Precision centering anti-tilting device with static pressure rotary workbench

A rotary table, anti-tilt technology, used in manufacturing tools, large fixed members, metal processing equipment, etc., can solve problems affecting processing precision and reliability, product quality cannot meet requirements, etc., to achieve compact structure and simple design. Reasonable, stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

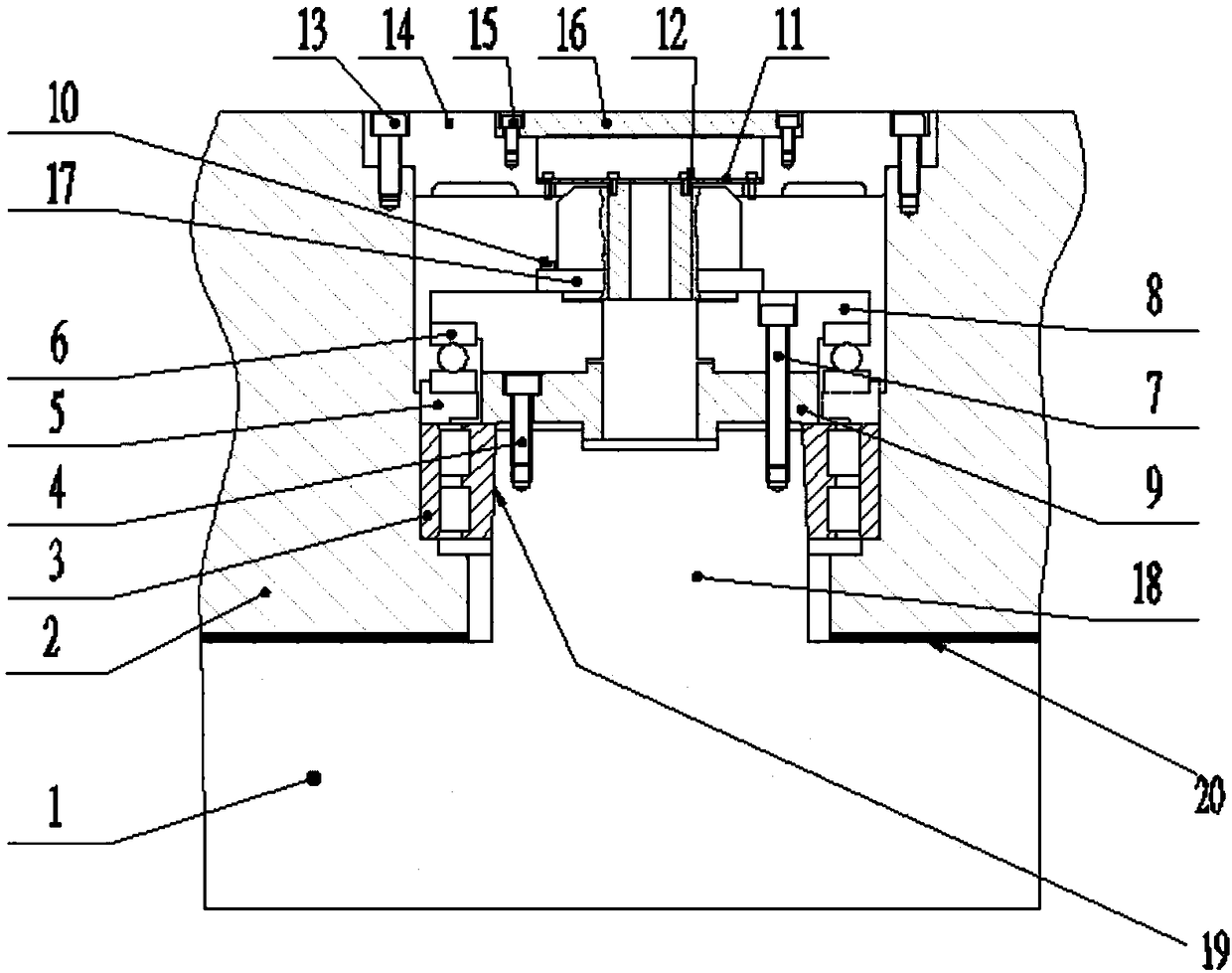

[0021] Such as figure 1 As shown, a precision centering anti-tilt device for a static pressure rotary table, including a static pressure rotary table mounting base 1, a static pressure rotary table 2, a double-row cylindrical roller bearing 3, a thrust ball bearing 6, and a ring pad Plate 5, bearing gland 8, preload ring 9, connecting plate 11, gland 14, angle encoder 17, central shaft 18 and fixing parts. The fixing parts are used for connection and fixing, including pre-tightening screws 4, gland screws 7, screws 10, screws 12, screws 13, and screws 15.

[0022] The static pressure rotary table mounting base 1 is generally installed on a certain part of the machine tool, and will not rotate together with the workpiece, while the static pressure rotary static pressure rotary table drives the workpiece fixed thereon to rotate together. When the static pressure rotary table does not rotate, the static pressure rotary table is directly pressed on the static pressure rotary tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com