Method for preparing slice type network resistor and slice type network resistor prepared by the same method

A technology of resistors and manufacturing methods, applied in the direction of resistors, non-adjustable metal resistors, impedance networks, etc., can solve problems such as product failure, difficulty in size and thickness, short circuit of terminal electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

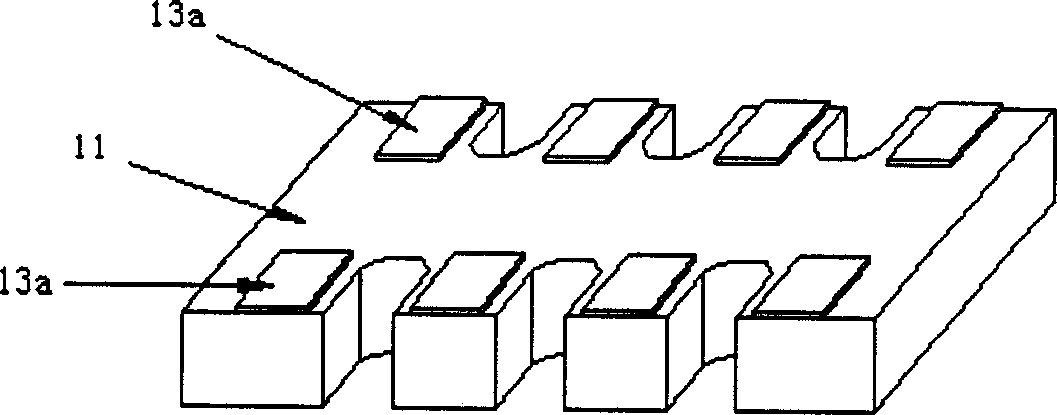

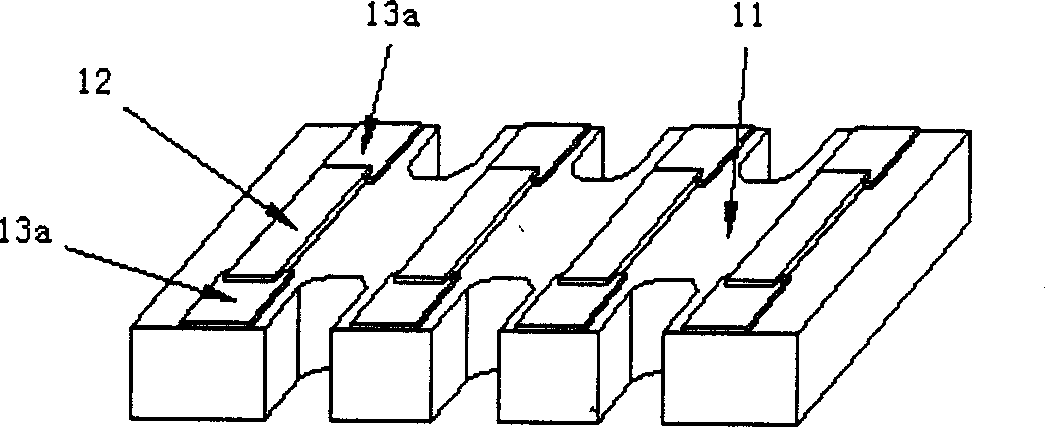

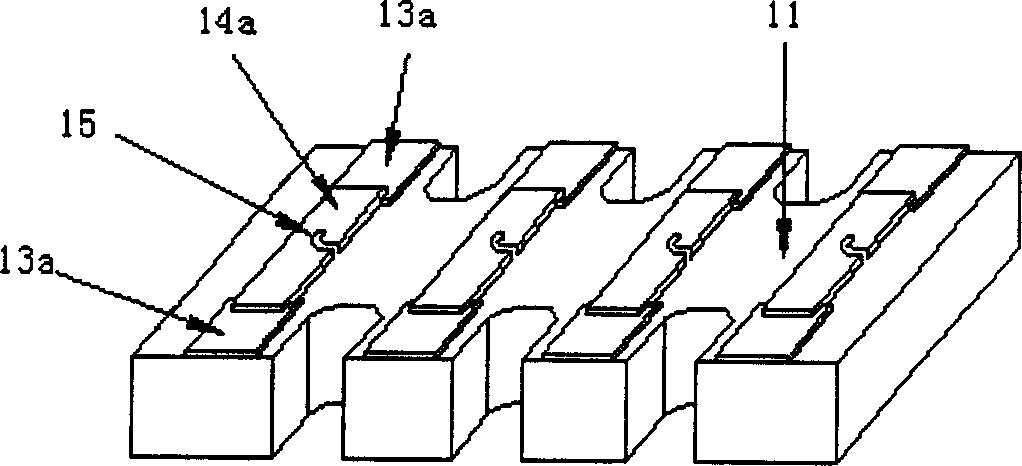

[0048] The present invention will be described in detail below with reference to the accompanying drawings; this embodiment takes a chip network resistor with four resistive layers as an example, but the present invention is not limited to a chip network resistor with four resistive layers.

[0049] according to Figure 6 and Figure 7 The chip network resistor shown includes: an insulating substrate 11 made of alumina or ceramic or glass insulating material, four pairs of separated front electrodes 13a located on the protruding parts of the insulating substrate 11, four pairs of front electrodes 13a connected to the front surface The electrodes 13a are connected to the resistive layer 12 with each other.

[0050] The resistive layer 12 is covered with a protective layer 14 . The protective layer 14 comprises an inner protective layer 14a of glass material directly overlying the resistive layer 12 and an outer protective layer 14b thereon. The resistance layer 12 and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com