Screw rod and threaded hole perpendicularity test tool with same

A threaded hole and screw technology, which is applied in the field of threaded hole verticality inspection tools, can solve the problems affecting the accuracy of detection results and the radial deflection of detection screws, etc., and achieve the effects of eliminating radial clearance, improving precision, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

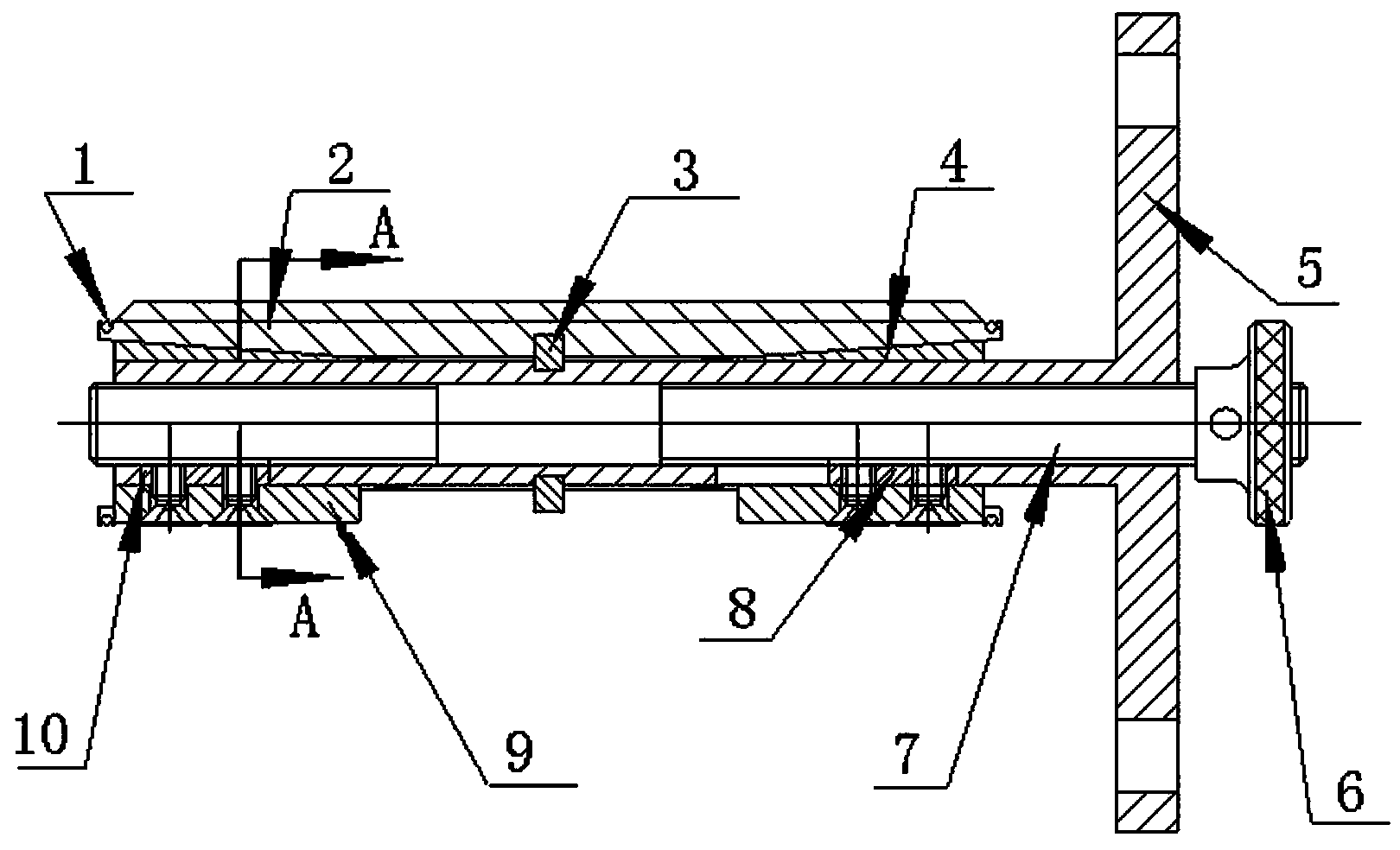

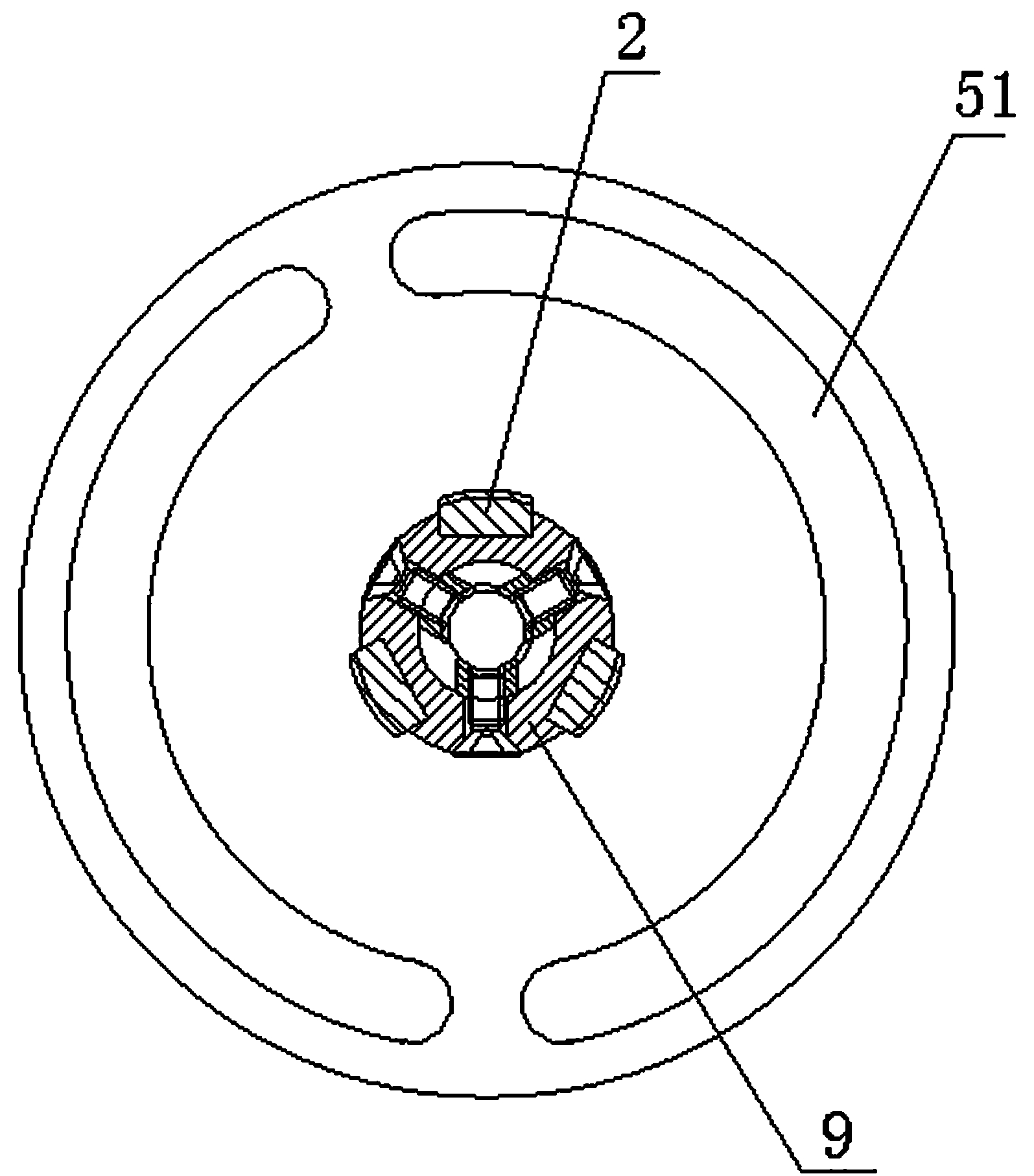

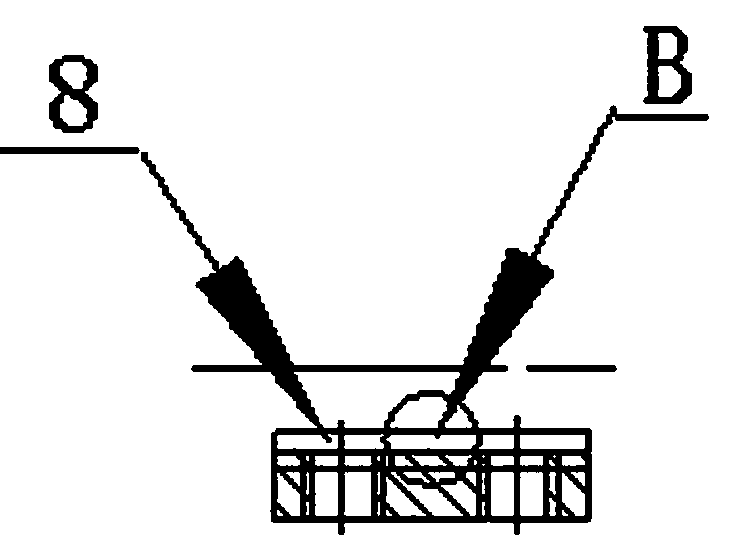

[0040] Embodiment of threaded hole verticality inspection tool among the present invention: as Figure 1 to Figure 22As shown, the threaded hole verticality inspection tool includes a reference base 5, the reference base 5 has a reference disc and a shaft sleeve integrally arranged with the reference disc, the axis of the shaft sleeve is perpendicular to the disc surface of the reference disc, and the reference circle The disc is provided with a central through hole 54 which communicates with the inner hole of the shaft sleeve and is used to wear the central screw 7. The reference disc is provided with a central through hole 54 extending along the arc to make the detection dial indicator 13 The guide slot 51 through which the measuring rod passes, two groups of circumferential limiting holes 52 are arranged at intervals along its axial direction on the shaft sleeve, and each set of circumferential limiting holes 52 is three slotted holes evenly distributed along the circumferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com