Annular balancing piston

A balancing piston, ring-shaped technology, applied in rotary piston/oscillating piston pump components, components of pumping devices for elastic fluids, machines/engines, etc., can solve difficult control, small balance force, pressure Almost the same problem, to achieve the effect of easy control of oil volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

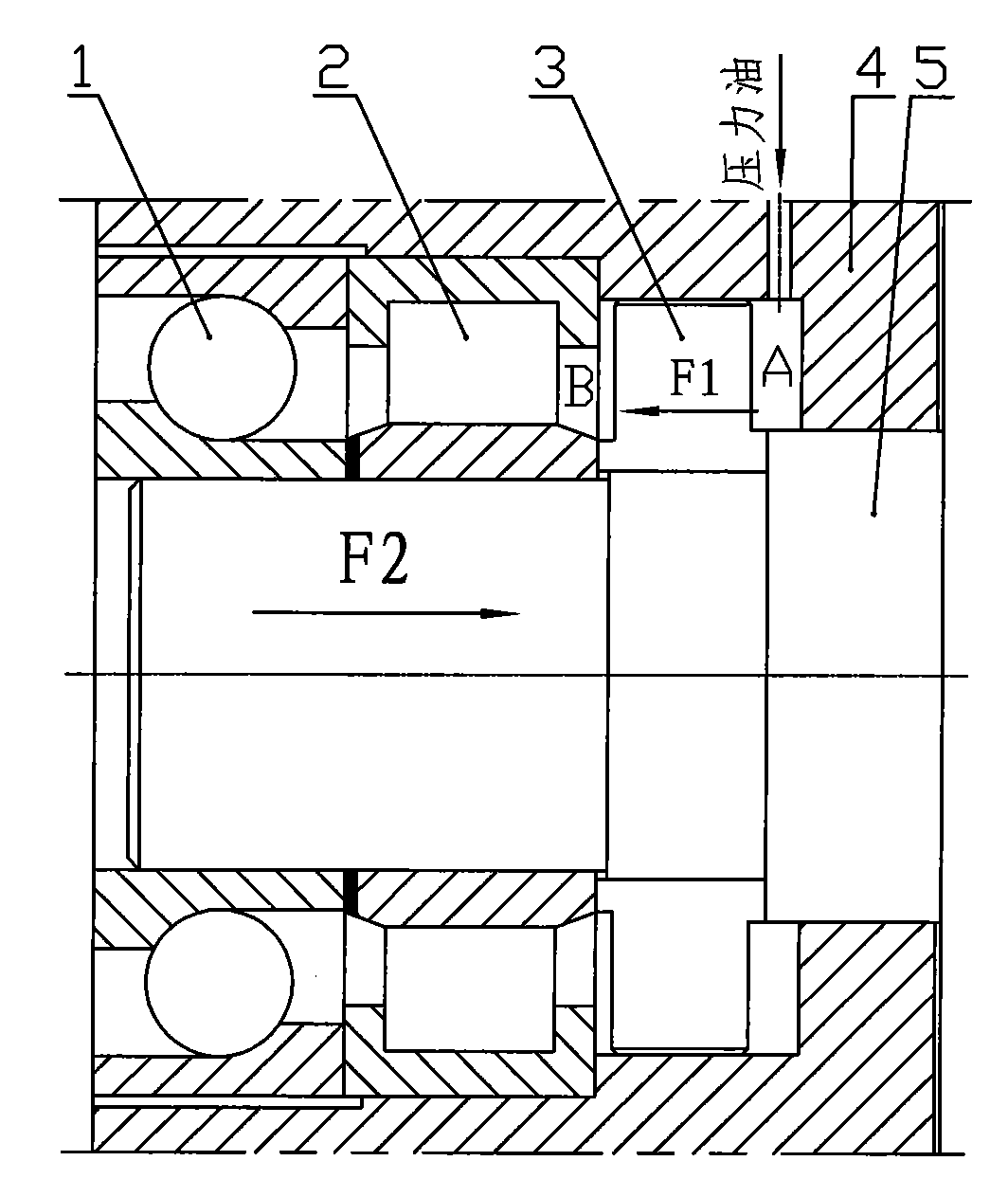

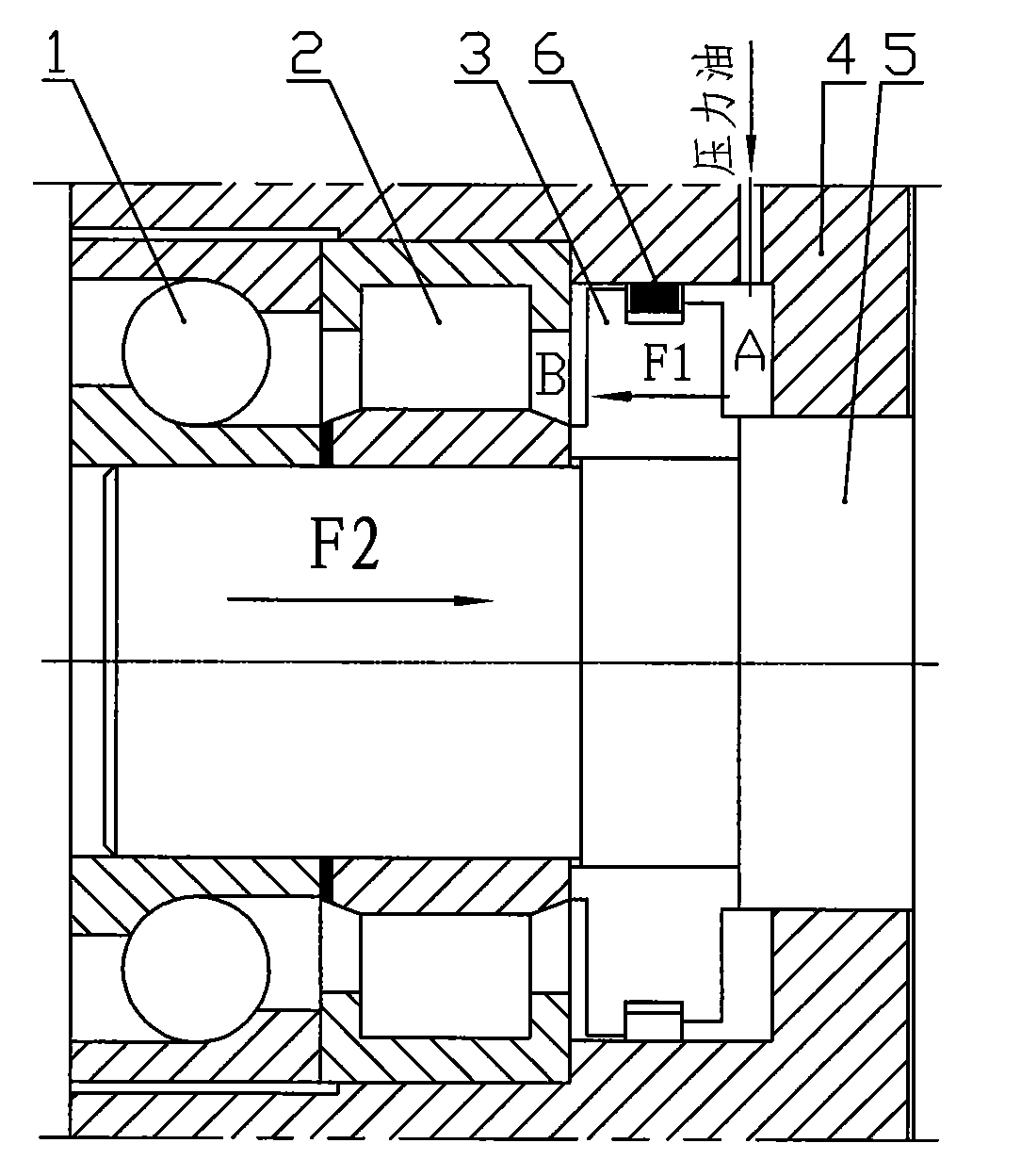

[0018] See figure 2 , is a partial structure using an oil-injected screw compressor of the present invention. The compressor rotor 5 is assembled on the rotor bearing seat 4, and the shaft head of the compressor rotor 5 is equipped with a cylindrical roller bearing 2 for bearing radial force and an