Patents

Literature

36 results about "Explosive train" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A triggering sequence, also called an explosive train, is a sequence of events that culminates in the detonation of explosives. For safety reasons, most widely used high explosives are difficult to detonate. A primary explosive of higher sensitivity is used to trigger a uniform and predictable detonation of the main body of the explosive. Although the primary explosive itself is generally a more sensitive and expensive compound, it is only used in small quantities and in relatively safely packaged forms. By design there are low explosives and high explosives made such that the low explosives are highly sensitive (i.e. their 'Figure of Insensitivity' is low) and high explosives are comparatively insensitive. This not only affords inherent safety to the usage of explosives during handling and transport, but also necessitates an explosive triggering sequence or explosive train. The explosive triggering sequence or the explosive train essentially consists of an 'initiator', an 'intermediary' and the 'high explosive'.

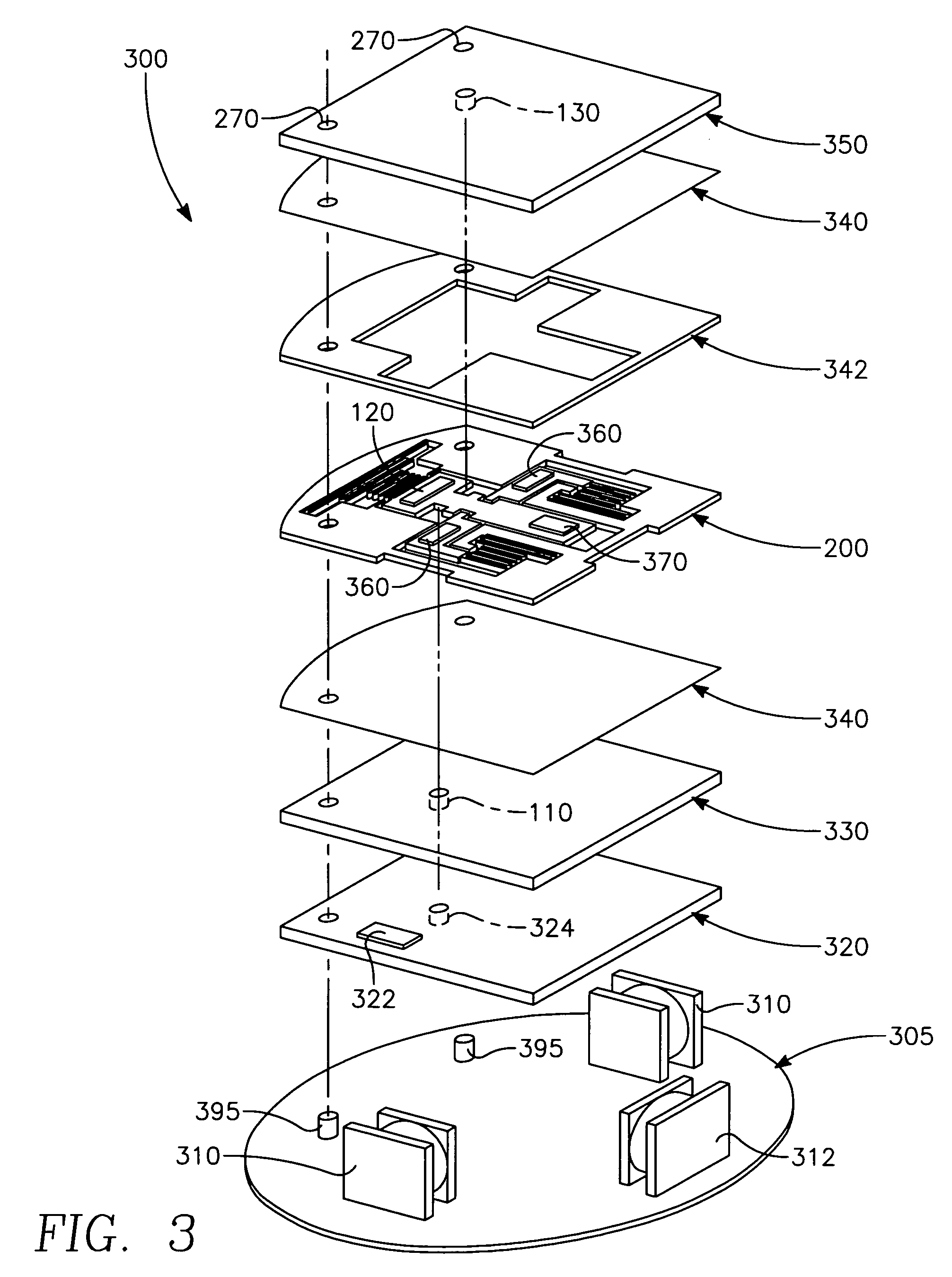

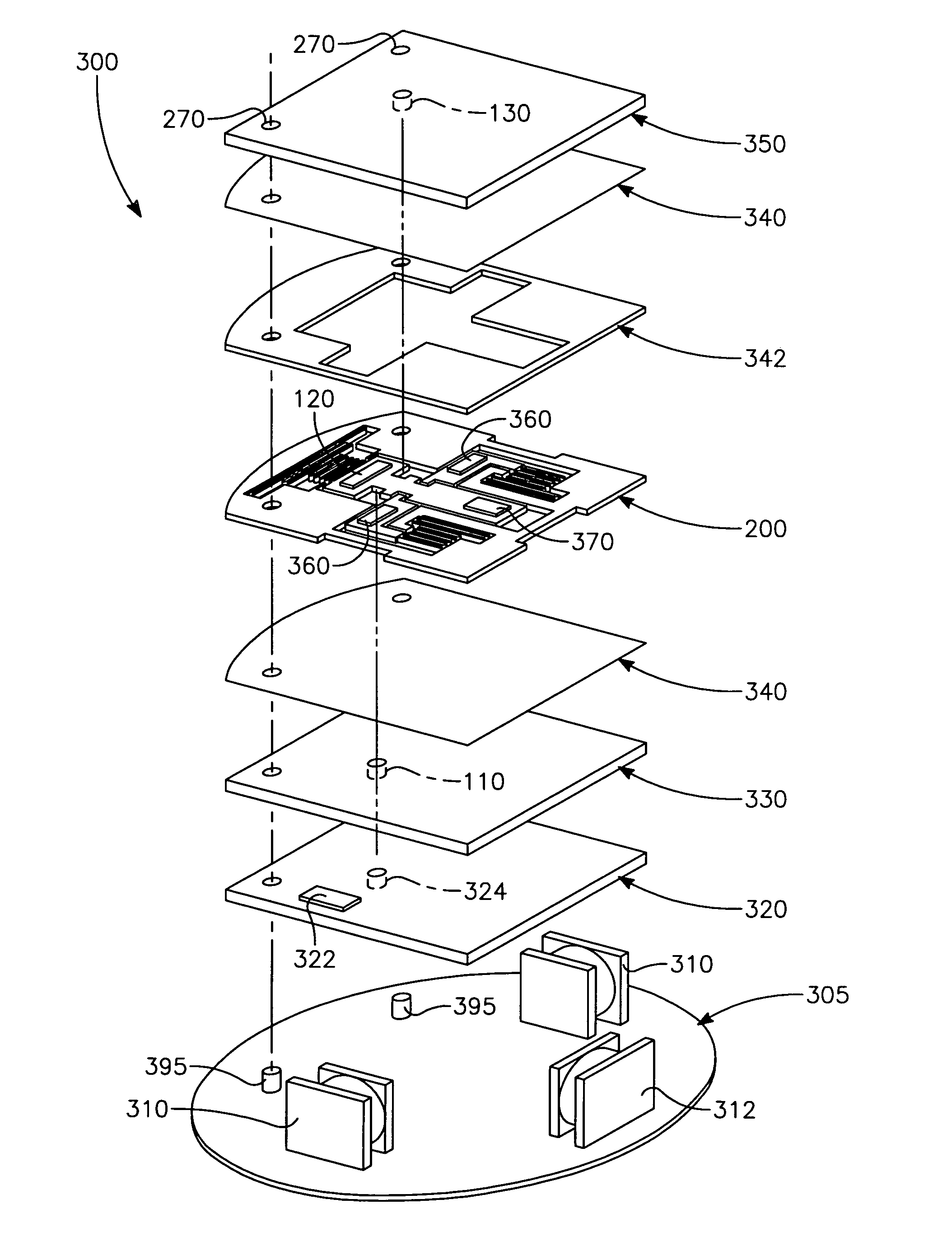

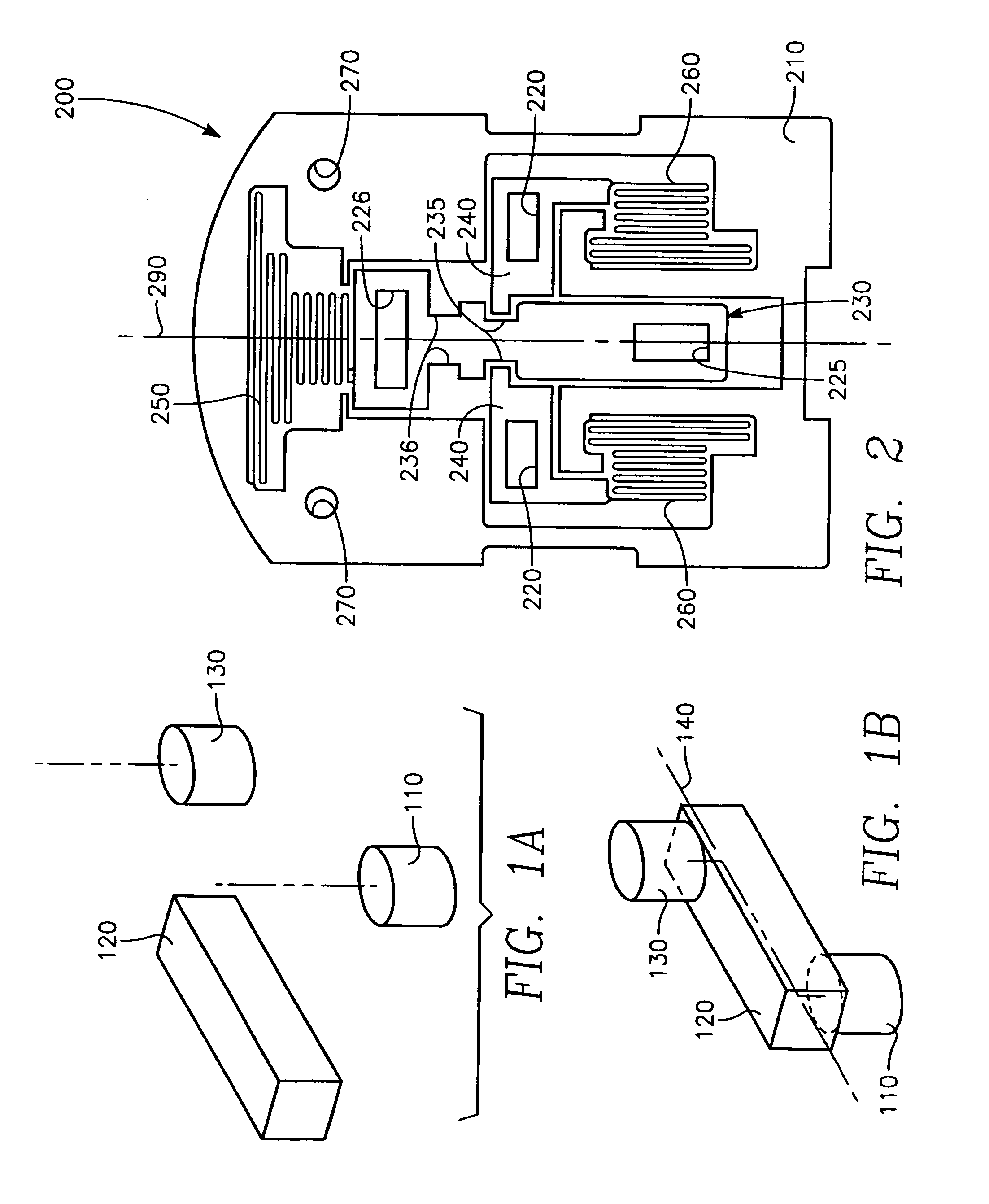

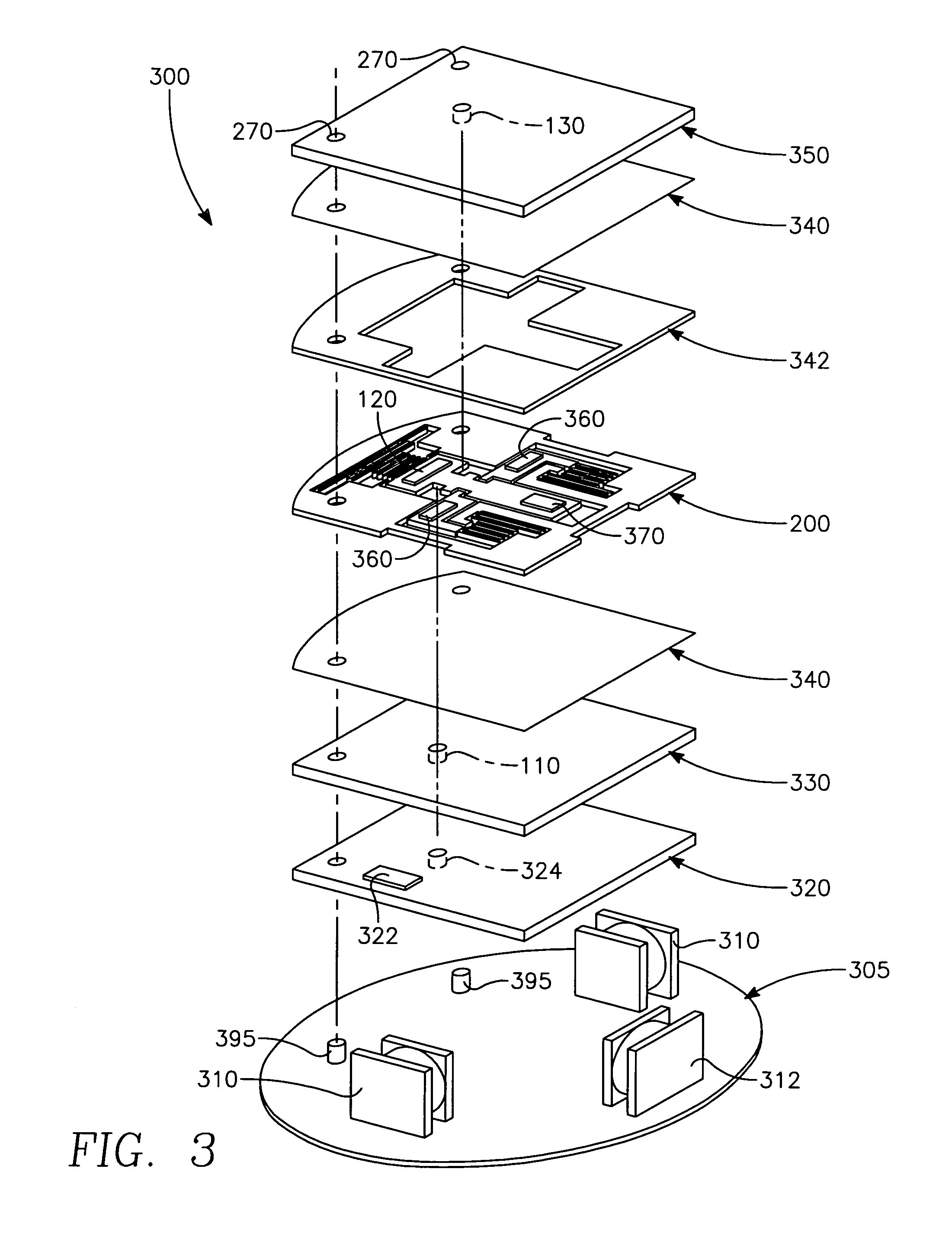

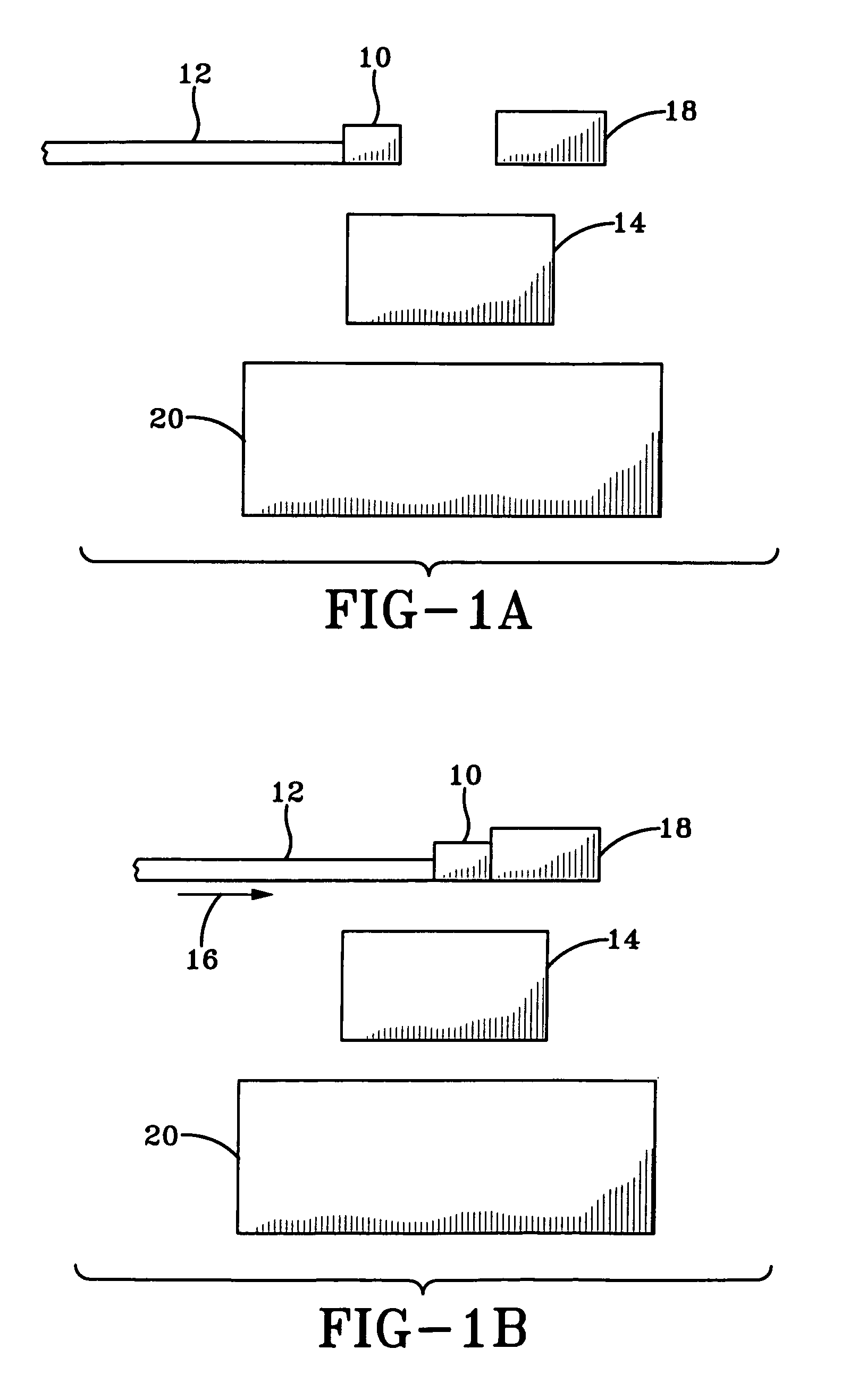

Microelectromechanical safing and arming apparatus

A two-stage acceleration sensing apparatus is disclosed which has applications for use in a fuze assembly for a projected munition. The apparatus, which can be formed by bulk micromachining or LIGA, can sense acceleration components along two orthogonal directions to enable movement of a shuttle from an “as-fabricated” position to a final position and locking of the shuttle in the final position. With the shuttle moved to the final position, the apparatus can perform one or more functions including completing an explosive train or an electrical switch closure, or allowing a light beam to be transmitted through the device.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

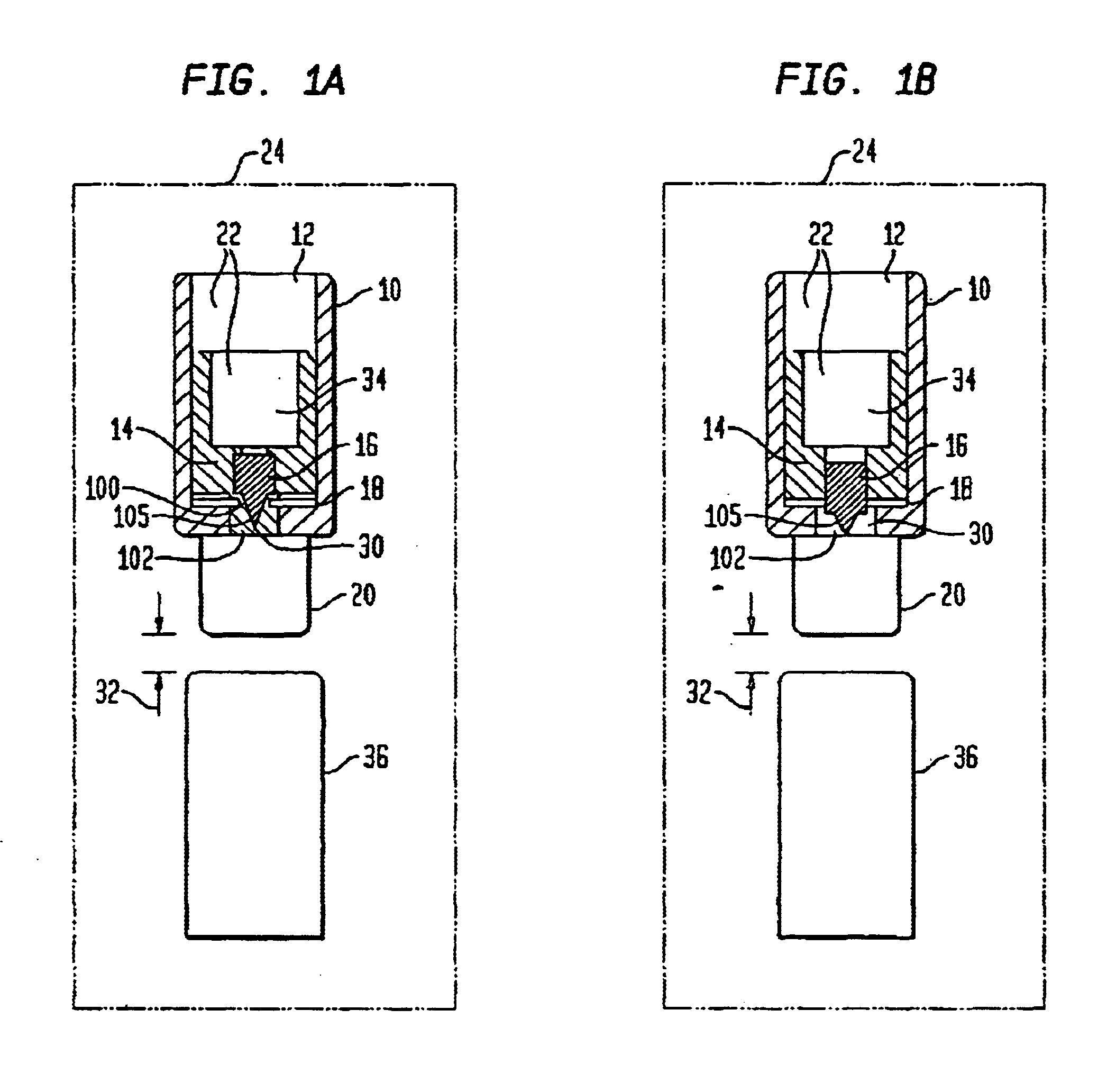

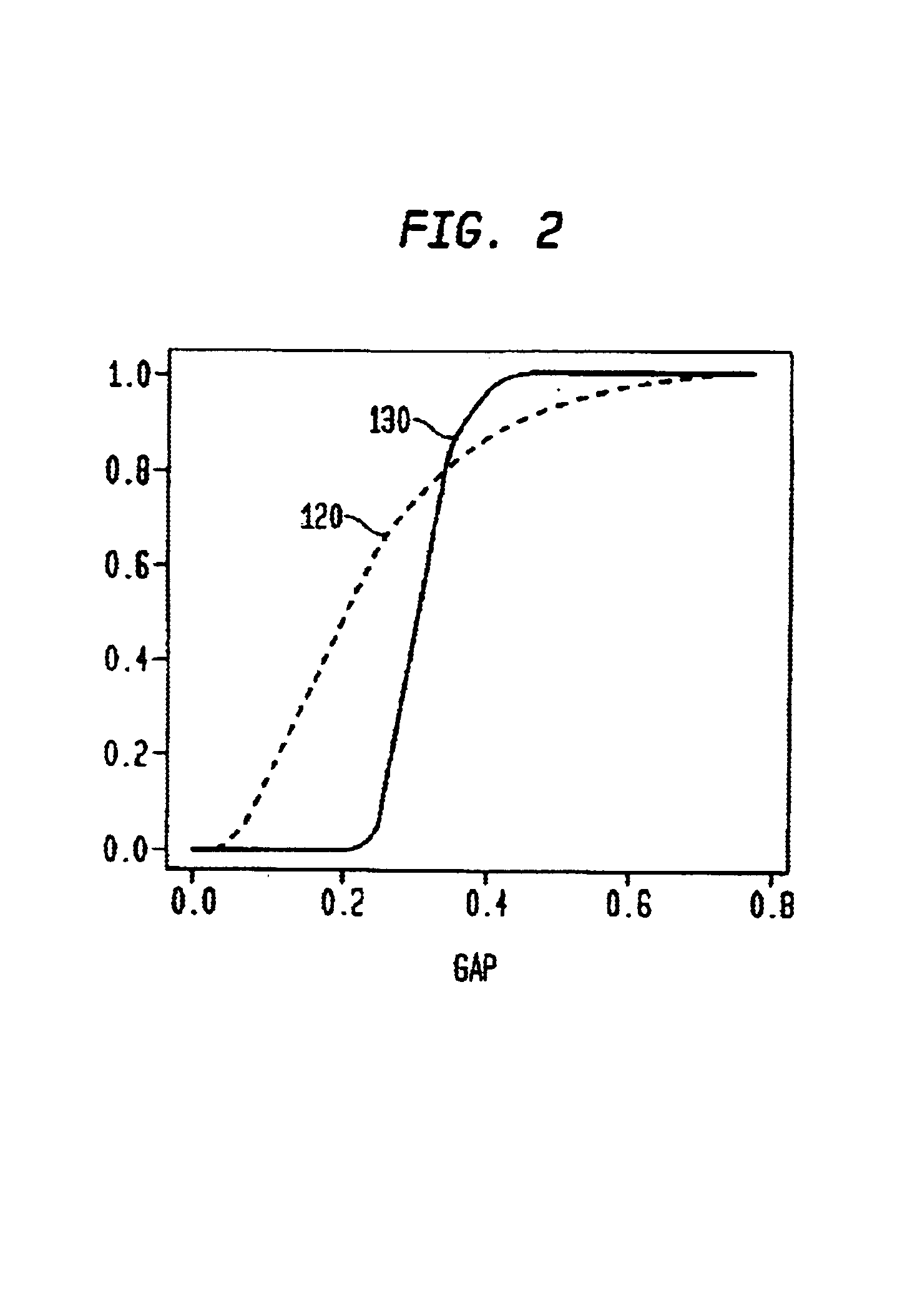

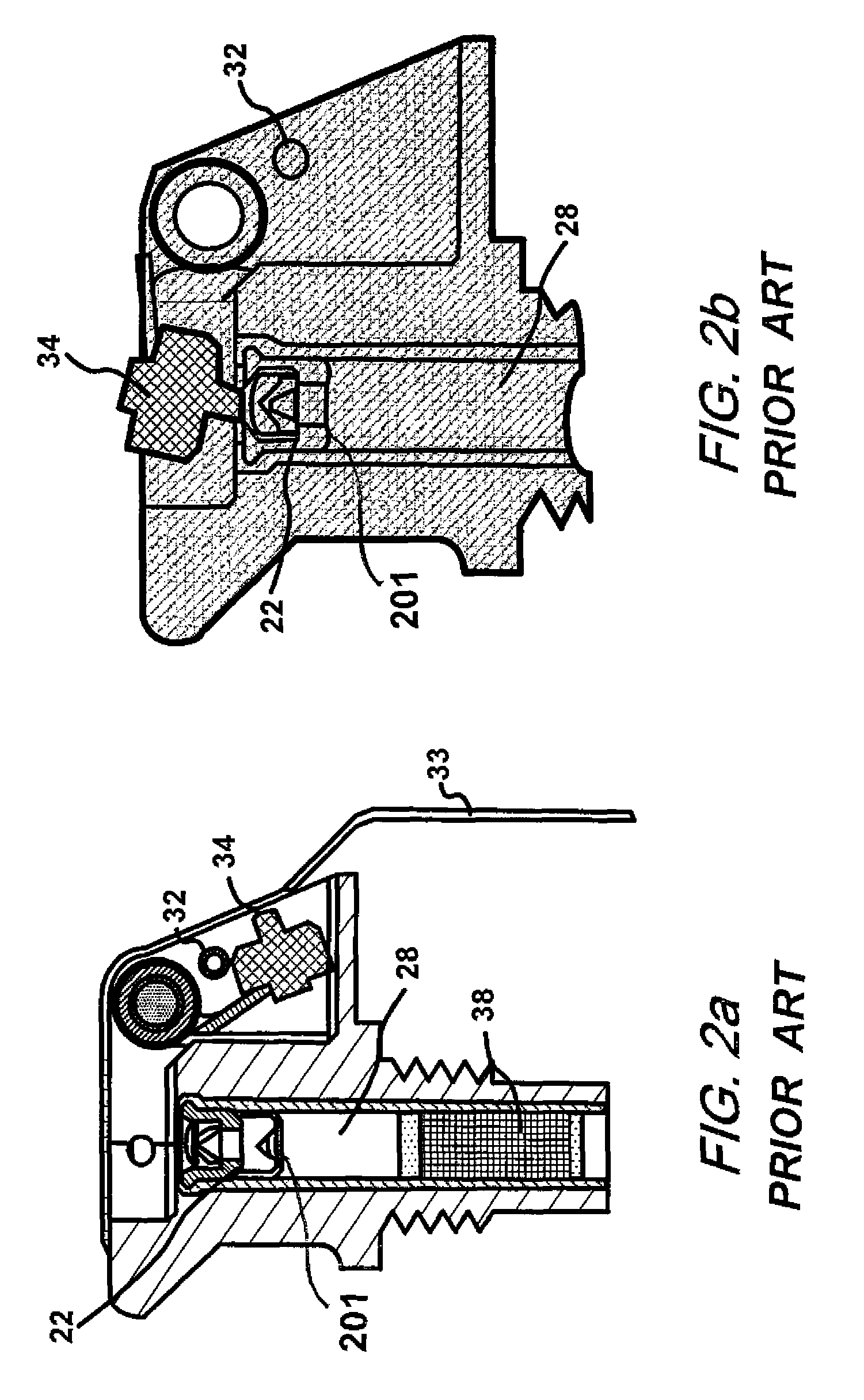

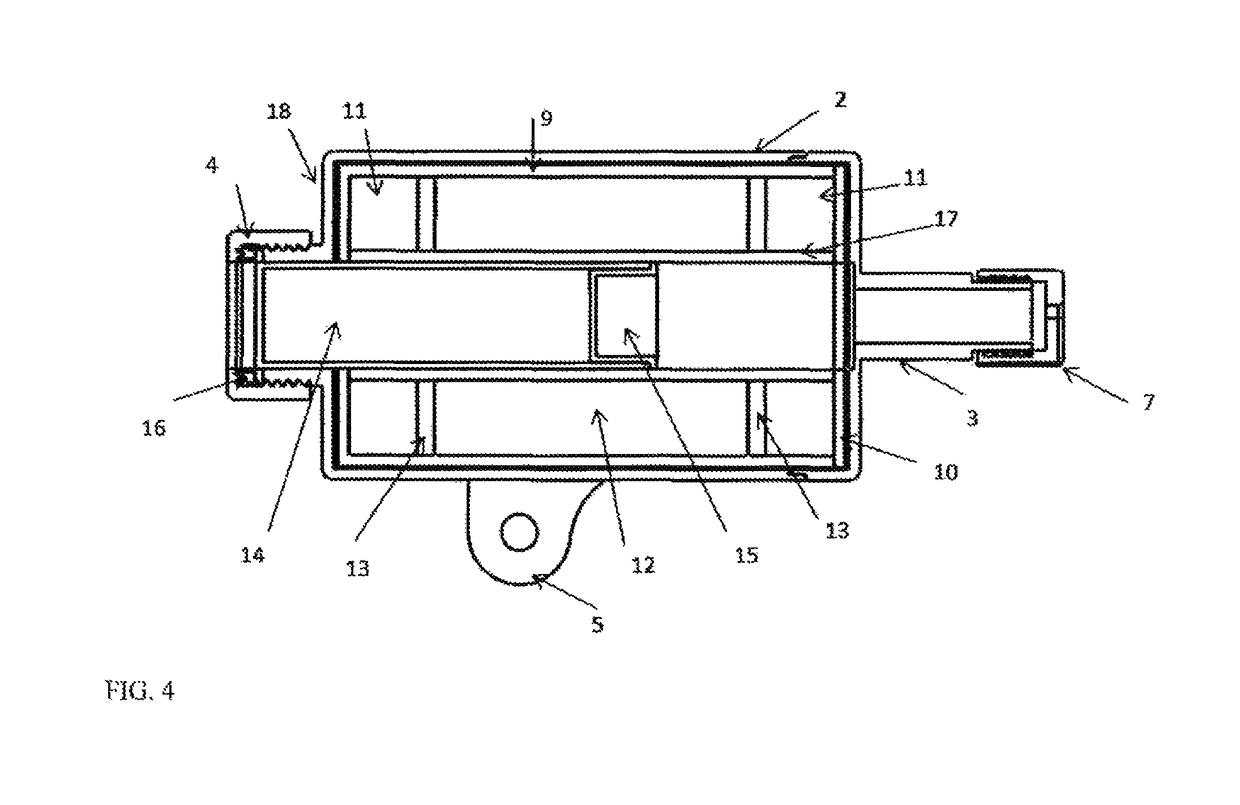

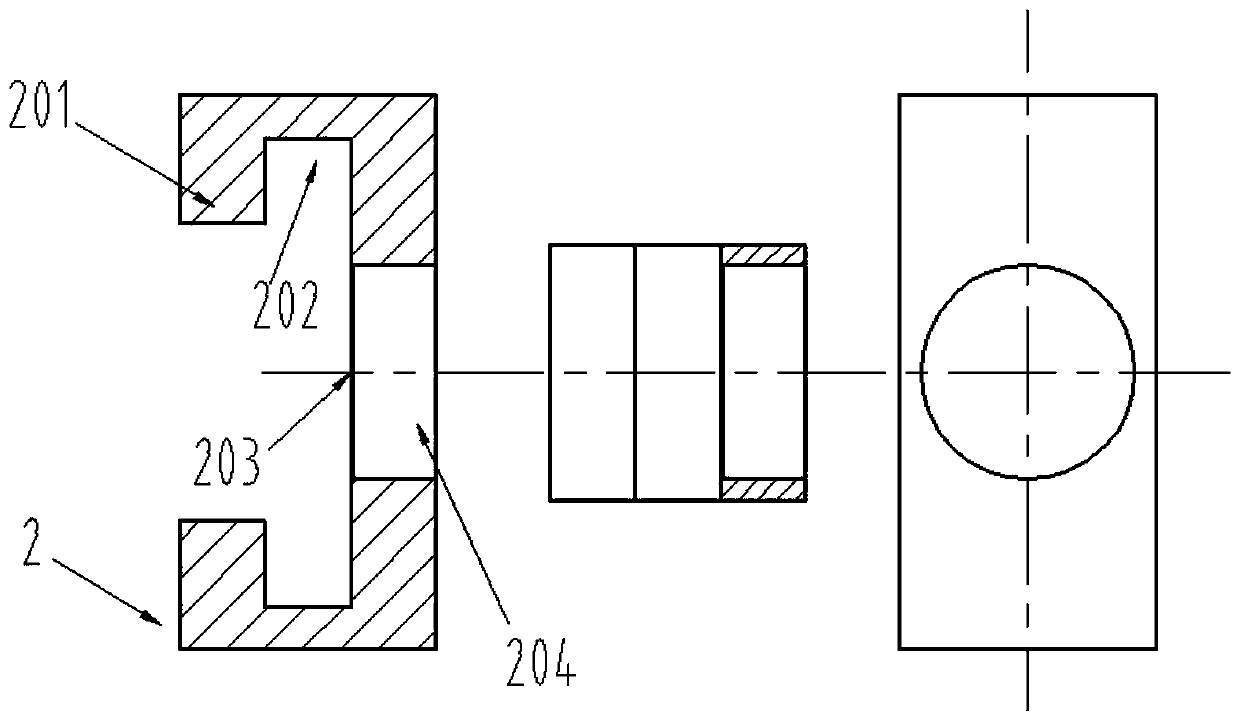

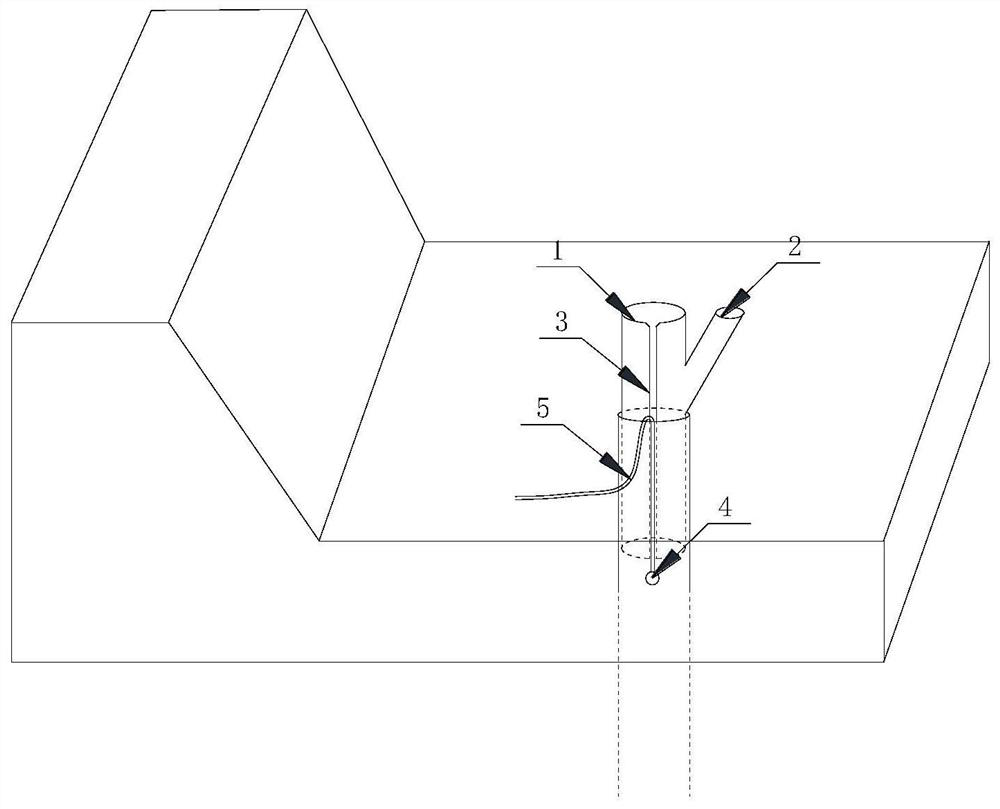

Fuze explosive train device and method

InactiveUS6640719B1Control delayEasy to controlAmmunition projectilesHand grenadesExplosive trainEngineering

