Preparation method of titanium-based anode surface composite coating for electrolytic manganese dioxide

A technology of electrolytic manganese dioxide and surface compounding, which is applied to coatings, electrodes, electrolytic components, etc., can solve the problems of many cracks on the coating surface, increased anode resistance, and large porosity, so as to reduce energy consumption and electrolysis The effect of groove pressure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

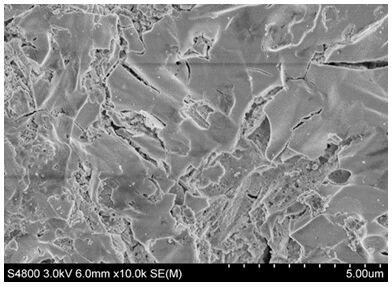

Image

Examples

Embodiment

[0013] (1) Select TA2 grade industrial pure titanium sheet as the base material, polish to remove the surface oxide film of the titanium sheet, then put it in a slightly boiling NaOH solution with a concentration of 10% by mass for 10 minutes, then take out the titanium sheet and rinse with distilled water Clean it, then put it in a 20% mass percentage of slightly boiling oxalic acid solution for acid etching for 2 hours, and finally rinse it with distilled water to obtain a gray hemp-like titanium sheet, which is immersed in absolute ethanol for use.

[0014] (2) Fully mix the 0.3 mol / L tin tetrachloride ethanol solution and the 0.3 mol / L manganese nitrate ethanol solution according to the molar ratio Sn:Mn=6:4 to prepare a coating mixture.

[0015] (3) Use the coating mixture prepared in step (2) to evenly brush the titanium flakes obtained in step (1), put the coated titanium flakes in an oven at 80°C for 15 minutes, and then dry The dried titanium flakes are calcined on an elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com