A Flyer Type Heat Sensitive Burst

A sensitive detonator and flyer type technology, which is applied in the field of flyer thermal detonator and detonator, can solve the problems of sudden pressure rise, explosion and low reliability in the airtight chamber, so as to ensure the sealing performance and solve the detonation difficulties , Enhance the effect of detonation growth constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

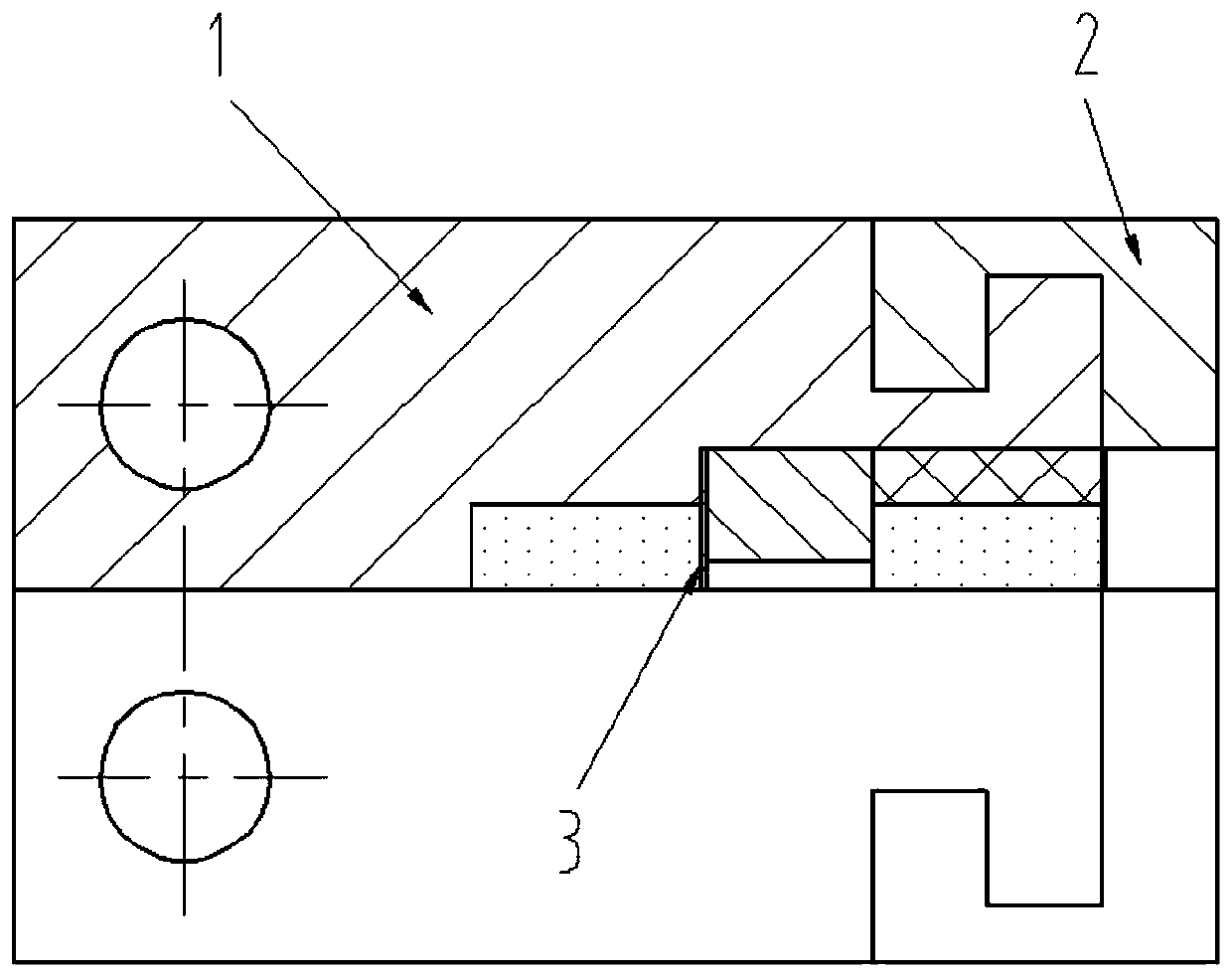

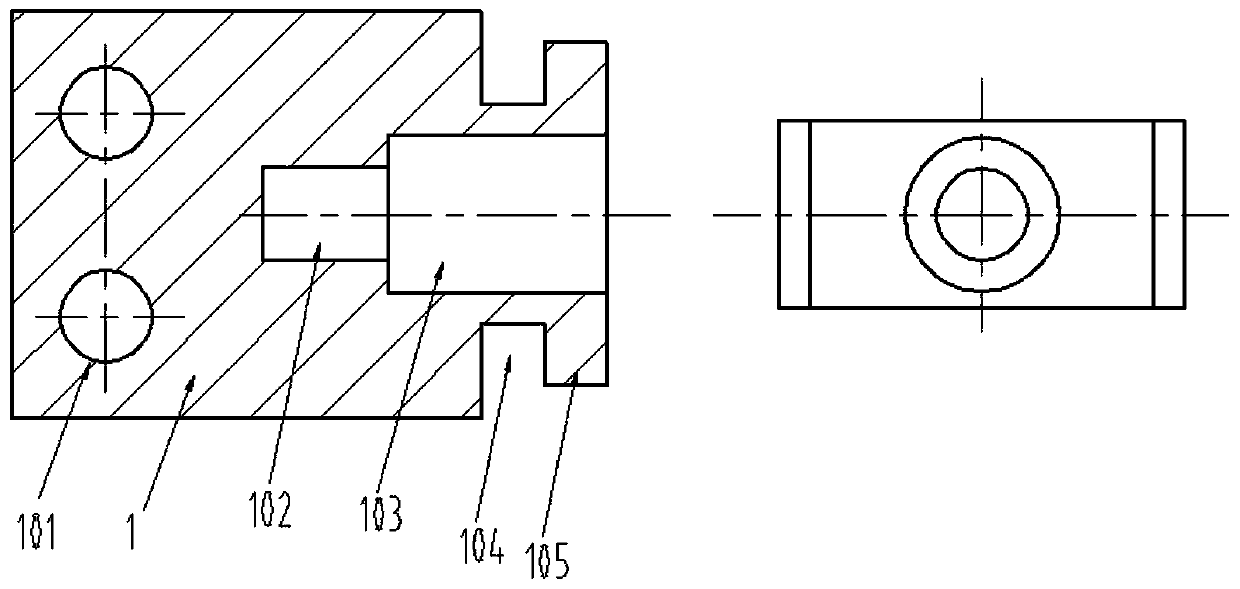

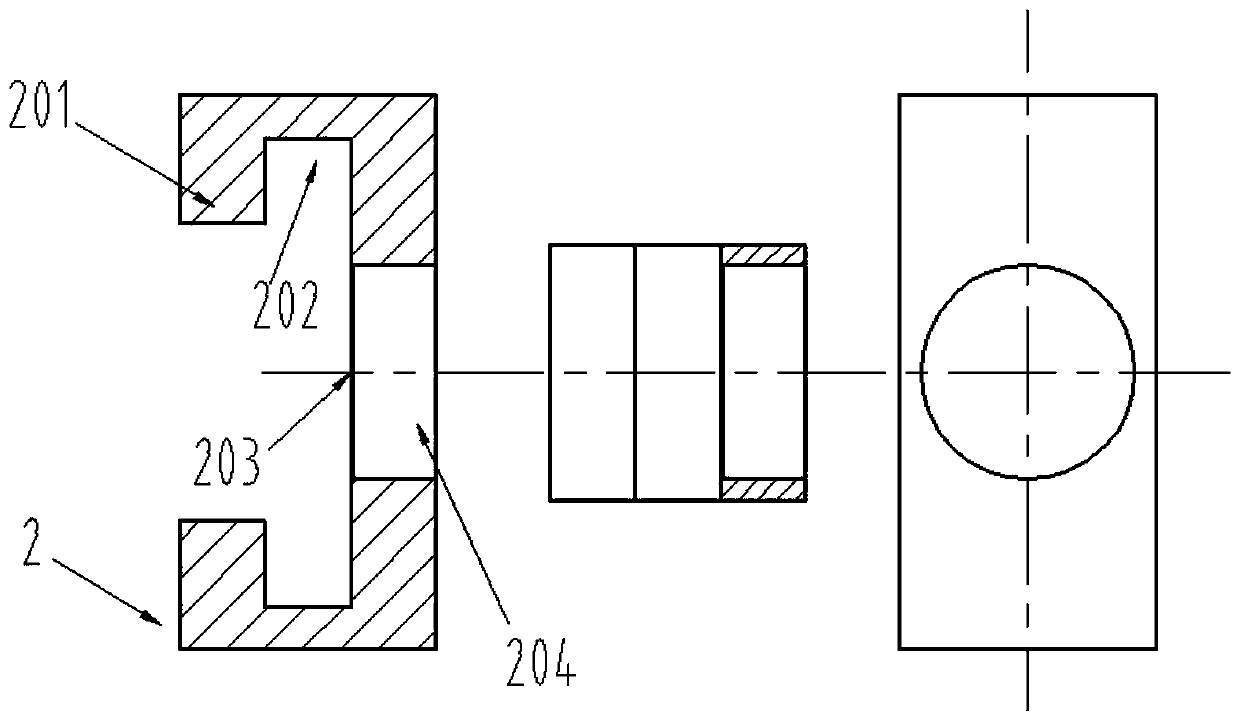

[0032] like Figure 1 to Figure 4 As shown, the flyer type thermal squib in this embodiment includes: a base 1 , an encapsulation seat 2 , and a detonation transfer sequence 3 . In this embodiment, the base 1 is machined from a whole piece of stainless steel substrate, including: a threaded hole 101, a first cylindrical cavity 102, a second cylindrical cavity 103, a square groove 104 of the base and a base Square boss 105. In this embodiment, the package seat 2 is machined from a whole piece of stainless steel base material, and includes: a package square boss 201 , a package square groove 202 , a sealing sheet 203 and a third cylindrical cavity 204 . The detonation transfer sequence 3 in this embodiment includes: a primary charge 301 , a fly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com