A fuze explosive train device for detonating a munition that uses a stab firing pin within a pressure cartridge, with the stab firing pin located between a gas generator and a stab detonator. The firing pin is capable of transferring an energy from the gas generator into the stab detonator in a manner that initiates the stab detonator to a high order explosive reaction. A method of initiating a stab detonator using a stab firing pin also is disclosed.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

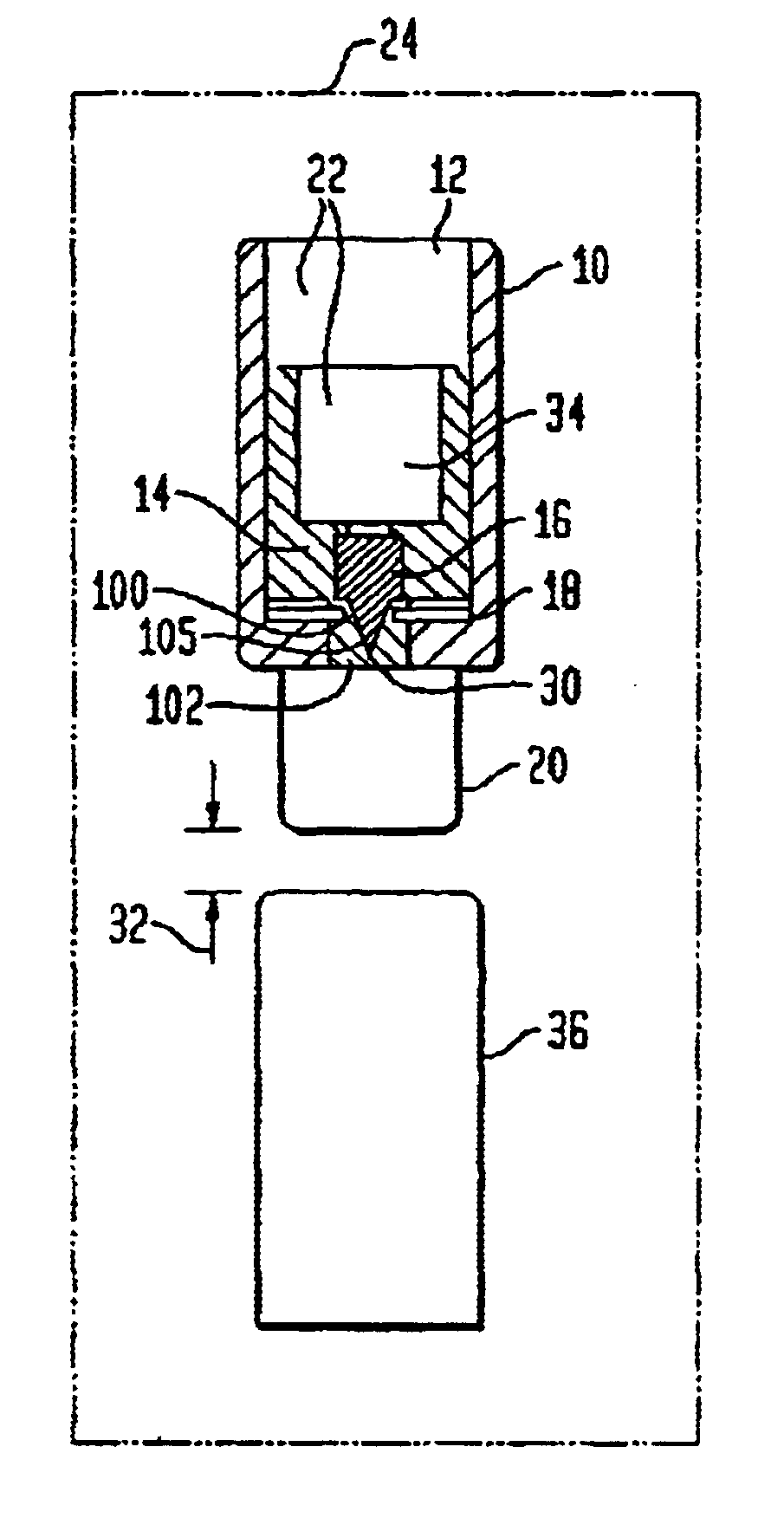

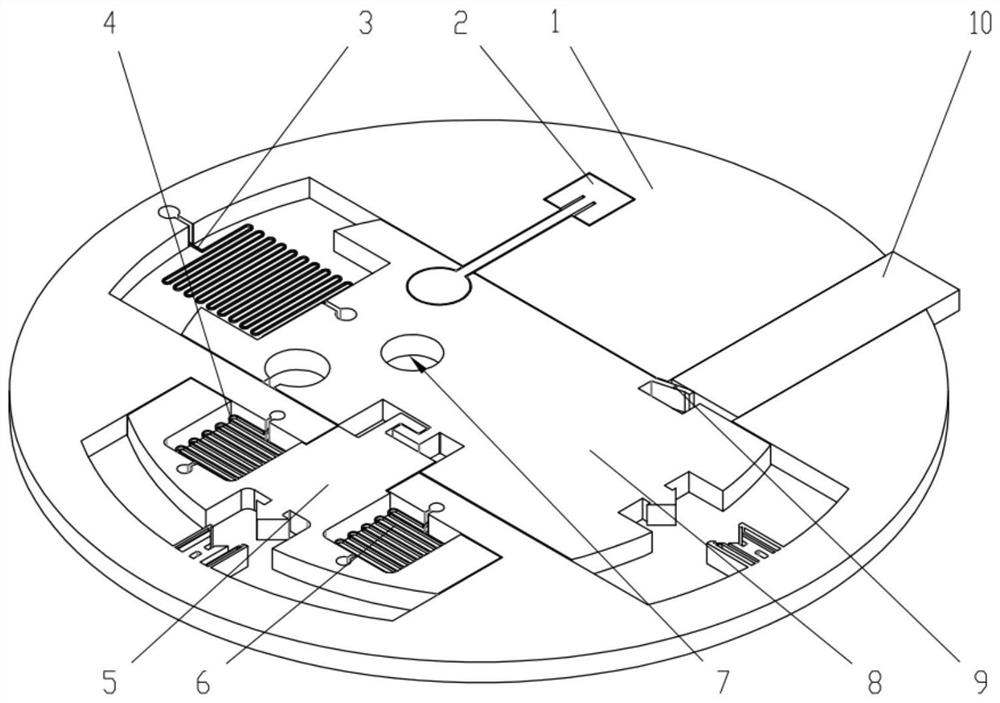

MEMS safe arm device for microdetonation

The present invention relates to a device for electronically arming and firing a MEMS-scale interrupted explosive train to detonate a main charge explosive. The device includes a MEMS slider assembly housing a transfer charge electrically actuated to move between safe and armed positions of the explosive train.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Method for utilizing a MEMS safe arm device for microdetonation

The present invention relates to a method utilizing a MEMS safe arm device for electronically arming and firing a MEMS-scale interrupted explosive train to detonate a main charge explosive. The device includes a MEMS slider assembly housing a transfer charge electrically actuated to move between safe and armed positions of the explosive train.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

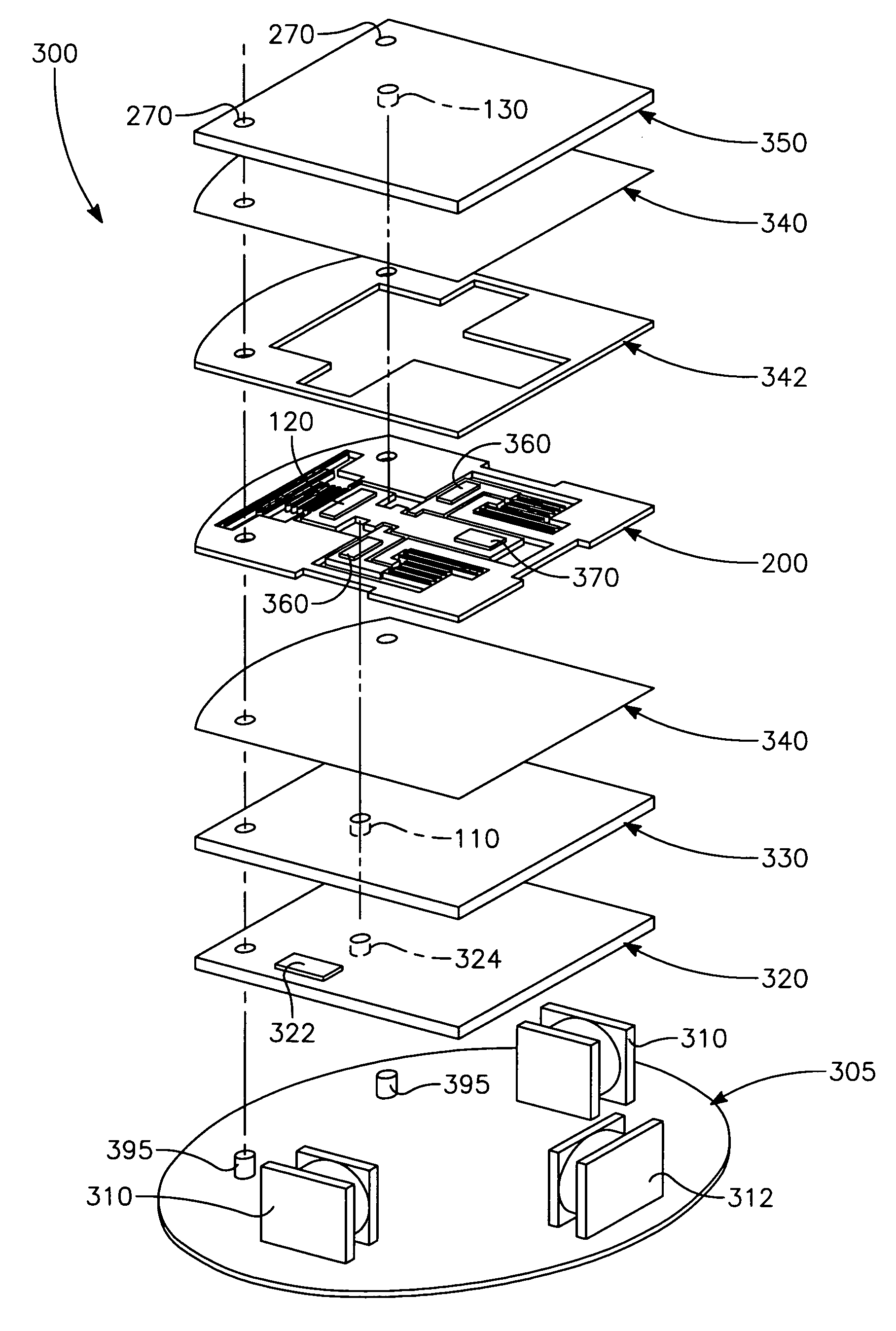

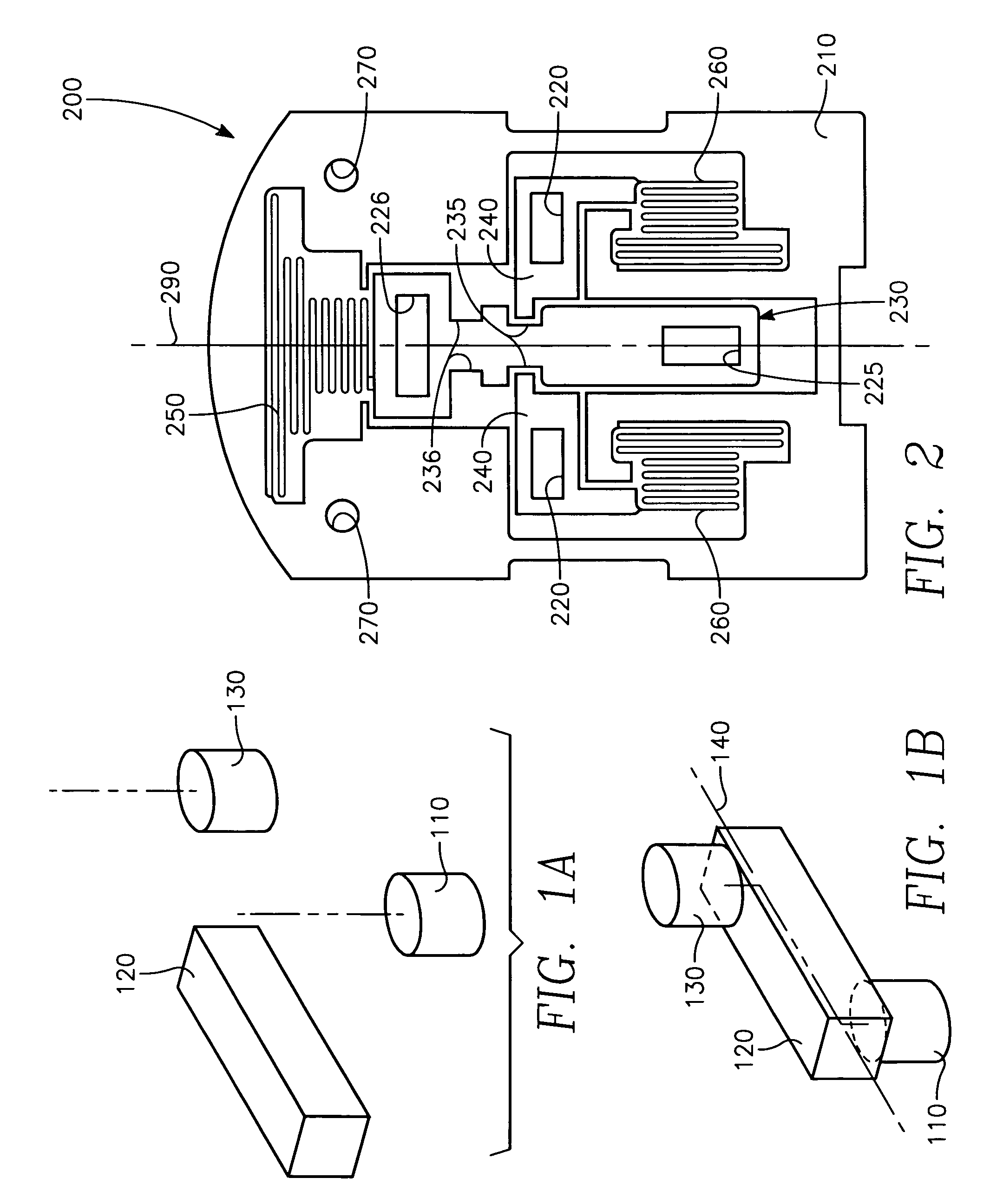

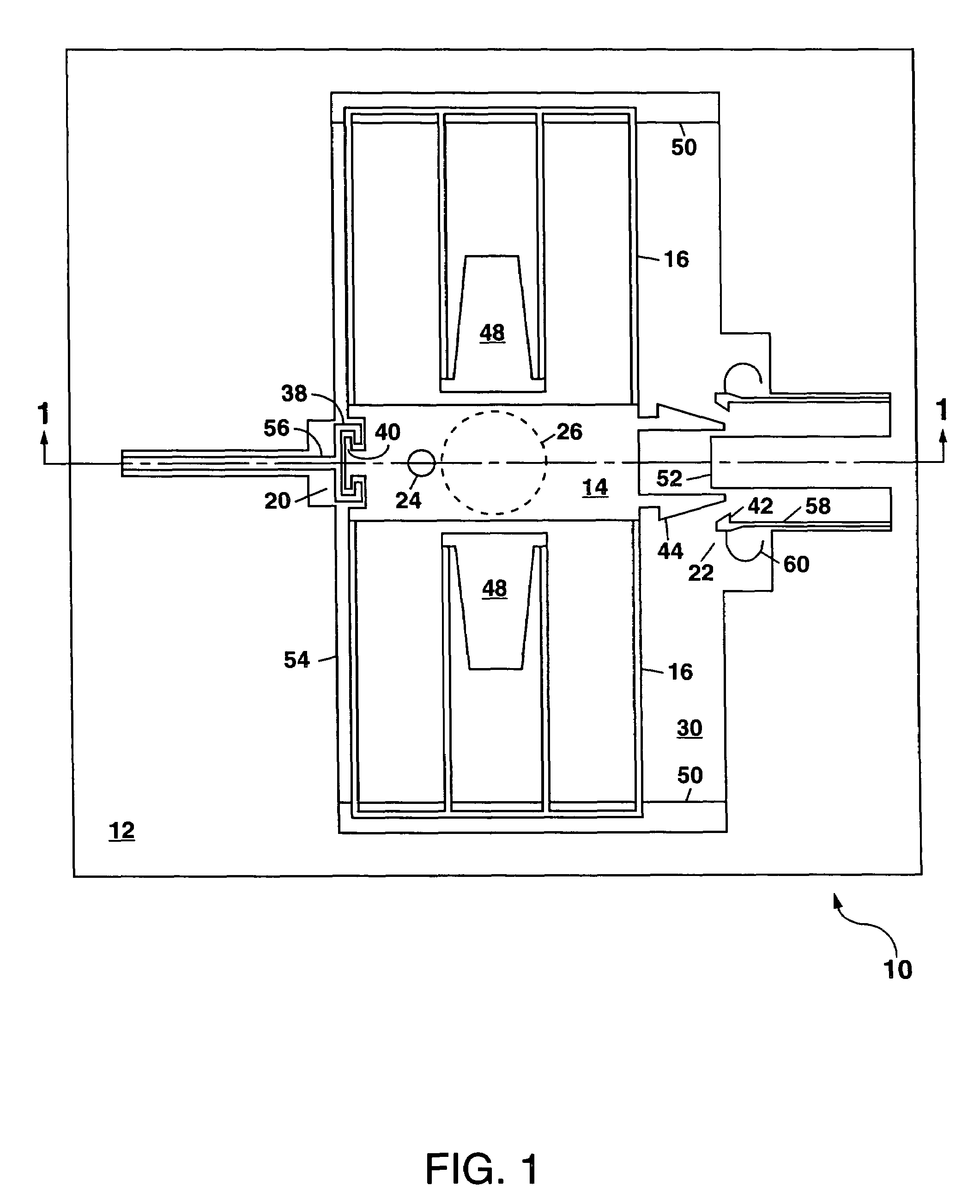

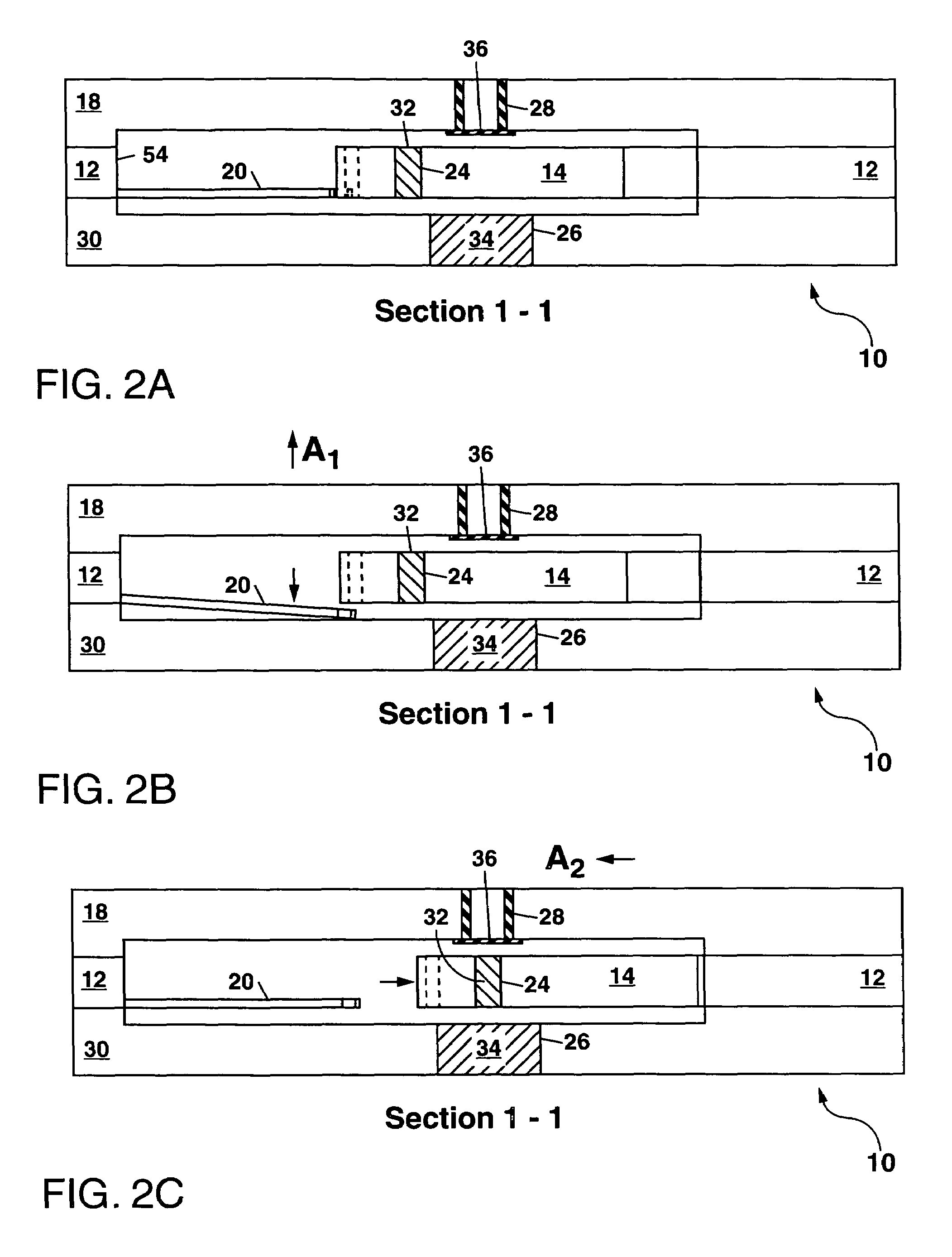

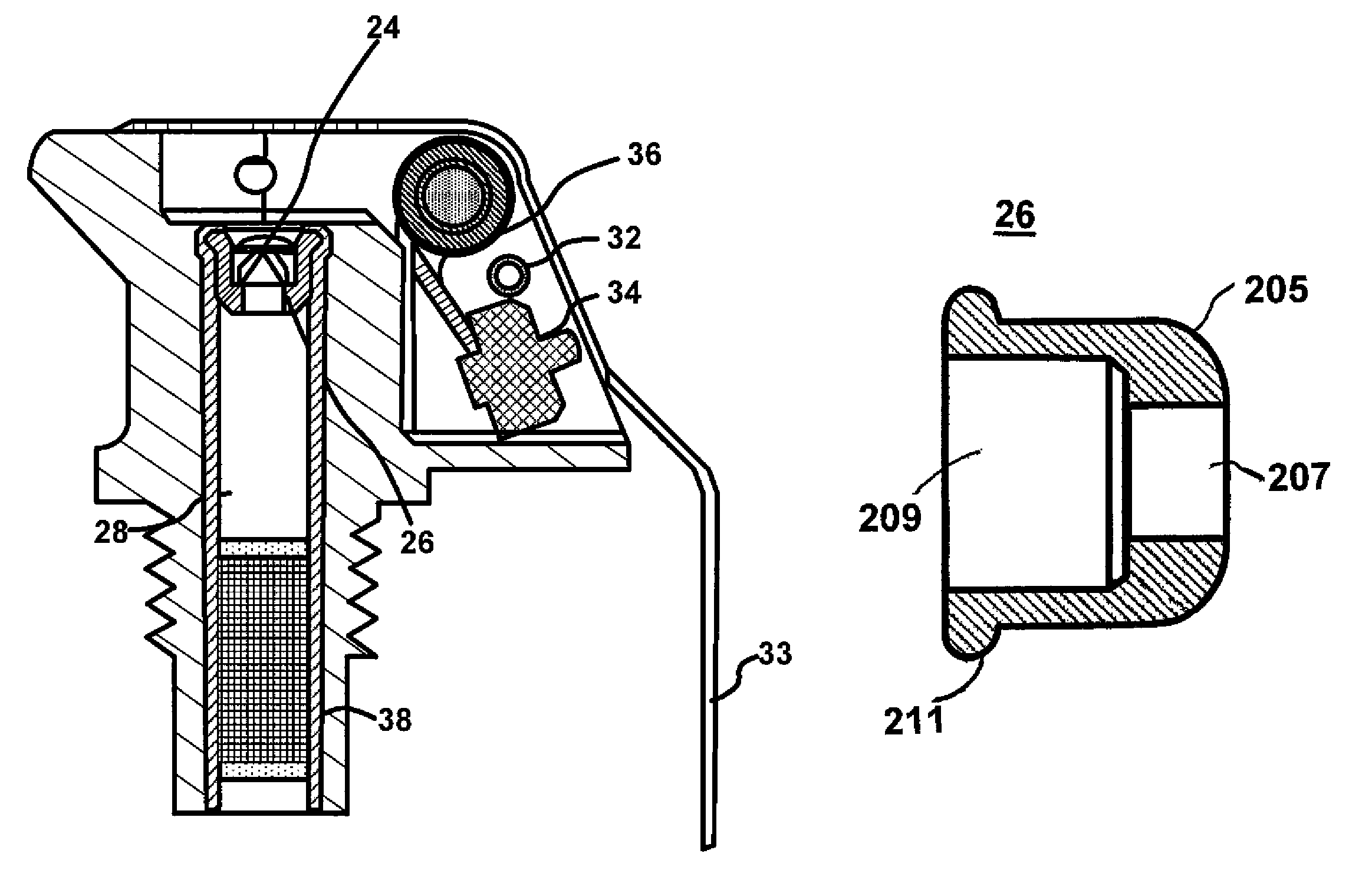

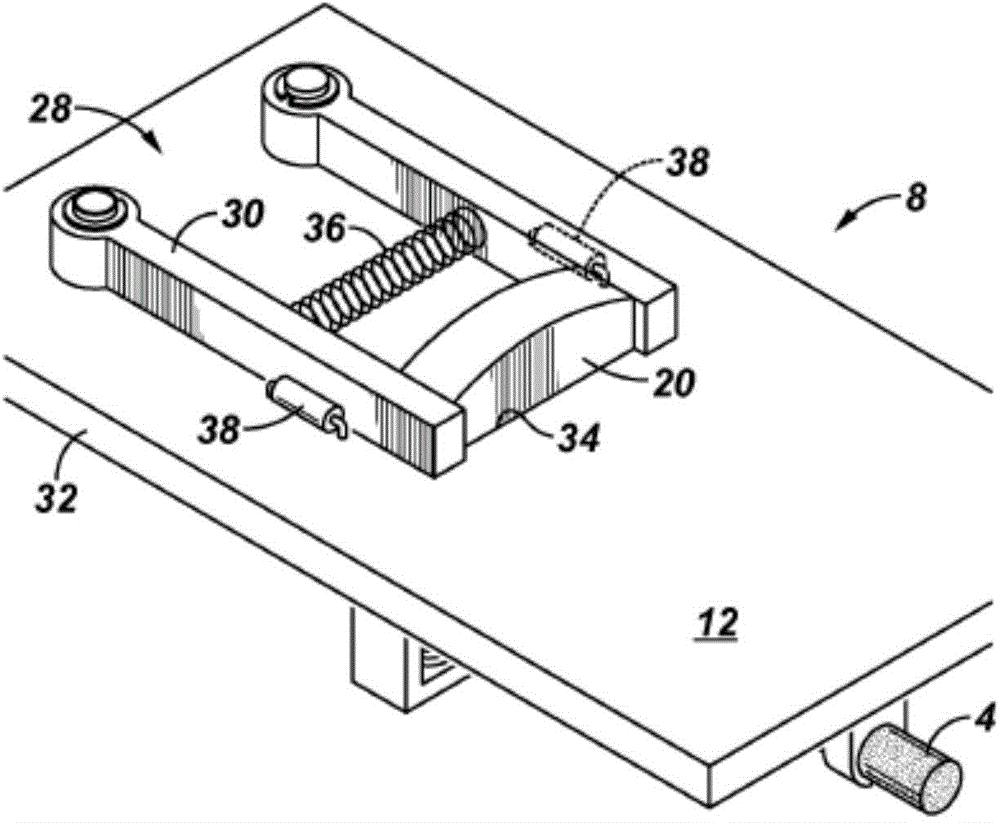

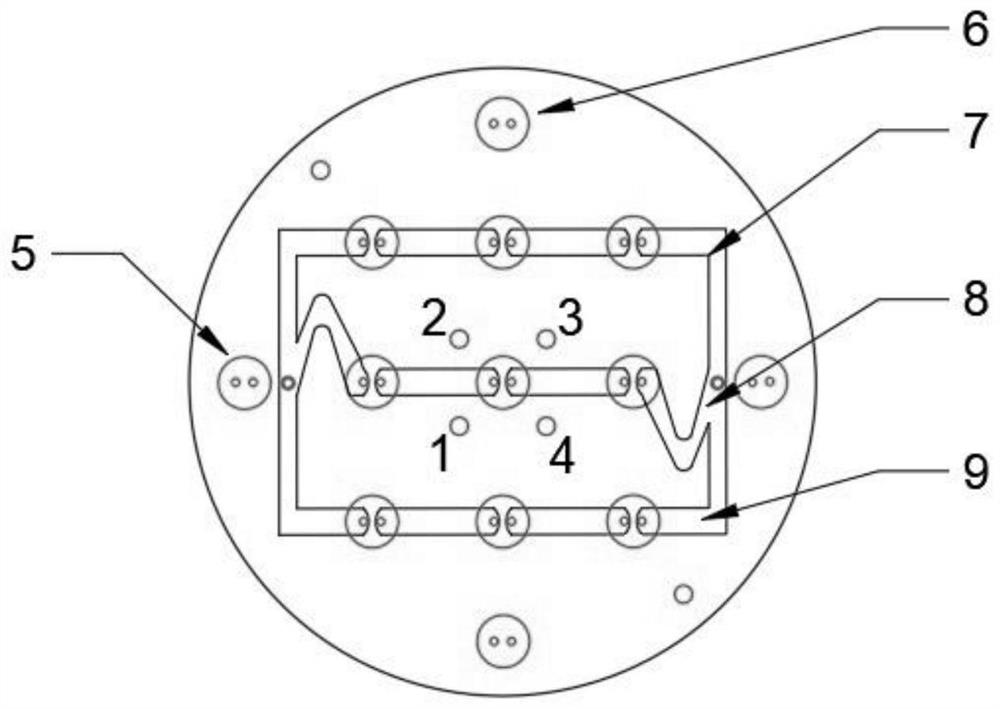

MEMS fuze assembly

A MEMS fuze having a moveable slider with a microdetonator at an end for positioning adjacent an initiator. A setback activated lock and a spin activated lock prevent movement of the slider until respective axial and centrifugal acceleration levels have been achieved. Once these acceleration levels are achieved, the slider is moved by a V-beam shaped actuator arrangement to position the microdetonator relative to a secondary lead to start an explosive train in a munitions round.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Single stage kinetic energy warhead utilizing a barrier-breaching projectile followed by a target-defeating explosively formed projectile

InactiveUS6868791B1Large caliberSimple deliveryExplosive chargesAmmunition projectilesExplosive trainSingle stage

A single stage kinetic energy warhead using multiple explosively formed projectile (EFP) liners in a stacked configuration is capable of breaching intermediate barriers and defeating a primary target. The main explosive charge is detonated and the subsequent shockwave causes the front liner to be shaped to breach an intermediate barrier. The main liner is formed into a more compact rod-shaped projectile designed to defeat the main target. The weight and volume of the stacked liner configuration of the present system is significantly lower than the weight and volume of current systems. The present system requires a single firing explosive train eliminating developmental cost and complex fusing. The present system utilizes explosive detonation, simplifying the delivery of a projectile and eliminating the need for a missile delivery system. The size and simplicity of the present system allows for portability and use by an individual.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Fuse capable of improving grazing impact and self-destruction reliability

ActiveCN111928742AImprove reliabilityReasonable use of internal spaceImpact fuzesMechanical fuzesExplosive trainForeign matter

The invention discloses a fuse capable of improving grazing impact and self-destruction reliability. On the basis of the original standard product design, a piston type part (such as a support barrelor a shearing barrel) capable of sliding axially is additionally arranged at the head of the fuse, the piston type part is pushed to move axially by the aid of target fragments produced when the fusecollides with a target or ground sediments during landing, a self-destruction spring is compressed, then a firing pin is pushed to trigger a detonator, the explosive sequence is detonated, and projectile detonation is realized. Meanwhile, the piston type part capable of sliding axially can stop foreign matters such as the ground sediments and the like from entering an inner cavity of the fuse to hinder movement of the firing pin when the fuse lands (particularly grazes), the firing pin stabs the detonator reliably, and the reliable grazing impact effect of the fuse is guaranteed. The fuse is simple in structure, and few changes are made on the original structure.

