Fixture special for mortise of broaching disc type part

A technology for special fixtures and disk parts, which is applied in the field of special fixtures for broaching disk parts, which can solve the problems of insufficient quality of the surface quality of the broaching parts, achieve the elimination of positioning radial gaps, and improve the product qualification rate , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

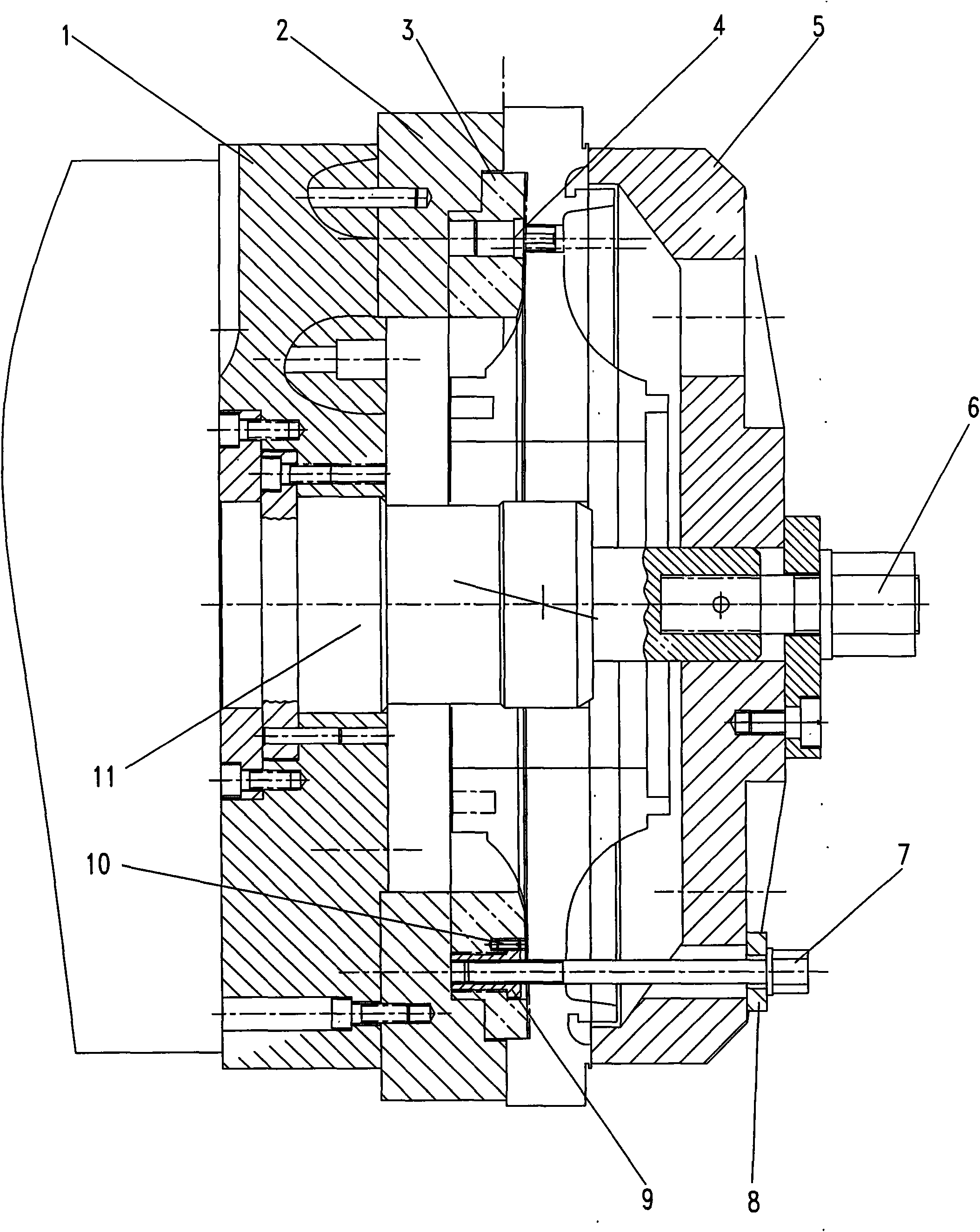

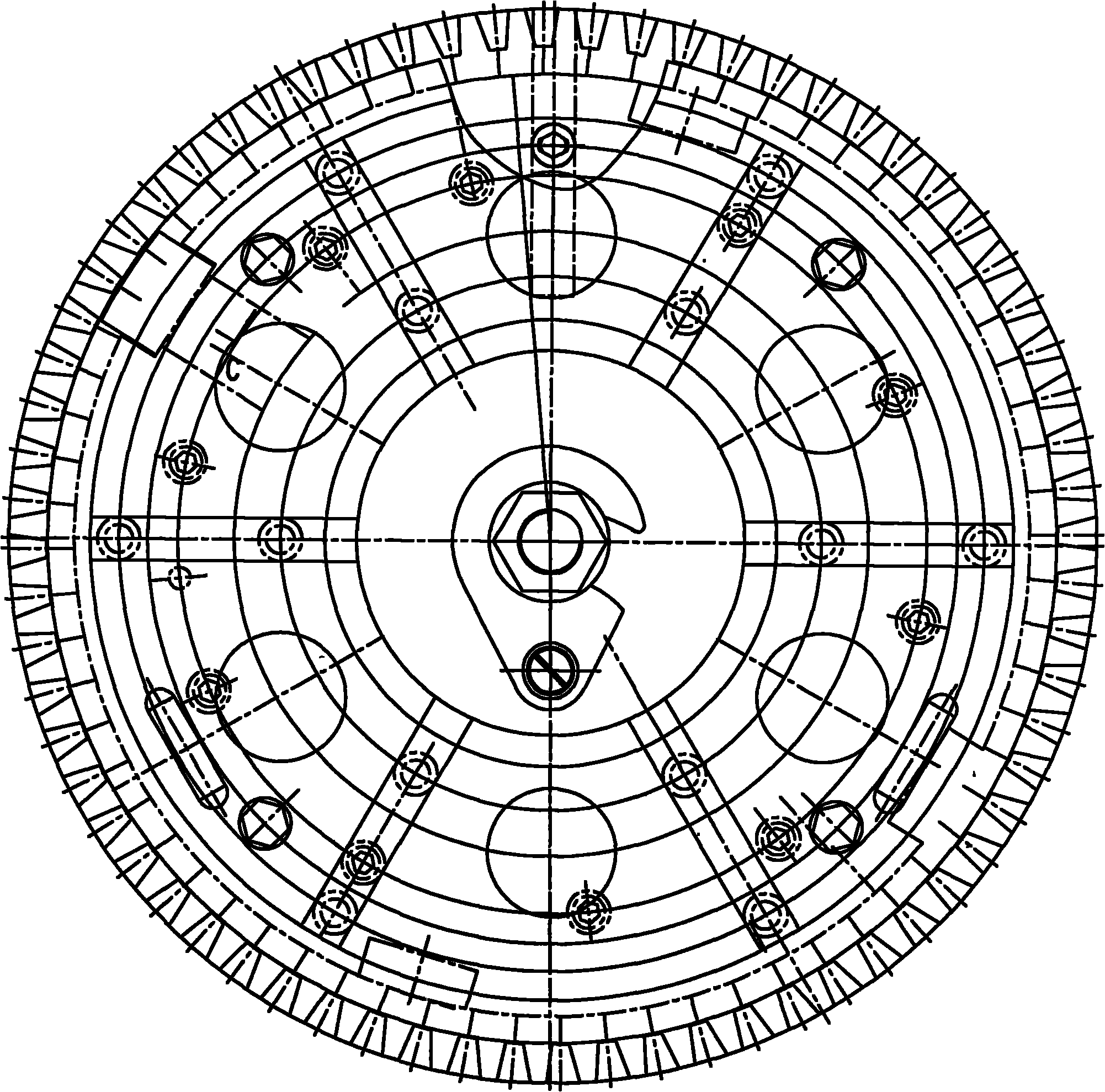

[0014] The detailed structure of a special jig for broaching disc-shaped parts tongue and groove according to the present invention will be described in conjunction with the accompanying drawings and specific implementation methods.

