Double-metal bush

A bimetal and bushing technology, applied in the bushing field, can solve the problems of high input cost and complex production process, and achieve the effect of reducing the number of sintering times and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be further described below with reference to the examples.

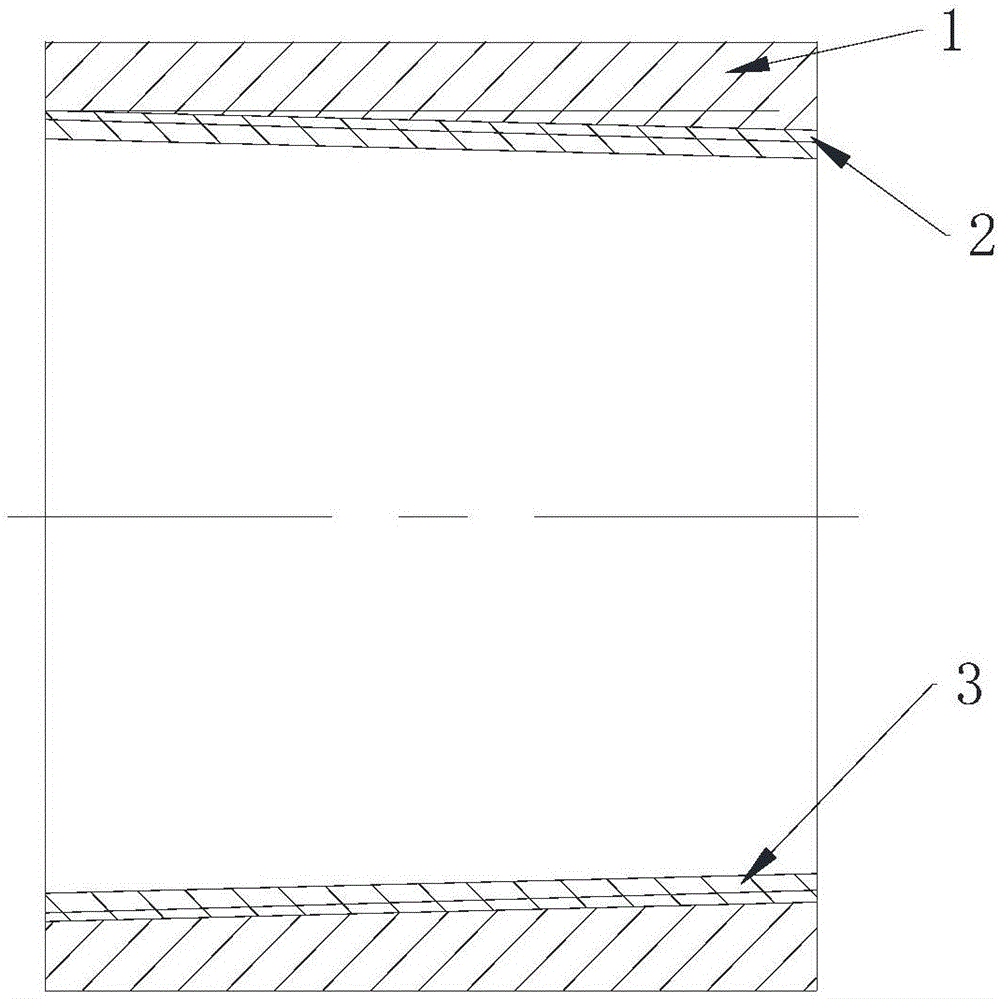

[0014] like figure 1 As shown, a bimetal bushing includes a steel sleeve body made of stainless steel, the inner surface of the steel sleeve body is provided with an electroplating layer, the surface of the electroplating layer is sintered with a wear-resistant layer, and the The angle between the inner surface of the steel sleeve body and the outer surface of the steel sleeve body is 1 degree 30 minutes ± 5 minutes, wherein the electroplating layer is an electroplated copper layer and its thickness is 0.5mm, and the material of the wear-resistant layer is It is CuPb30 and powder, and its thickness is 2.5±0.04mm.

[0015] For those skilled in the art, the technical solutions described in the foregoing embodiments can still be modified, or some technical features thereof can be equivalently replaced, and any modifications made within the spirit and princip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com