Owner:NANJING UNIV OF SCI & TECH

MEMS fuze assembly

A MEMS fuze having a moveable slider with a microdetonator at an end for positioning adjacent an initiator. A setback activated lock and a spin activated lock prevent movement of the slider until respective axial and centrifugal acceleration levels have been achieved. Once these acceleration levels are achieved, the slider is moved by a V-beam shaped actuator arrangement to position the microdetonator relative to a secondary lead to start an explosive train in a munitions round.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

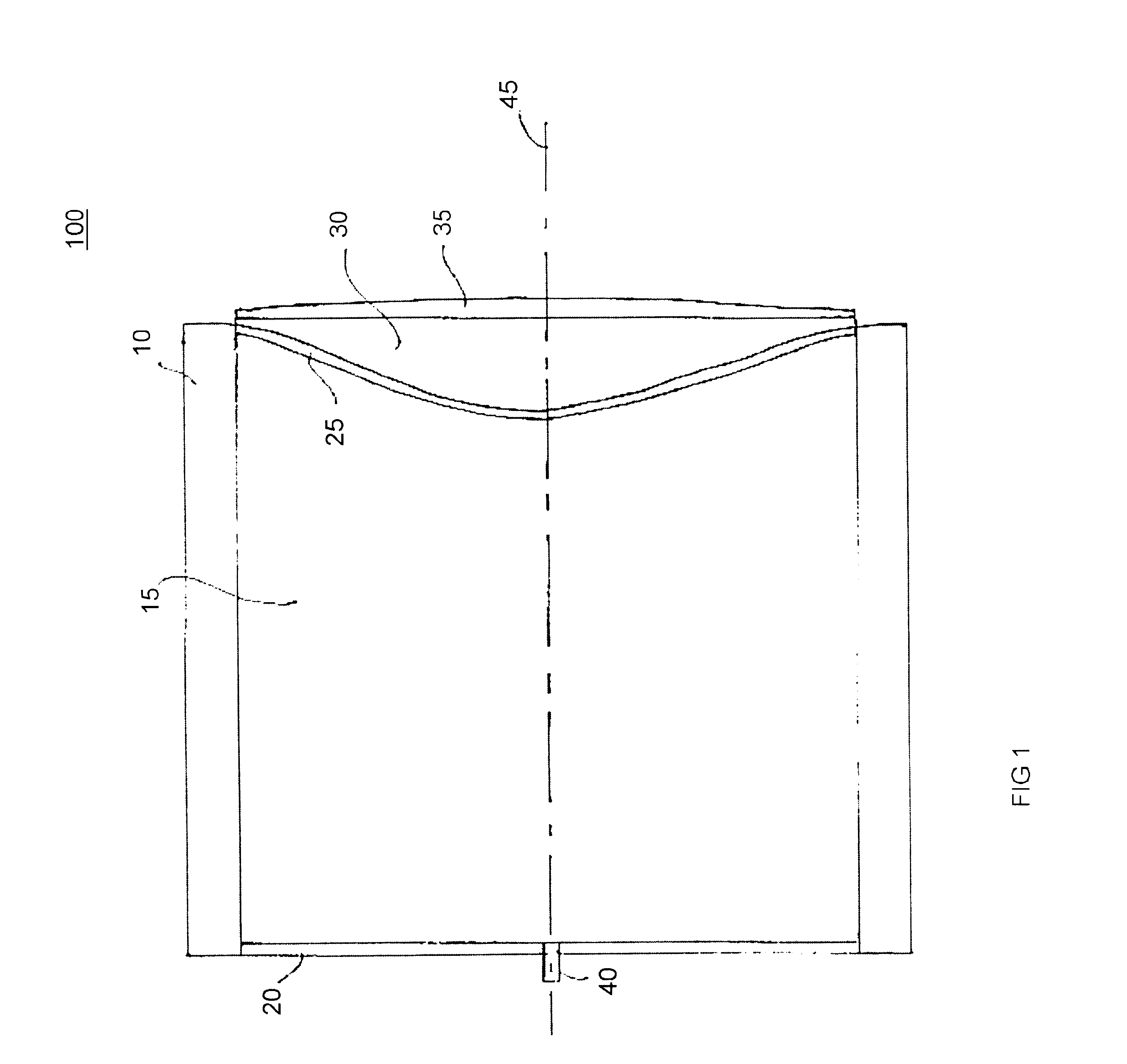

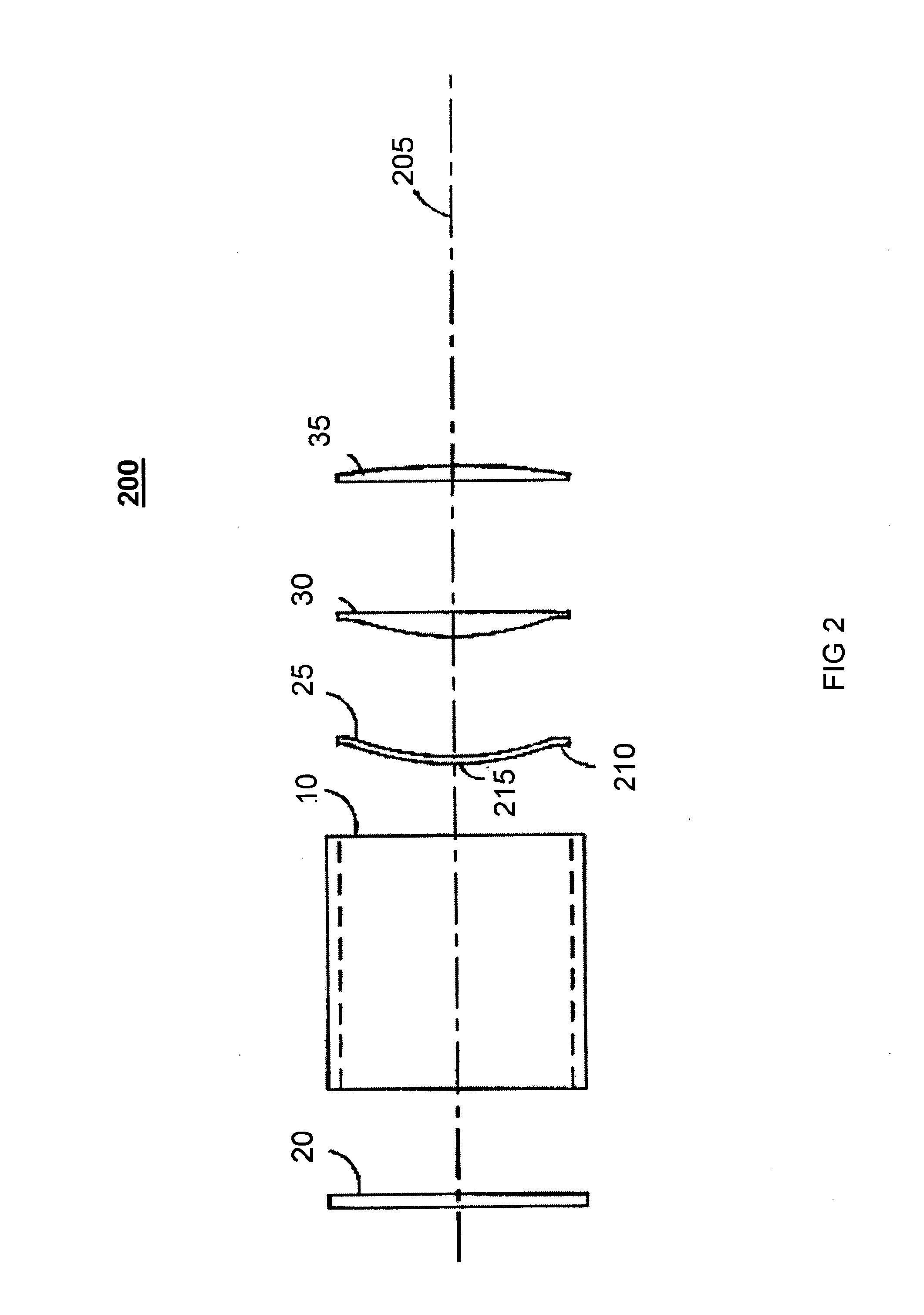

Microelectromechanical safing and arming apparatus

A two-stage acceleration sensing apparatus is disclosed which has applications for use in a fuze assembly for a projected munition. The apparatus, which can be formed by bulk micromachining or LIGA, can sense acceleration components along two orthogonal directions to enable movement of a shuttle from an “as-fabricated” position to a final position and locking of the shuttle in the final position. With the shuttle moved to the final position, the apparatus can perform one or more functions including completing an explosive train or an electrical switch closure, or allowing a light beam to be transmitted through the device.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

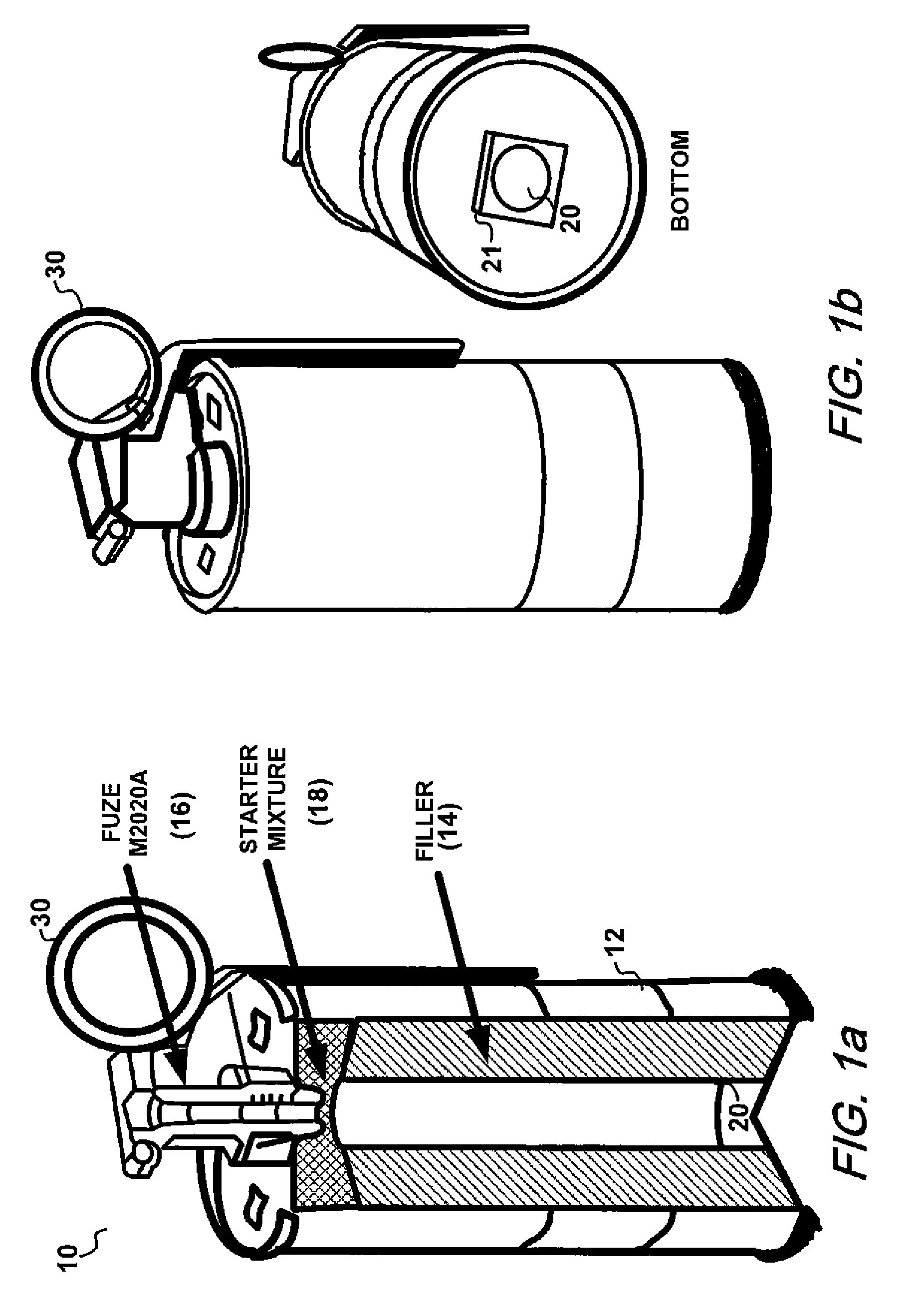

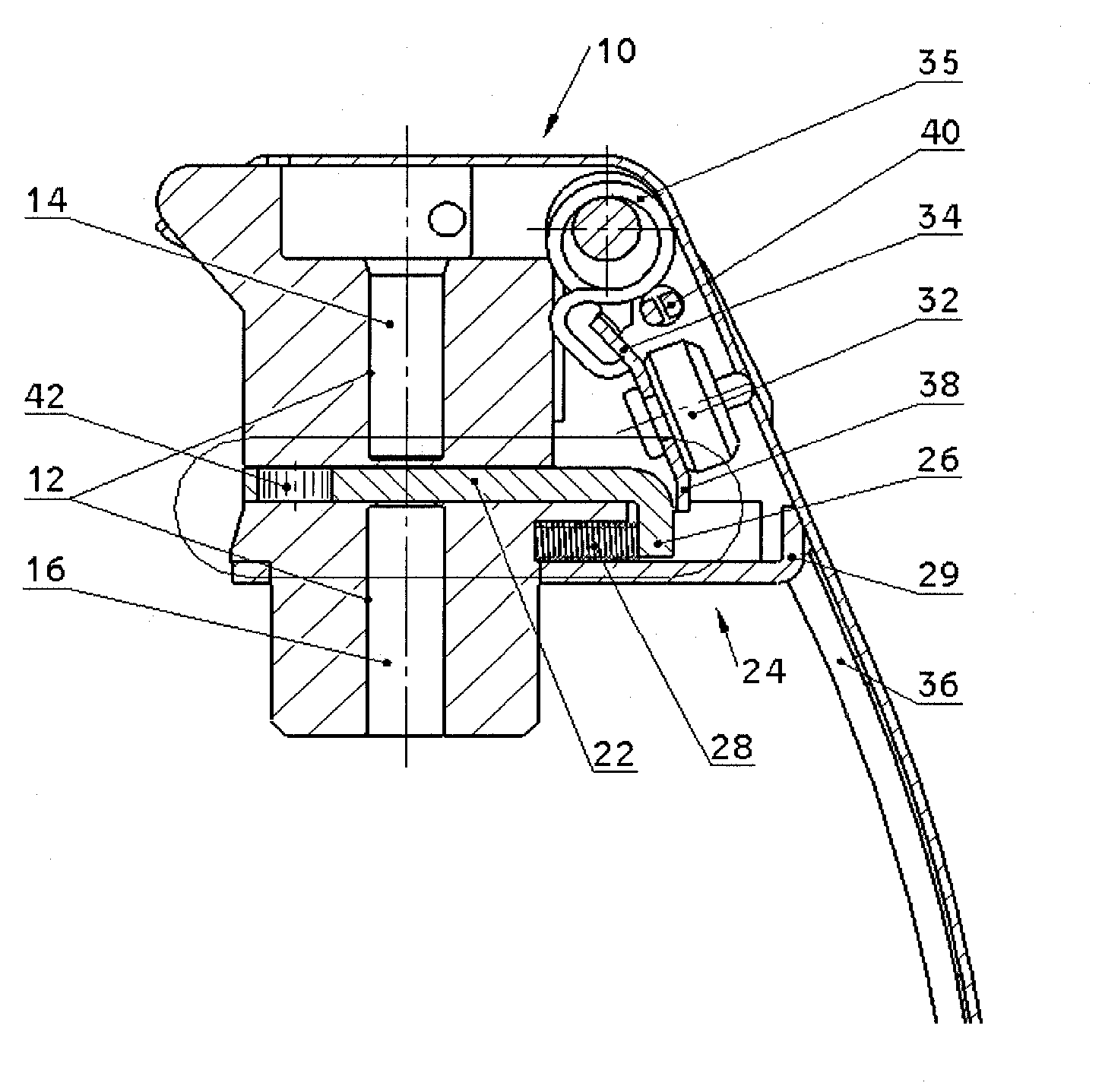

Primer adapter for hand grenade fuze

InactiveUS8453573B1History of reliabilityImprove reliabilityHand grenadesAmmunition fuzesExplosive trainEngineering

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

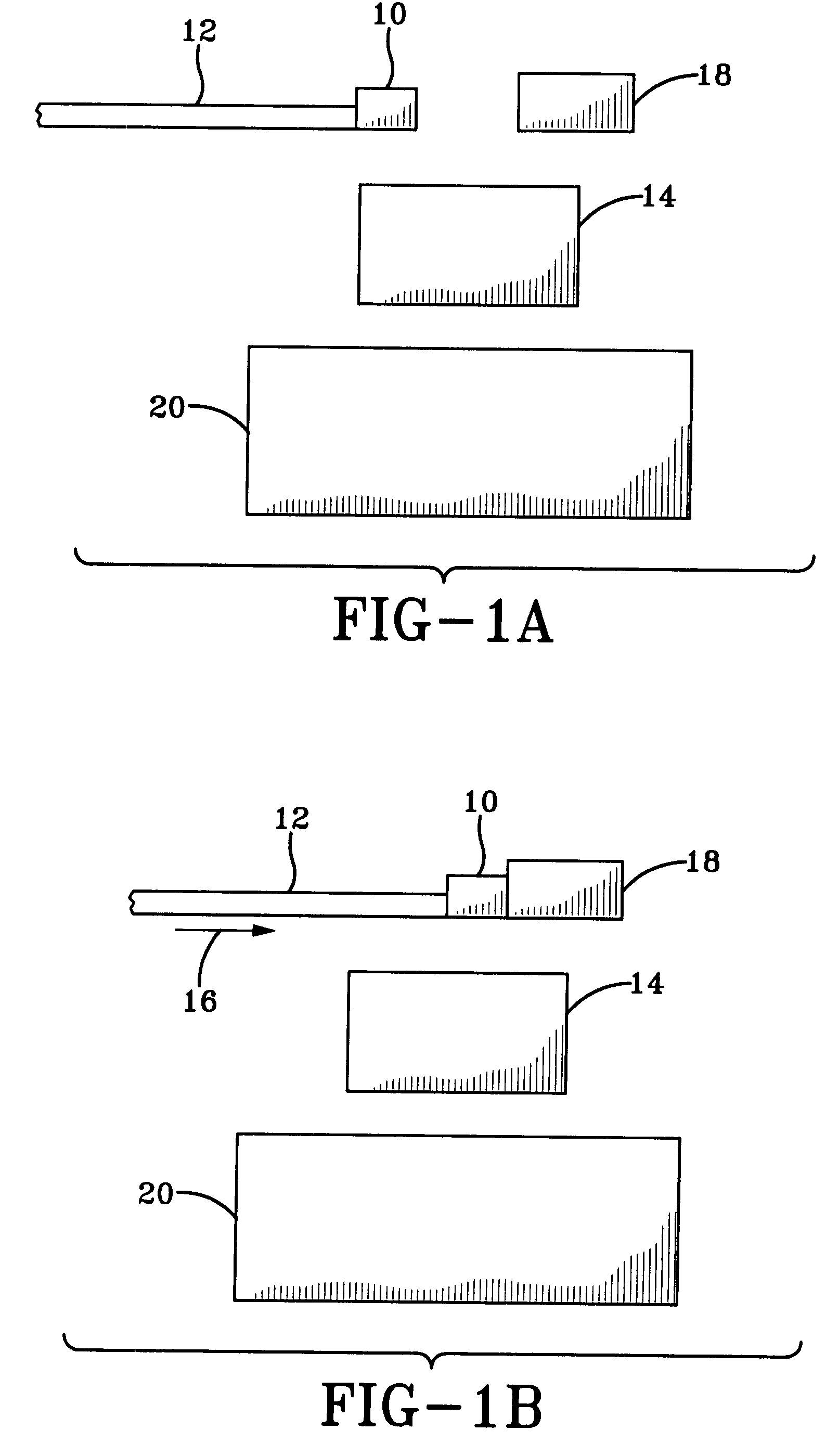

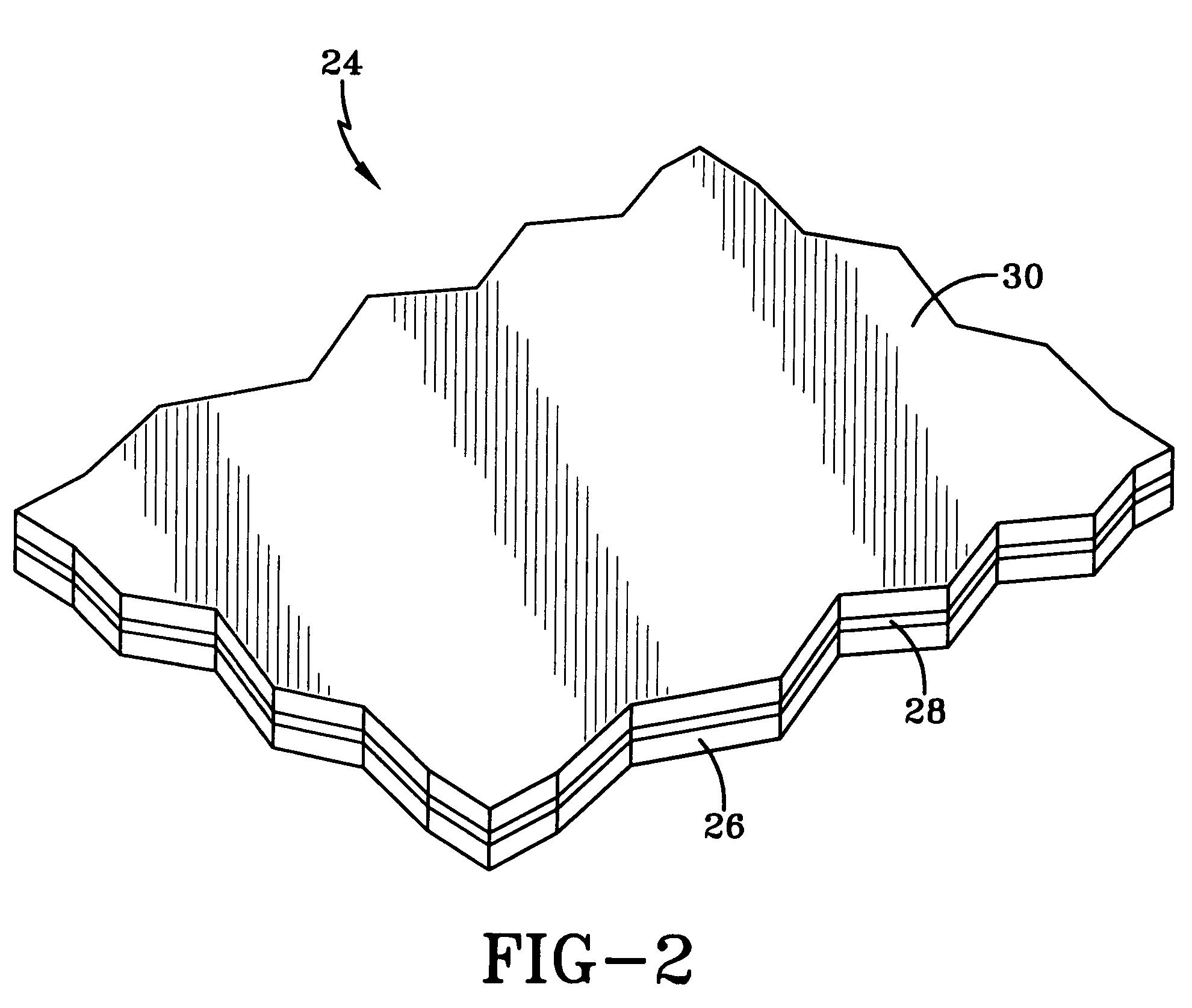

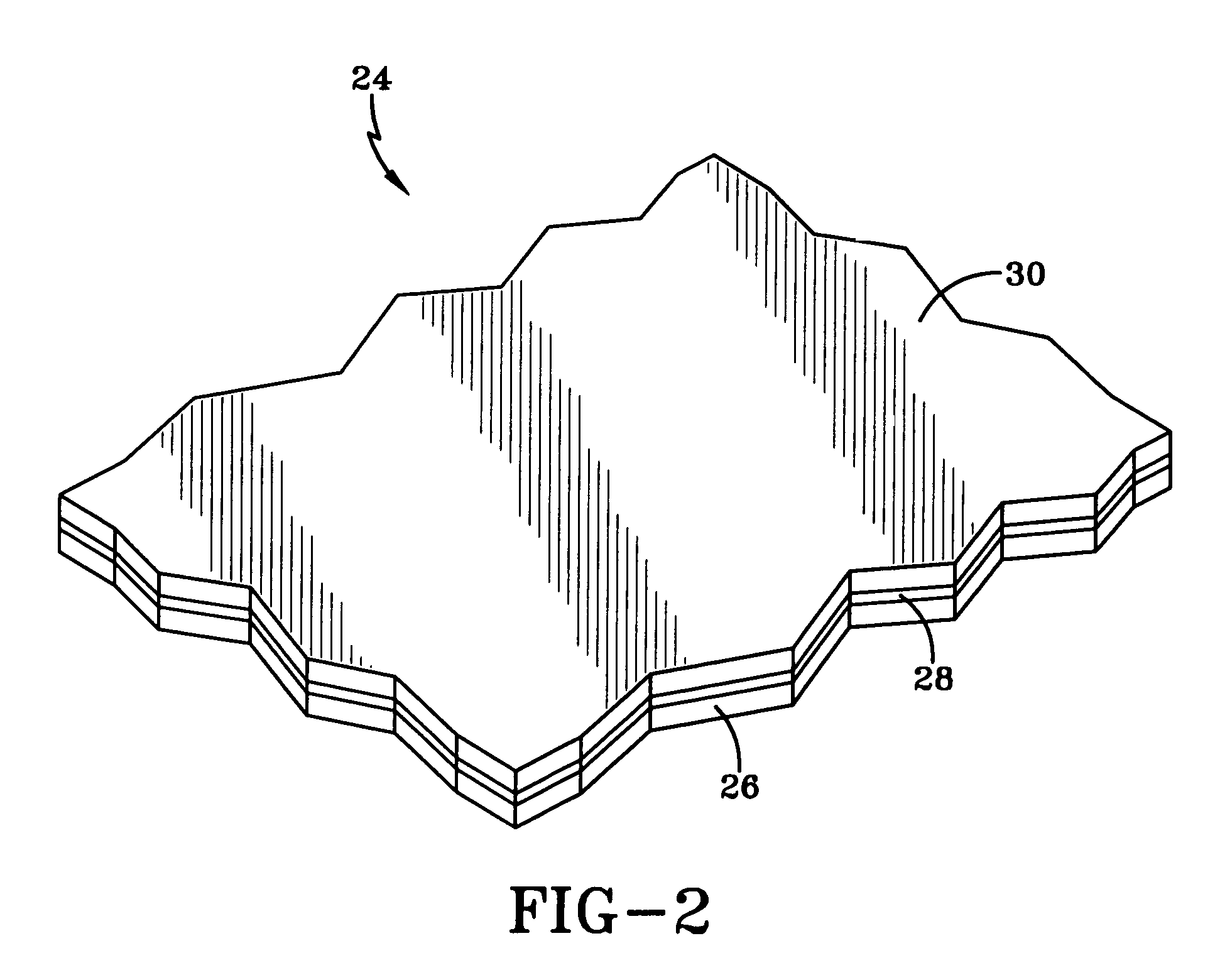

Ink jet printing and patterning of explosive materials

A method of forming a very small, i.e. microliter, finely detailed explosive train for the ignition of energetic munitions—which train is formed by ink jetting picoliter volume droplets of an explosive ink onto the substrate; which explosive ink is a pure liquid that will not clog the ink jet printer. The explosive ink being a solution composed of a secondary organic explosive solute, a polymeric binder solute, and a polar aprotic organic solvent. Where the ink jet printer is a commercial piezoelectric type, drop-on-demand, ink jet printer capable of precisely delivering the subject picoliter volume droplets. And, which printer is capable of heating said substrate to an elevated temperature to more rapidly evaporate the solvent, leaving the desired, finely detailed, efficacious, crystalline explosive train.

Owner:STEVENS INSTITUTE OF TECHNOLOGY +1

Linear explosive disruptor

A lightweight linear explosive disruption tool that may be used to fire a high speed projectile at a hazardous device in order to separate the components of the explosive train, thereby rendering it safe. The linear explosive disruption tool utilizes open cellular foam materials to prevent collateral damage of explosive gases and fragmentation that would otherwise prevent the device from being fired from a robot. An internal clapper tube distributes forces to the ligaments of cellular foam material and an external support tube contains the explosive fragmentation and blast overpressure. An internal barrel provides projectile travel in a single precision oriented direction and also reduces recoil which also enables the device to be fired from a robot as well. Such a tool prevents explosive gases and fragmentation from causing unnecessary collateral damage to the surroundings or supporting robot with reduced recoil effects.

Owner:BENSON MARK

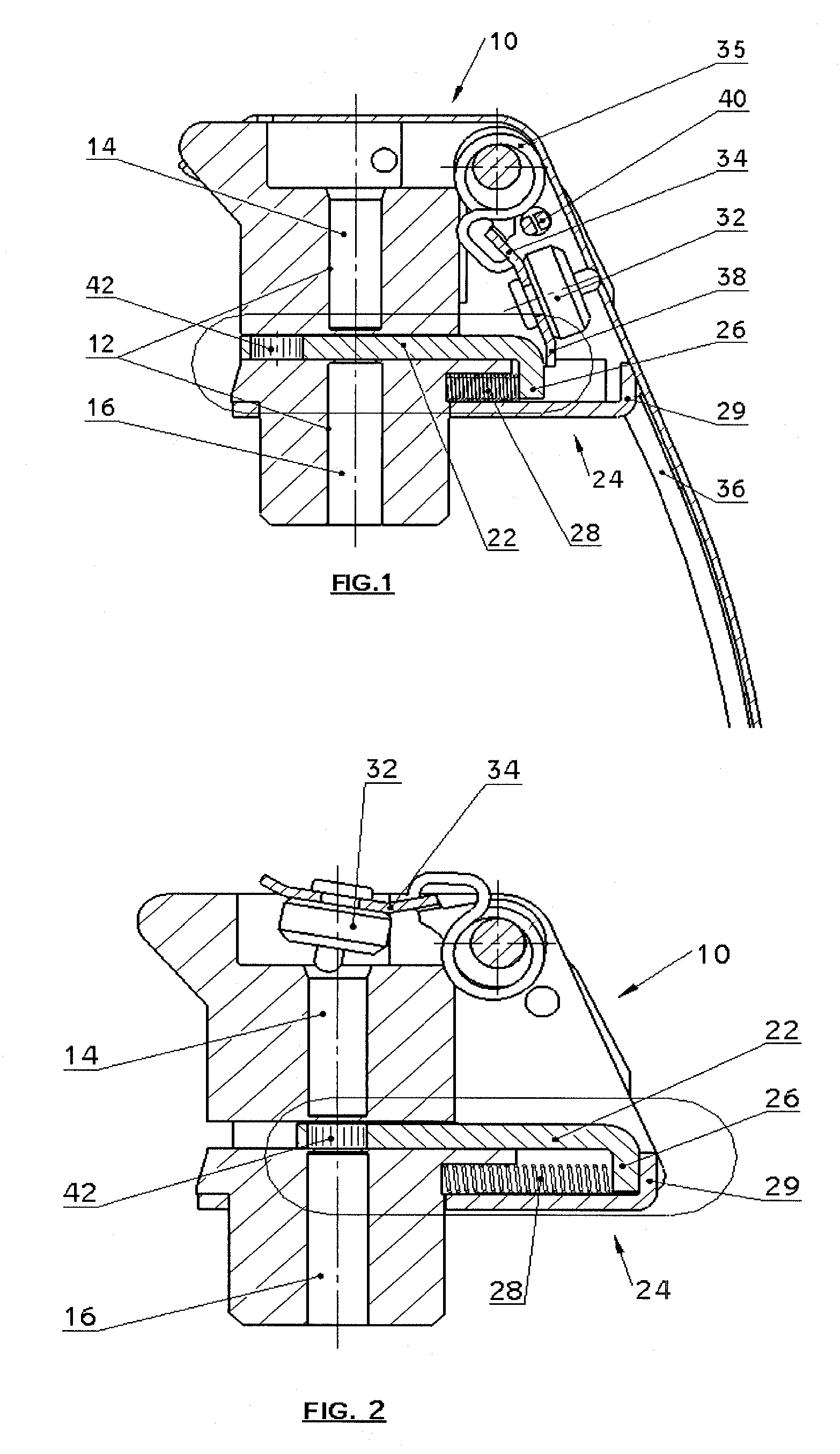

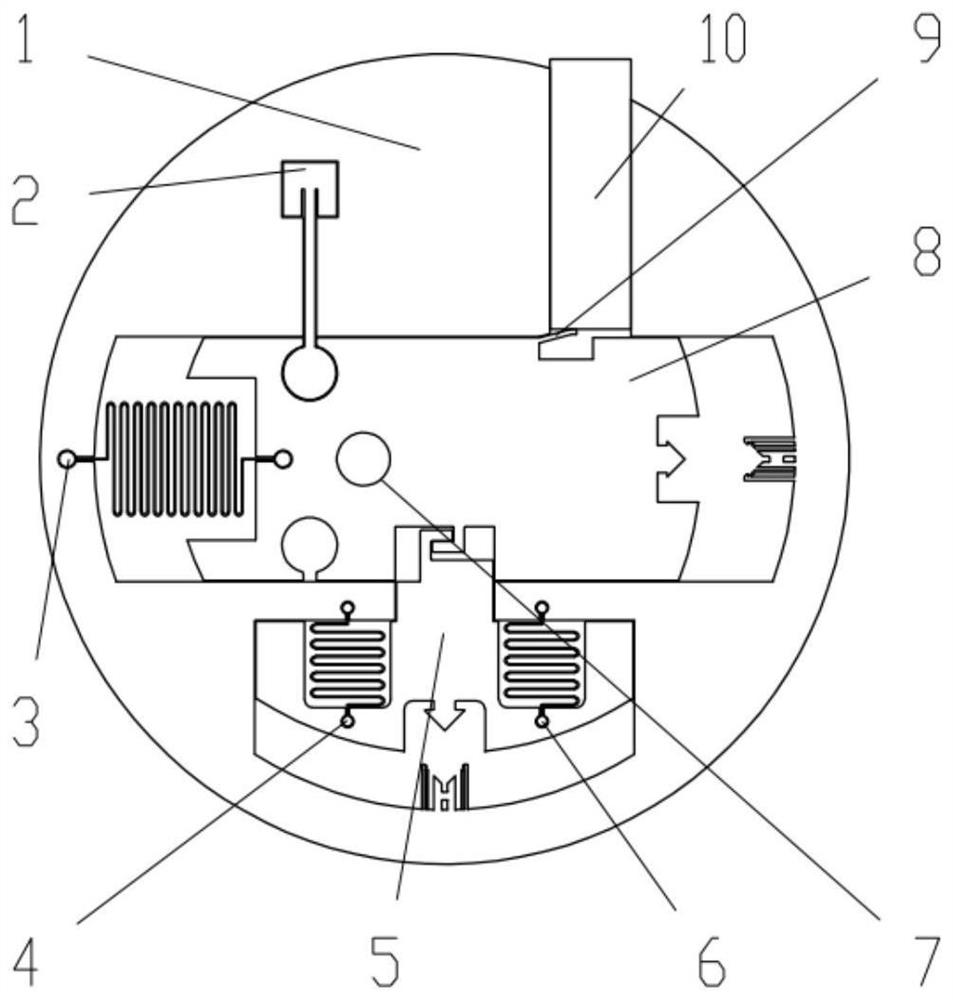

Grenade mechanism

ActiveUS8661979B2Prevent accidental explosionReduce pressureHand grenadesAmmunition loadingExplosive trainEngineering

An auxiliary safety mechanism for a grenade to prevent detonation from shockwaves, heat, fragments, etc., the grenade including a fuse housing containing a delay detonator and explosive train. In at least one embodiment, the fuse housing includes a reversible slider element interposed between the delay detonator and the rest of the explosive train to form a barrier therebetween when the grenade is in an unarmed condition, and when the slider element is withdrawn the barrier between the delay detonator and explosive train is removed leaving the grenade in an armed condition. In another embodiment, a further safety mechanism involves connecting the two sections of the housing with a weak connection that ruptures prior to the explosive contained therein reaching the critical explosive temperature / pressure.

