A pressure-compensated end-face oil-distribution double-row radial piston variable pump with annular piston

A pressure compensation, annular piston technology, applied to variable displacement pump components, components of pumping devices for elastic fluids, pumps, etc., can solve the problems of large wear, loss of energy, wear compensation, etc. Achieve the effect of strong continuous working ability, high space utilization rate and reduced mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

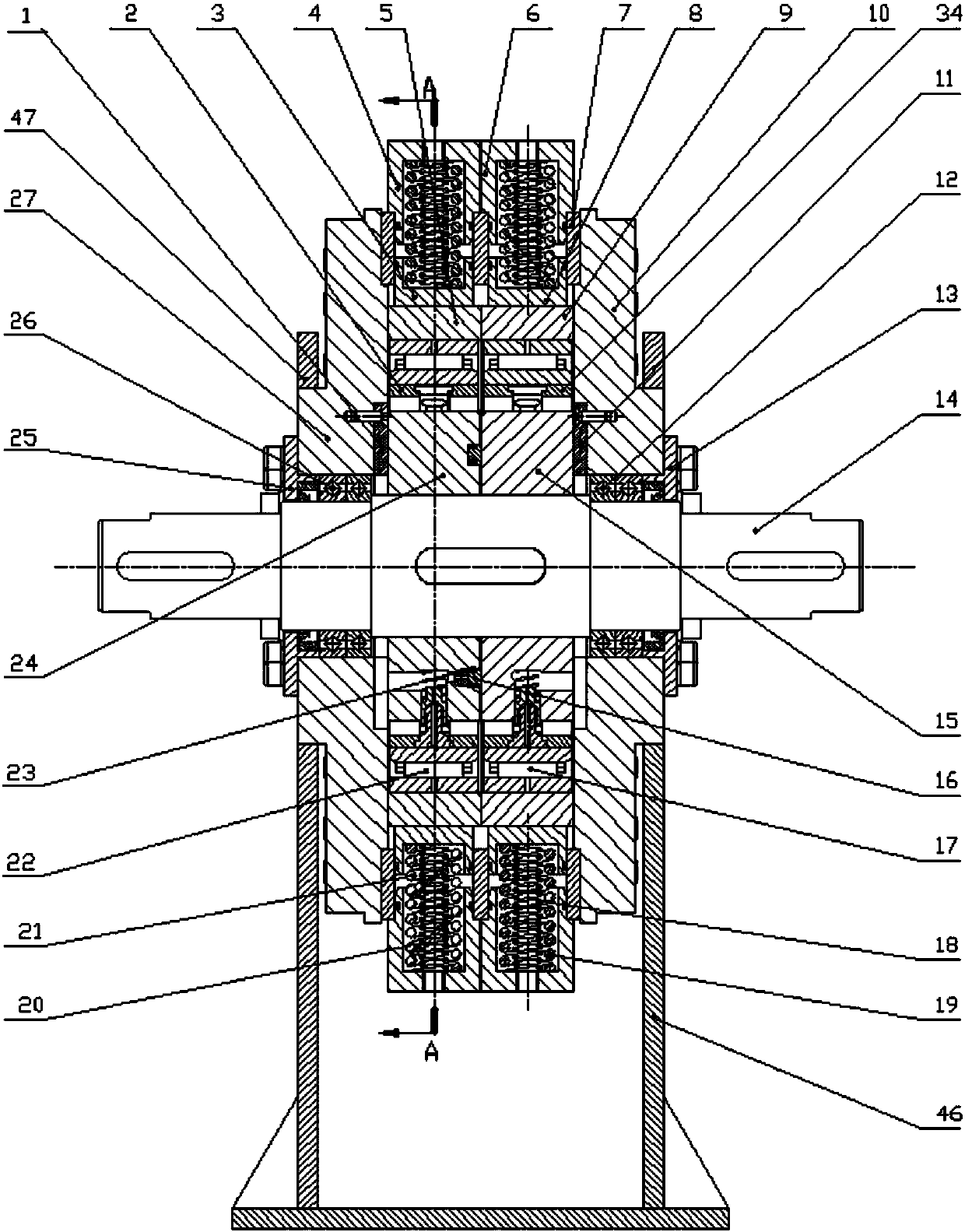

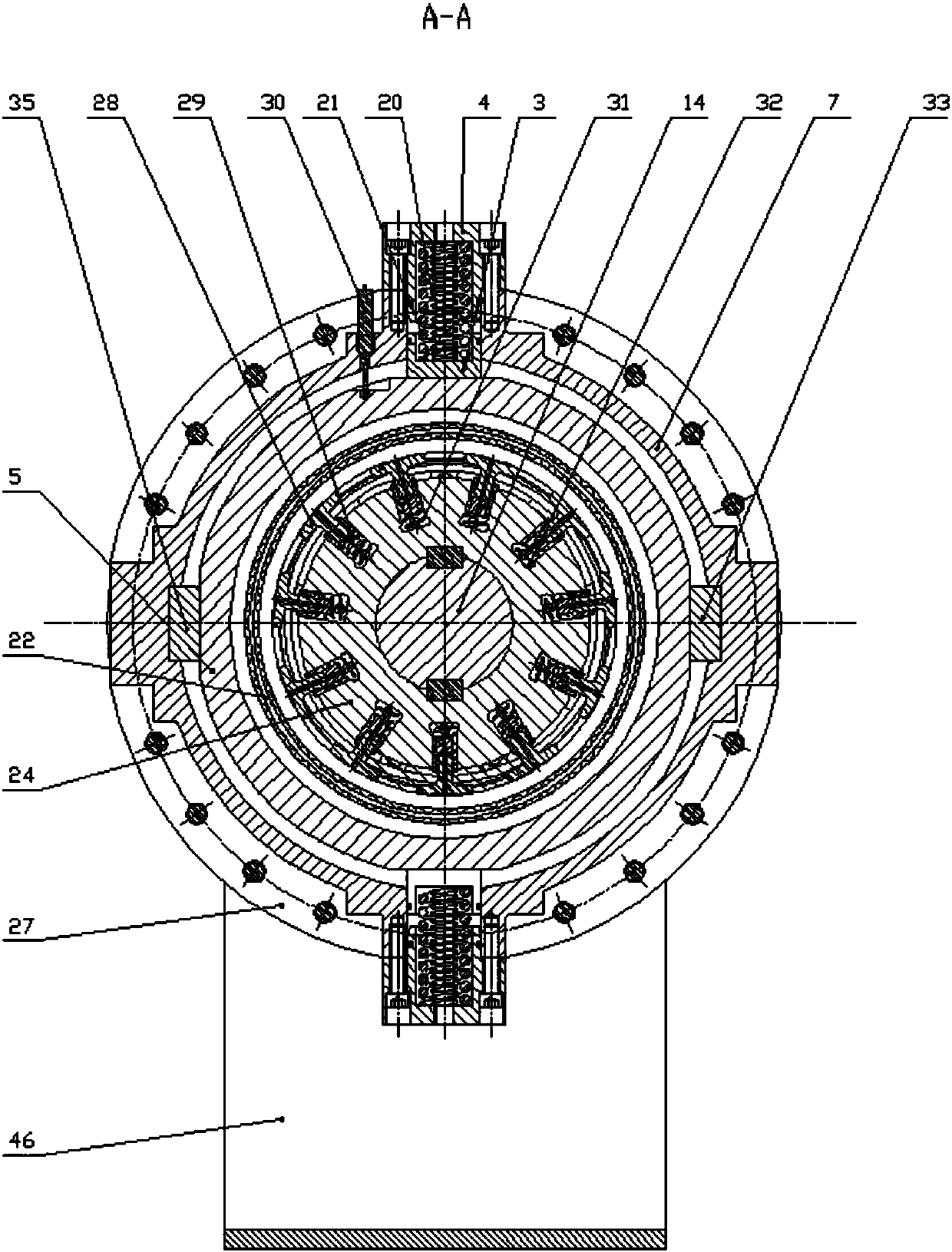

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings.

