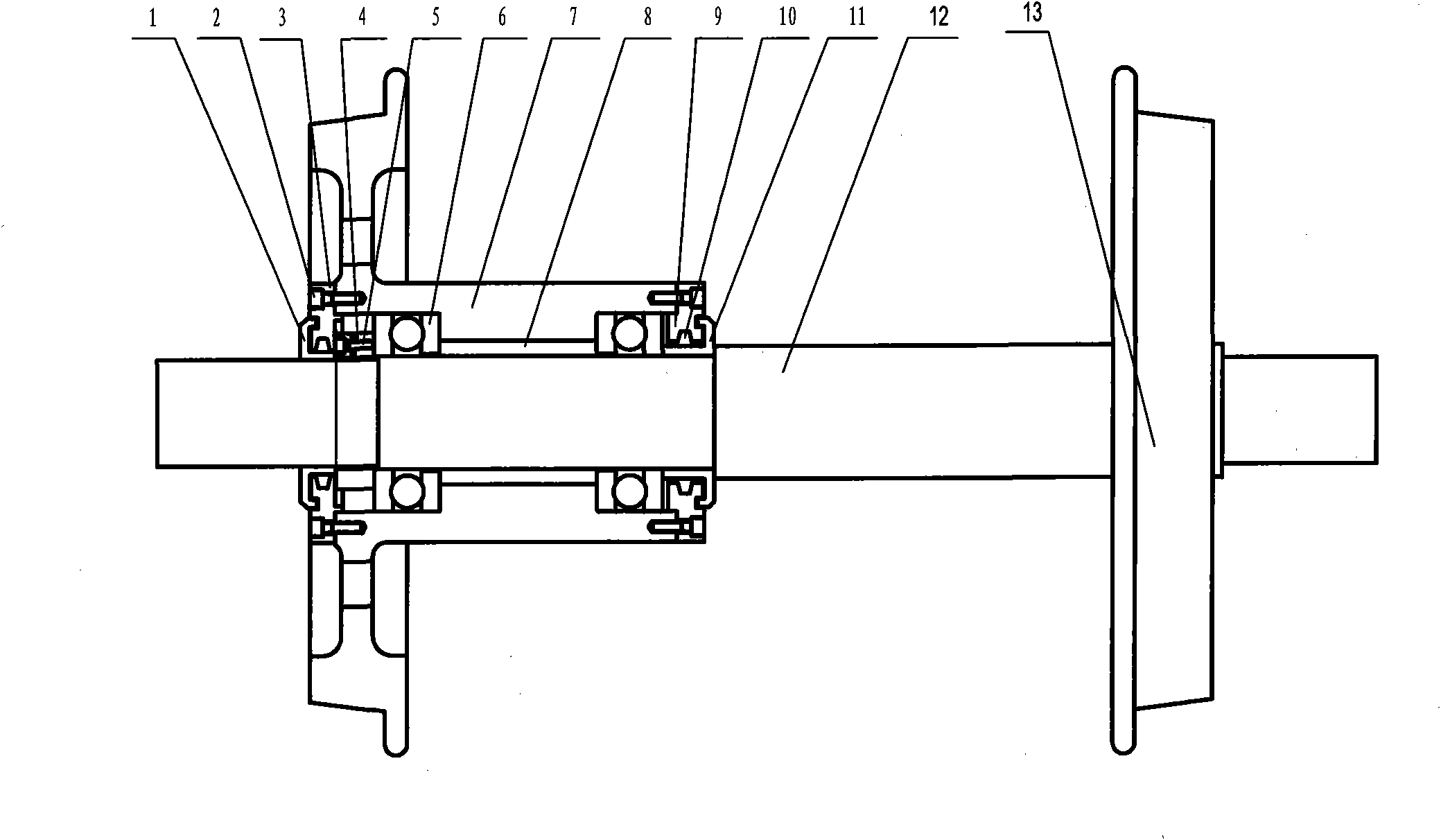

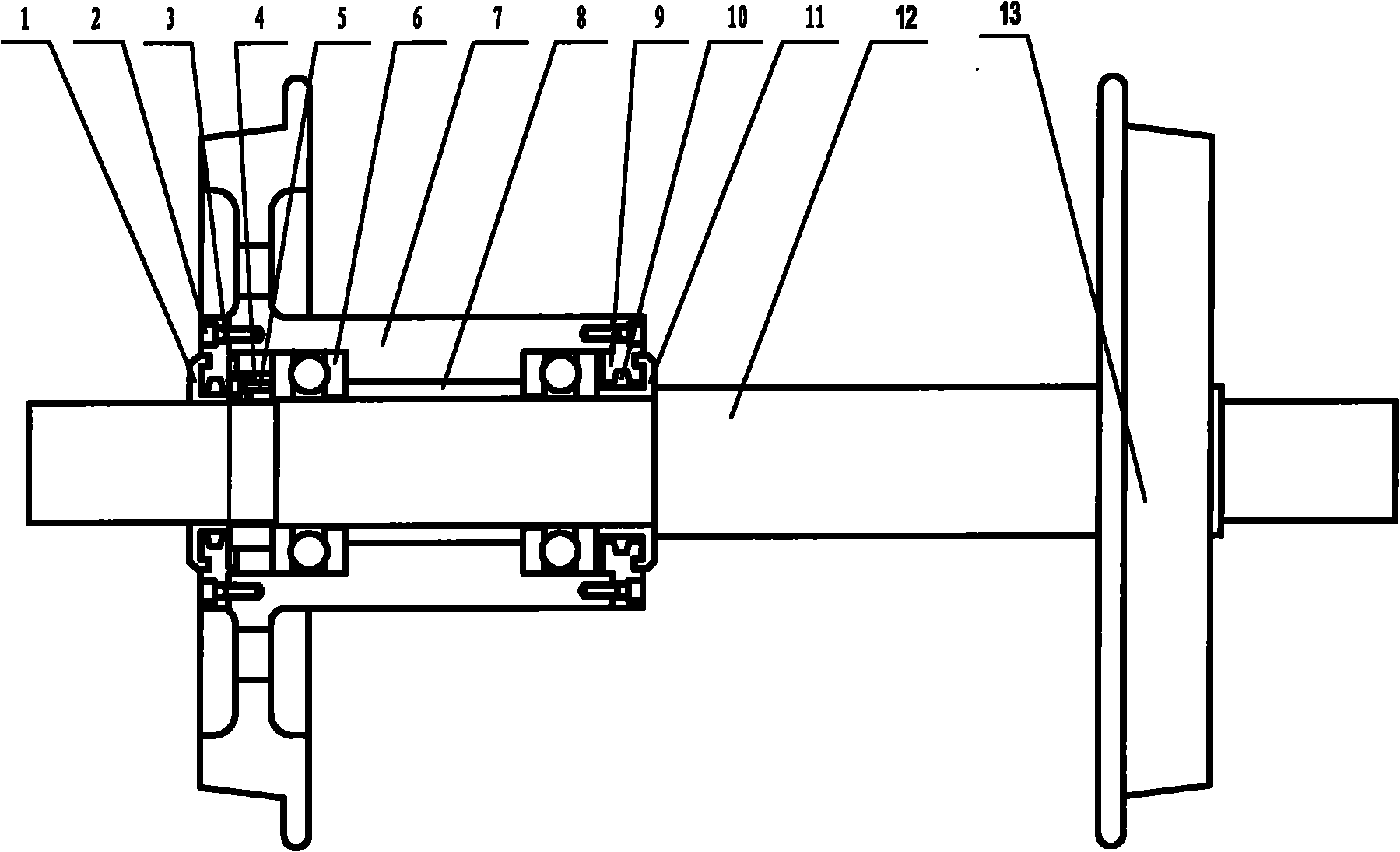

[0011] like figure 1 , which is an embodiment of a train coaxial unequal speed energy-saving wheel of the present invention, one side of the train axle 12 is a stationary wheel 13 (relative to the train axle), and the other side is a live wheel. On the side of the live wheel, the bearing of the live wheel body 7 that bears the main load is the sliding bearing 8. The axial direction of the two sides of the sliding bearing 8 is provided with a thrust bearing 6, and the outer side of the live wheel body 7 is provided with a locking ring 4 and an outer end from the inside to the outside. Cover 3, dustproof sealing ring 1, locking ring 4 is fixed by the locking ring loosening screw 5, the outer end cover 3 is fixed by tightening the hexagon socket head bolt 2, the inner side of the live wheel body 7 is provided with an inner end cover 9 from the inside to the outside , sealing ring 10, dust ring 11.

[0012] The treads of the two wheels can be cylindrical or conical.

[0013] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com