Owner:IMI SYST LTD

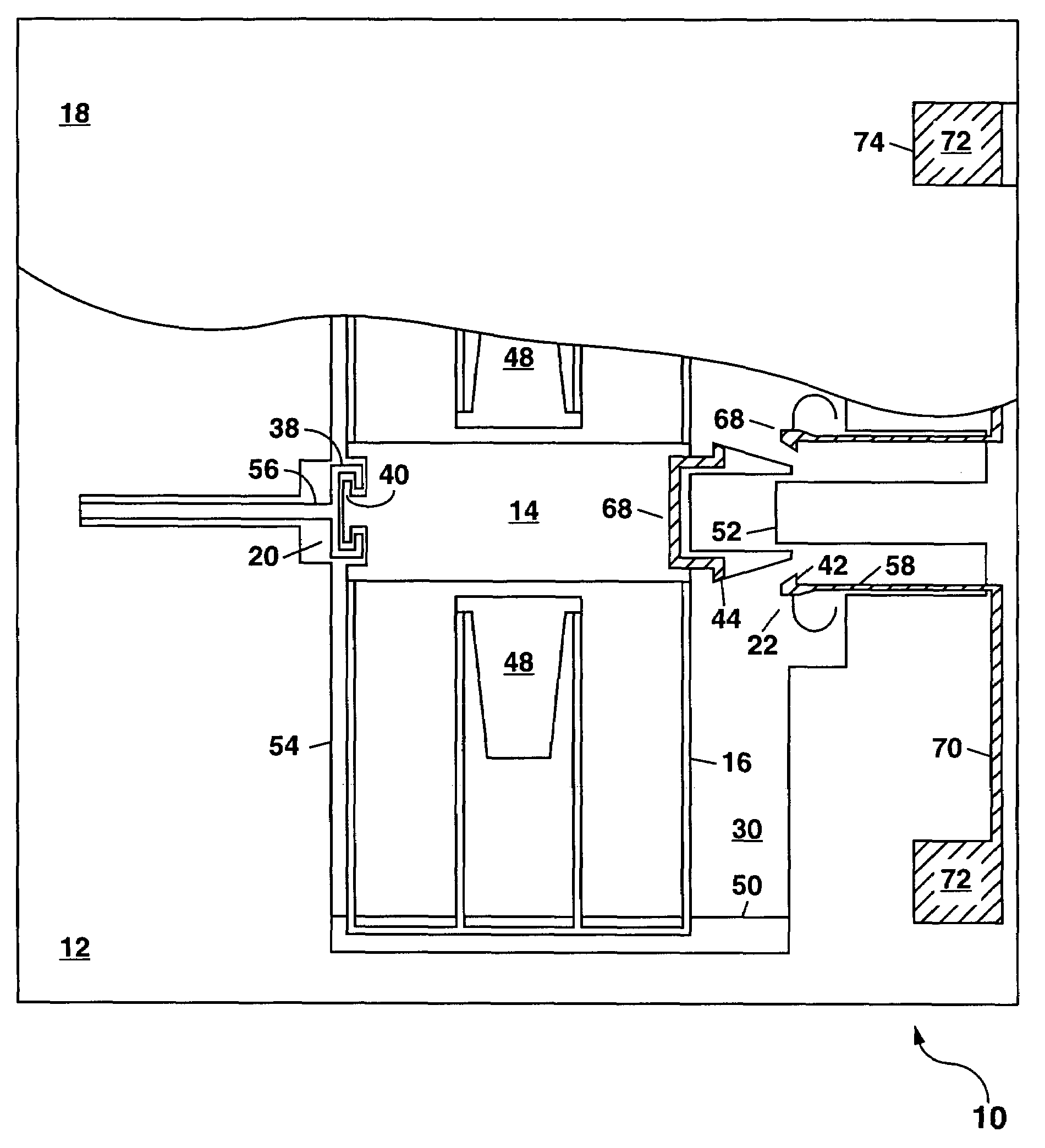

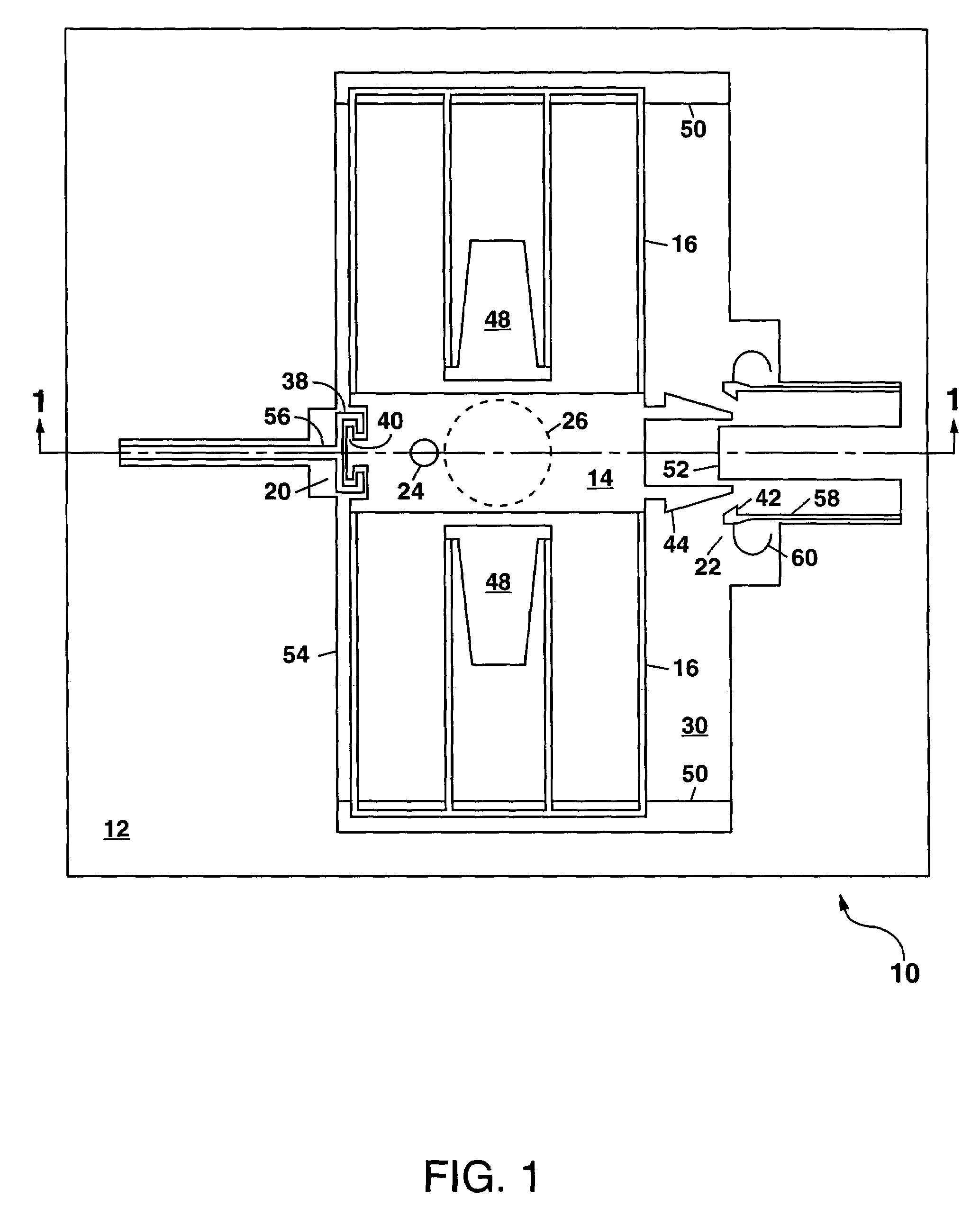

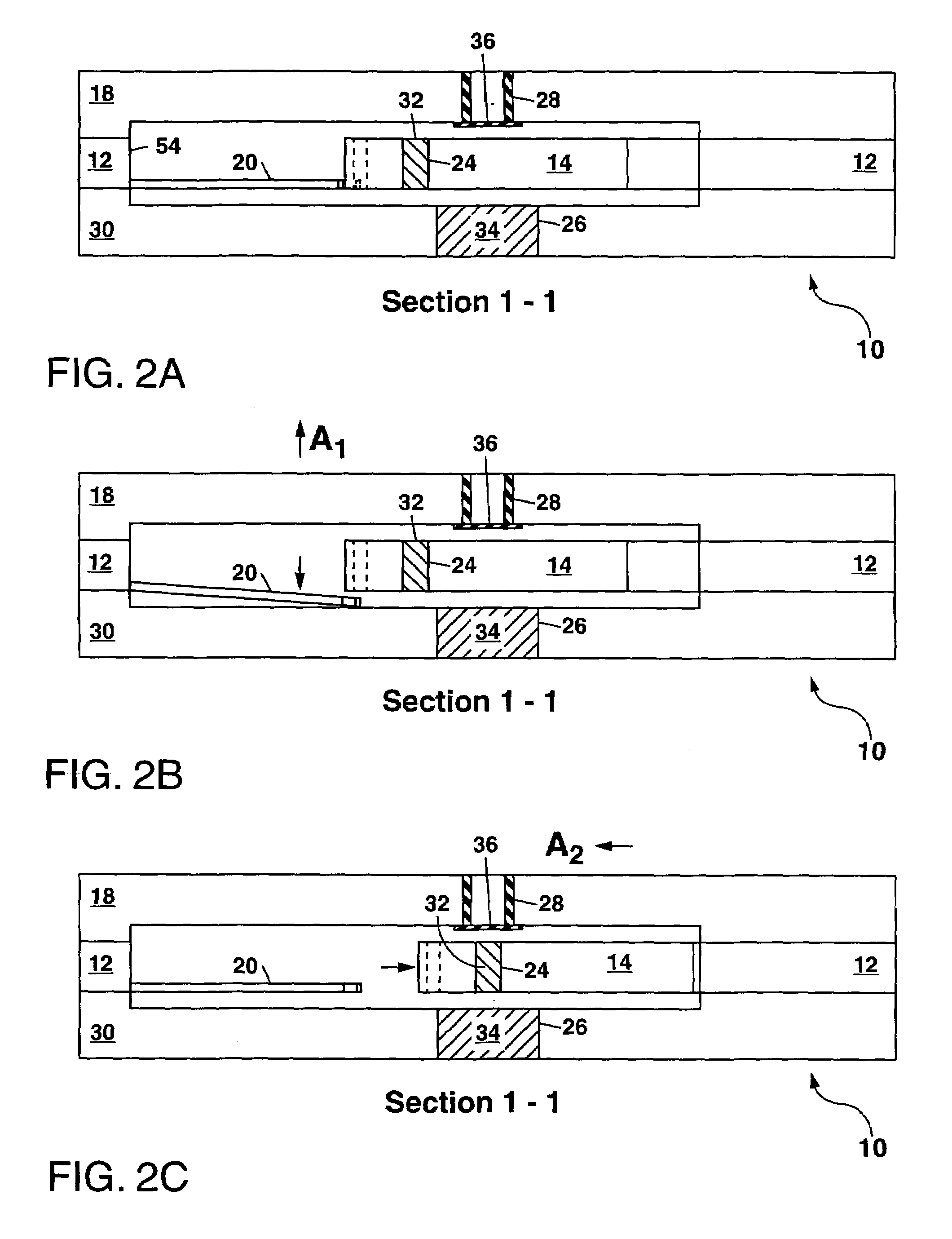

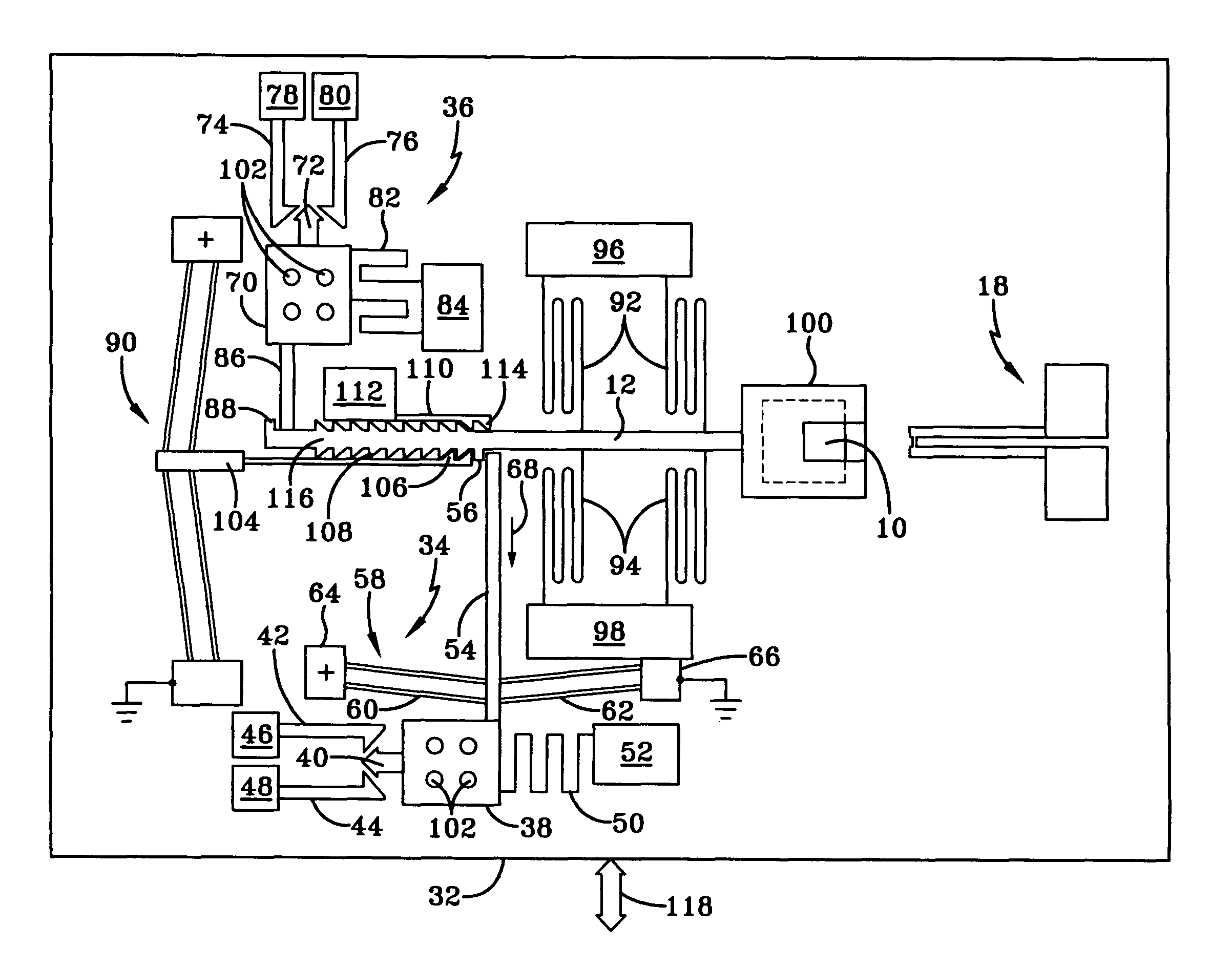

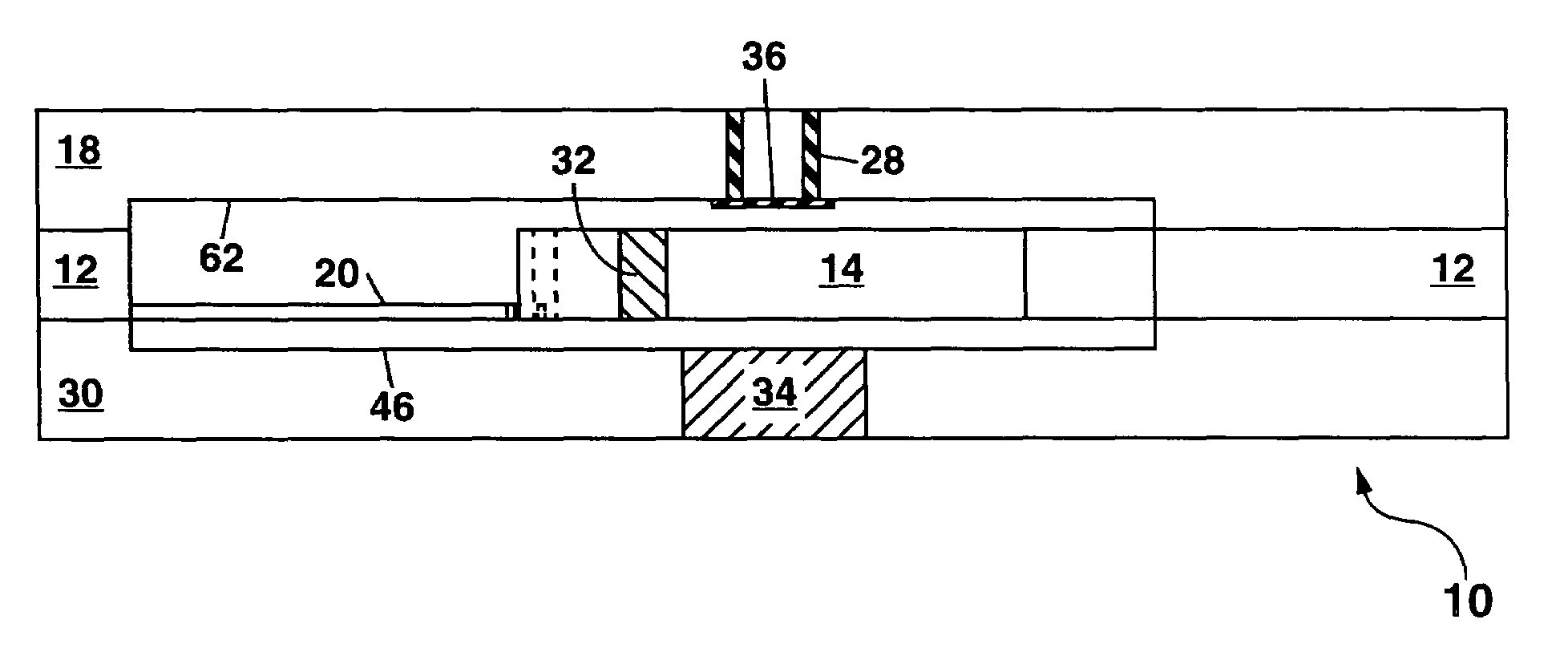

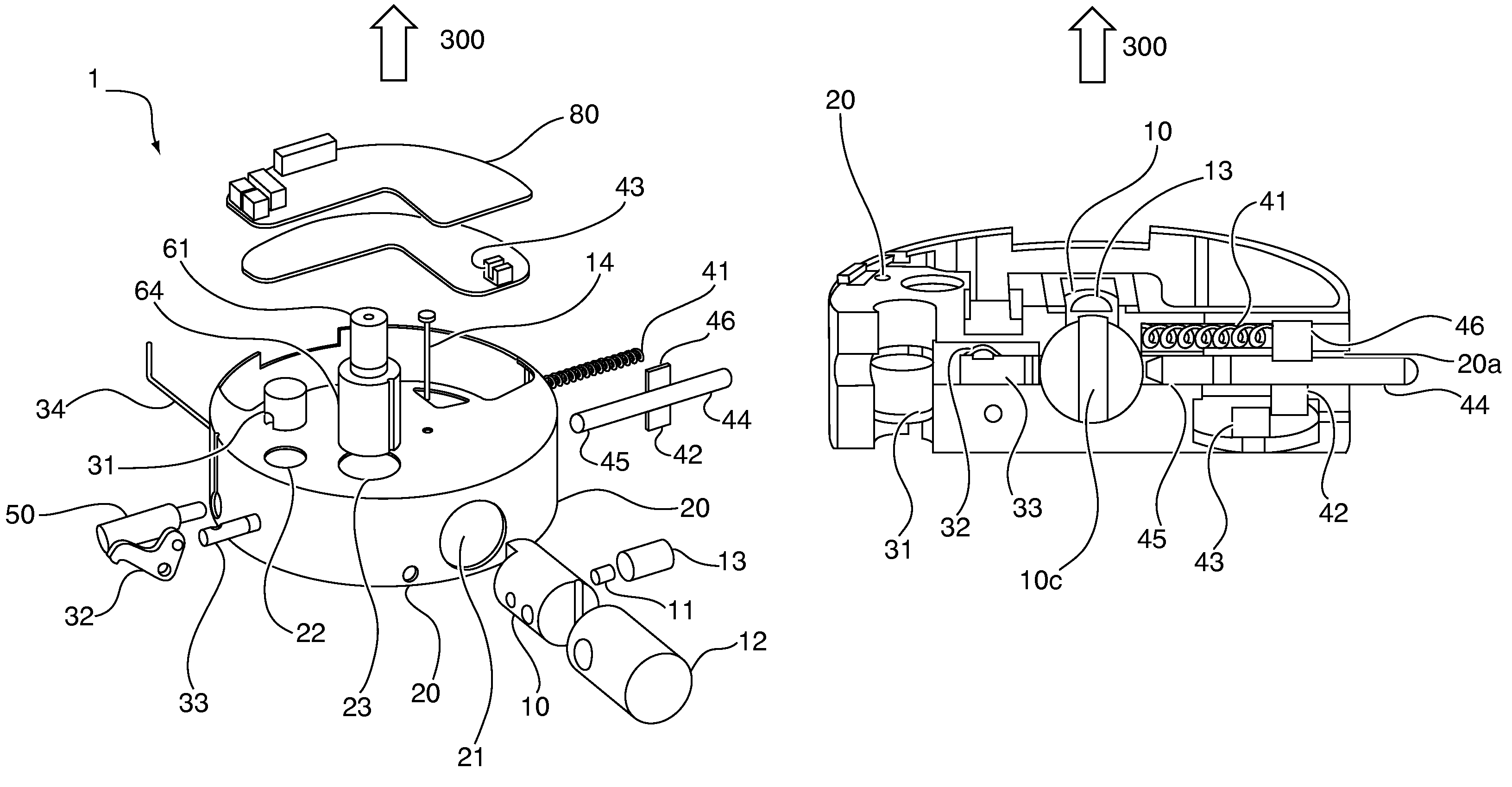

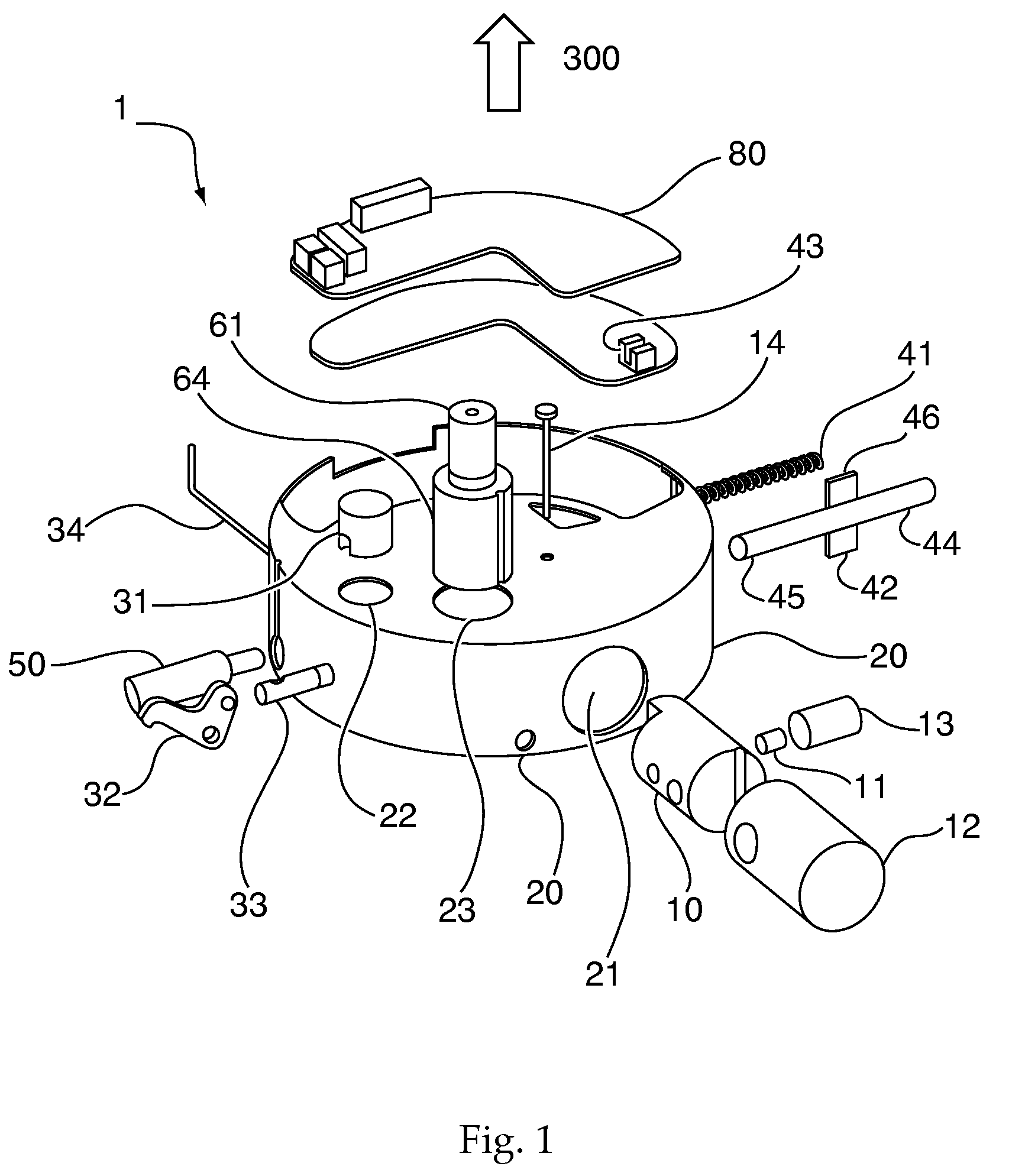

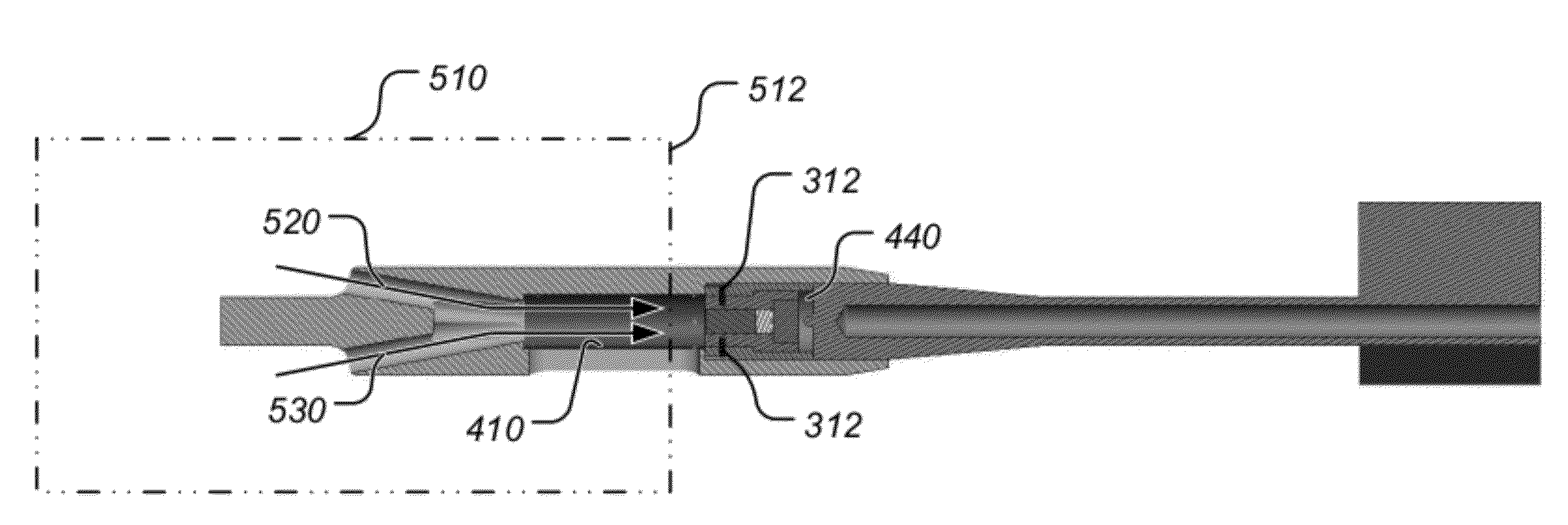

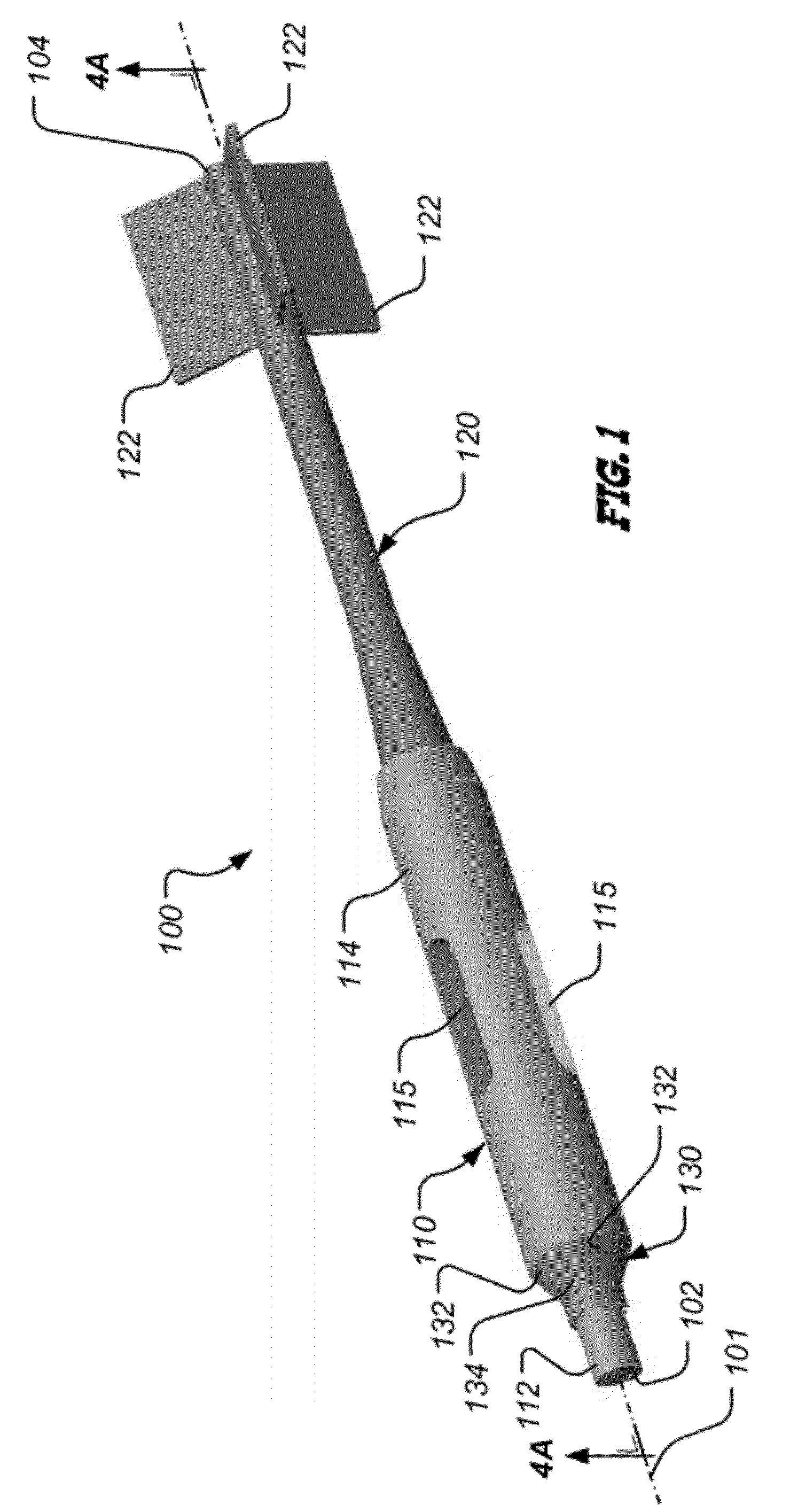

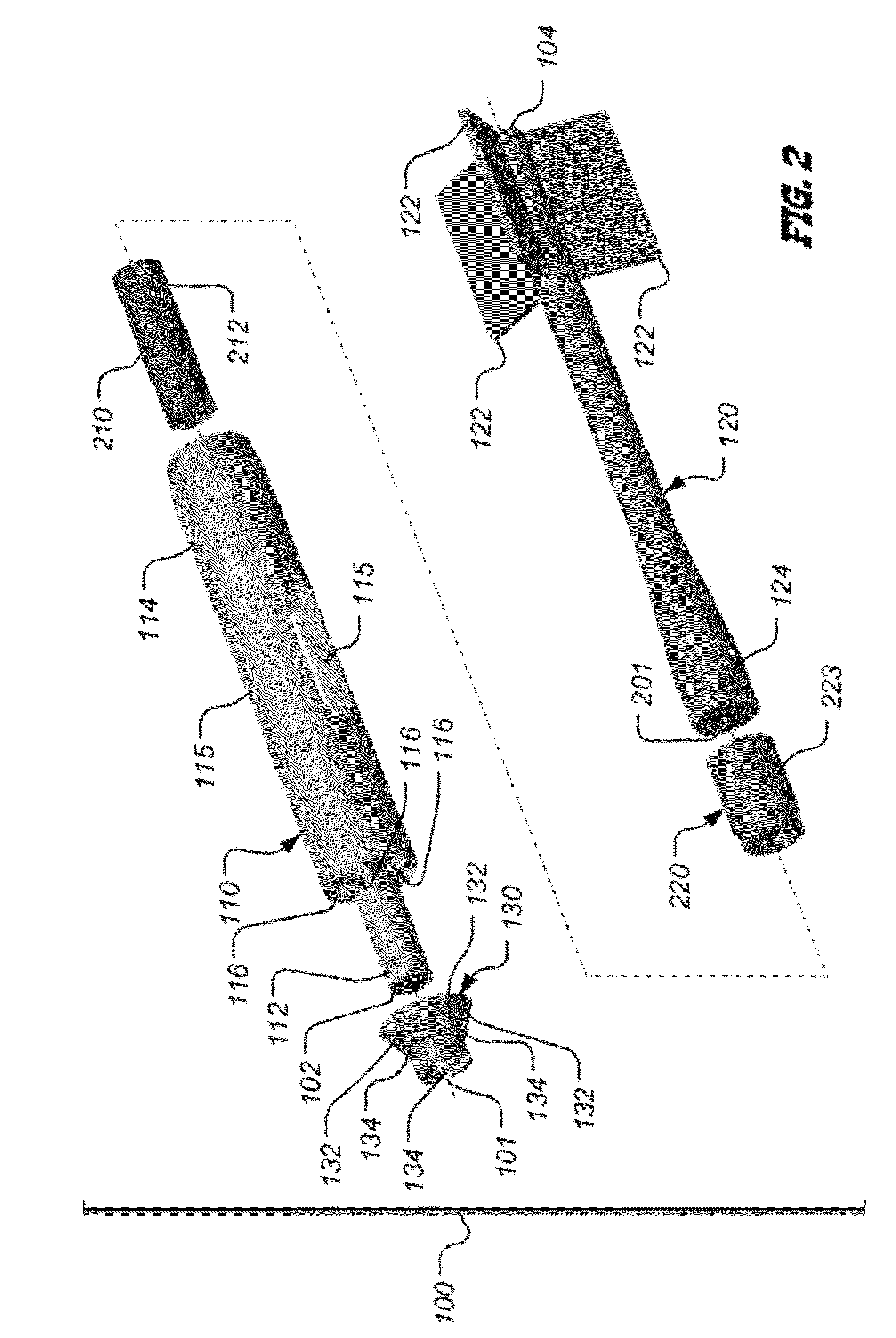

System and method for safing and arming a bore-launched projectile

A safing and arming (SA) system and method for a bore-launched projectile is provided. The SA system includes an arming switch, including a detonator, movable from a first position to a second position. When the arming switch is in the first position, the detonator is separated from an explosive train of the projectile. When the arming switch is in the second position, the detonator is substantially aligned with the explosive train, allowing the projectile to be armed. Safing systems are provided for retaining the arming switch in the first (safe) position. Various embodiments also allow for release of the arming switch so as to allow the arming switch to be moved to the second (armed) position, wherein the release may be triggered by a selected acceleration force exerted on the projectile and / or a determination that the projectile has been launched from the launch bore.