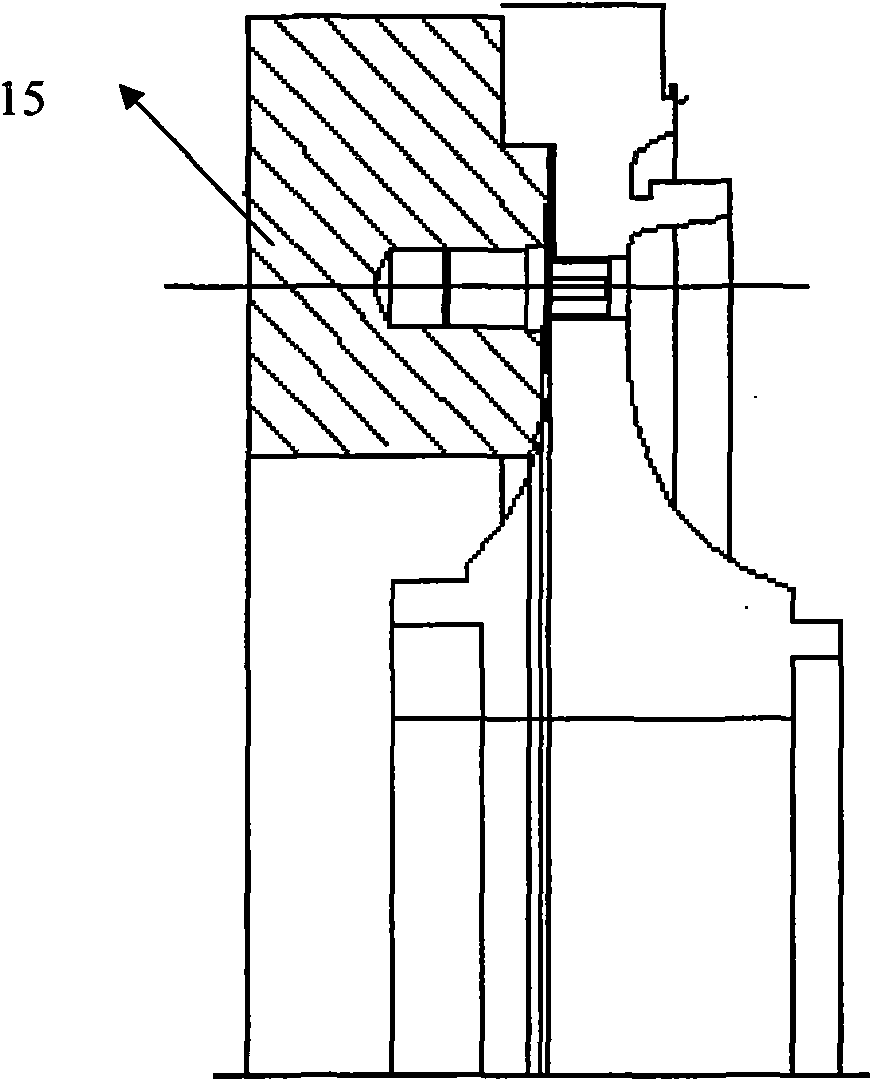

[0015] The fixture as figure 1 and 2 As shown, the fixture includes a chassis 1, an angular positioning pin 4, a gland 5, a compression nut 6, a compression screw 7, a washer 8, a threaded bush 9, a locking screw 10, a positioning mandrel 11 and a radial Gap mechanism; eliminate radial gap mechanism such as Figure 4 As shown, it includes a positioning end face ring 2, a positioning lip ring 3, a top block 13 for adjusting the radial positioning gap, a tightening screw 12 and a spring 14.

[0016] The connection of the fixture is: the bottom surface of the positioning end face ring 2 is connected to the chassis 1, the top surface is connected to the positioning seam ring 3, the side is connected to the top block 13 for adjusting the radial pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com