Integrated electromagnetic protective bearing device

A bearing protection, integrated technology, applied in magnetic bearings, bearings, shafts and bearings, etc., can solve the problems of slow response speed and complex structure of the bearing protection device, and achieve the effect of simplified structure, multiple functions and fast response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

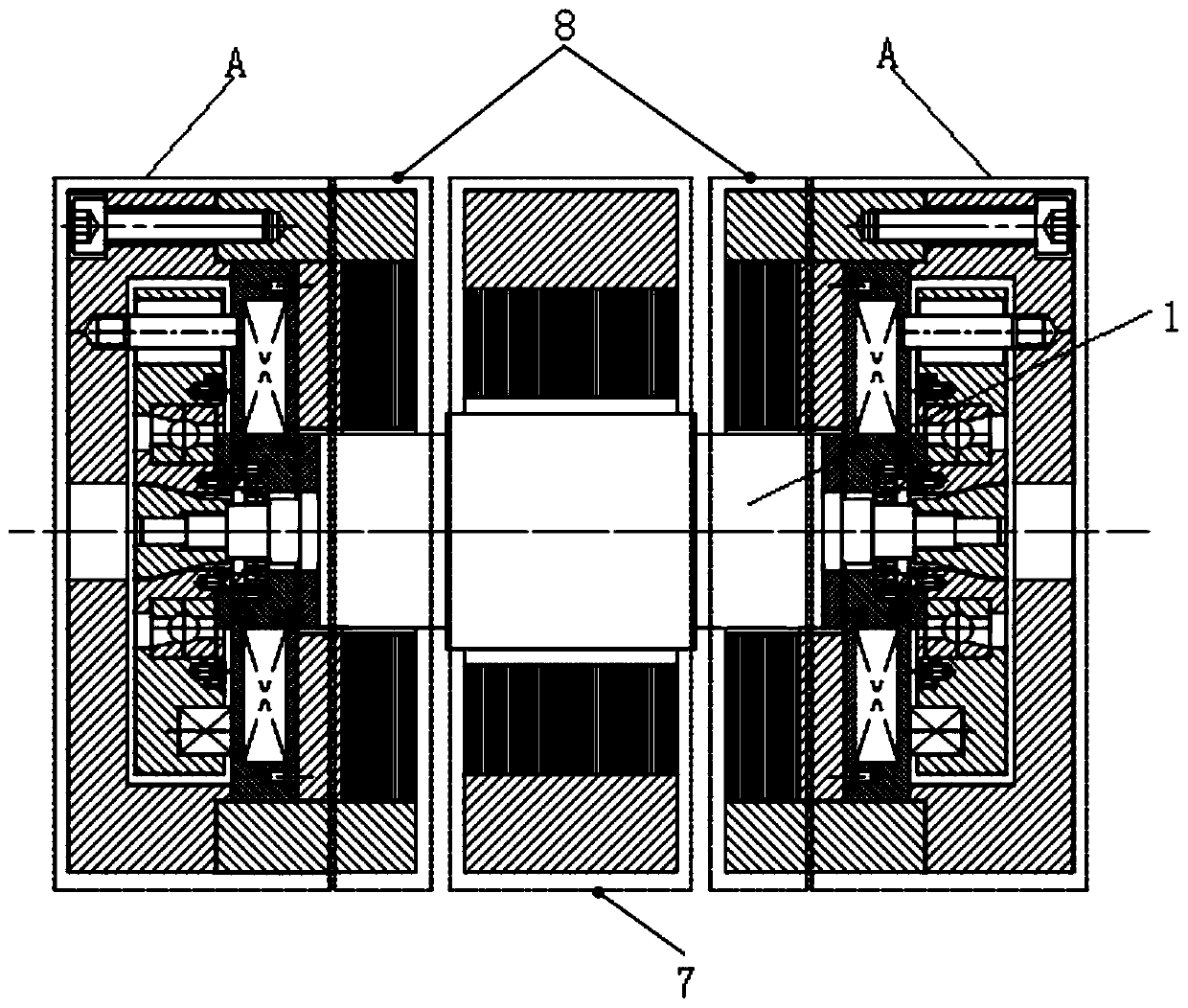

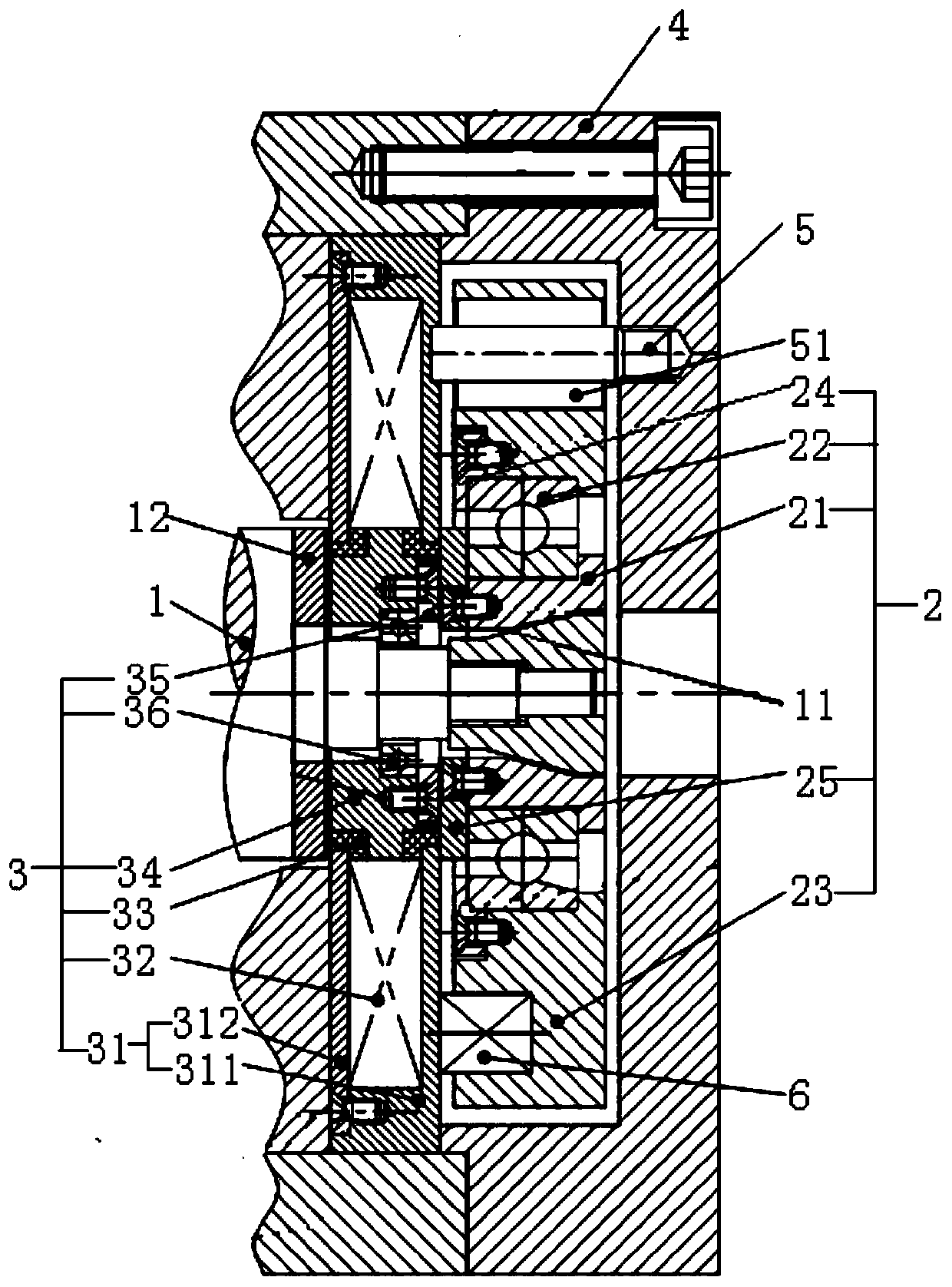

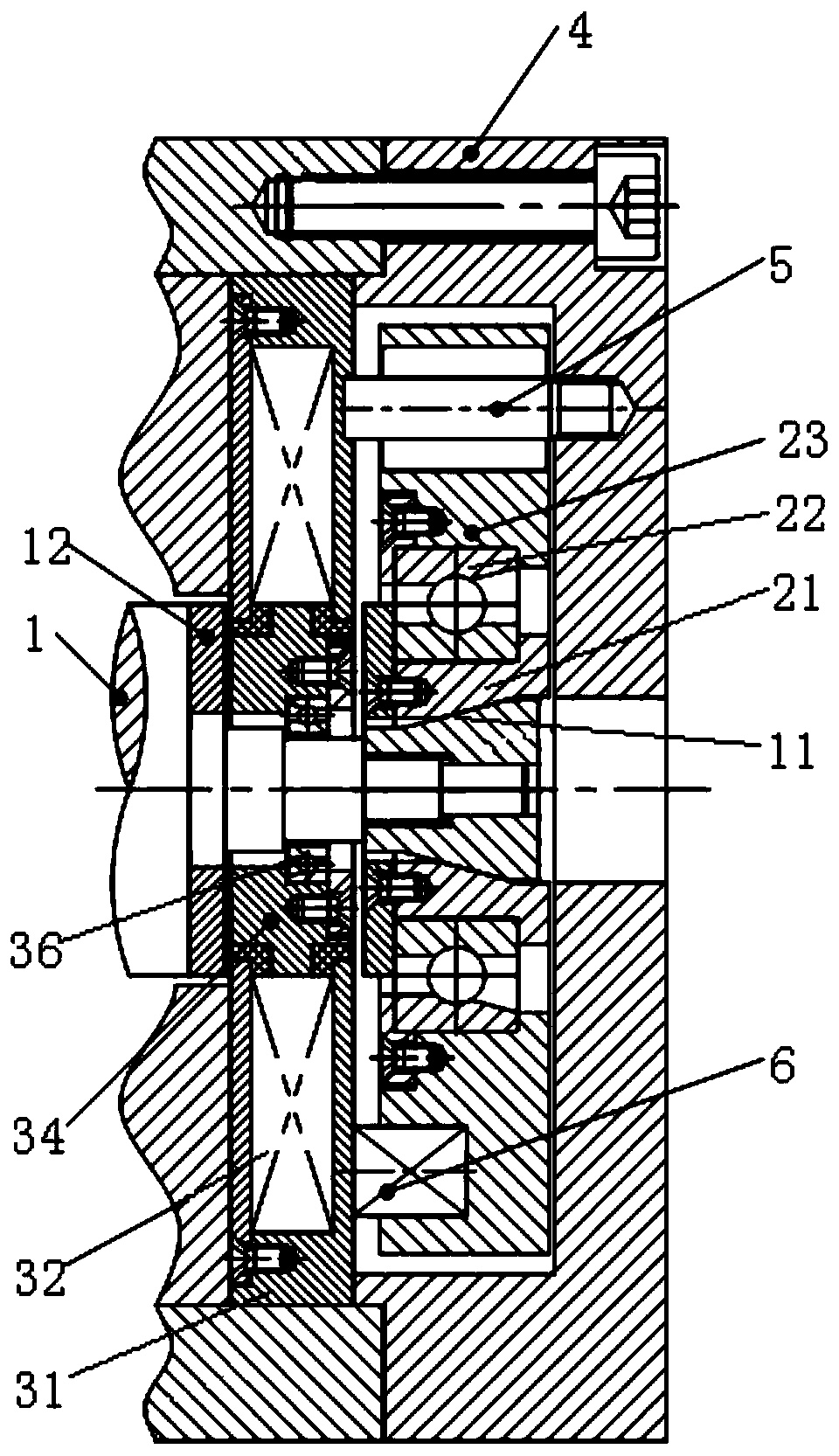

[0031] Such as Figure 1-3 As shown, this embodiment provides an integrated electromagnetic protection bearing device, which is installed at both ends of the rotor 1. Under normal circumstances, the role of electromagnetic adsorption force in the radial magnetic bearing 8 and the integrated electromagnetic protection bearing device Next, the rotor 1 can be in the center position in the radial direction and the axial direction, and rotate at high speed under the action of the motor 7; when the magnetic levitation system is powered off or fails, the integrated electromagnetic protection bearing device can support the rotor 1 , to protect the role of radial magnetic bearing 8. Such as figure 1 As shown, the motor 7 is located in the middle of the rotor 1, the two radial magnetic bearings 8 are symmetrically arranged on both axial sides of the motor 7, and the integrated electromagnetic protection bearing device A is symmetrically arranged on the axial outer side of the two radia...

Embodiment 2

[0043] This embodiment is basically the same as the first embodiment, the only difference is: in this embodiment, the axial thrust disc 12 is located on the axial outer side of the support assembly 2, and the axial inner side of the axial thrust disc 12 abuts against the stepped surface of the rotor 1 , the axial outer side of the axial thrust plate 12 is limited by the limiting member 13 fixed on the rotor 1 . The tapered outer surface 11 in this embodiment is directly processed on the outer peripheral surface of the rotor 1 , and the outer diameter of the axially inner end of the tapered outer surface 11 is larger than the outer diameter of the axially outer end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com