Owner:CHANG IND INC

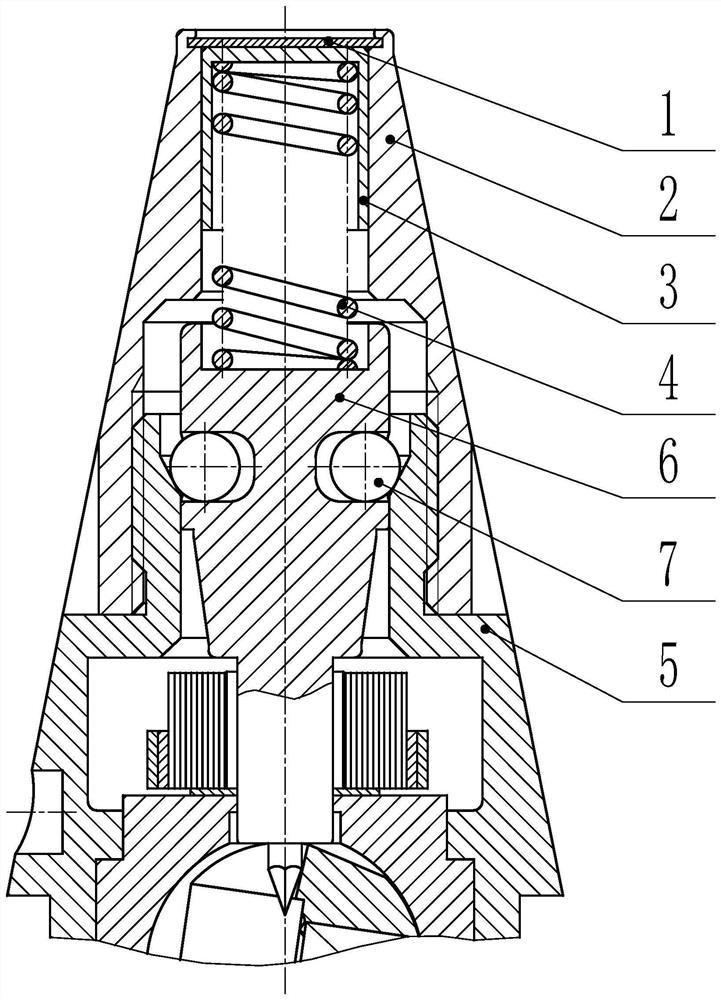

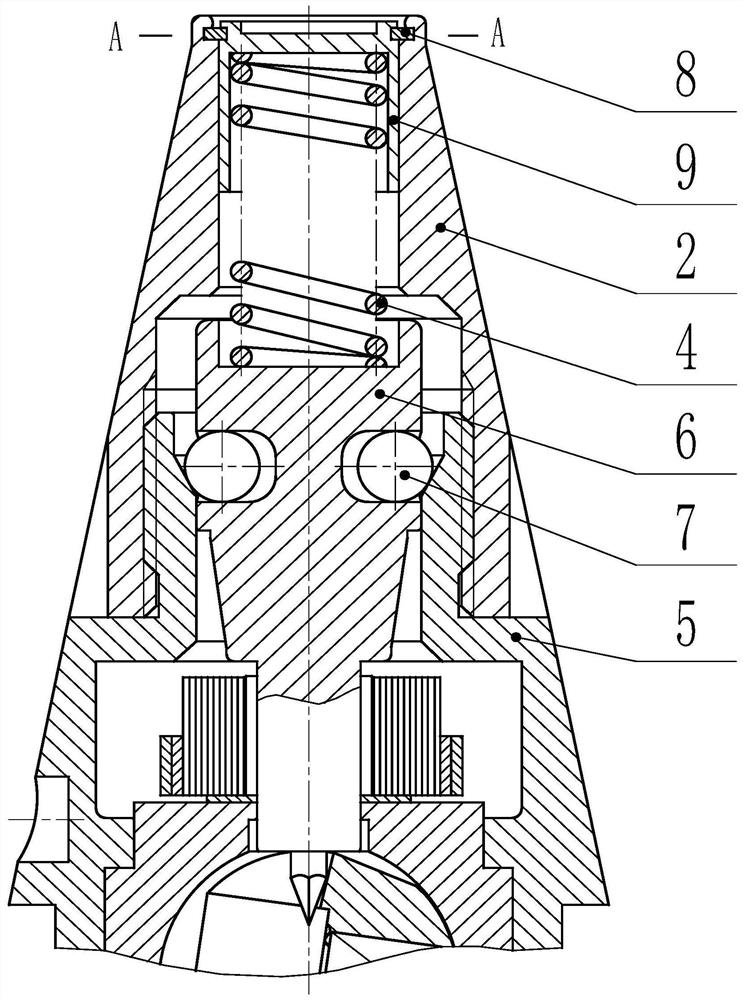

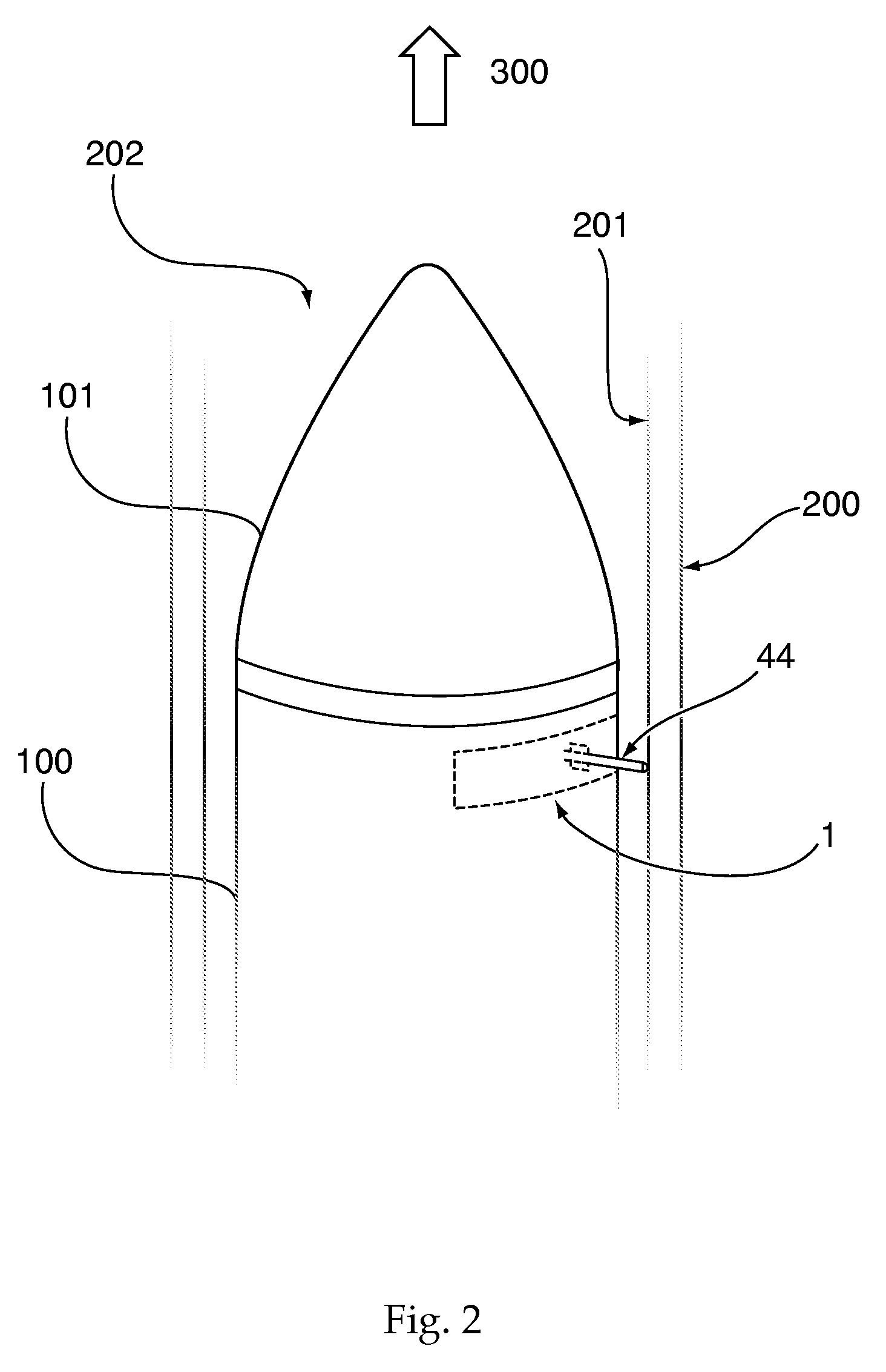

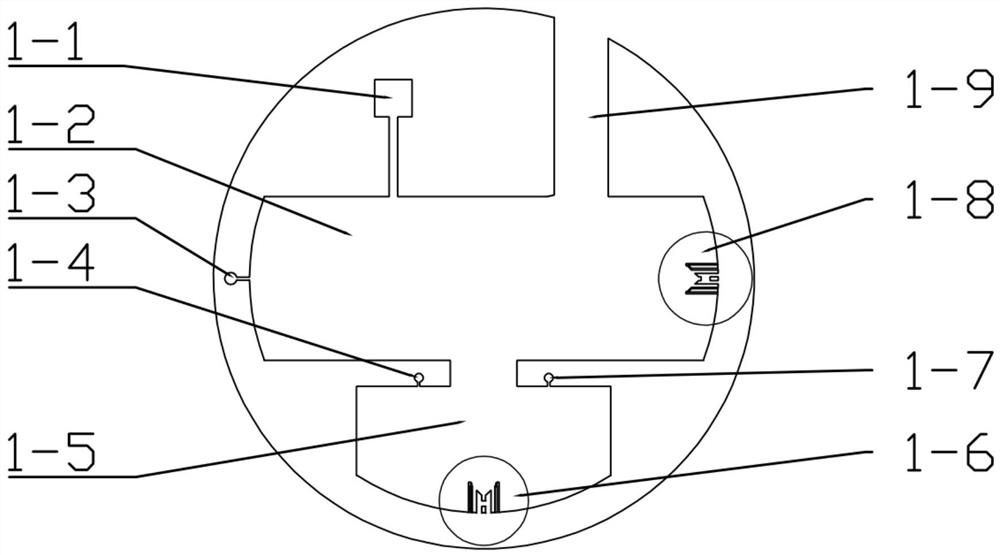

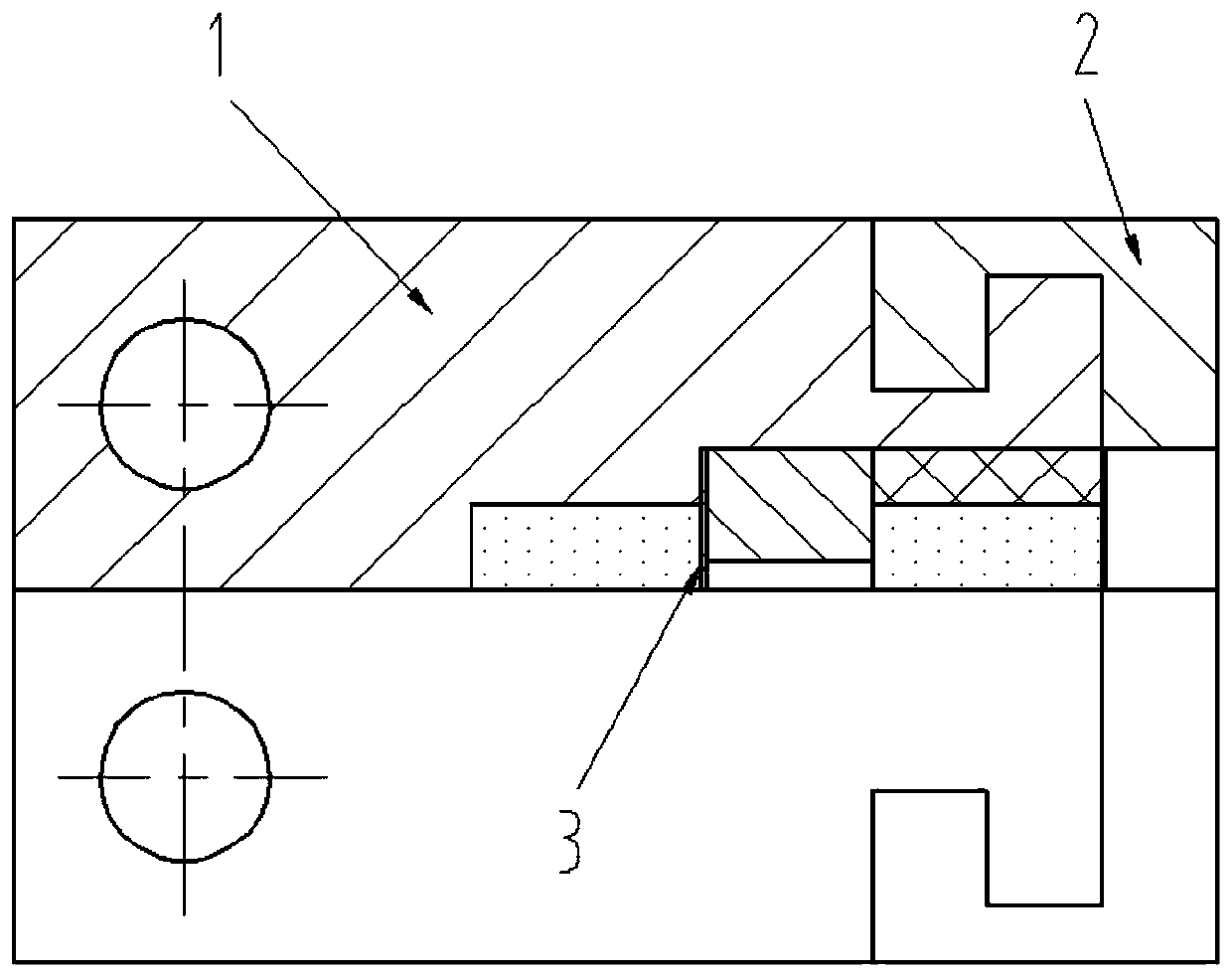

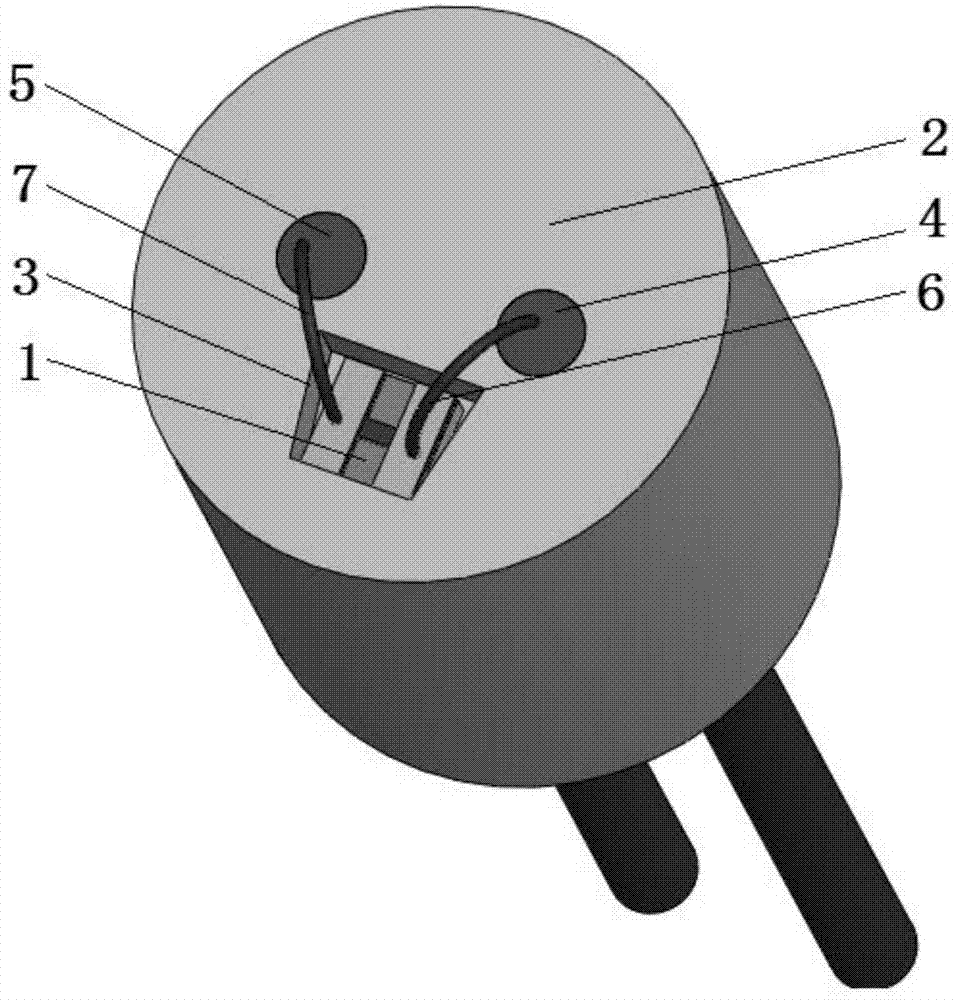

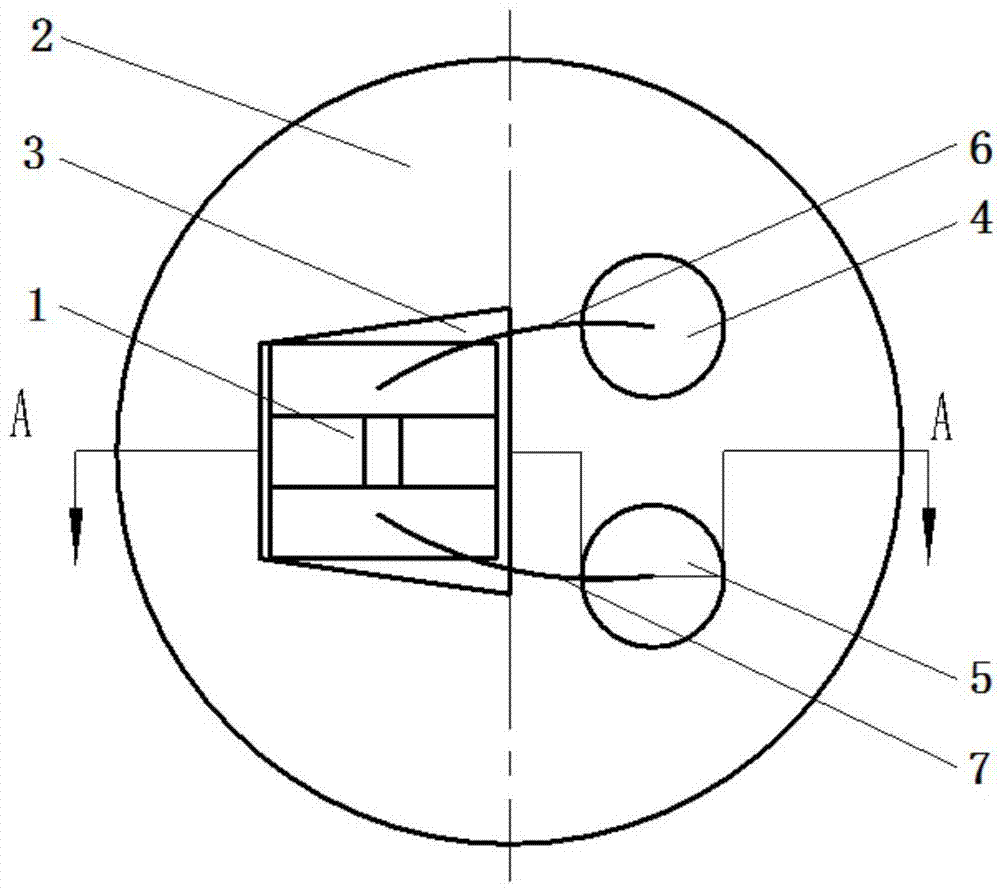

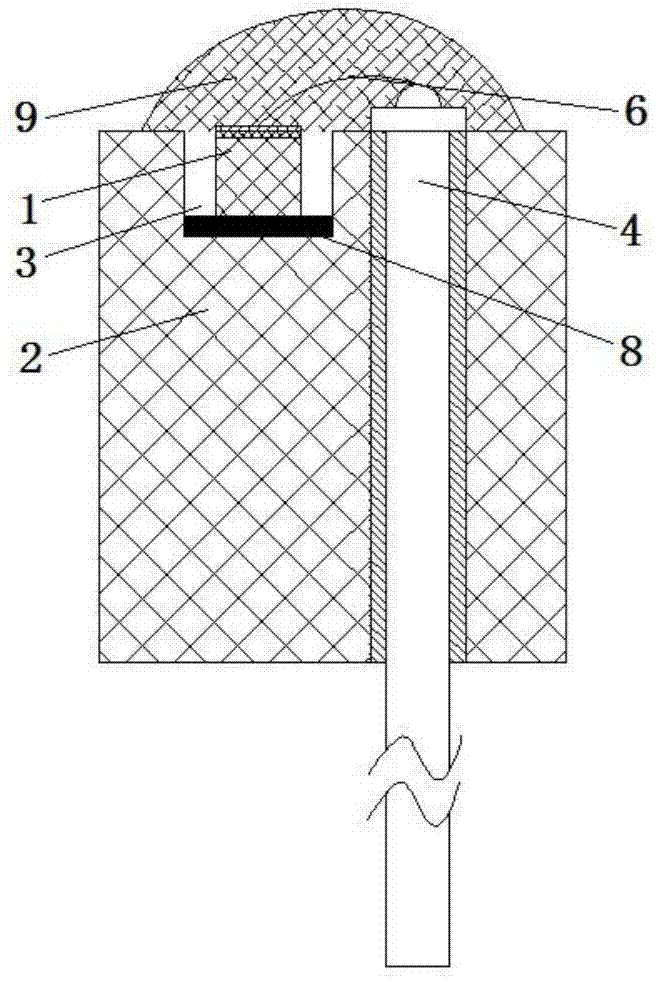

Modularly-designed fuse safety insurance mechanism

ActiveCN112525022AGuaranteed processing securityQuestions Guaranteed to AnswerAmmunition fuzesCantilevered beamExplosive train

The invention discloses a modularly-designed fuse safety insurance mechanism which is composed of three times of safety insurances, the first time of safety insurance is a recoil insurance; the secondtime of safety insurance is a centrifugal insurance; the third time of insurance is a long-distance insurance; and the three times of insurances and an explosion-proof sliding block form a main bodyof the safety insurance mechanism. At ordinary times, the explosion-proof sliding block is clamped by a recoil safety device composed of a cantilever beam mass block and a centrifugal safety device composed of a spring mass block, an explosion propagation sequence is separated, and the safety of a fuse is guaranteed. In the launching state, the safety insurance mechanism sequentially relieves thethree times of insurances by recognizing recoil force, centrifugal force and other environmental force, the explosive-proof sliding block relieves corresponding constraints, locking is completed, a detonating hole is aligned, and the safety insurance mechanism relieves the insurances. Based on the three-dimensional additive manufacturing technology, the size and the complexity of the safety insurance mechanism can be effectively reduced, the mechanism is convenient to assemble due to the modular design principle, and meanwhile the workload of optimization design of the mechanism in the futureis greatly reduced.

Owner:NANJING UNIV OF SCI & TECH

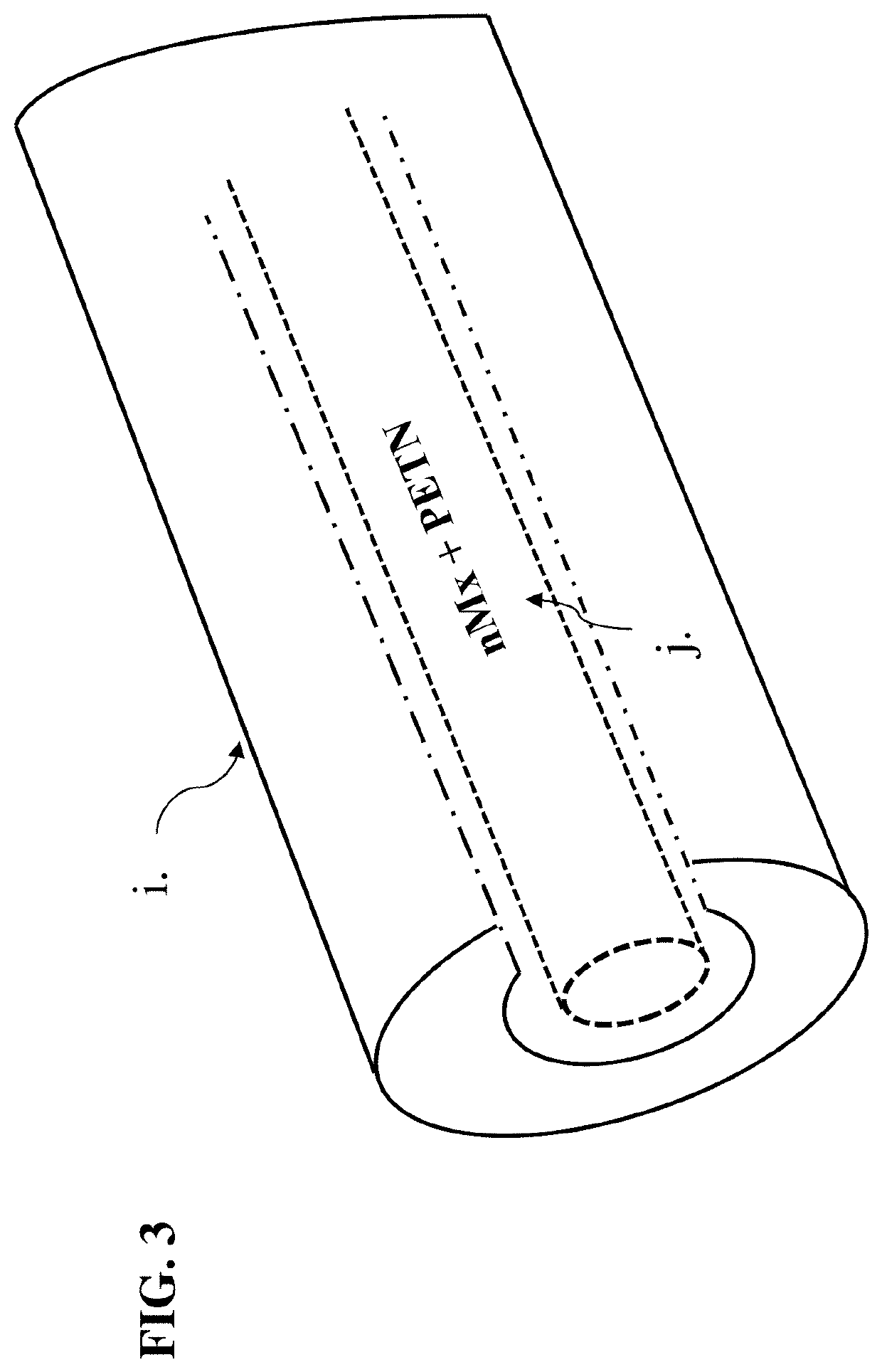

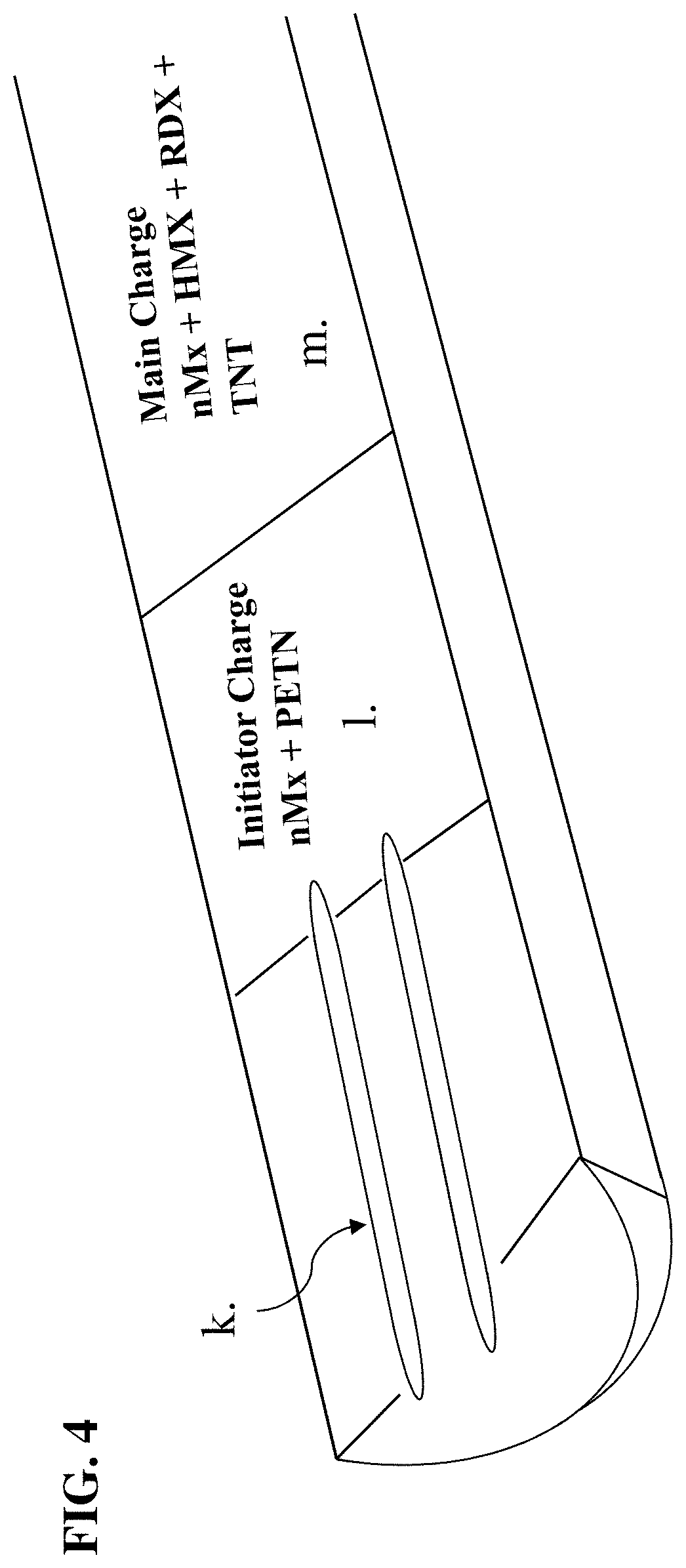

Nano-enhanced explosive material

The present invention generally concerns a nano-enhanced explosive that is integrated at many points across an explosive train. More specifically, a nano-enhanced explosive is formed when a nanocomposite we call nMx is combined with a secondary high explosive. nMx is made of Li3AlH6 nanoparticles, elemental Al nanoparticles, an amount of Ti metal, and a nanoscale organic layer having unique burning profiles that lend energy to the explosive process including increased shockwave propagation through a chemical explosive and increased temperatures and gaseous pressure build up and release in and about the same. Our nano-enhanced explosive can be integrated at various points across an explosive train, e.g. use within a detonation cord (fuse), or as a detonation charge (initiator), or as the main charge, where the use of the nano-enhanced explosive can be characterized by the energy lent to projectiles from munitions, bubbles formed by underwater explosive trains, or blast profiles.

Owner:SAINT LOUIS UNIVERSITY

Mine-defeating projectile

A mine defeating projectile includes a housing defining an inner cavity, a plurality of channels extending through a front surface of the housing and to the inner cavity, and a plurality of cutout sections extending through as side wall thereof. The projectile further includes a fragmentation sleeve disposed in the inner cavity of the housing and a slider sleeve disposed in the inner cavity of the housing abutting an aft end of the fragmentation sleeve. The slider sleeve includes an explosive train and the slider sleeve is frangibly attached to the housing. The projectile further includes a finned section attached to an aft end of the housing. The finned section defines a protrusion for initiating the explosive train. The protrusion is spaced apart from the explosive train.

