Fuse capable of improving grazing impact and self-destruction reliability

A technology of reliability and fuze, which is applied in the field of fuzes, can solve the problems of low firing rate at small drop angles of projectiles, hindering the movement of firing pins, and unreliable firing, etc., so as to improve the reliability of self-destruct action, improve the reliability of action, and improve the structure The effect of small changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

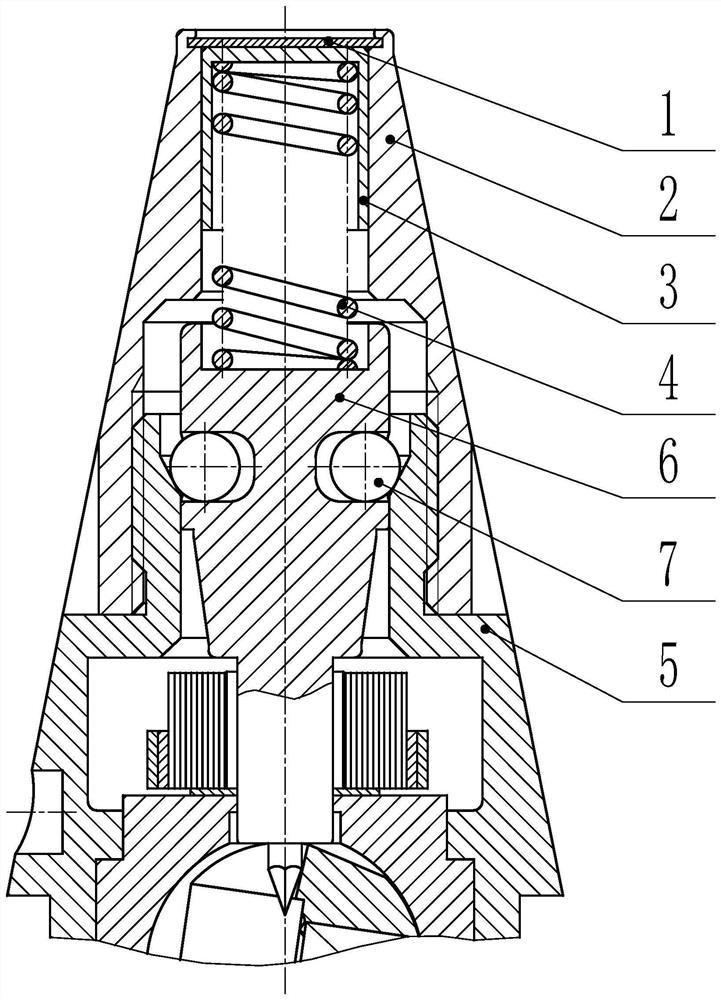

[0020] Such as figure 1 As shown, a fuze that improves the reliability of ground-wiping and self-destruction functions includes a moisture-proof sheet 1, an upper body 2, a support tube 3, a self-destruction spring 4, a body 5, a firing pin 6 and several centrifugal balls 7. The upper body 2 and the main body 5 are connected by threads, and the moisture-proof sheet 1, the support tube 3, the self-destruct spring 4, and the firing pin 6 are arranged coaxially in the chamber formed by the upper body 2 and the main body 5 from top to bottom.

[0021] The outer contour of the upper body 2 is frustum-shaped, and the inside is provided with three-step stepped holes from top to bottom along its central axis, which are the first-step holes, the second-step holes and the third-step holes, wherein the diameter of the first-step holes is larger than The diameter of the second-order hole, and the third-order hole is provided with internal threads. The moisture-proof sheet 1 is a circular...

