Method and device for initiating an explosive train

A kind of gunpowder system and gunpowder technology, applied in the direction of weapon accessories, fuzes, offensive equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

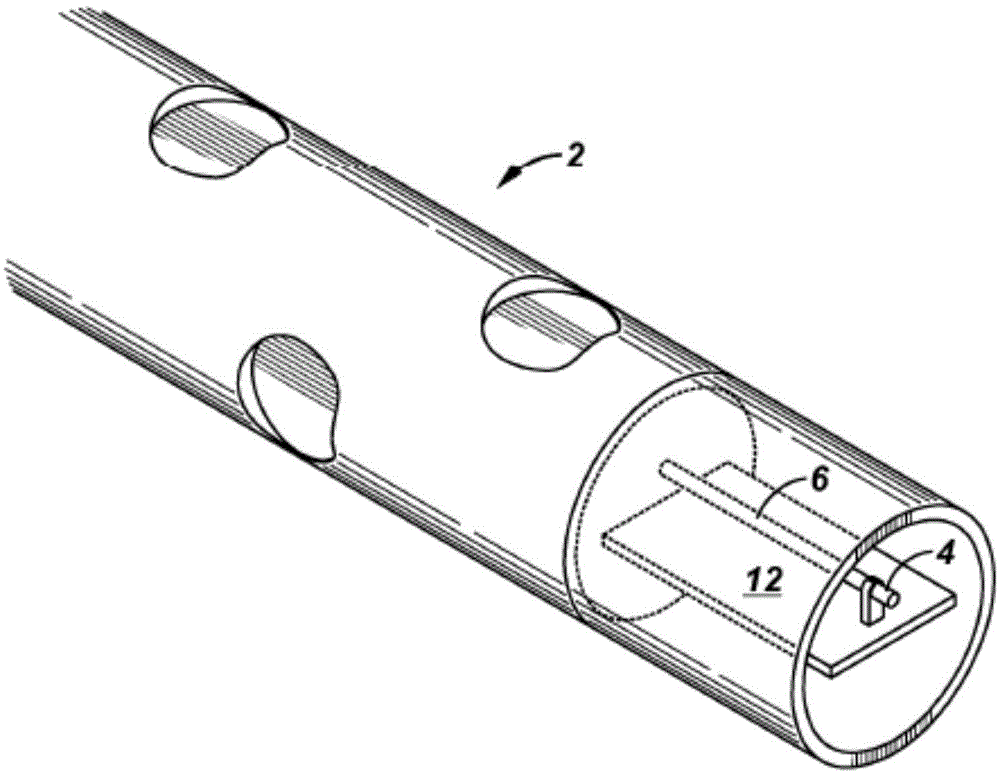

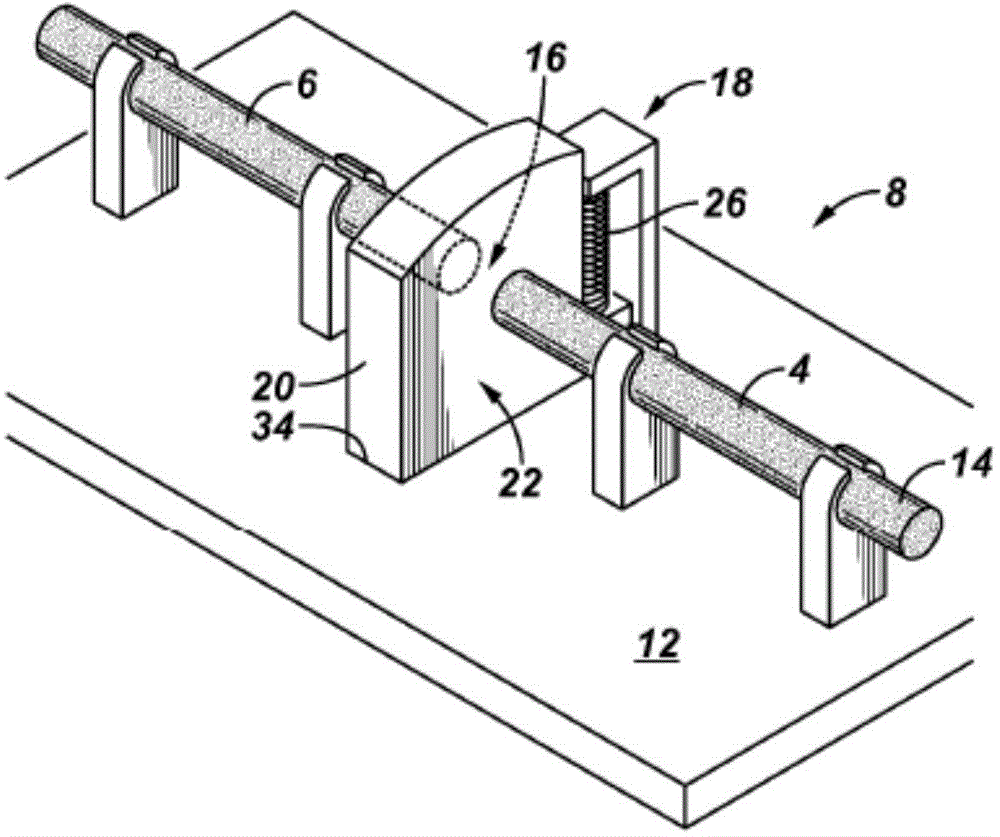

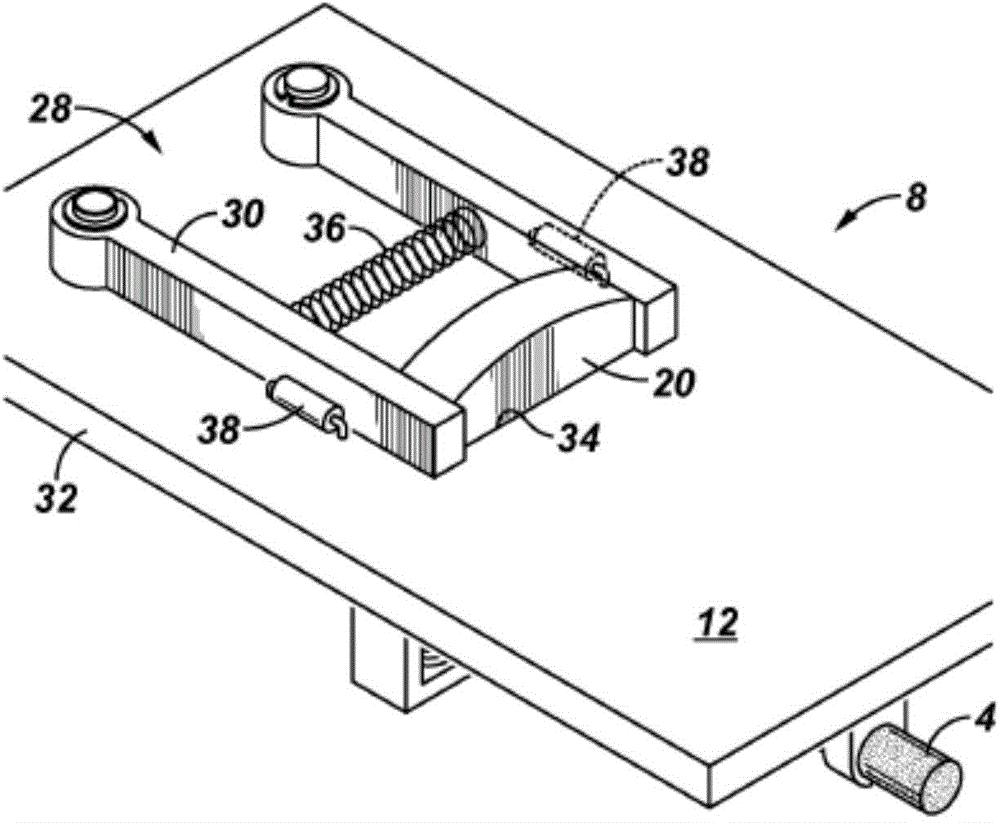

[0022] exist figure 1 In , a system 2 is shown having a detonating device 4 connected to a powder train 6 . A charge train 6, such as a detonating cord, extends from the detonating device 4 towards the charge or other combustible material. As shown in the figure, the detonating device 4 is configured to move from an out-of-line orientation 8 to an in-line orientation 10 in which activation of the detonating device 4 does not result in ignition of the explosive system 6, and in an in-line orientation 10 in Activation of the detonator 4 allows ignition of the explosive train 6 . The detonating device 4 includes an electronic switch 12 for receiving a signal from a remote location, which allows the repositioning of the detonating device 4 without physical manipulation by the operator and just before the detonating device 4 is activated. Thus, the detonating device 4 may remain in the off-line orientation 8 until the detonating device 4 is in a predetermined position and ready t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com