Owner:LOCKHEED MARTIN CORP

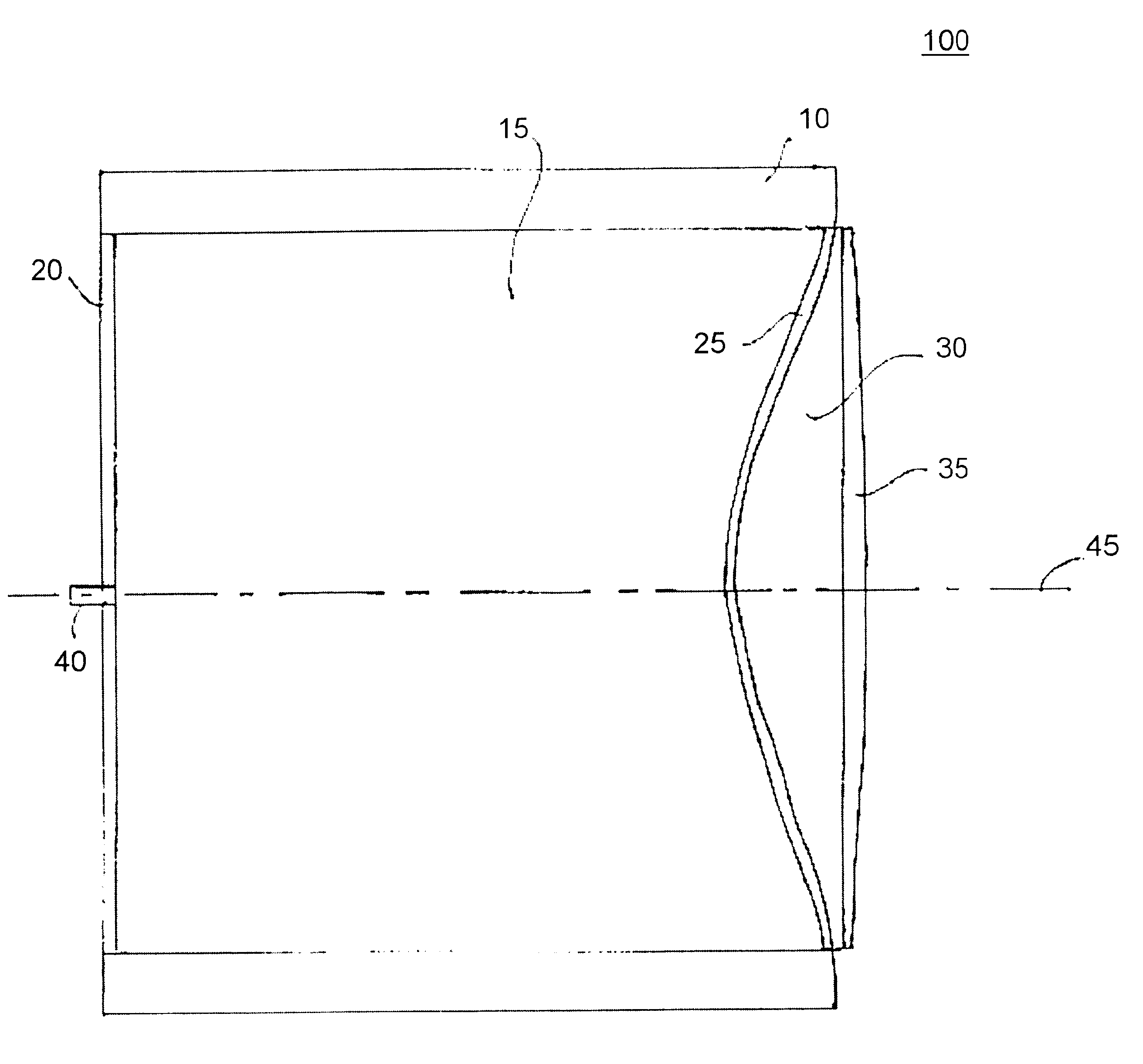

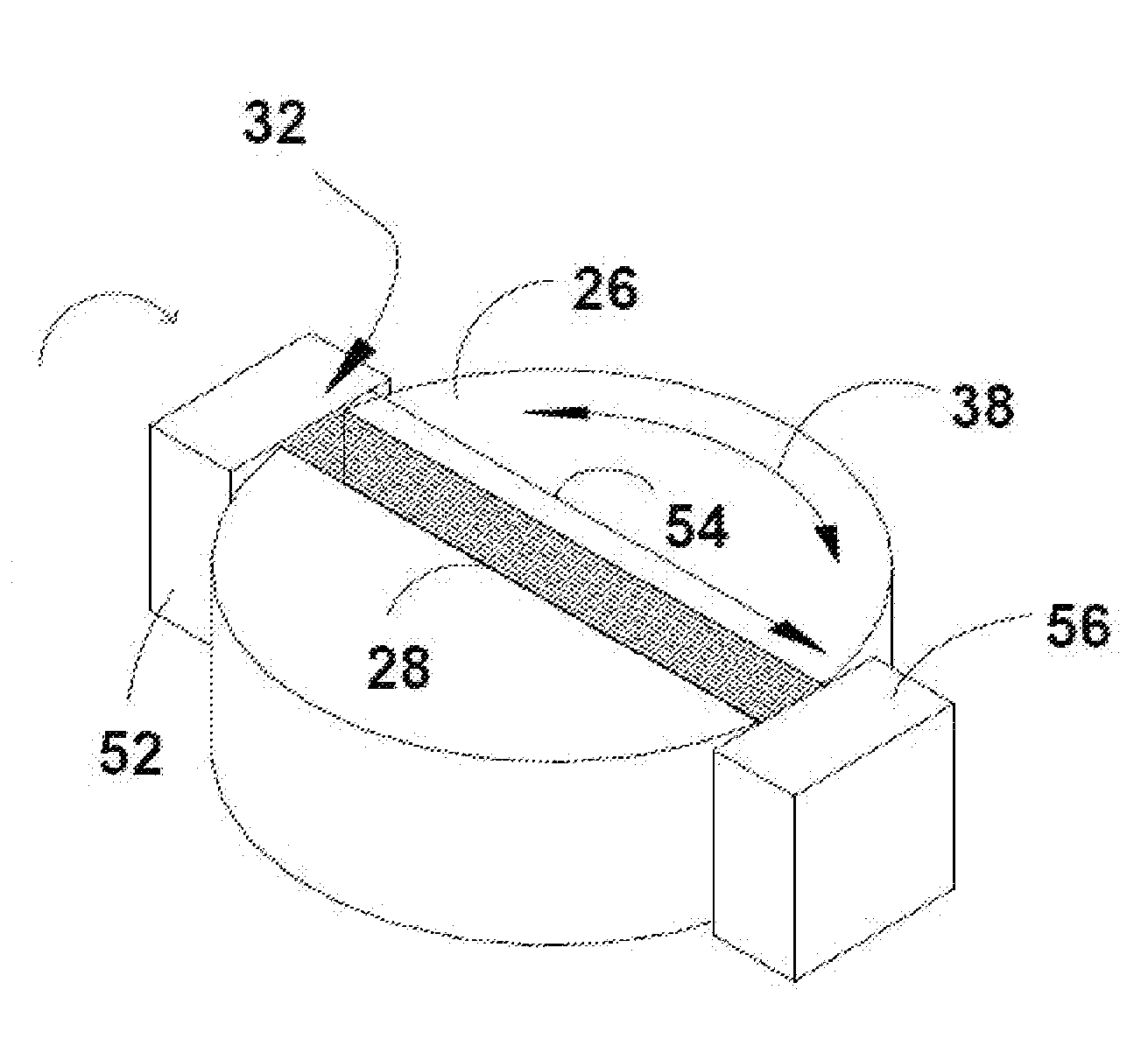

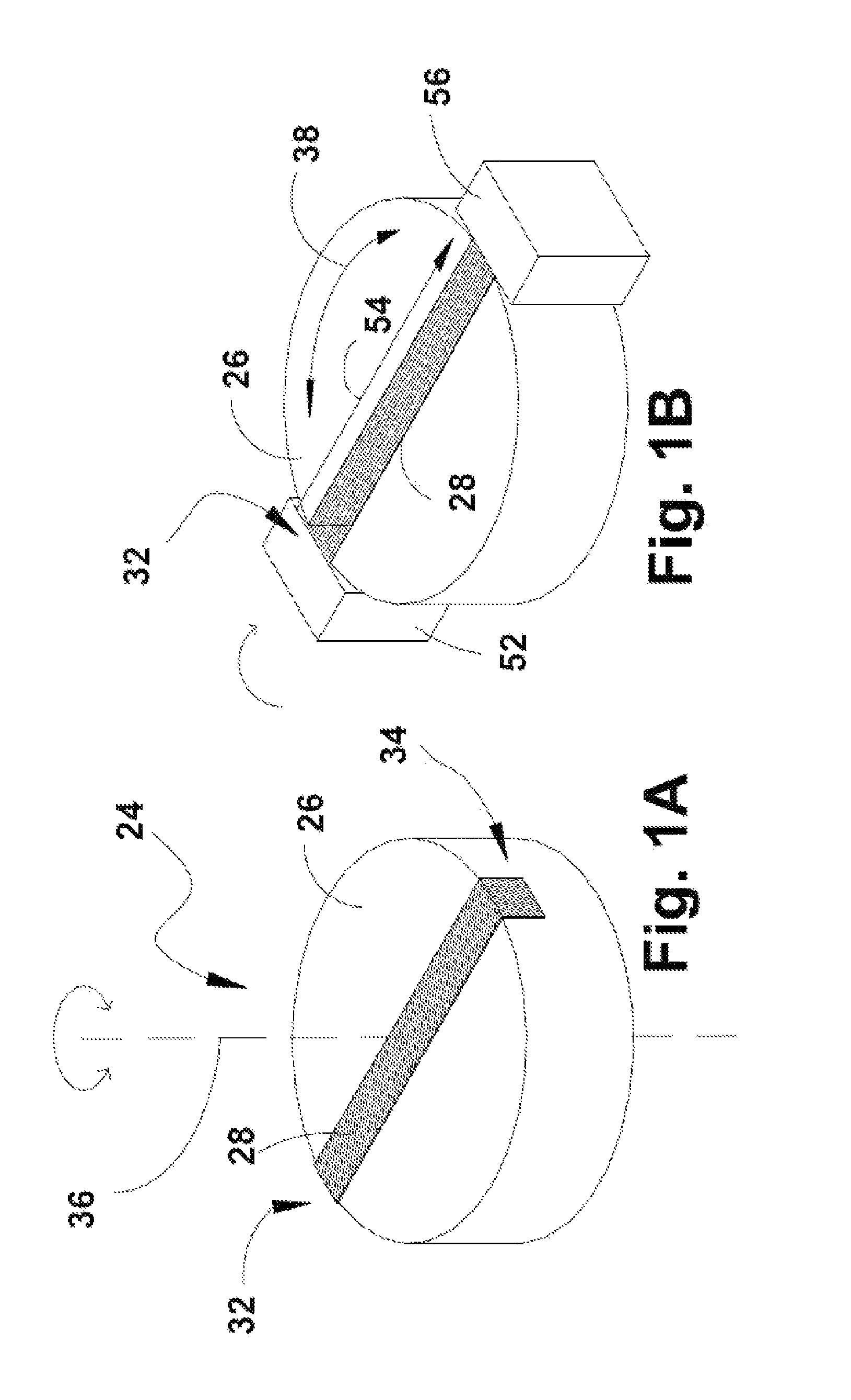

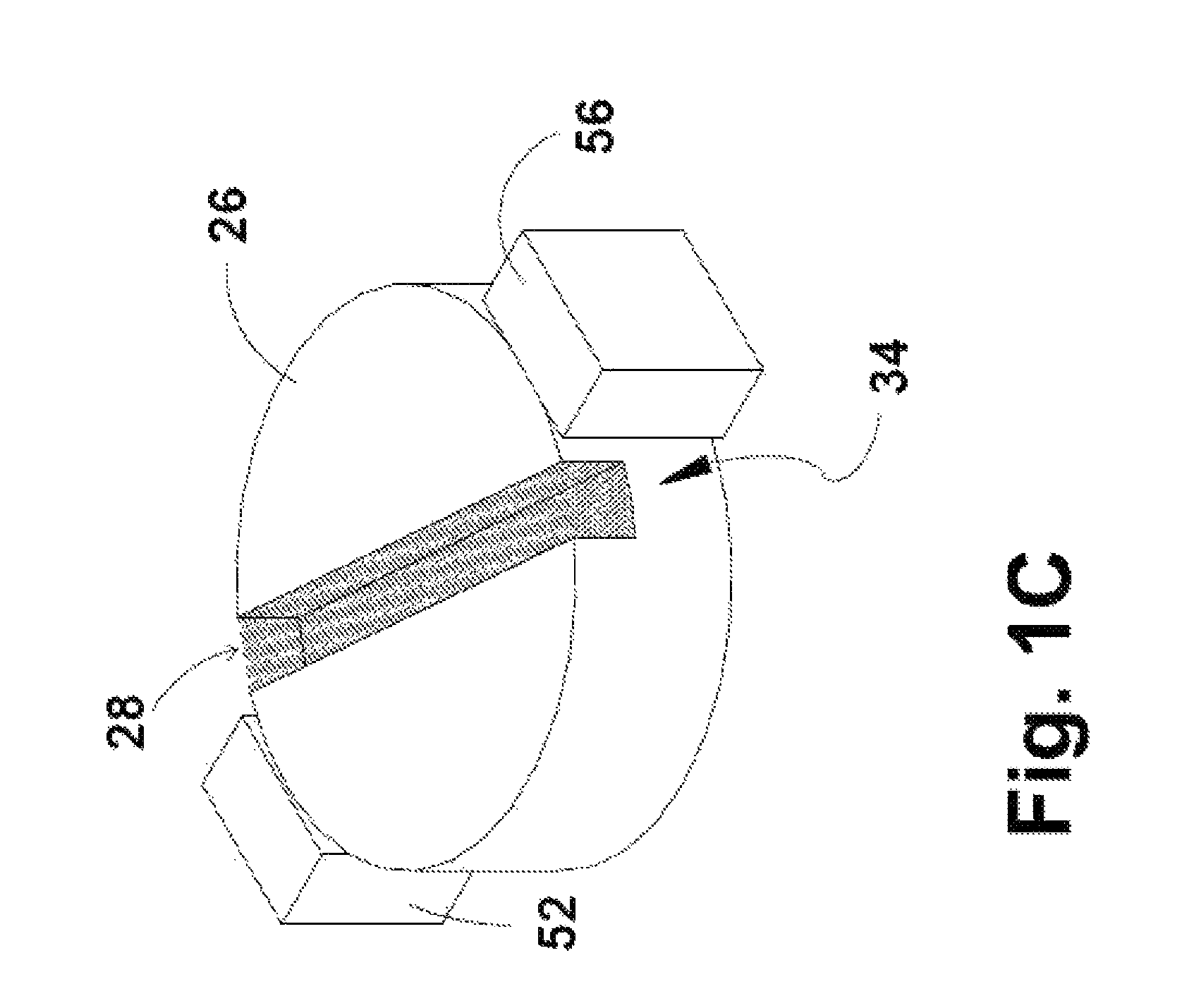

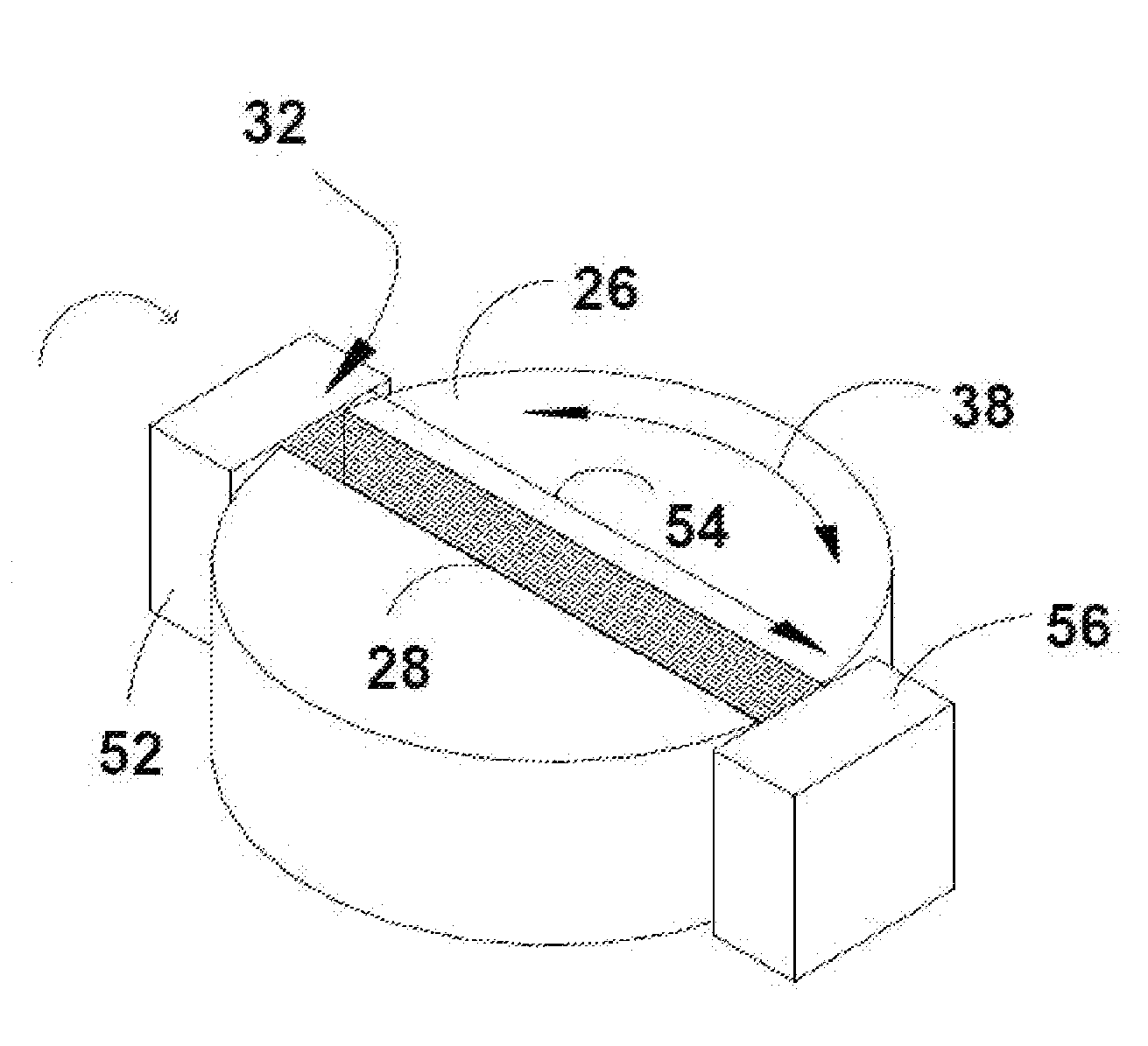

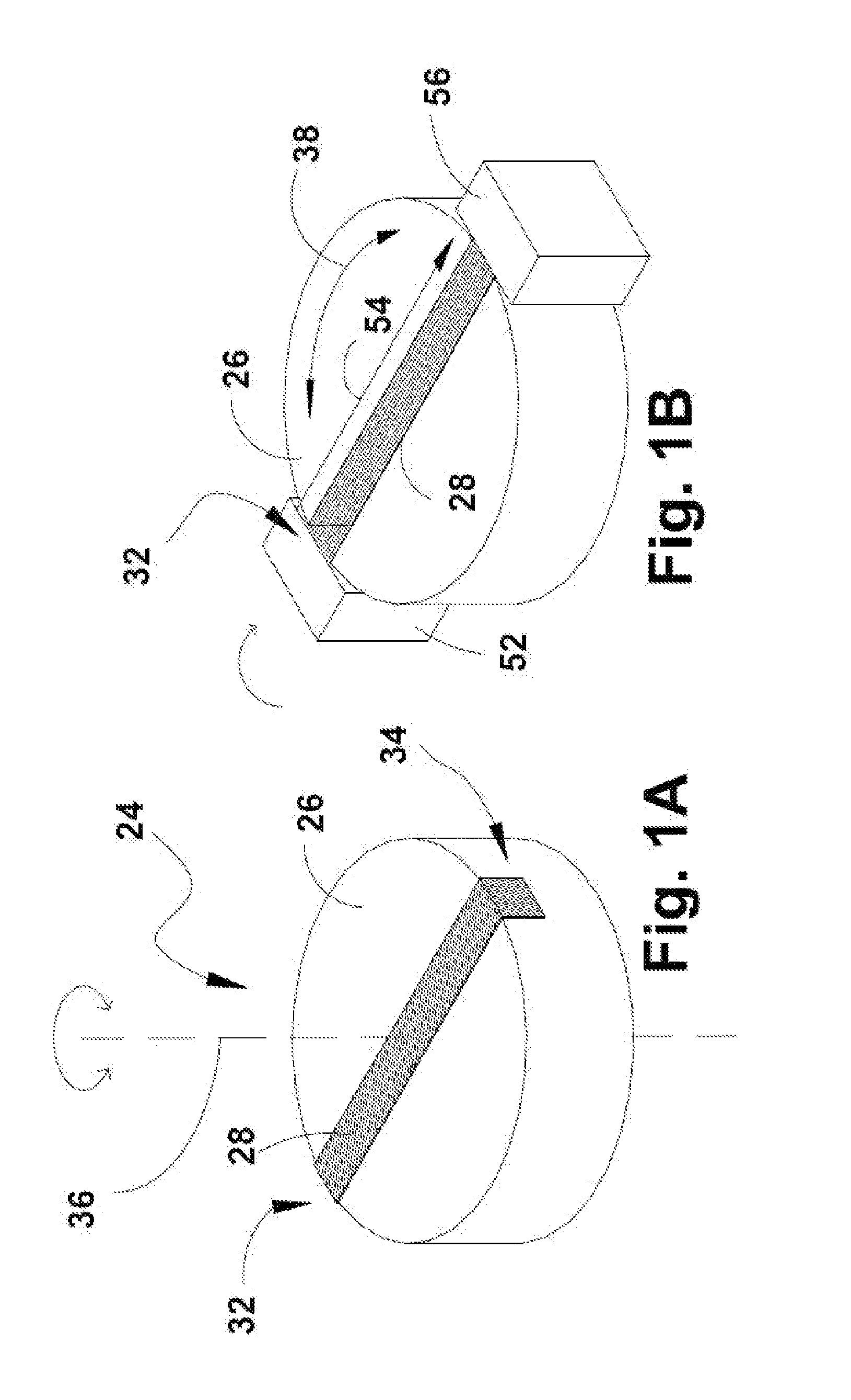

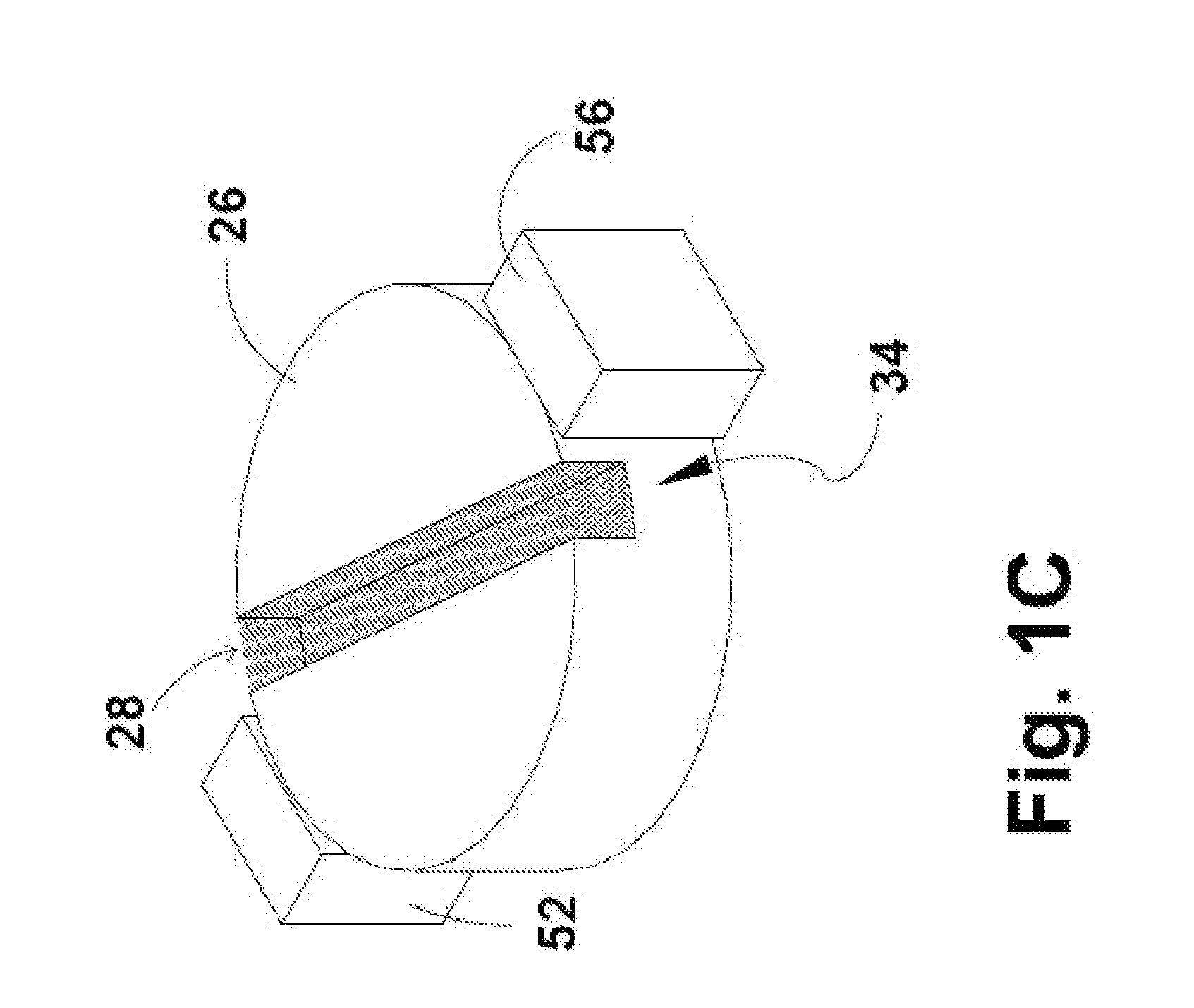

Safe and arm explosive train

A Safe-and-Arm system for the prevention of unintentional operation of an explosive device by interrupting a detonation train, the system employing an interruptive transfer assembly made of silicon and suitable for implementing in a MEMS device, the assembly including a silicon based transfer charge carrier on a porous explosive passageway made by etching, the passageway extending between at least two ports on the circumference of the transfer assembly, and a drive means that can mechanically bring about at least one armed state of a detonation train.

Owner:RAFAEL ADVANCED DEFENSE SYSTEMS

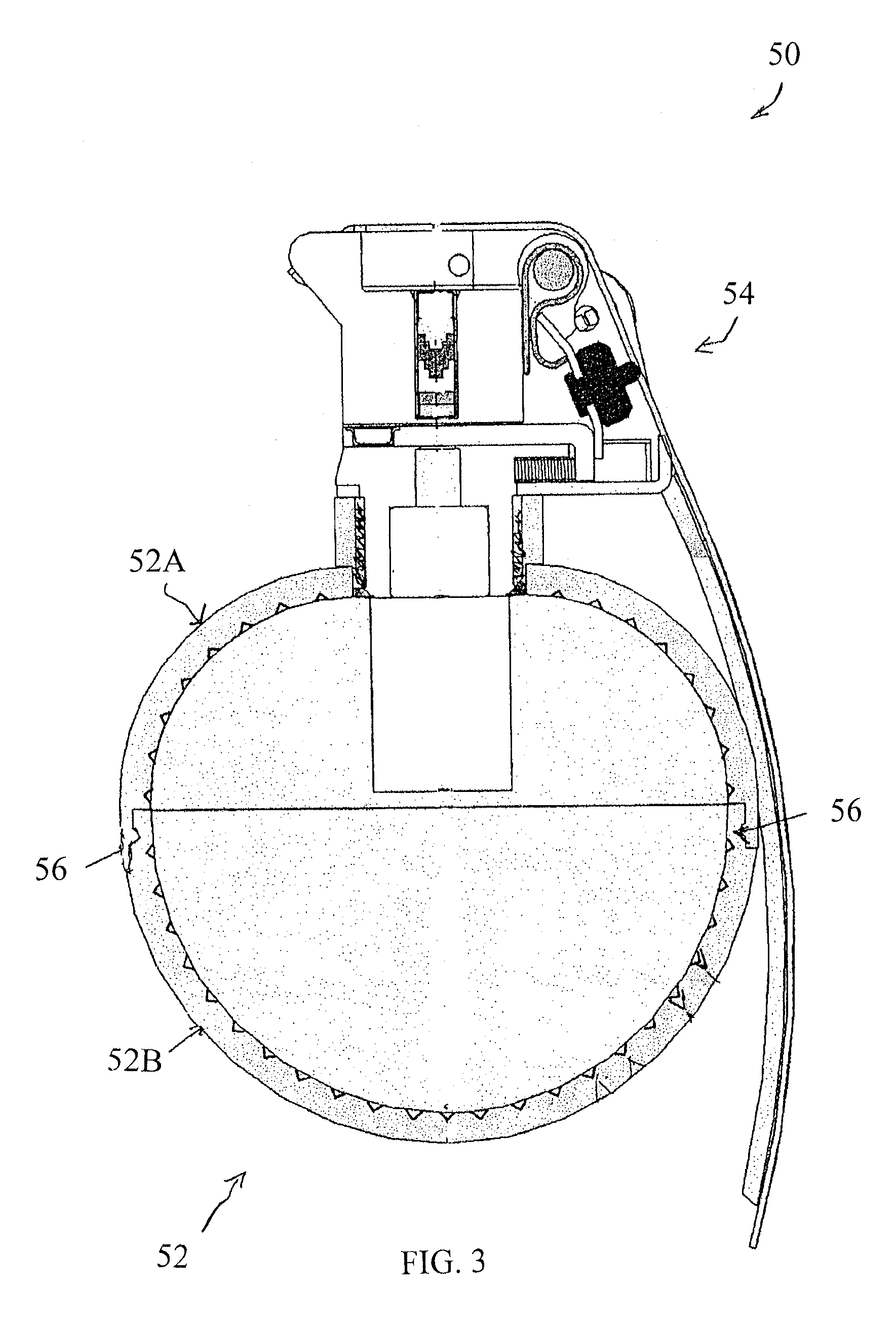

Self-destruction equipment based on in-line fuze

PendingCN109489507AAchieving safe detonationImprove securityAmmunition fuzesExplosive trainEngineering

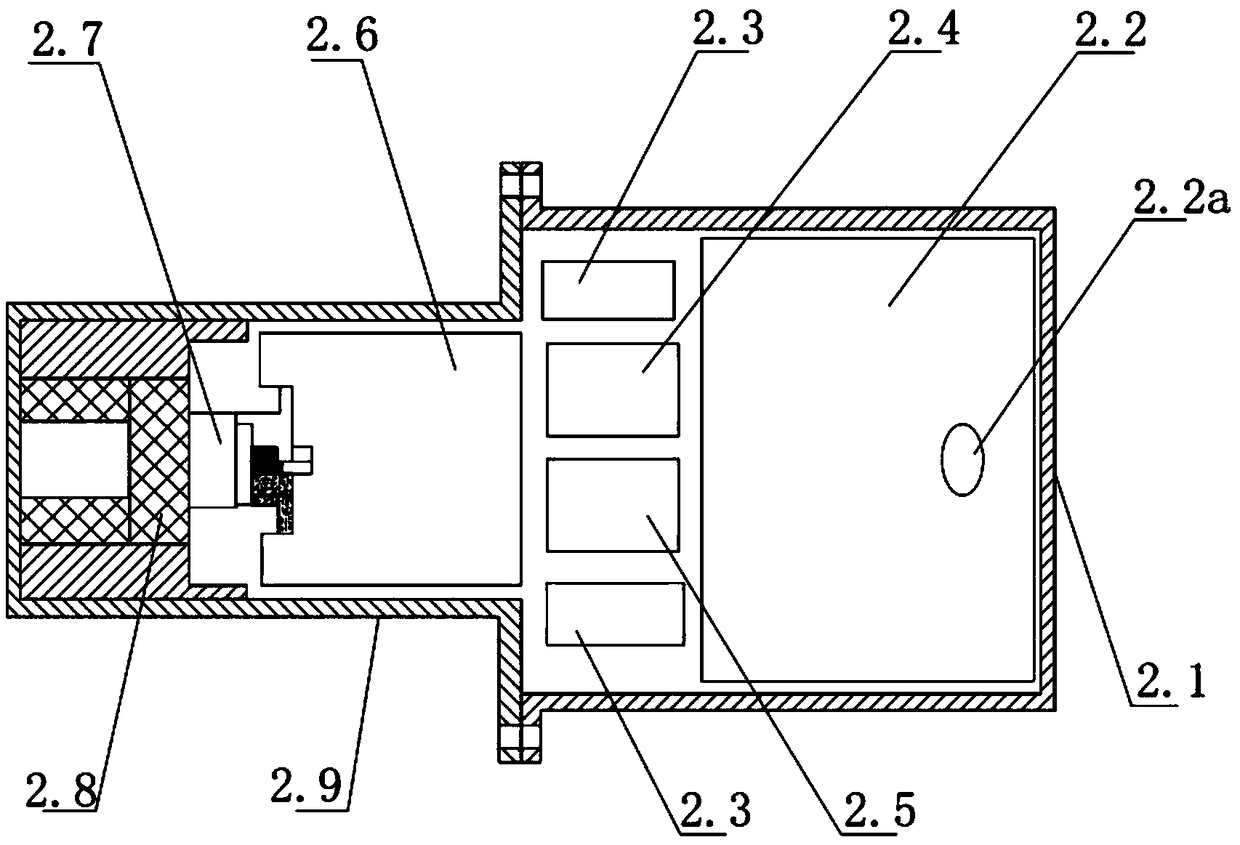

The invention discloses self-destruction equipment based on an in-line fuze. The self-destruction equipment based on the in-line fuze comprises an installation plate and an in-line priming device, wherein the in-line priming device is fixedly connected with the installation plate; the installation plate is fixedly connected with an underwater mine baffle plate; the in-line priming device comprisesa battery assembly, a sensor module, a full electronic logic assembly and a switch assembly arranged in a first shell, and a high-pressure priming module, a slapper plate detonator and an energy-gathered detonating primer arranged in a second shell; and the first shell is fixedly connected with the second shell. According to the self-destruction equipment based on the in-line fuze provided by theinvention, an in-line explosive train technology is applied to underwater ordnance self-destruction equipment, the self-destruction equipment is started when the underwater ordnance service time doesnot reach to the predetermined condition or exceeds the service time, so that the safe priming of underwater ordnance is realized, the safety in manoeuvre or actual combat is improved, and the technology service safety is ensured.

Owner:NAVAL UNIV OF ENG PLA

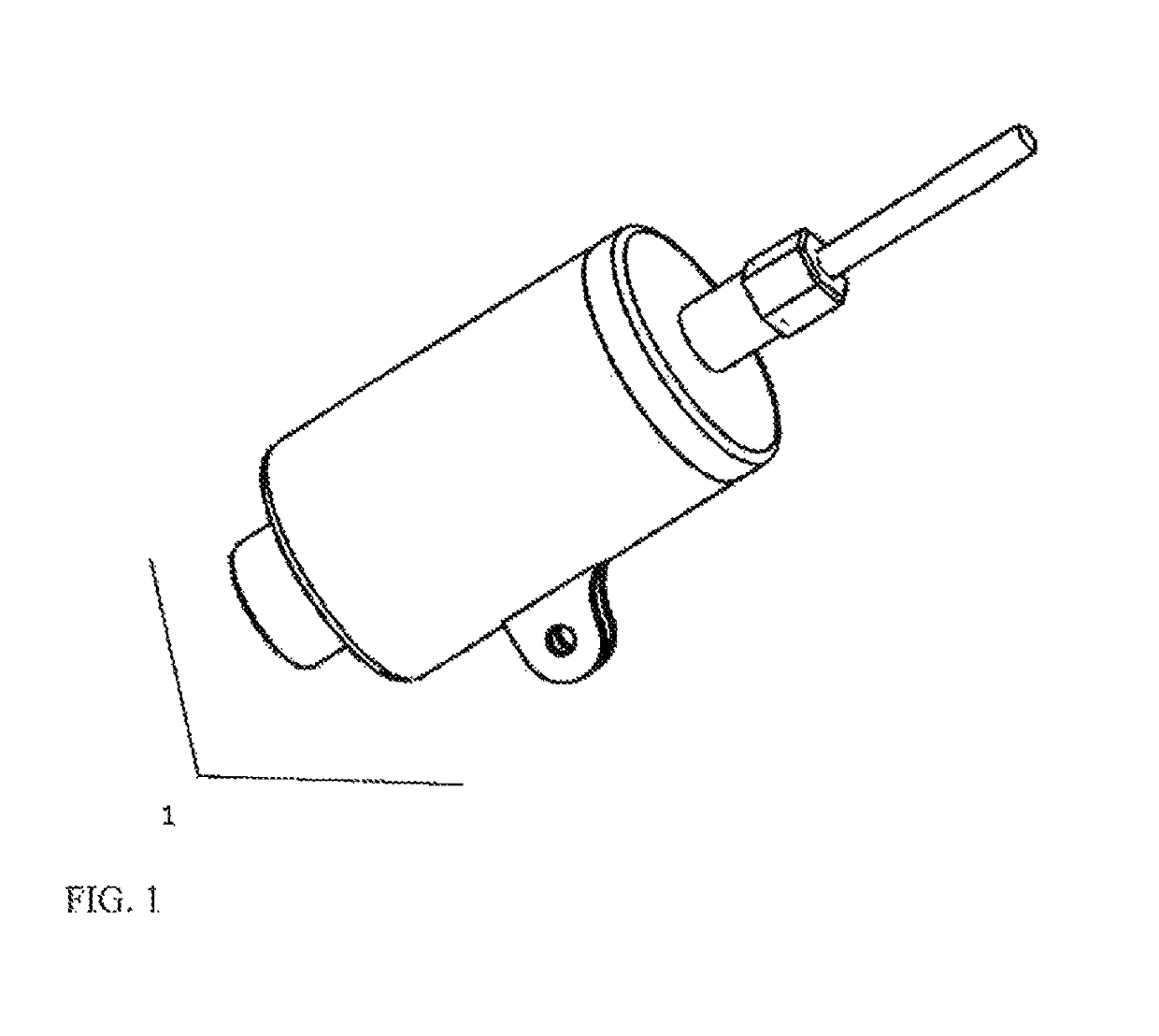

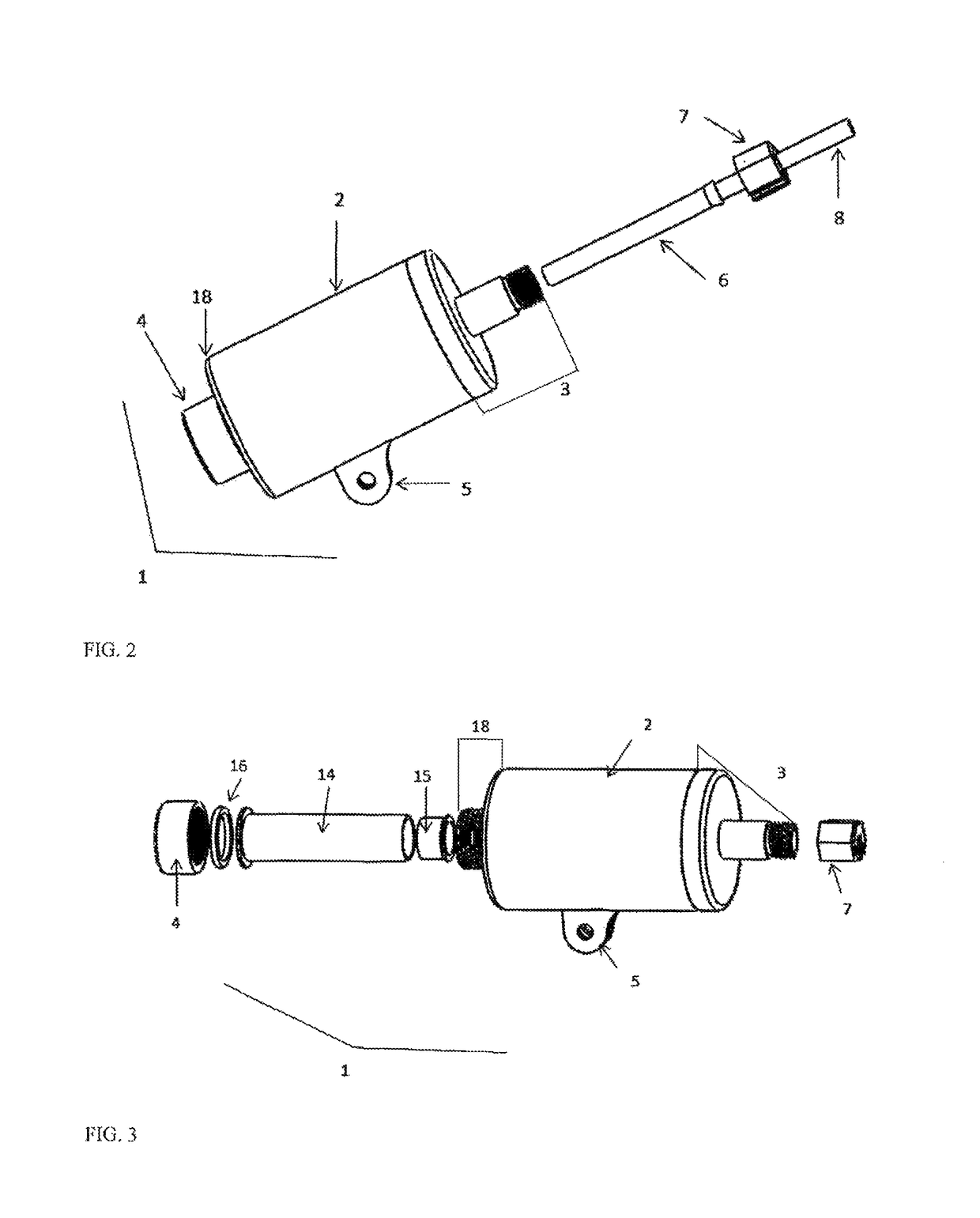

Method and device for initiating an explosive train

A detonator device includes a mechanism for shifting between an out-of-line orientation, wherein initiation of a detonator does not result in initiation of the explosive train, and an in-line orientation, wherein initiation of the detonator results in initiation of the explosive train.

