Damper fixing structure and method

A technology for fixing structures and shock absorbers, applied in the direction of elastic suspension, vehicle components, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

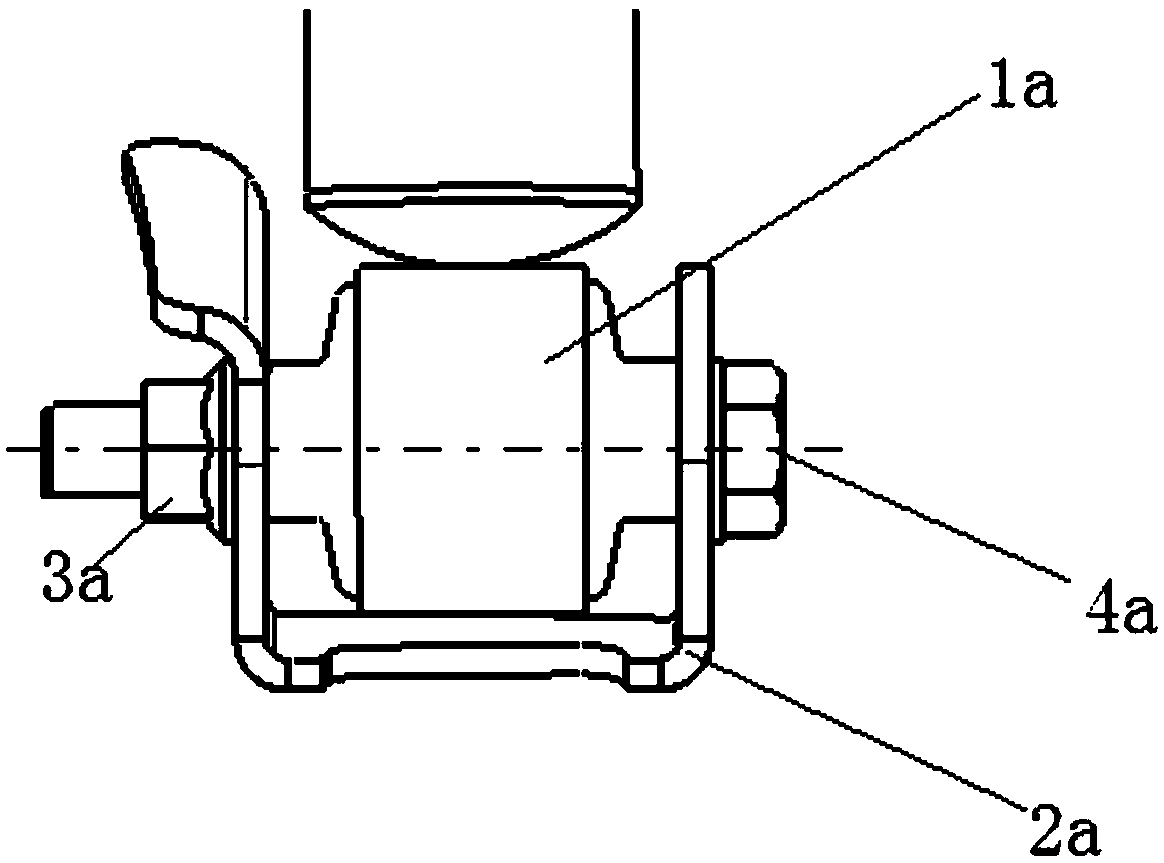

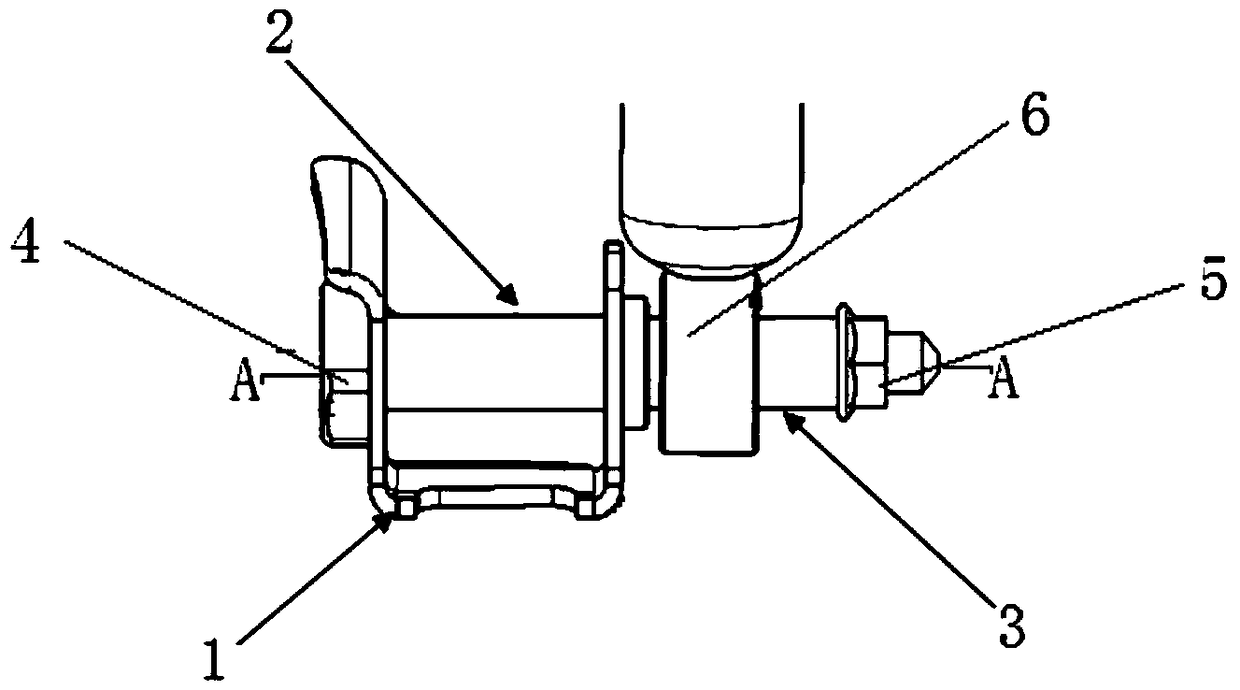

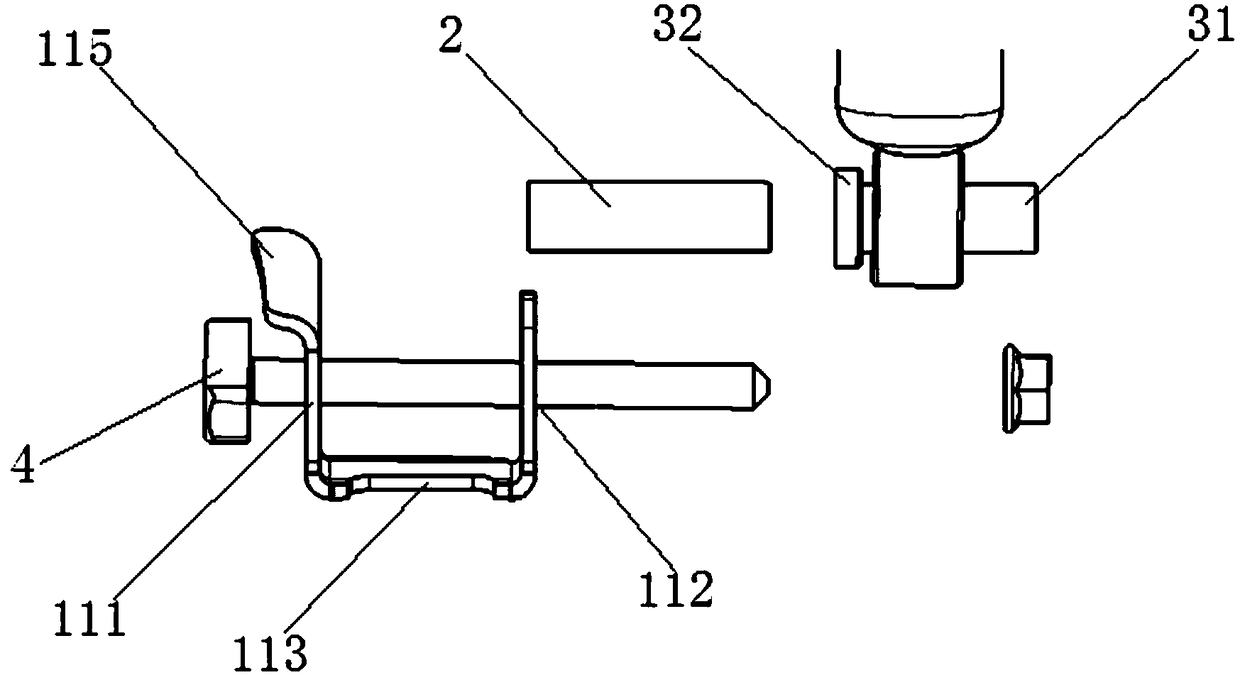

[0024] Such as Figure 2-4 As shown, it is a shock absorber fixing structure provided by the embodiment of the present invention, which is used to fix the shock absorber ring 6, including: a shock absorber mounting bracket 1, and the shock absorber mounting bracket 1 is fixed on the chassis of the vehicle body. In the solution, the shock absorber mounting bracket 1 is a U-shaped structure with an upward opening, which is welded to the chassis of the vehicle body. Specifically, the shock absorber mounting bracket 1 includes a first side 111, a second side 112 and a bottom 113. The first side 111 and the second side 112 are respectively provided with a via hole 114 opposite to each other.

[0025] The supporting sleeve 2 is overlapped between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com