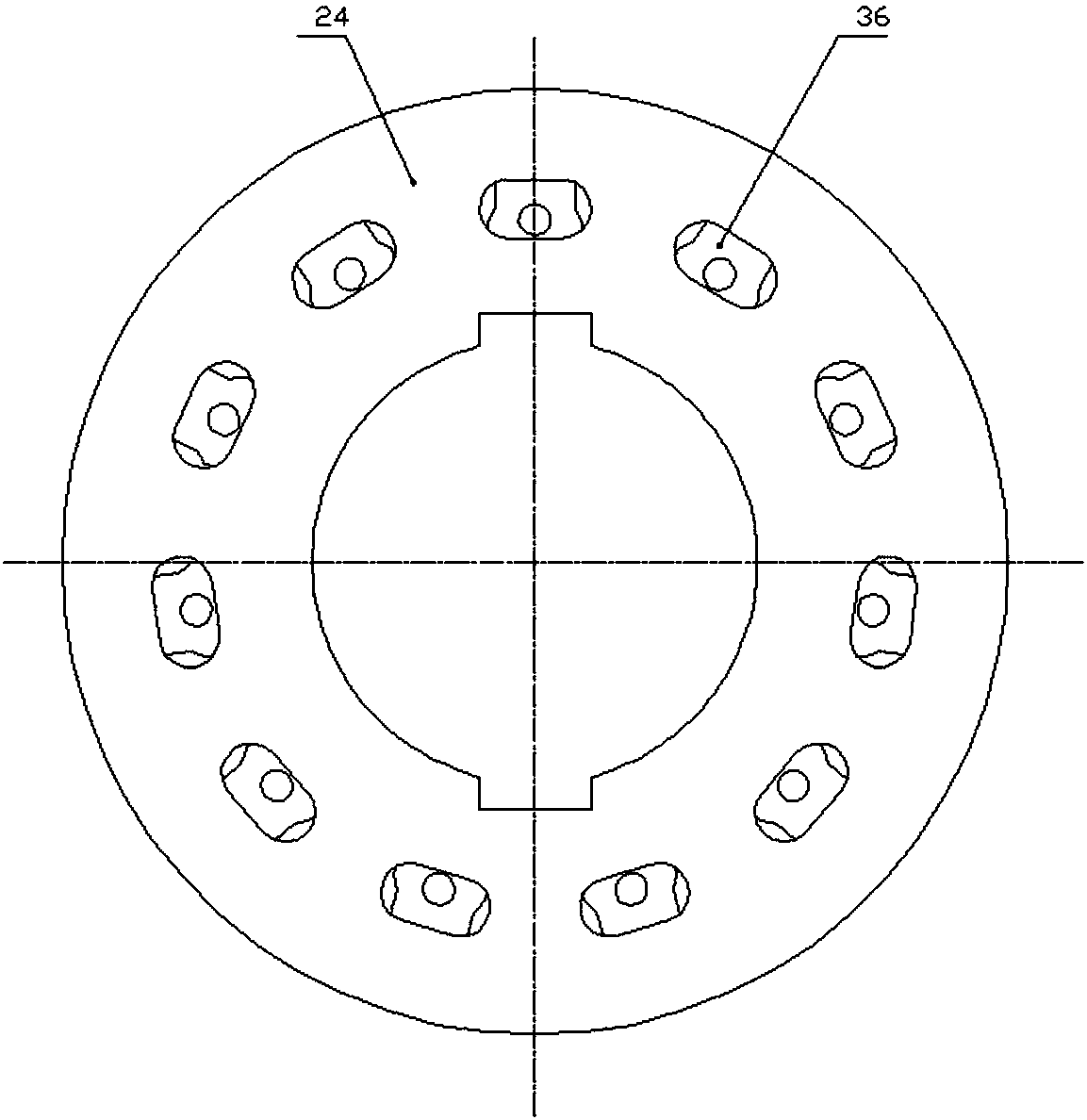

[0034] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5, a pressure-compensated end-face oil-distribution double-row radial piston variable pump with annular pistons, including a transmission shaft 14, a first cylinder 24 and a second cylinder 15 are installed side by side in the middle of the transmission shaft 14, and are connected with the transmission The shaft 14 is connected by a flat key, the first cylinder 24 has an annular groove 37 on the side opposite to the second cylinder 15, and the pressure compensation ring piston 16 is installed in the annular groove 37 and pressed against the second cylinder 15 A row of radial plunger holes 32 are respectively parallelly opened on the outer circular surfaces of the first cylinder body 24 and the second cylinder body 15. The number of plunger holes 32 is more than two and evenly distributed. A pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com