Owner:PRAD RES & DEV LTD

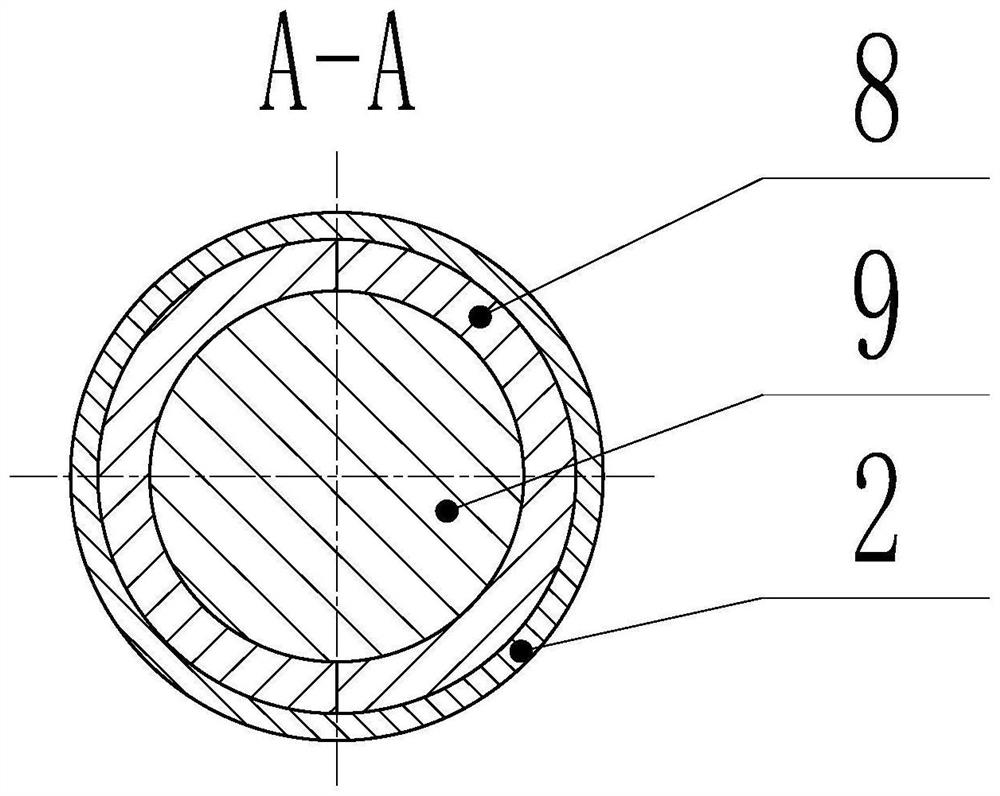

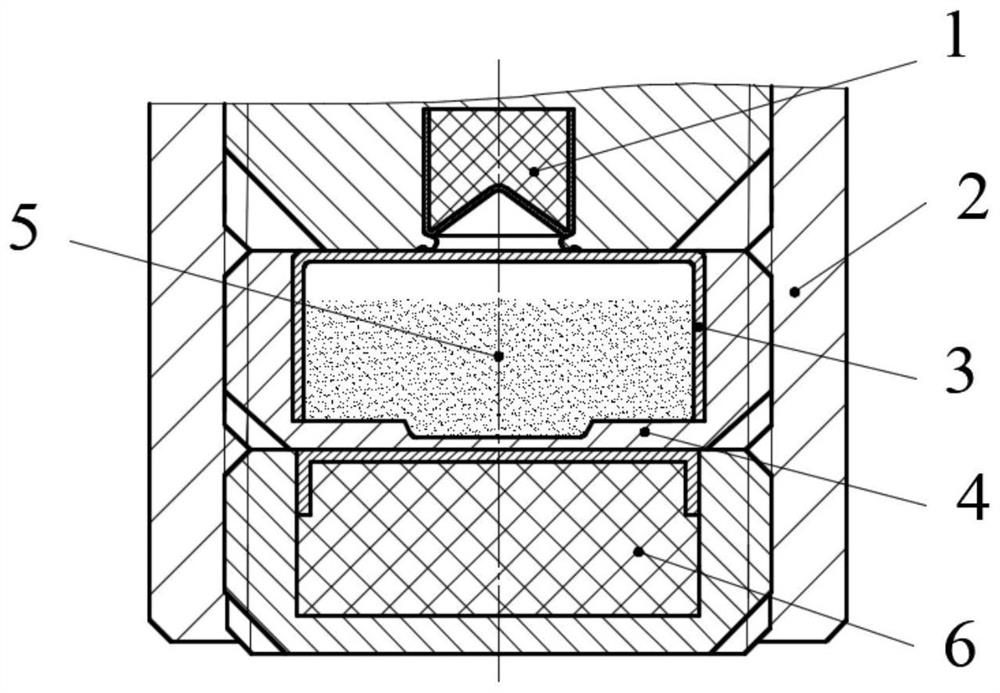

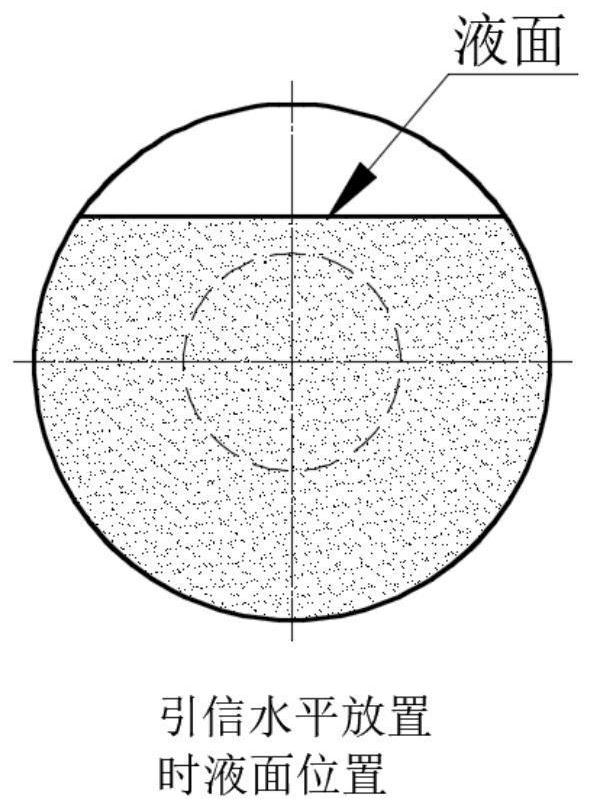

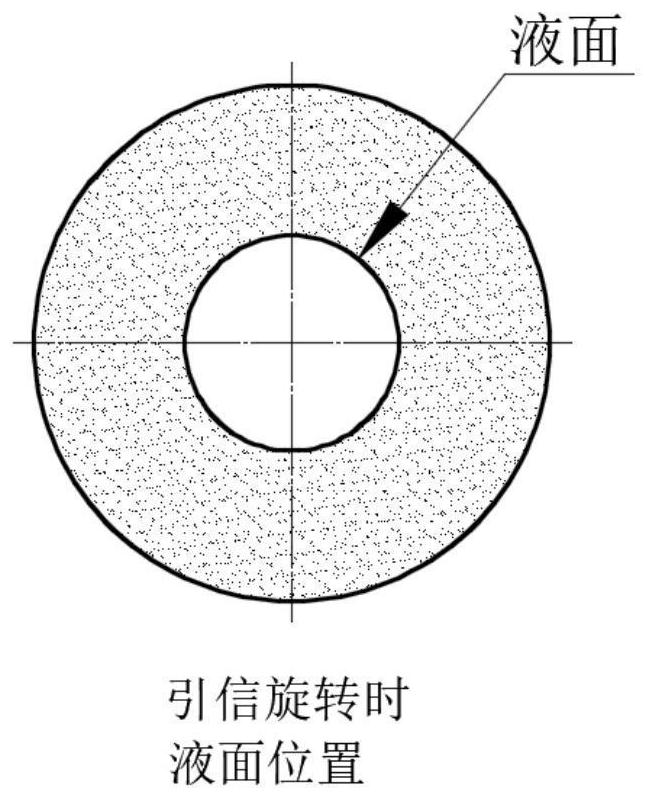

Rotating bomb fuse explosion propagation isolation mechanism capable of realizing explosive treatment and insensitive characteristics

PendingCN113091537AAchieve securityImplement featuresAmmunition fuzesExplosive trainCentrifugal force

The invention discloses a rotating bomb fuse explosion propagation isolation mechanism capable of realizing explosive treatment and insensitive characteristics. The rotating bomb fuse explosion propagation isolation mechanism comprises an isolation medium, a cover cap and an isolation seat. The cover cap and the isolation seat form a closed cavity for accommodating the isolation medium, and the isolation medium is not filled but a part of the cavity is reserved. The rotating bomb fuse explosion propagation isolation mechanism is located between a detonating tube and a booster tube. If the fuse detonating tube does not work normally, after a projectile falls to the ground and stops moving, due to the fact that no centrifugal force exists, the isolation medium closes an explosion energy-gathered jet explosion channel formed between the detonating tube and the booster tube due to rotation under the action of gravity; therefore, even if the detonating tube explodes due to accidental ignition of detonating sequence sensitive explosion elements such as a detonator, the booster tube cannot be detonated; and if the detonating tube is accidentally ignited due to baking of the fuse and impact of bullets, jet flow or fragments during service treatment, the isolation medium can prevent the detonating tube from detonating and does not detonate the detonating tube; The rotating bomb fuse explosion propagation isolation mechanism capable of realizing the explosive treatment and insensitive characteristics can be matched with various rotating bomb instant firing, near-explosion or air-explosion fuses, and the original structure is not changed and is only increased by about 5-10mm.

Owner:NANJING UNIV OF SCI & TECH

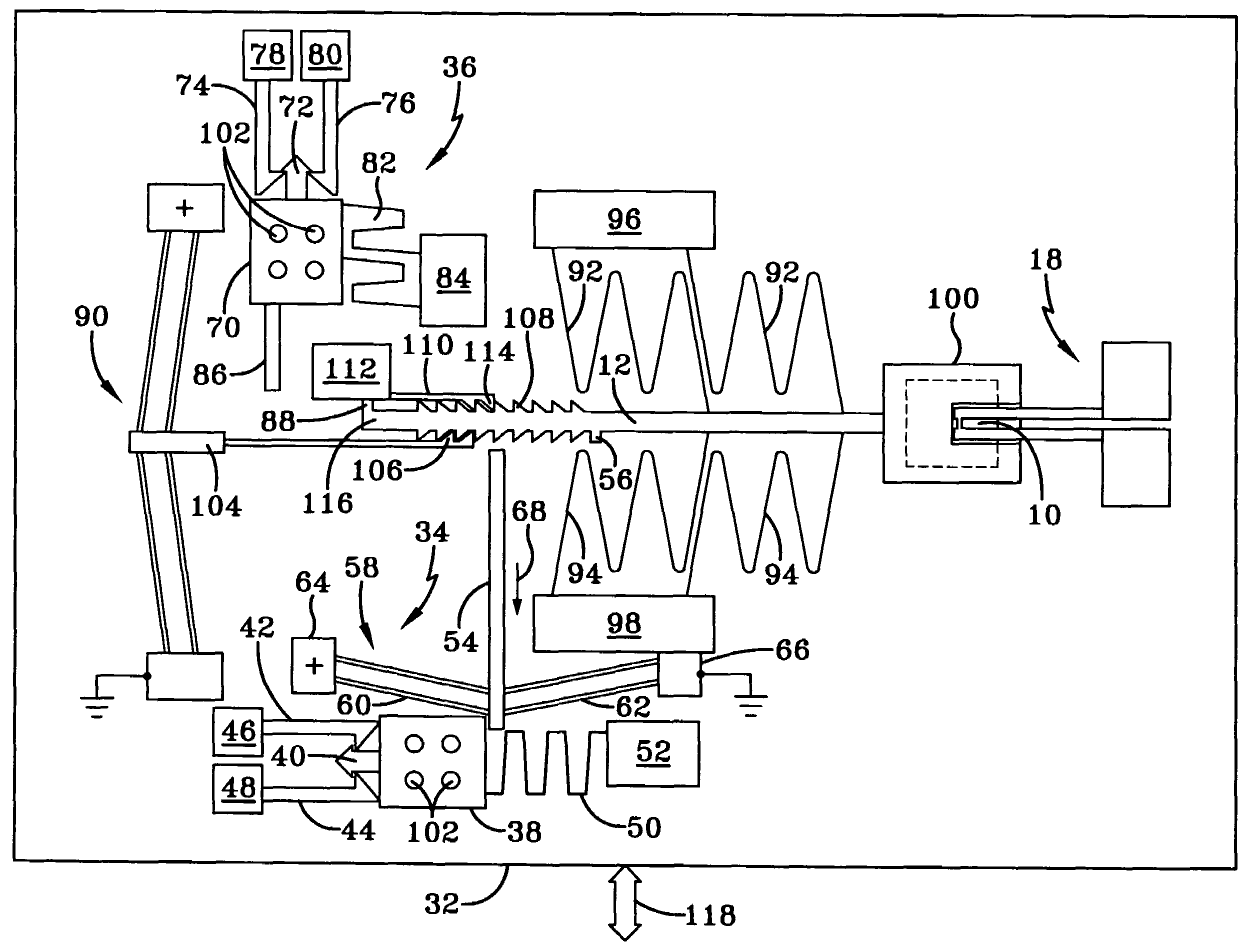

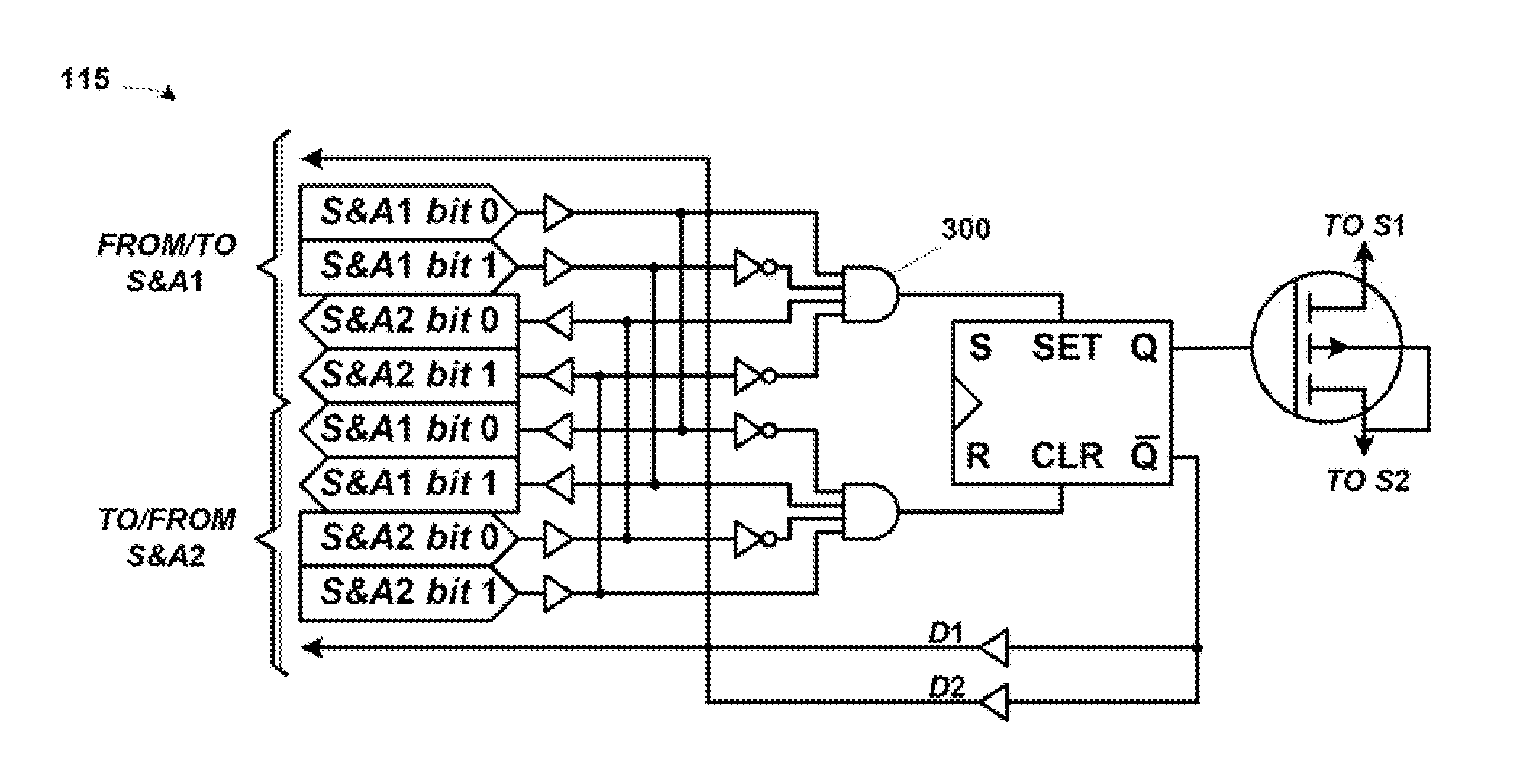

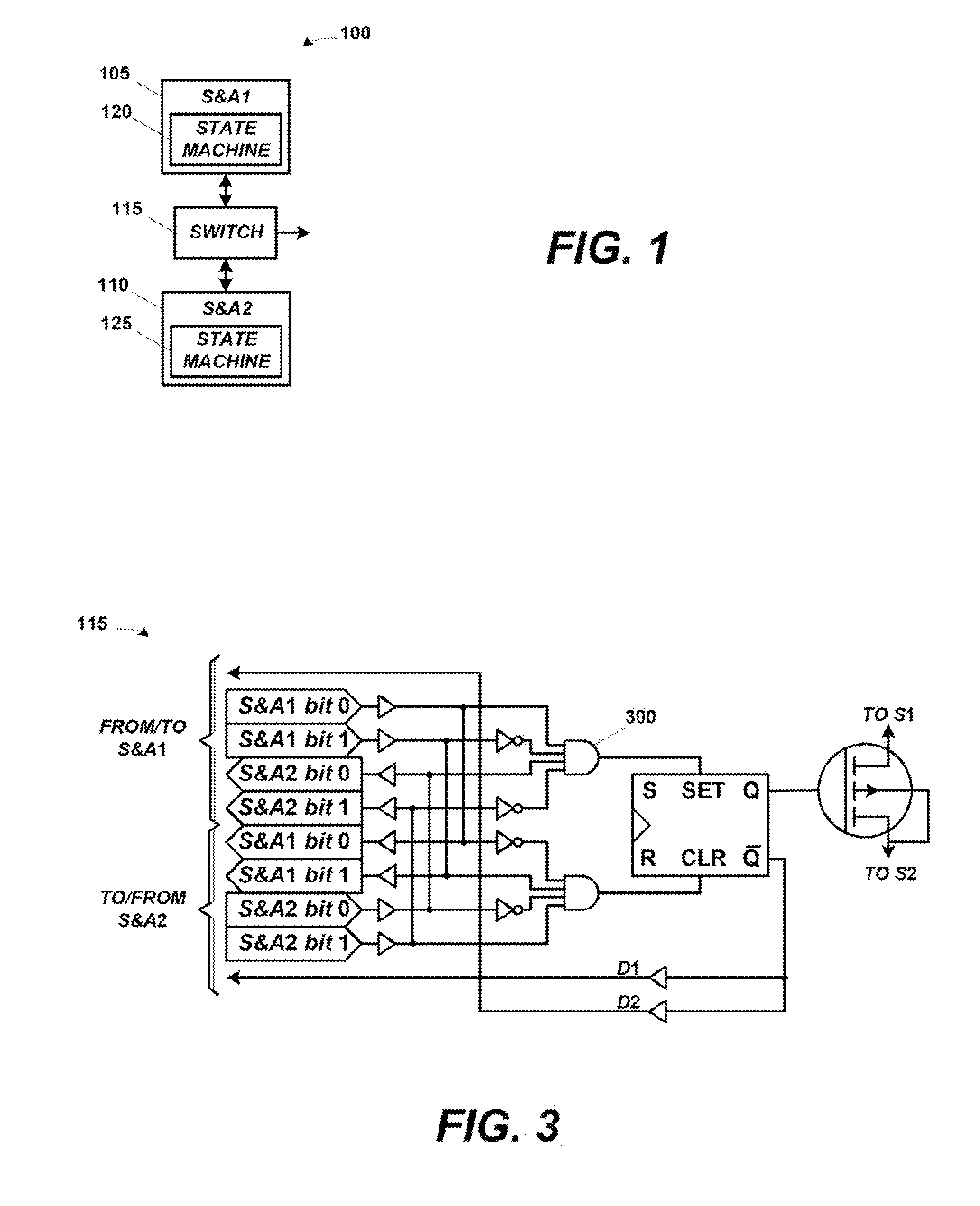

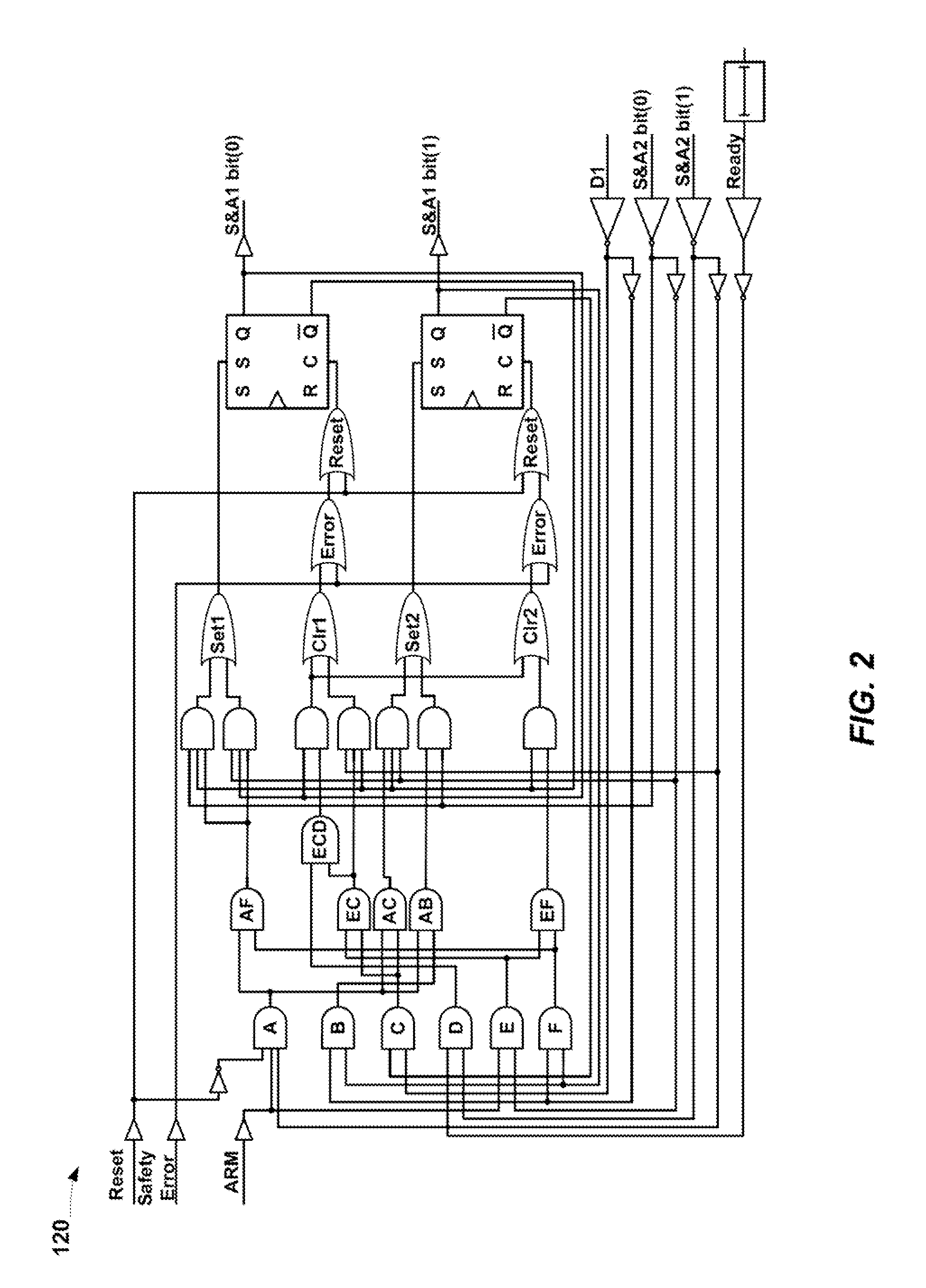

Dynamic Switching System for Use in In-Line Explosive Trains

The presently disclosed technique pertains to in-line explosive trains, and, more particularly, to a dynamic switch for use in an in-line explosive train. In a first aspect, the presently disclosed technique includes a method for use in arming an in-line explosive train comprising: arming two S&A circuits independently of one another; transitioning each arming circuit to a dynamic control start state to initiate a pair of state machines, each state machine associate with a respective one of the S&A circuits; transitioning through the states of the state machine to turn a switch on and off. In a second aspect, the presently disclosed technique includes a dynamic safety switch for use in an in-line explosive train comprising: a pair of S&A circuits; a pair of state machines entering a predetermined cycle upon indication to arm from both the S&A circuits and cooperatively transitioning through the cycle; and a switch controlled by the cooperative transition of the state machines.

