A kind of preparation method of hmx explosive with snow flake structure

A sheet-like structure and explosive technology, which is applied in the direction of nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, etc., can solve the problems of high cost, unenvironmental preparation process, complicated technological process, etc., and achieves low cost and preparation process. The effect of environmental protection and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

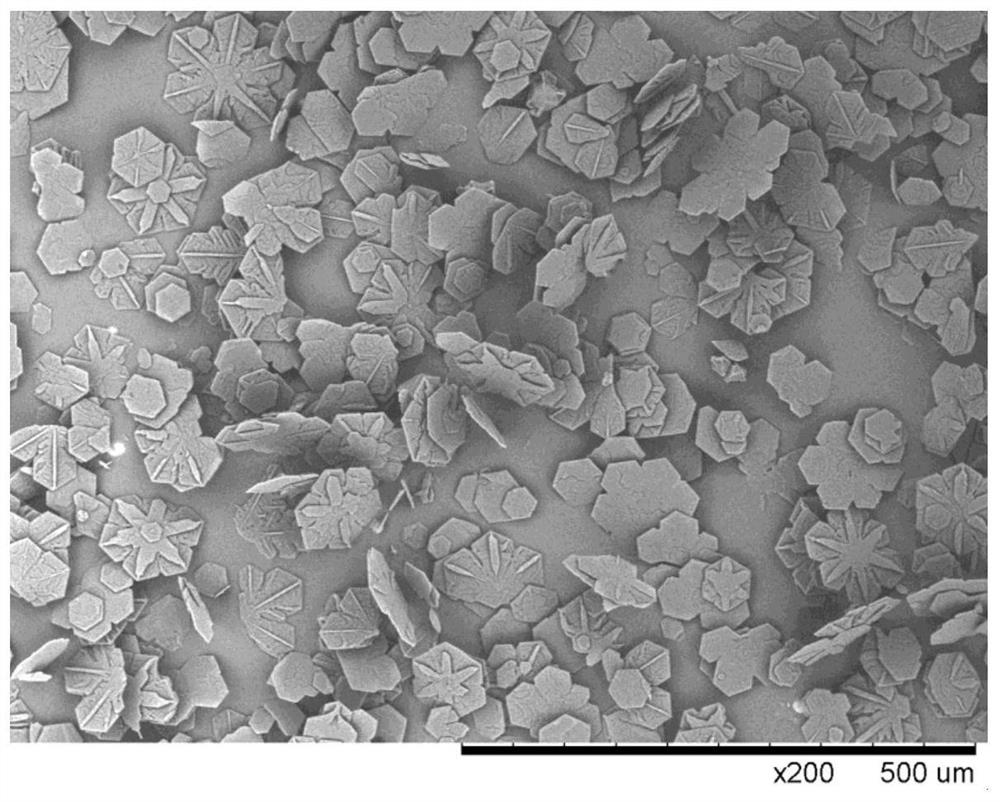

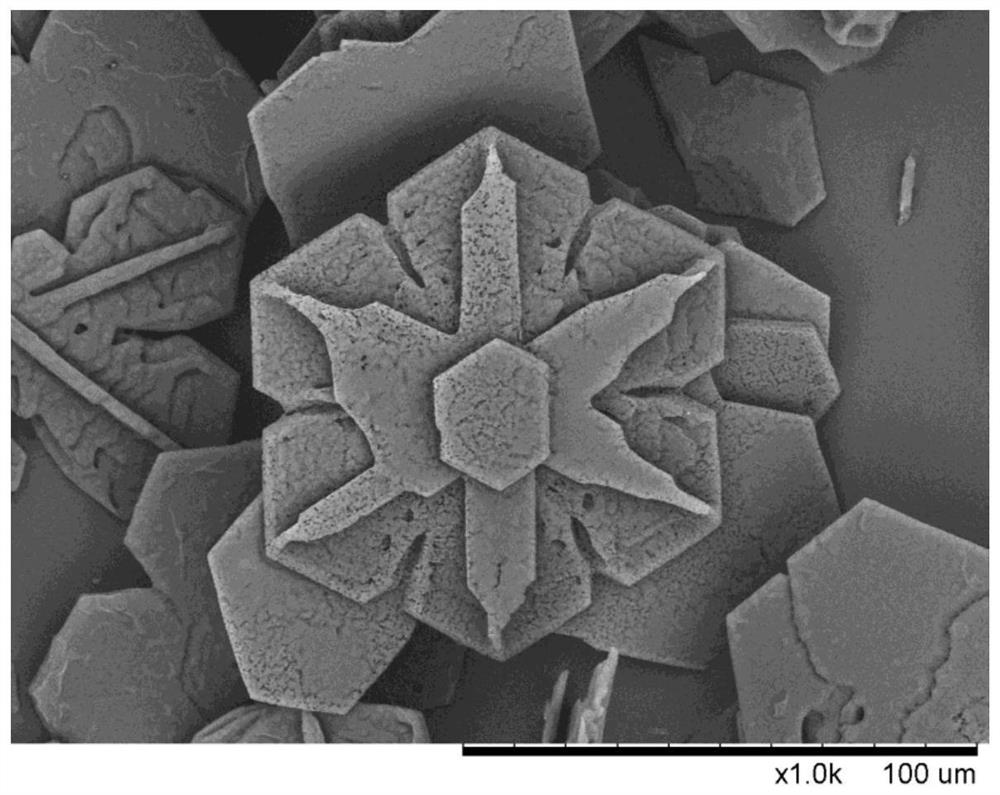

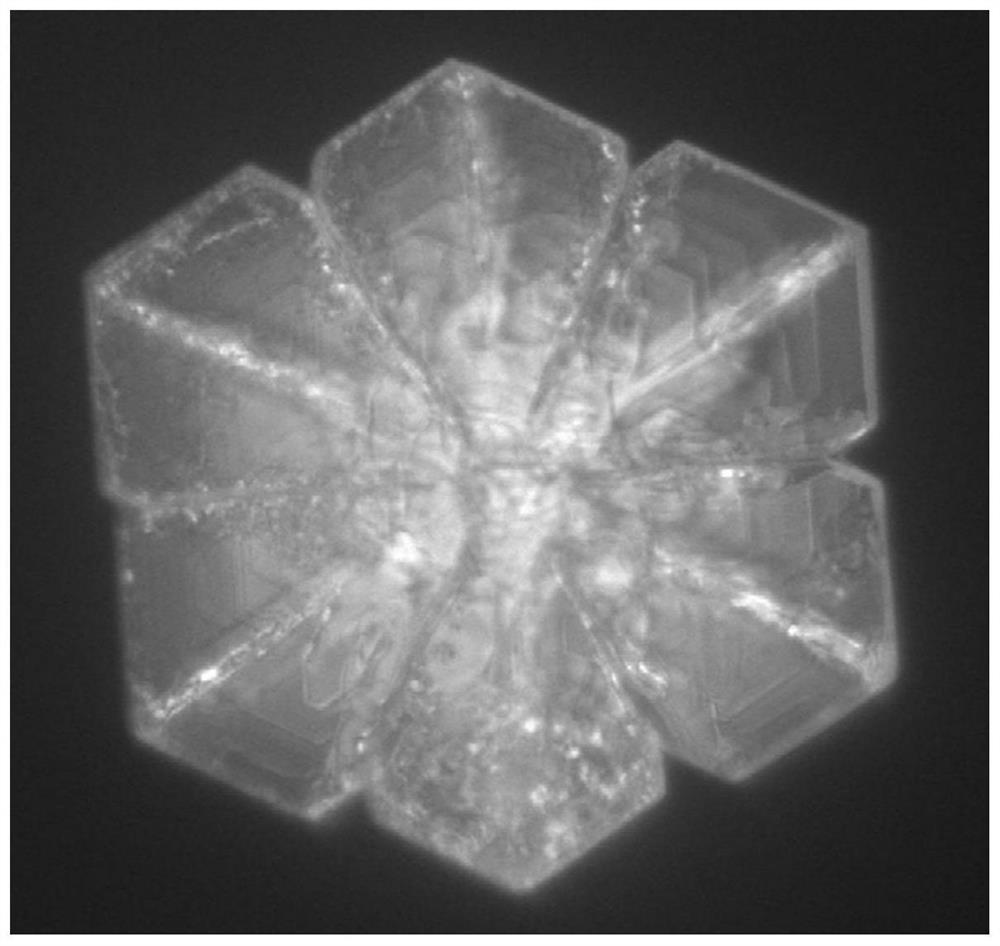

[0027] At room temperature, weigh 2.5g of HMX crystals, add them to 47.5g of N,N-dimethylformamide, completely dissolve the HMX crystals by mechanical stirring, and obtain a clear and transparent HMX solution with a mass concentration of 5%. . Use a syringe with a pore size of 0.4mm to draw 20g of the dissolved HMX solution, and inject it into 40g of absolute ethanol under the stirring condition of 200r / min, and the injection speed is 1mL / s. After maintaining stirring for 2 minutes, the material was filtered, washed with deionized water, and dried to obtain HMX explosive with a snow flake structure. figure 1 with figure 2 Respectively according to the 200 times and 1000 times scanning electron microscope pictures of the HMX explosive of the snow flake structure obtained according to the present embodiment, image 3 An optical microscope picture. The particle size of the explosive sheet is about 100 μm, the thickness is about 2 μm, and the product purity is 99.3%.

Embodiment 2

