Plastic hook piece rolling mold

A plastic hook and rolling technology, which is applied in the field of plastic molds, can solve the problems of uneven thickness of plastic hook pieces, sticking of hook posts, failure to meet the use requirements, etc., achieve neat distribution of hook posts of plastic hook sheets, and improve coaxiality Degree and roundness, the effect of eliminating radial clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

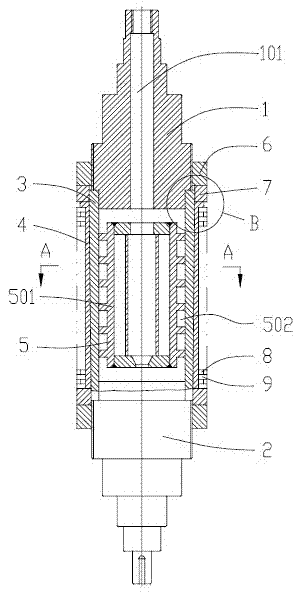

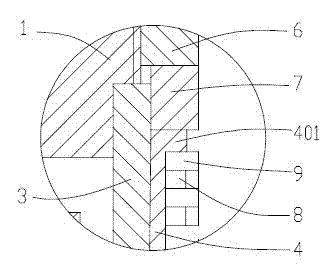

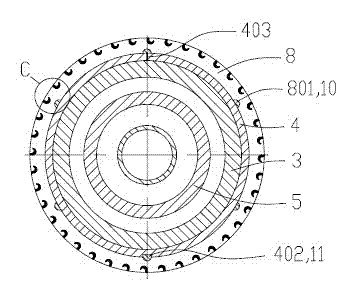

[0018] see figure 1 and figure 2 , a plastic hook piece rolling mold, including a hollow shaft consisting of an upper shaft head 1, a lower shaft head 2, an outer cone cylinder 3 and an inner cone expansion sleeve 4 arranged between the upper shaft head 1 and the lower shaft head 2. The inner hole of the outer cone tube 3 is a cylindrical hole, and the outer circumference is a conical surface, and the inner hole of the inner cone expansion sleeve 4 is a conical hole and the outer peripheral surface is a cylindrical surface. The taper of the outer cone 3 is adapted to the taper of the inner cone expansion sleeve 4 , and the inner cone expansion sleeve 4 is sleeved on the outer cone 3 . A cooling liner 5 is arranged in the outer cone 3 of the hollow shaft, and the cooling liner 5 includes an inner liner cylinder 501 with three spiral grooves 502 on the outer periphery. The inner cylinder 501 is next to the cylindrical inner hole of the outer cone 3 . Both the upper shaft hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com