Owner:LOCKHEED MARTIN CORP

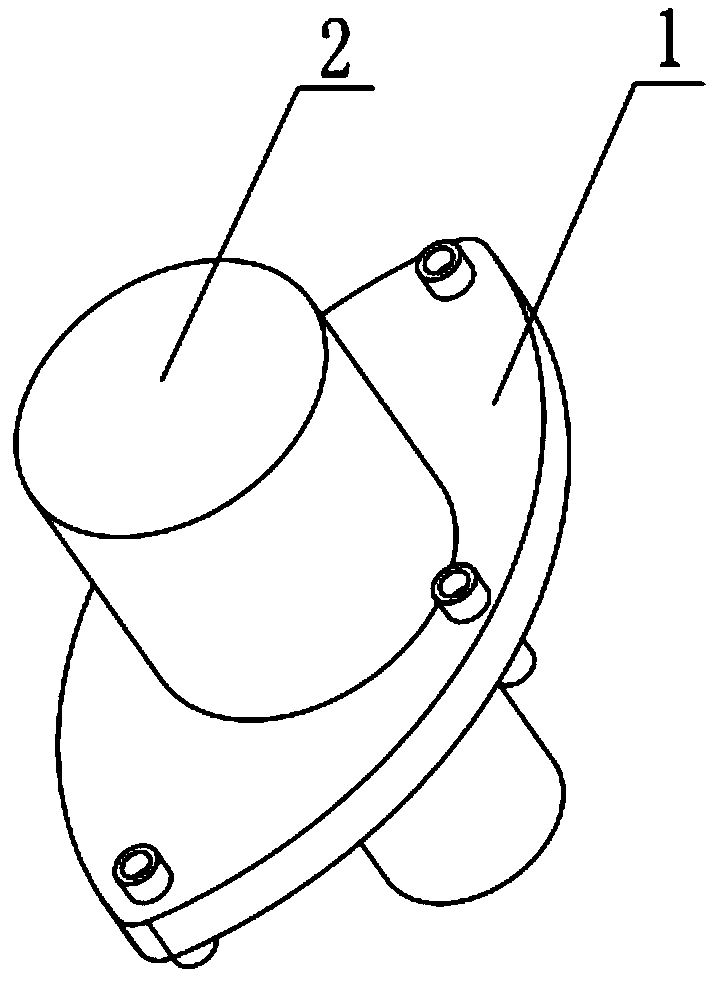

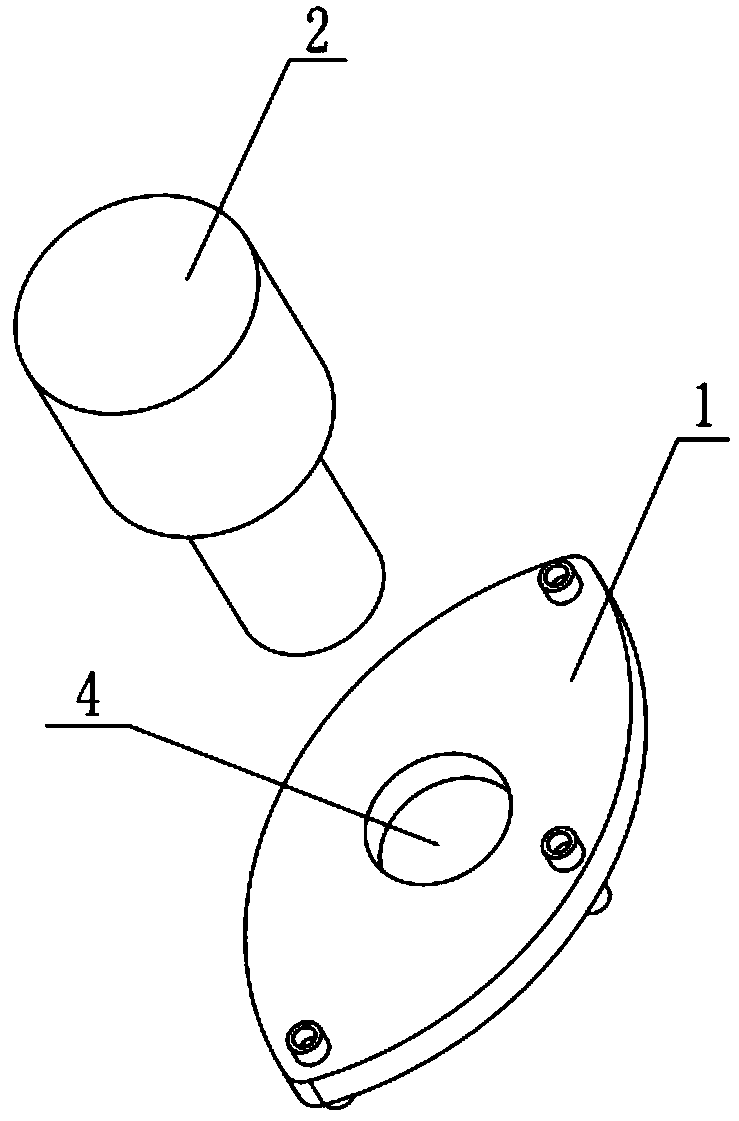

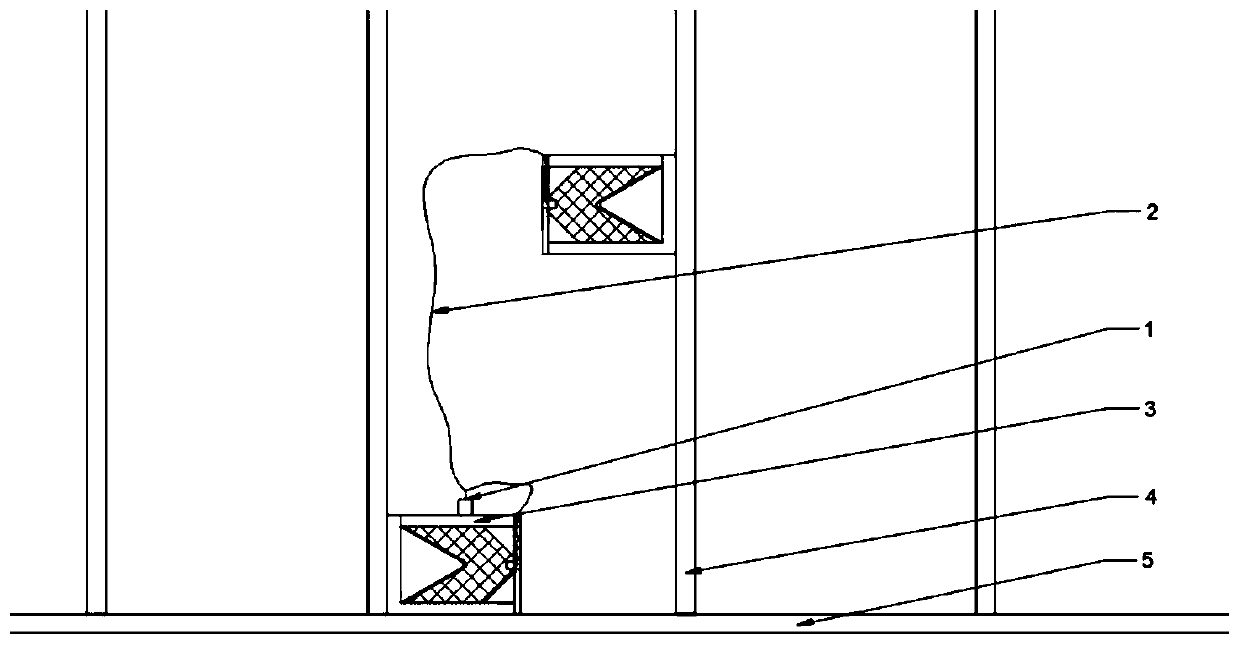

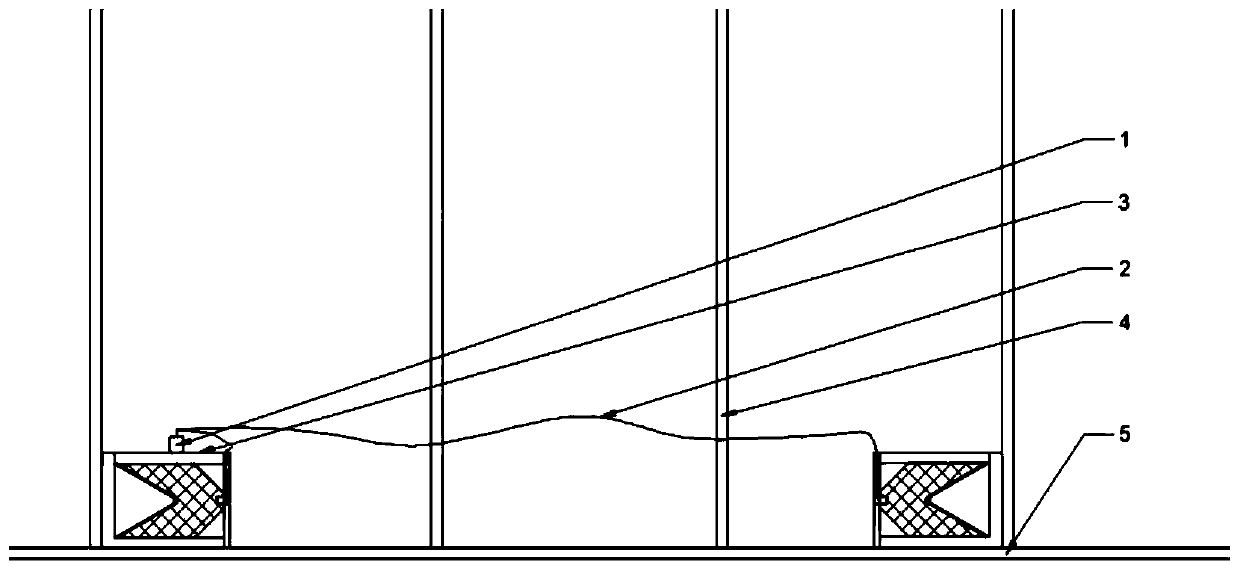

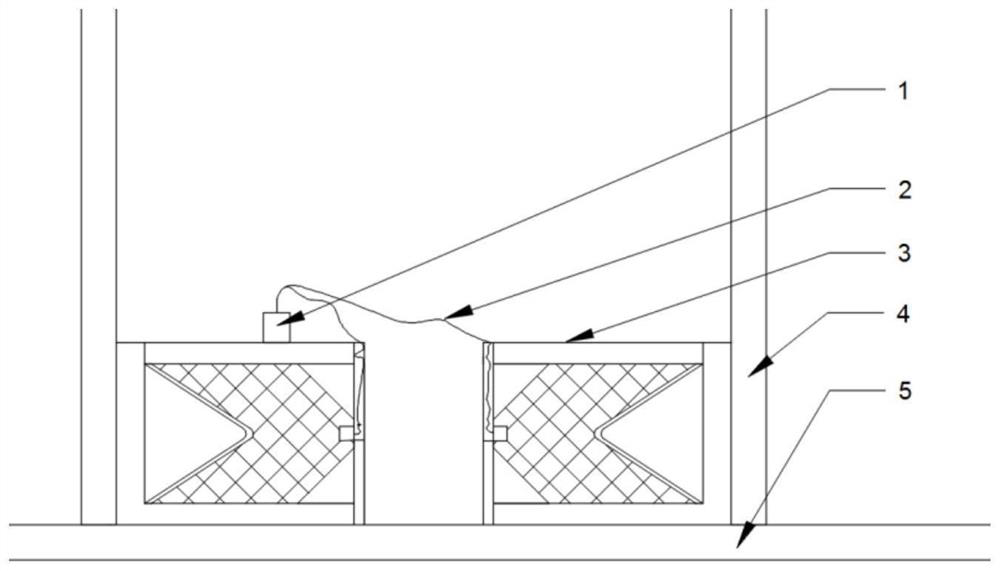

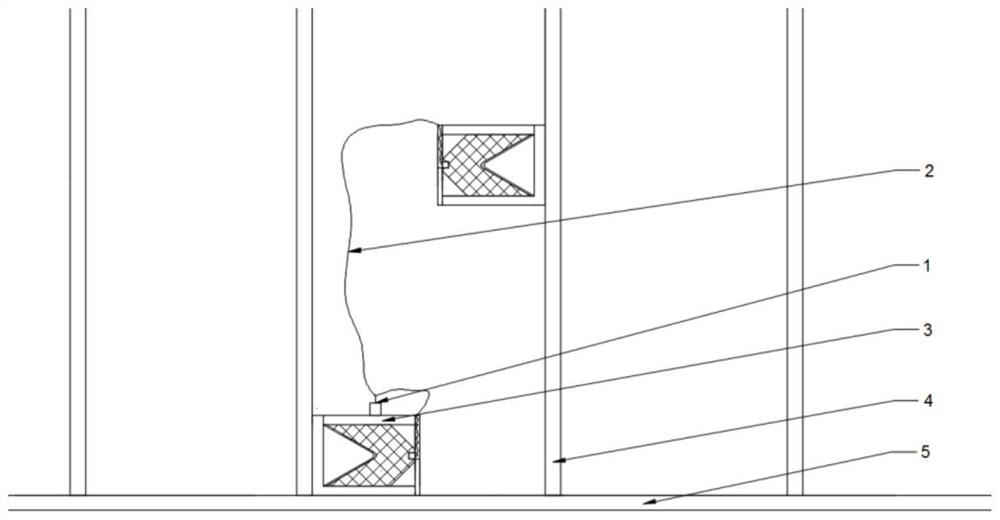

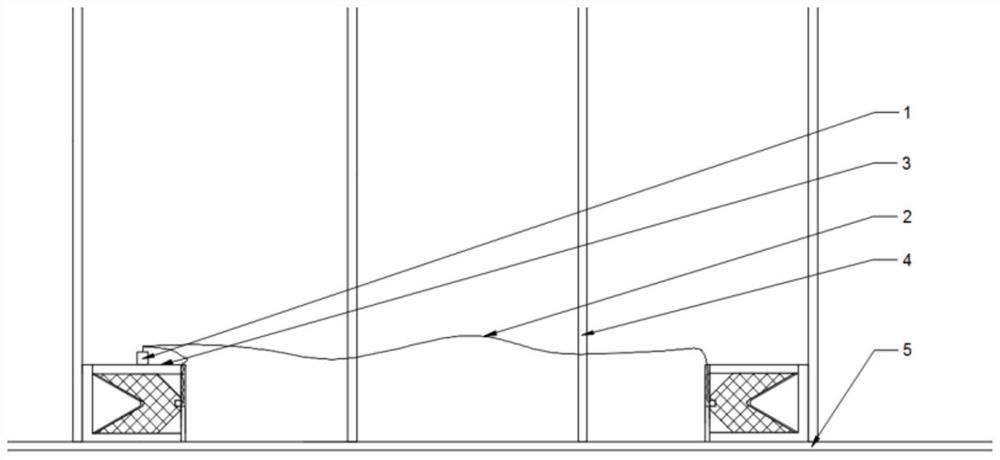

Deformable energy-collecting cutting device for fence breaking

The invention discloses a deformable energy-collecting cutting device for fence breaking and belongs to the technical field of ammunition. The cutting device comprises two acting units, a detonation transmission sequence, a detonator and elastic clamping sleeves; the two acting units are connected through the detonation transmission sequence, and the acting units are connected to fence rods through the elastic clamping sleeves fixedly connected with the acting units; and the detonator is installed on one of the acting units, and the detonator receives an external detonation signal and transmits the detonation signal to the other acting unit through the detonation transmission sequence, so that explosives in the two acting units are synchronously detonated, and energy generated by the explosives realizes cutting damage to a fence. According to the device, the fence is cut and damaged by the energy-collecting effect of the explosive charge, the device can cut the fence rods on both sidesseparately, and can also cut each certain fence rod from opposite sides or the same side, and therefore a fence door can be quickly and efficiently broken and disassembled.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A deformable energy-gathering cutting device for grid breaking

The invention discloses a deformable energy-gathering cutting device for grid breaking, which belongs to the technical field of ammunition. The cutting device includes two action units, an explosion transfer sequence, a detonator and an elastic ferrule; the two action units are connected through an explosion transfer sequence, and the action unit is connected to the fence bar through an elastic ferrule fixed to itself; The detonator described above is installed on one action unit, and the detonator receives an external detonation signal and transmits the detonation signal to another action unit through the detonation transmission sequence, so that the explosives in the two action units are detonated synchronously, and the energy generated by the explosive is realized on the fence. Cut damage. The invention uses the energy-gathering effect of the charge to realize cutting and destroying the fence. The device can not only cut the fence bars on both sides separately, but also cut the opposite side or the same side of a certain fence bar, so as to realize the rapid and efficient demolition of the fence gate. .

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Safe and arm explosive train

A Safe-and-Arm system for the prevention of unintentional operation of an explosive device by interrupting a detonation train, the system employing an interruptive transfer assembly made of silicon and suitable for implementing in a MEMS device, the assembly including a silicon based transfer charge carrier on a porous explosive passageway made by etching, the passageway extending between at least two ports on the circumference of the transfer assembly, and a drive means that can mechanically bring about at least one armed state of a detonation train.

Owner:RAFAEL ADVANCED DEFENSE SYSTEMS

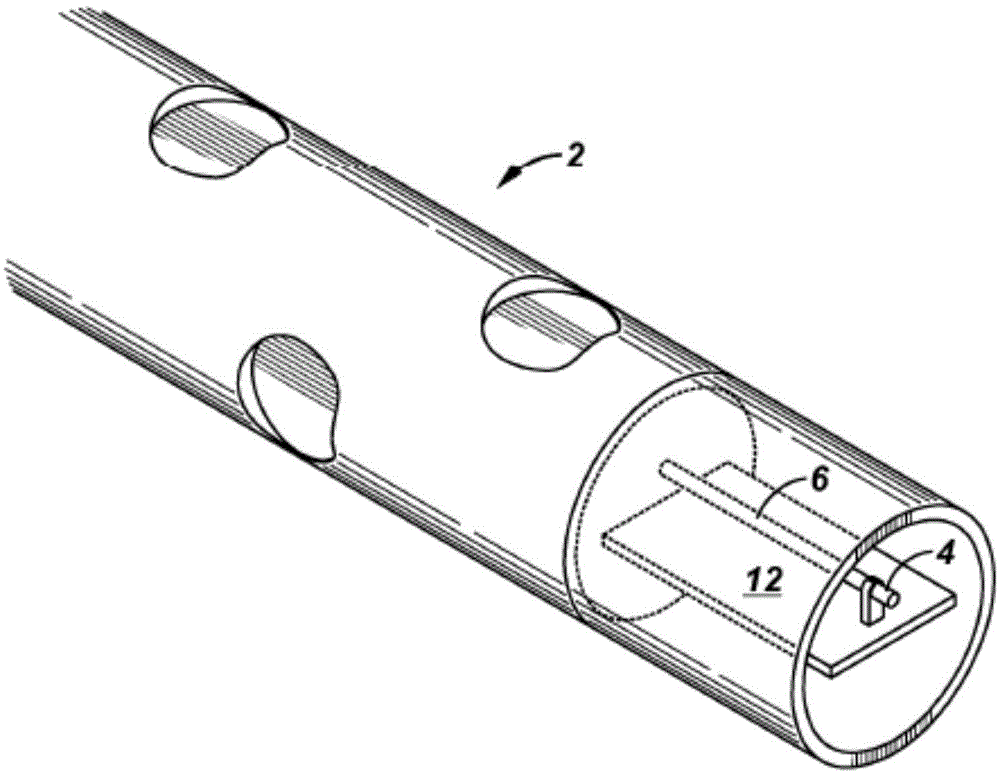

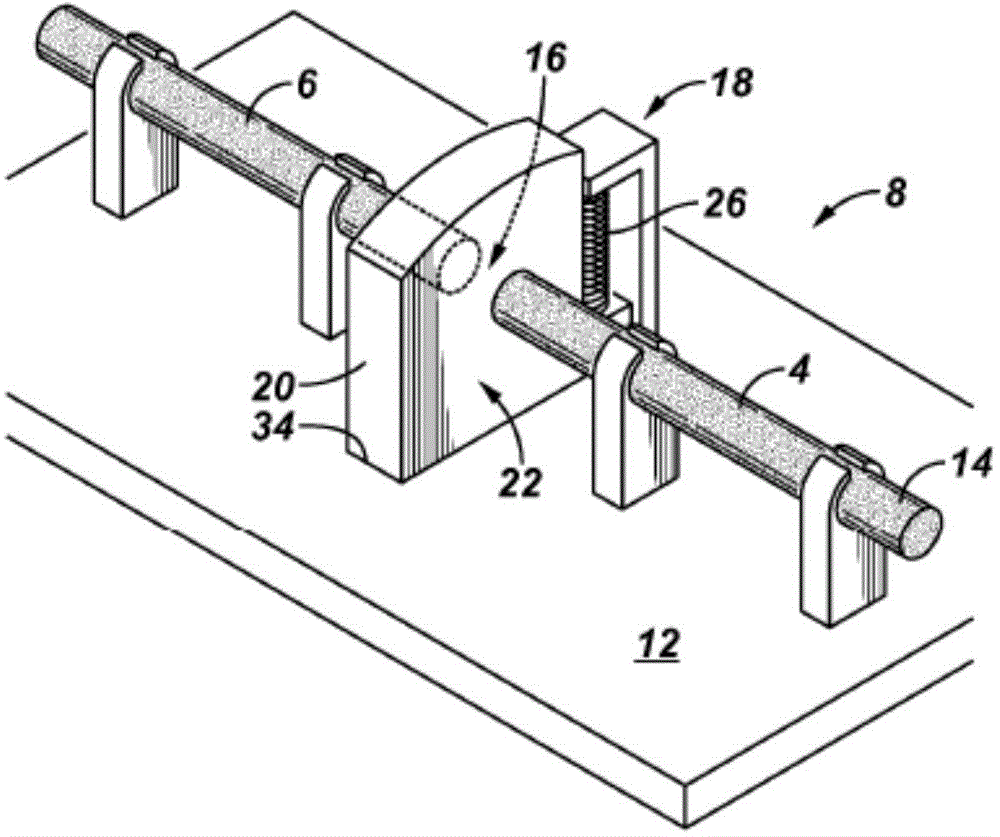

Device for controlling multi-point detonation transmission sequentiality of detonating cord

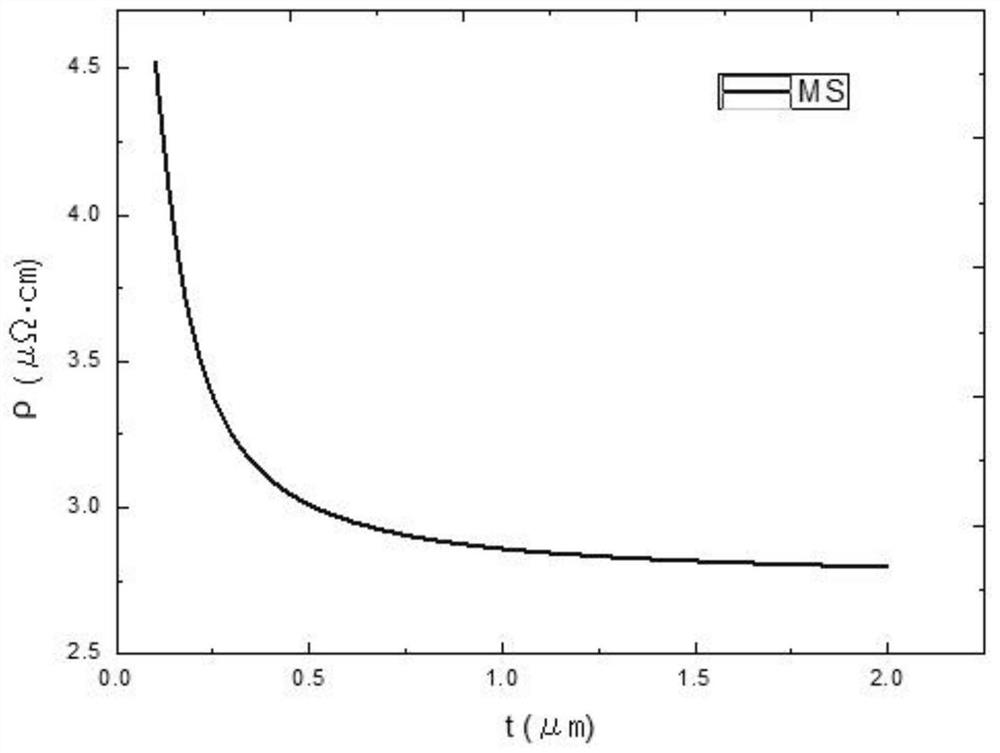

PendingCN111649635ARealize intelligenceControllable detonation sequenceBlastingExplosive trainMetallic materials

The invention discloses a device for controlling multi-point detonation transmission sequentiality of a detonating cord. The device comprises a base plate, a copper-clad plate and an electrode plug are arranged on the base plate, multiple rows of metal bridge membranes are arranged in the middle of the base plate, and are connected in sequence to form a detonation network, multiple booster explosives are arranged on each row of metal bridge membranes, a positive electrode and a negative electrode are arranged on the base plate, and are connected with the center of a detonating network, the different rows of metal bridge membranes select different metal materials or under the condition that the metal materials are certain, different bridge film thicknesses are selected, through the differences of specific resistance of the metal bridge membranes, the sequentiality detonation transmission can be achieved, through the non-linear distribution characteristics of specific resistance under the micron scale, the metal membrane material, thickness and length are controlled to achieve multi-point detonation transmission sequentiality of the detonating cord, the detonation transmission sequentiality is manually controllable, the detonation transmission manner is intelligent, and the disorder of the prvious detonation transmission can be solved.

Owner:XIAN TECHNOLOGICAL UNIV

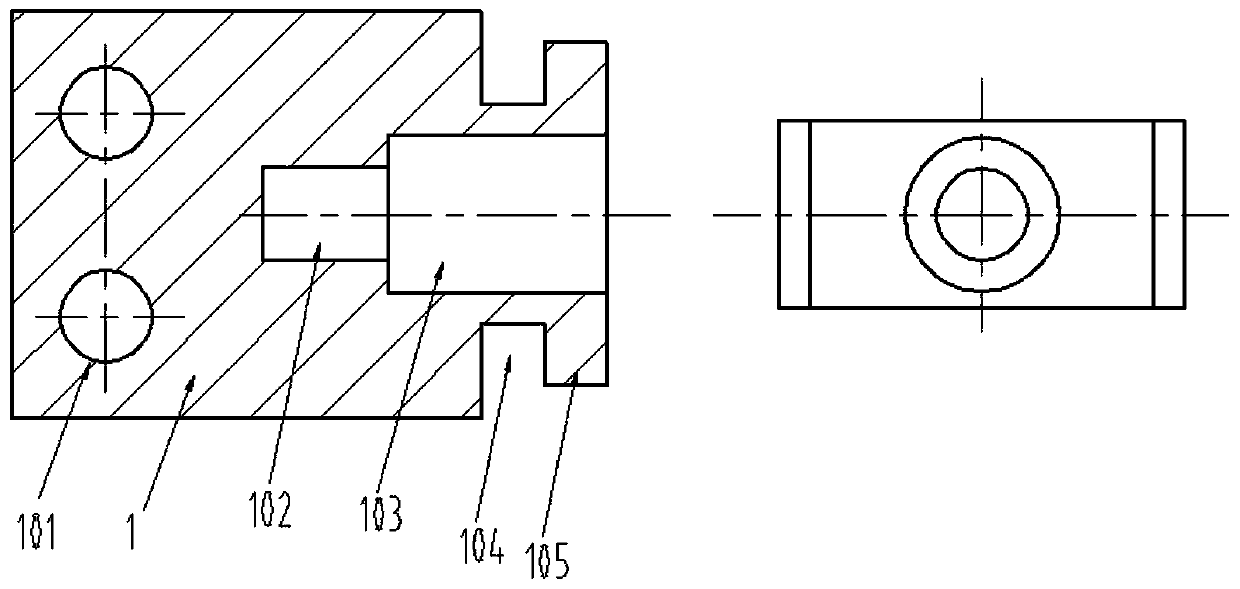

A Flyer Type Heat Sensitive Burst

ActiveCN108225133BFix security issuesSolving Detonation Reliability IssuesAmmunition fuzesExplosive trainExplosive Agents

The invention discloses a flying plate thermosensitive squib which includes a pedestal, a packaging base and a detonation propagation sequence which is installed on the pedestal and is packaged by thepackaging base. A first columnar accommodating chamber and a second columnar accommodating chamber are arranged on the pedestal and are connected to each other. A square pedestal groove and a squarepedestal boss are arranged at one side of the second columnar accommodating chamber. The square groove is located at the inner side of the square boss. The detonation propagation sequence comprises first charge and second charge, wherein a flying plate is located beside the first charge. A gun barrel is disposed at the outer side of the flying plate. A charging ring is arranged on the outer side of the gun barrel. The packaging base includes a square packaging boss and a square packaging groove. A third columnar accommodating chamber is arranged on the packaging base in the opening direction of the second columnar accommodating chamber, wherein a thin sheet is arranged on the inner side of the third columnar accommodating chamber. The flying plate thermosensitive squib guarantees action spontaneity in special status, such as fire hazard, and solves a problem of difficult of conversion from combustion to detonation of an insensitive explosive, and can enhance detonation development constrain.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

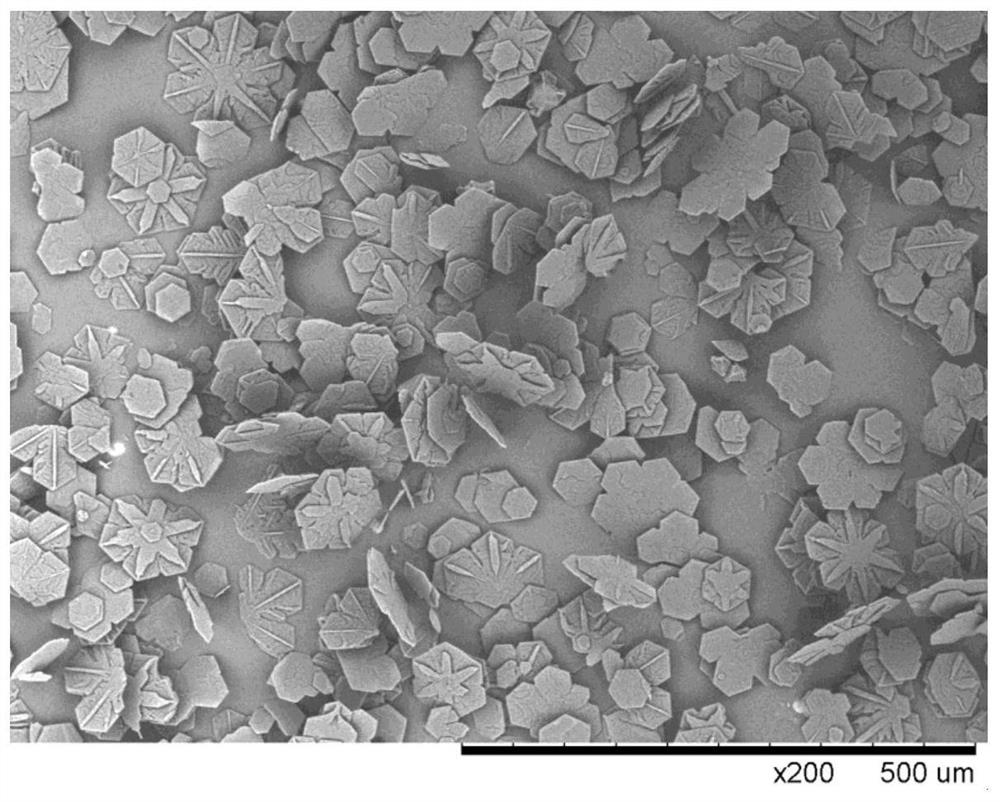

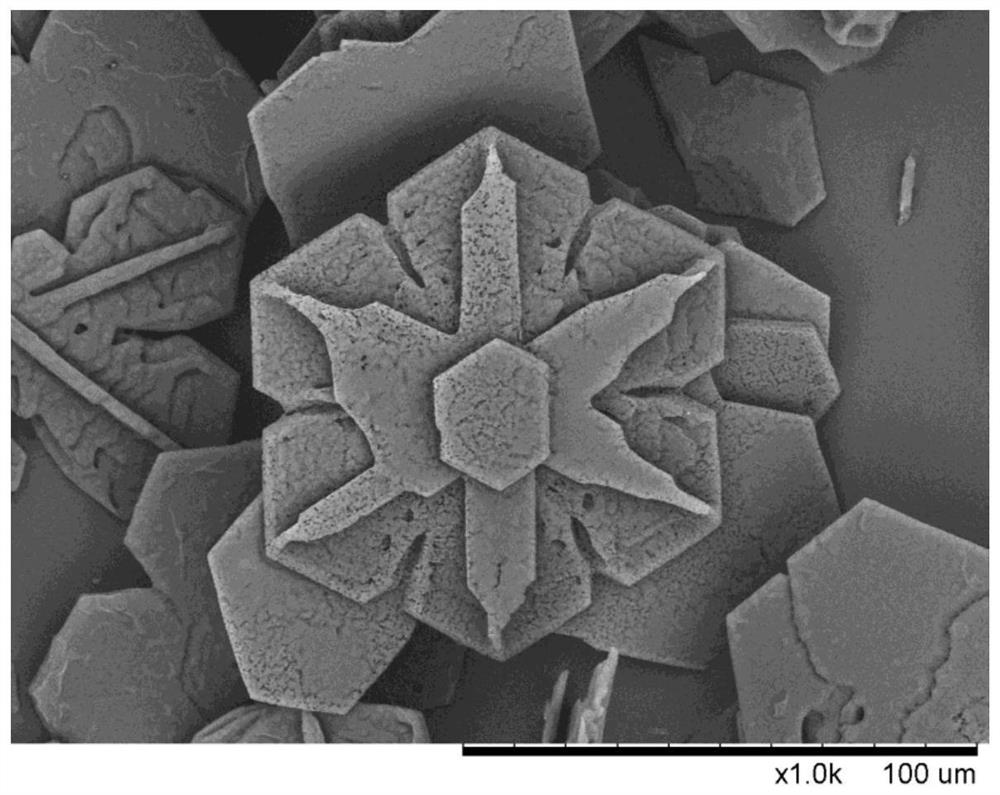

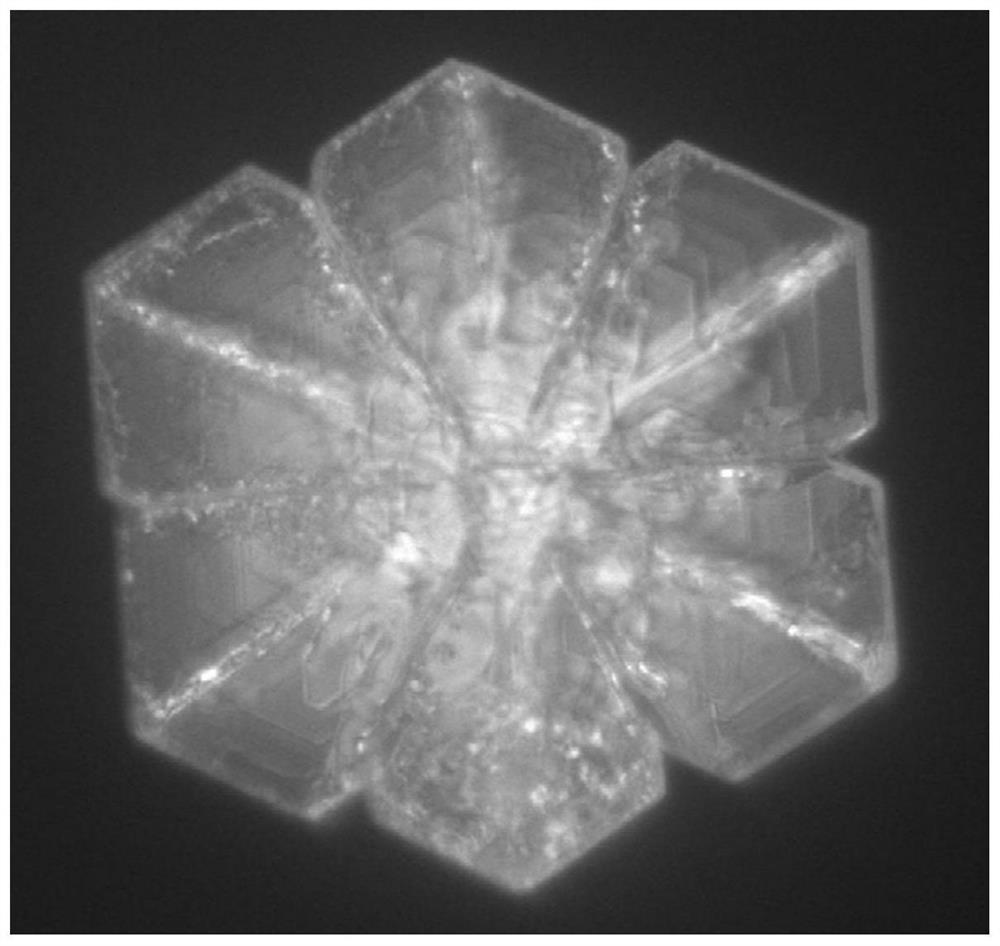

A kind of preparation method of hmx explosive with snow flake structure

ActiveCN109761730BUniform shapeGood dispersionNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsExplosive trainExplosive Agents

The invention discloses a preparation method for an HMX explosive with a snowflake-shaped structure and belongs to the technical field of energetic materials. The preparation method comprises the following steps: 1) adding HMX crystal into a first organic solvent under room temperature, and then fully dissolving HMX crystal in the manner of mechanical stirring, thereby acquiring a clear transparent HMX solution; 2) using an injector for sucking the HMX solution acquired in step 1), injecting to a second organic solvent under a stirring condition, keeping stirring for a period of time, and thenfiltering, washing with deionized water and drying, thereby acquiring the HMX explosive with the snowflake-shaped structure. The HMX explosive prepared according to the invention has a unique fractalstructure and has an important significance in national defense fields, such as technologies of initiation and explosion-propagation sequence of weapon charging, miniature initiation instruments andinitiating explosive devices. The preparation method disclosed by the invention has the advantages of simple process, short period, mild reaction conditions, easiness in amplification, low cost, and the like, and has an excellent application prospect.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

A Microdetonator with Low Firing Voltage and High Power Output

The invention discloses a low-ignition-voltage and high-power-output miniature detonator. The low-ignition-voltage and high-power-output miniature detonator mainly comprises a foot line, a ceramic electrode plug, a detonator shell, a semiconductor bridge chip, an ignition explosive, a primary explosive and a high explosive. The Cl-20 high explosive and the carboxymethyl cellulose lead azide primary explosive are sequentially pressed into the detonator shell to increase the axial output power of the miniature detonator, and a semiconductor bridge ignition component is fixed at a mouth part of the detonator shell by performing a detonator shell necking-in process and coating a sealant at the mouth part. The technical indicators of the miniature detonator disclosed by the invention are characterized in that the minimum full-ignition voltage is as low as 3.83V (10 micro F), the minimum full-ignition energy is 0.074mJ, the safe current is not less than 200mA, the size of the detonator is not more than phi 2.5*4 mm, and when the output detonation pressure of the detonator is tested by a manganin pressure gauge, the maximum output power of the miniature detonator achieves 13-15 GPa. Compared with the technical indicators of an existing bridge wire type electric detonator, the comprehensive performance of the detonator is greatly improved. The low-ignition-voltage and high-power-output miniature detonator disclosed by the invention is suitable for design of explosive trains of micro-electromechanical systems requiring low ignition voltage and high power output.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

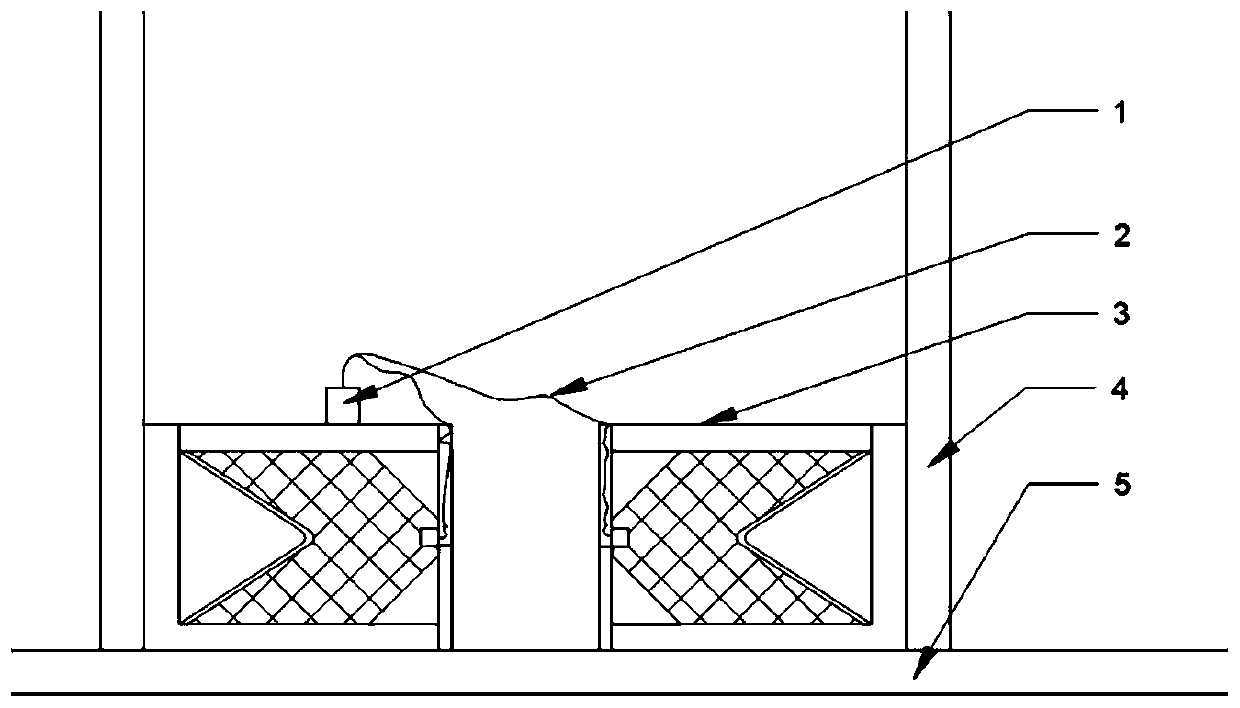

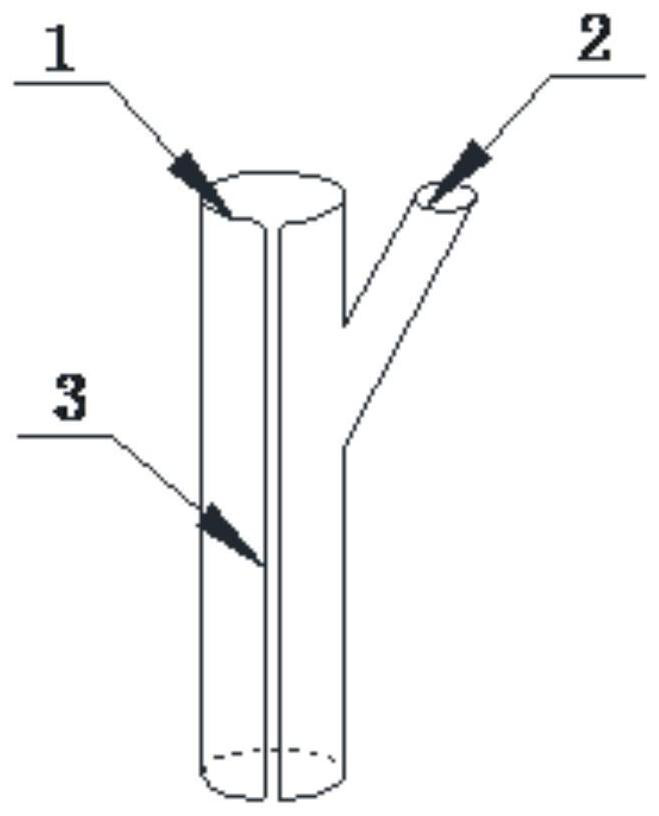

Auxiliary device for blasthole charging and its use method

ActiveCN111397459BImprove work efficiencySave charging timeBlastingOpen-pit miningExplosive trainLoad time

The invention relates to an auxiliary device for blasthole charging, which comprises a standpipe and a charge pipe. The charge pipe is obliquely connected to the side wall of the standpipe. The side wall of the tube is provided with an open groove parallel to the axis, and the top of the open groove is tapered gradually expanding from bottom to top. When charging the gun barrel, connect the charge tube with the explosive vehicle charging hose; put the lower opening of the standpipe into the blast hole; put the detonating bomb into the blast hole from the upper mouth of the standpipe, Put it into the open slot; the explosive vehicle starts to charge the blast hole until it reaches the charge height for installing the spacer, and the explosive vehicle stops conveying the explosive; put the spacer into the blast hole from the upper mouth of the standpipe 1; continue charging until the blast hole is reached. The gun hole requires charge. The device quickly places the spacer and the detonating bomb, improves the work efficiency of workers, and reduces the charging time. The production cost is low, and it is easy to carry, and solves practical engineering problems such as complex charging process, time-consuming, and labor-consuming.

Owner:UNIV OF SCI & TECH LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com