Embodiment 2

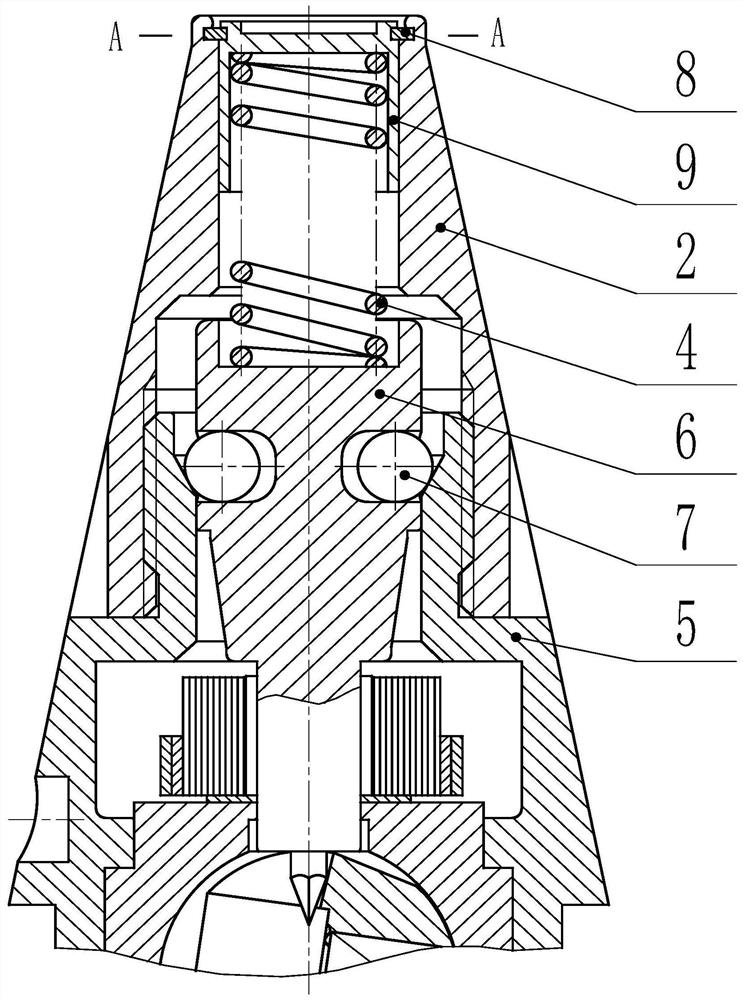

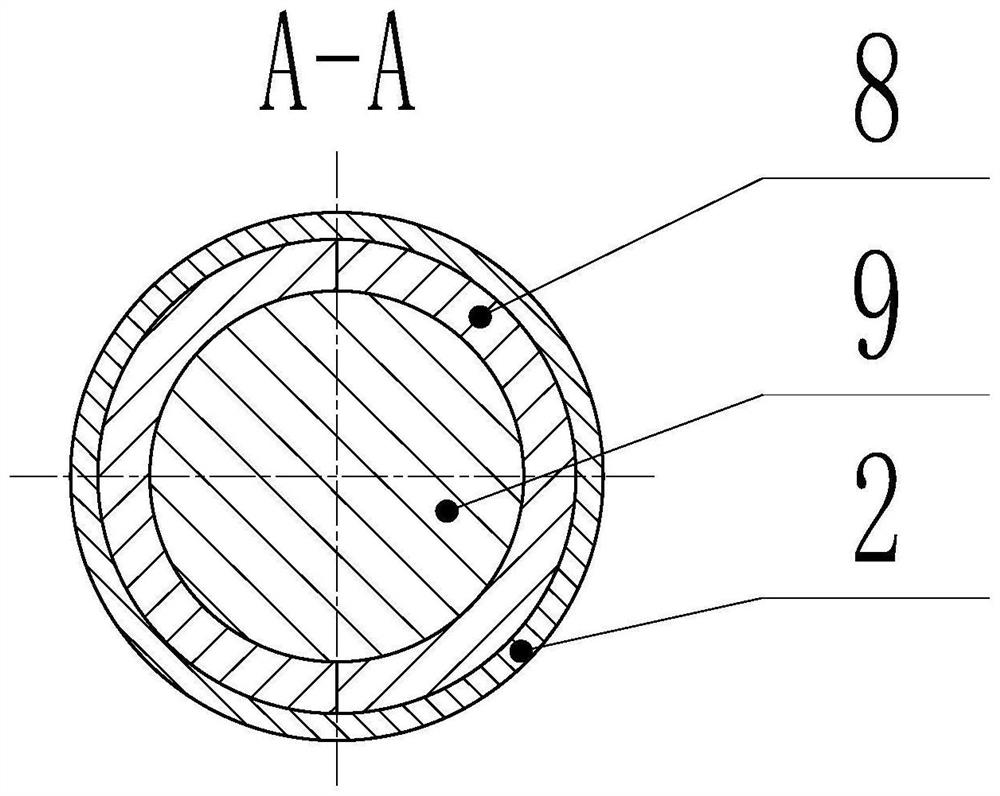

[0030] Such as figure 2As shown, a fuze that improves the reliability of ground wiping and self-destruction functions includes an upper body 2, a self-destruction spring 4, a body 5, a firing pin 6, several centrifugal balls 7, a shear cylinder 9 and two snap rings 8 etc. Wherein the states of the upper body 2, the self-destruct spring 4, the body 5, the firing pin 6 and the centrifugal ball 7 are exactly the same as those of the embodiment 1.

[0031] The outer contour of the shear cylinder 9 is composed of a coaxial combination of a first cylinder, a second cylinder and a third cylinder from top to bottom. Wherein the diameter of the second cylinder is smaller than the diameters of the first cylinder and the third cylinder, and the maximum value of the diameter of the first cylinder is smaller than the minimum value of the diameter of the third cylinder. The third cylinder and the second-stage hole on the body 5 are in a precision clearance fit. While providing guidance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com