Novel axial fixing structure for constant velocity universal joint internal spline

A constant velocity universal joint, axial fixing technology, used in couplings, elastic couplings, mechanical equipment, etc., can solve the problems of spline wear, axial movement, and external spline axial clearance, etc. To achieve the effect of solving the axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

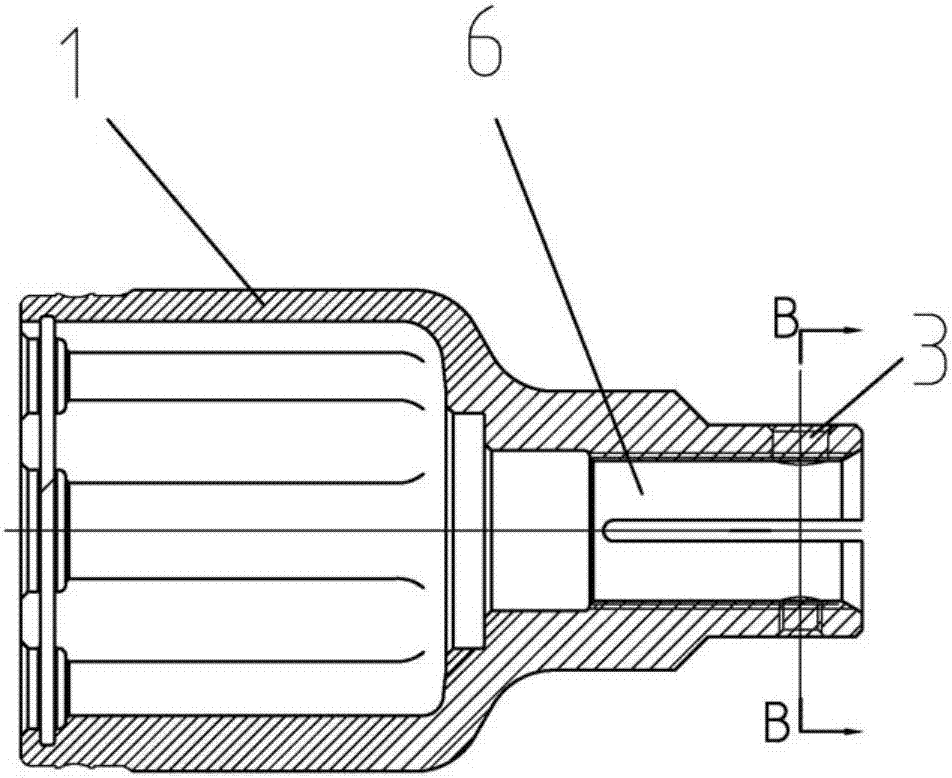

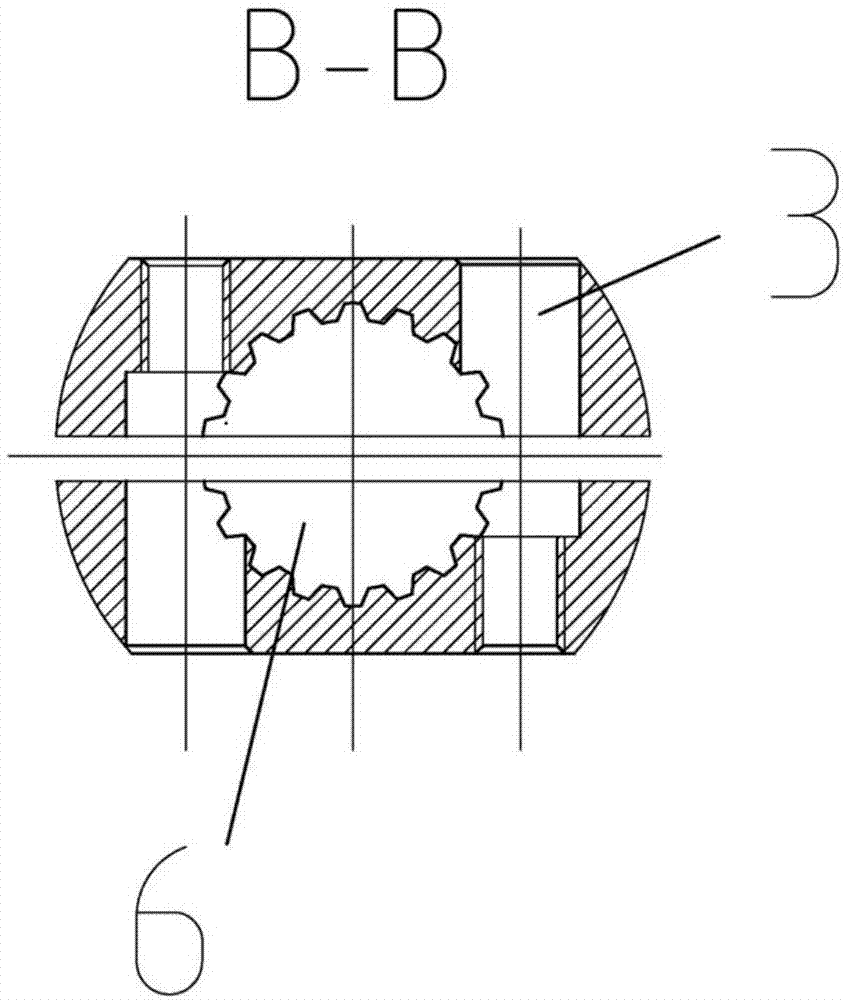

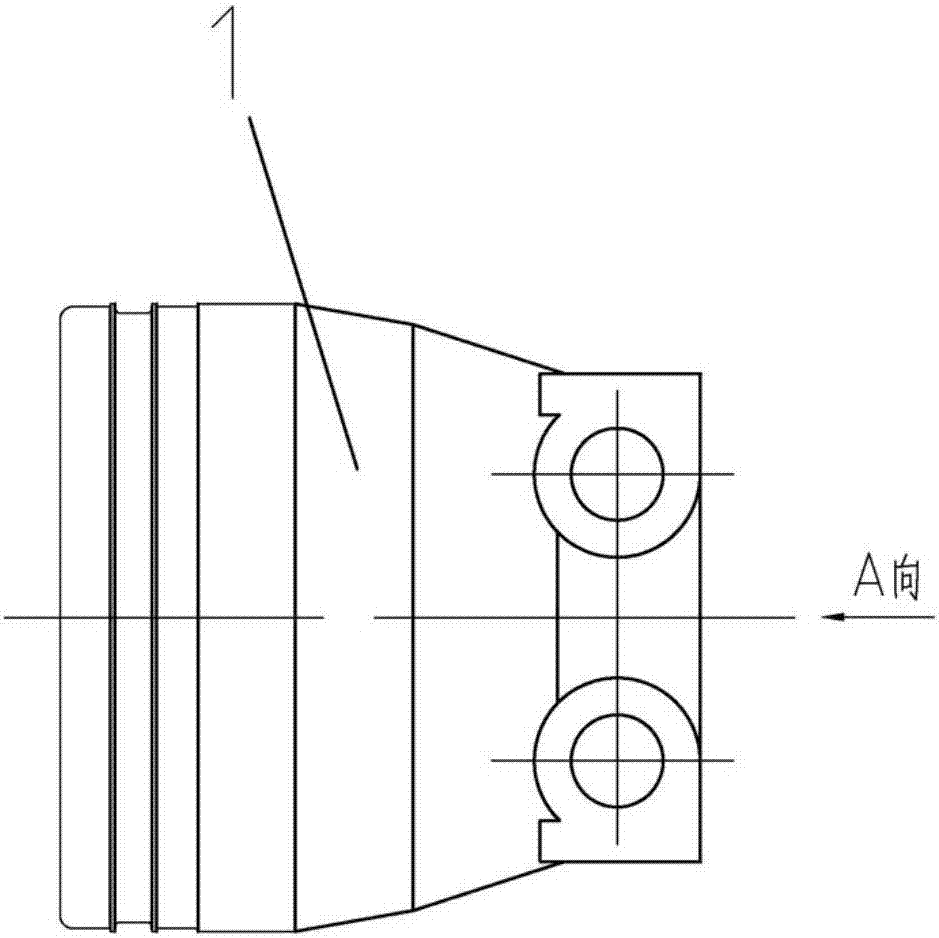

[0026] As shown in the figure, this new constant velocity universal joint inner spline axial fixing structure mainly includes the inner spline housing 1 and the outer spline shaft 2, the outer spline shaft 2 and the inner spline housing 1 The assembling hole 6 is matched and fixed, and the shape of the inner spline housing 1 is a cylindrical shell or a bell-shaped shell. The end of the inner spline housing 1 close to the assembly is provided with a bolt hole 3 , and a bolt 4 is assembled in the bolt hole 3 . The end of the inner spline housing 1 close to the assembly is provided with two bolt holes 3 , and the two bolt holes 3 are located on both sides of the assembly hole 6 with opposite directions.

[0027] Another way is that the end of the inner spline housing 1 close to the assembly is provided with a bolt hole 3 , and the bolt hole 3 is located at the central axial p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com