[0029] At room temperature, 2.5 g of HMX crystals were weighed, added to 22.5 g of γ-butyrolactone, and the HMX crystals were completely dissolved by mechanical stirring to obtain a clear and transparent HMX solution with a mass concentration of 10%. Use a syringe with a pore size of 1.2mm to draw 20g of the dissolved HMX solution, and inject it into 20g of methanol under the condition of 300r / min, and the injection speed is 2mL / s. After maintaining stirring for 5 minutes, the material was filtered, washed with deionized water, and dried to obtain HMX explosive with a snow flake structure. Figure 4 It is the 1000 times scanning electron microscope picture of the HMX explosive of the snow flake structure obtained according to the present embodiment, Figure 5 An optical microscope picture. The particle size of the explosive sheet is about 120 μm, the thickness is about 1.5 μm, and the product purity is 99.5%.

Embodiment 3

[0031] At room temperature, 2.5 g of HMX crystals were weighed, added to 247.5 g of dimethyl sulfoxide, and the HMX crystals were completely dissolved by mechanical stirring to obtain a clear and transparent HMX solution with a mass concentration of 1%. Use a syringe with a pore size of 1.0mm to draw 20g of the dissolved HMX solution, and inject it into 400g of isopropanol under the condition of 300r / min, and the injection speed is 5mL / s. After maintaining stirring for 15 minutes, the material was filtered, washed with deionized water, and dried to obtain HMX explosive with a snow flake structure. The particle size of the explosive sheet is about 150 μm, the thickness is about 2 μm, and the product purity is 99.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com