Device for controlling multi-point detonation transmission sequentiality of detonating cord

A detonation transfer sequence and detonating cord technology, which is applied in the field of devices for controlling detonation cord multi-point detonation transfer, can solve problems such as detonation transfer sequence, and achieve the effect of solving disorder or large time jitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In the present embodiment, aluminum film (Al) is selected as the metal bridge film;

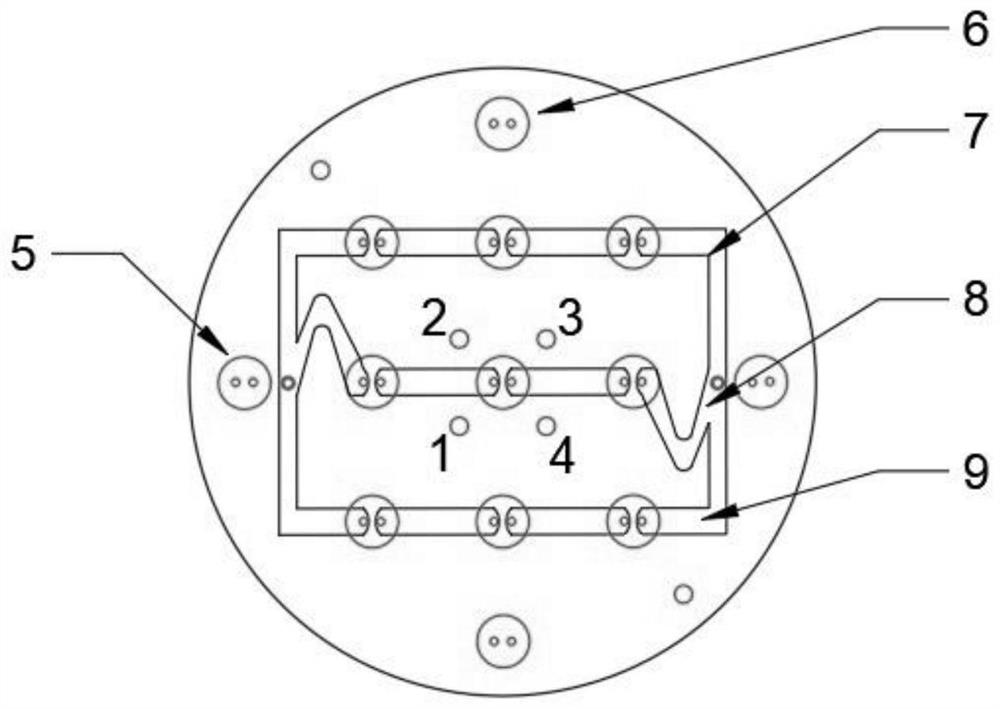

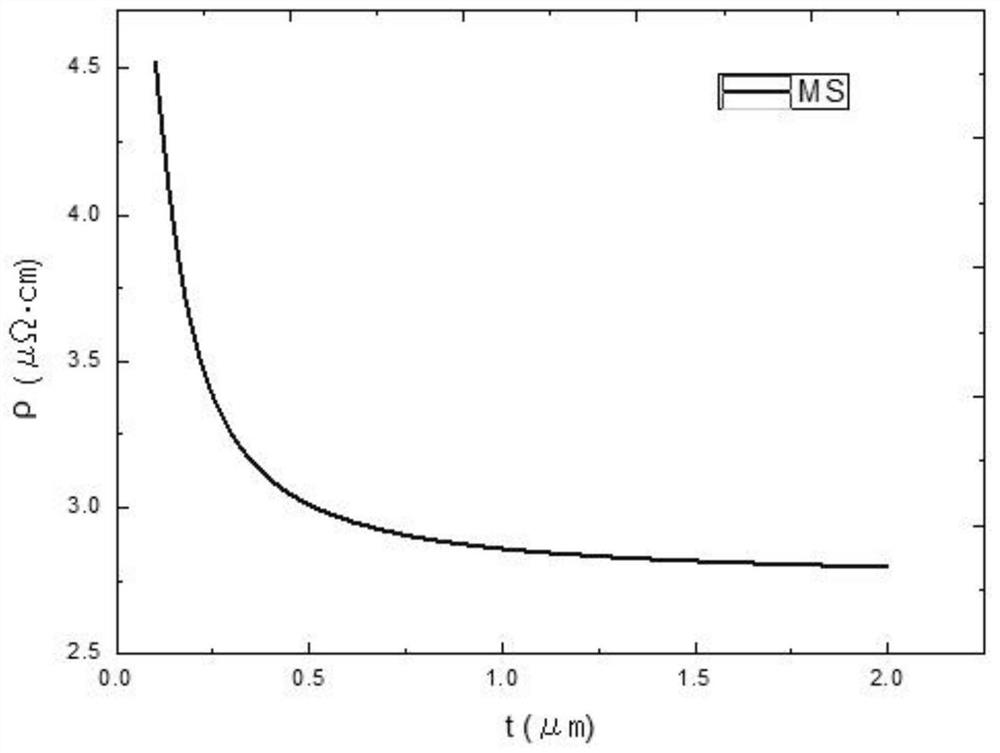

[0026] according to figure 1 The output point of the plane shown above is set to connect positive electrode 1 and positive electrode 3 to the positive pole of the detonation network, and negative electrode 2 and negative electrode 4 to connect to the negative pole of the detonation network. The delay of the three boosters between the single row of metal bridge membranes can be ignored , only by changing the delay between the first row of metal bridging membranes 7, the second row of metal bridging membranes 8, and the third row of metal bridging membranes 9 to meet the requirements. The sequential detonation of the three rows can be achieved by changing their resistivity. In this implementation case, the metal material and the explosion transfer length of the three rows are the same, so only the metal material length of each row needs to be considered. Due to the scale effect of the ...

Embodiment 2

[0028] In this embodiment, the metal bridge film is selected from copper thin film (Cu), aluminum thin film (Al) and chromium thin film (Cr)

[0029] according to figure 1 The output point of the plane shown above is set to connect positive electrode 1 and positive electrode 3 to the positive pole of the detonation network, and negative electrode 2 and negative electrode 4 to connect to the negative pole of the detonation network. The delay of the three boosters between the single row of metal bridge membranes can be ignored , only by changing the delay between the first row of metal bridging membranes 7, the second row of metal bridging membranes 8, and the third row of metal bridging membranes 9 to meet the requirements. The sequential detonation of the three rows can be achieved by changing their resistivity. In this embodiment, the length of each row of metal materials is controlled to be constant, the first row of metal is set to copper (Cu), and the resistivity is 1.678...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com