angular contact ball bearing 1 for bearing axial thrust. A balance piston 3 is mounted on the shaft of the compressor rotor 5 between the cylindrical roller bearing 2 and the side wall of the rotor bearing housing 4 . The balance piston 3 divides the space between the cylindrical roller bearing 2 and the side wall of the rotor bearing seat 4 into two chambers, namely the pressure oil chamber A and the low pressure bearing chamber B.

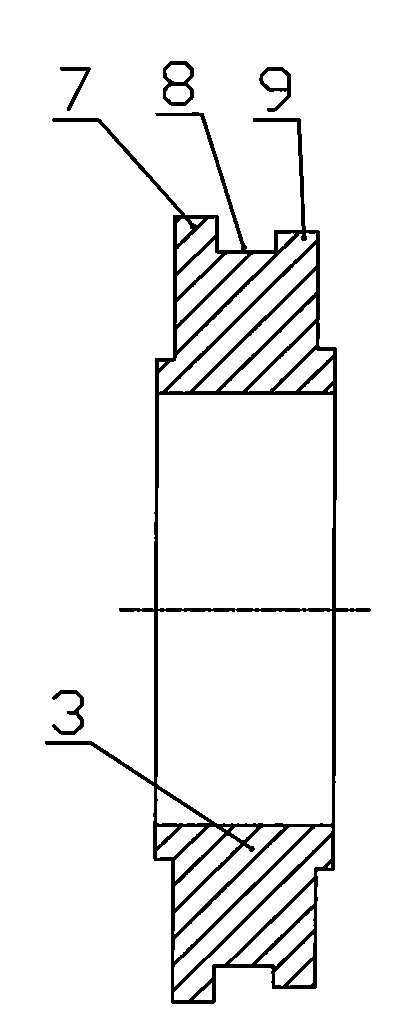

[0019] The present invention is an improvement on the structure of the balance piston 3 described above. An annular groove 8 is arranged on the outer circumference of the piston 3, and the movable device in the annular groove 8 has a piston ring 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com