Machine vision based turn plate angle high-precision online measurement method

A measurement method and machine vision technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems that the measurement process is easily affected by human errors, the traditional methods cannot well meet the automation of industrial production, and the measurement efficiency is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

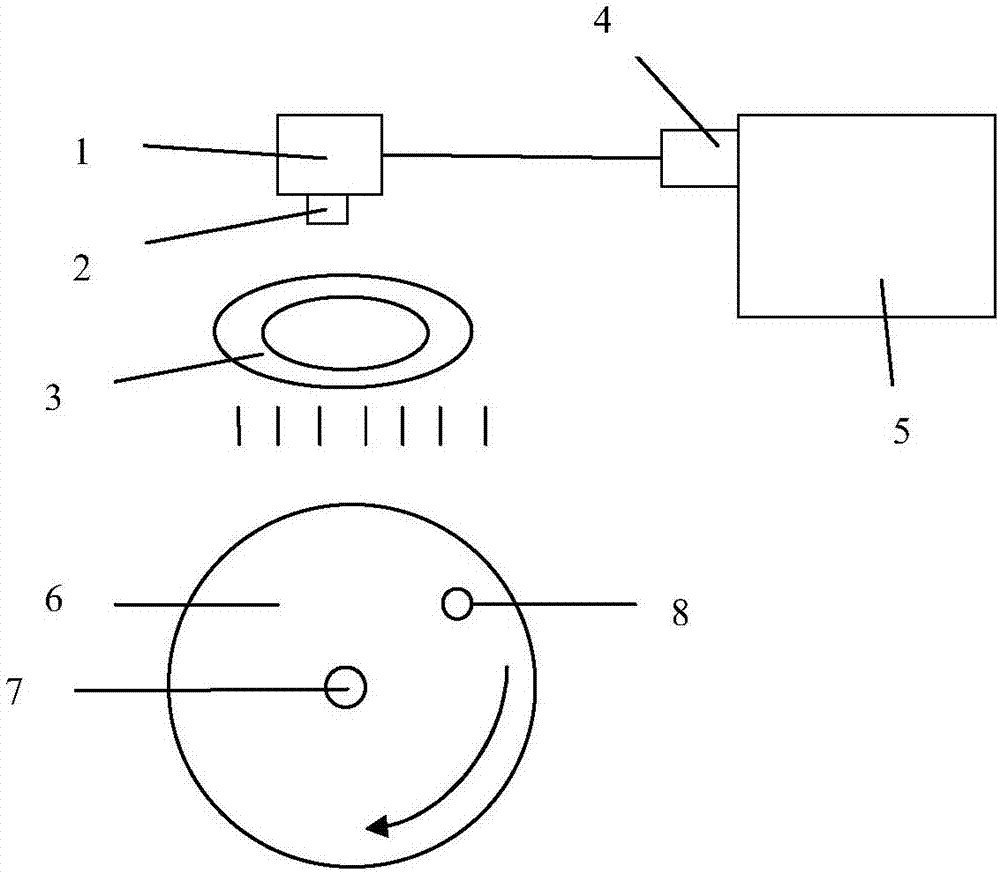

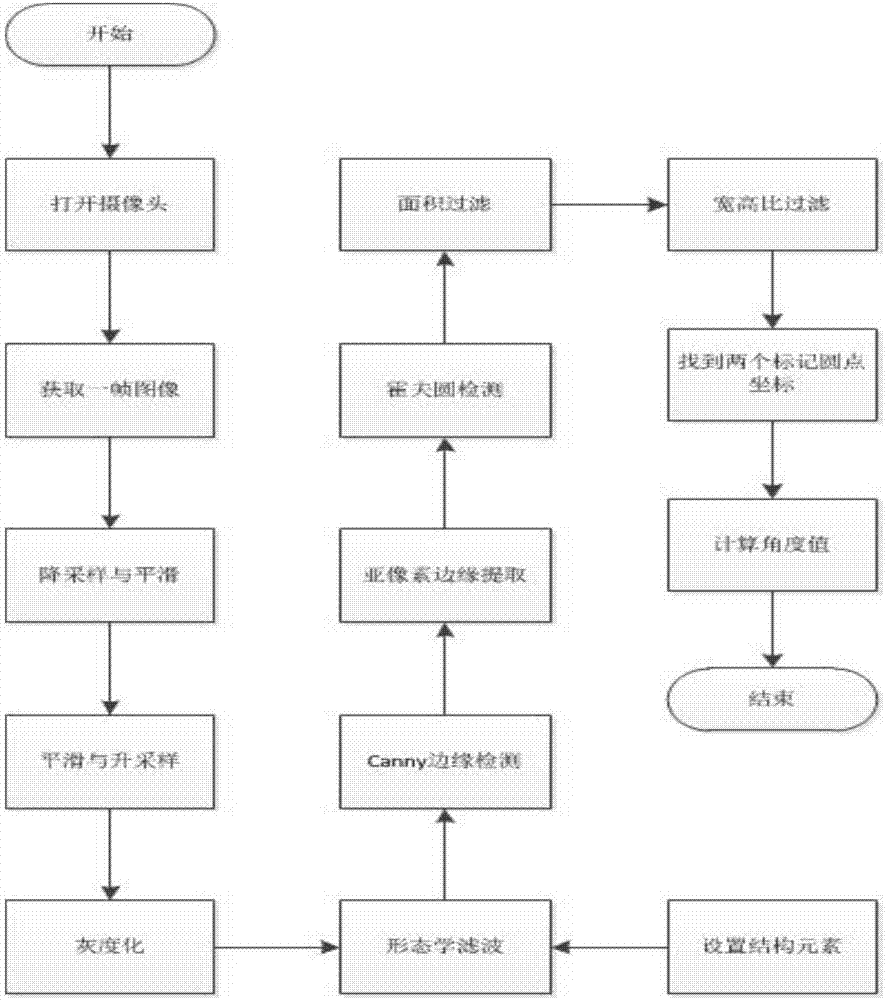

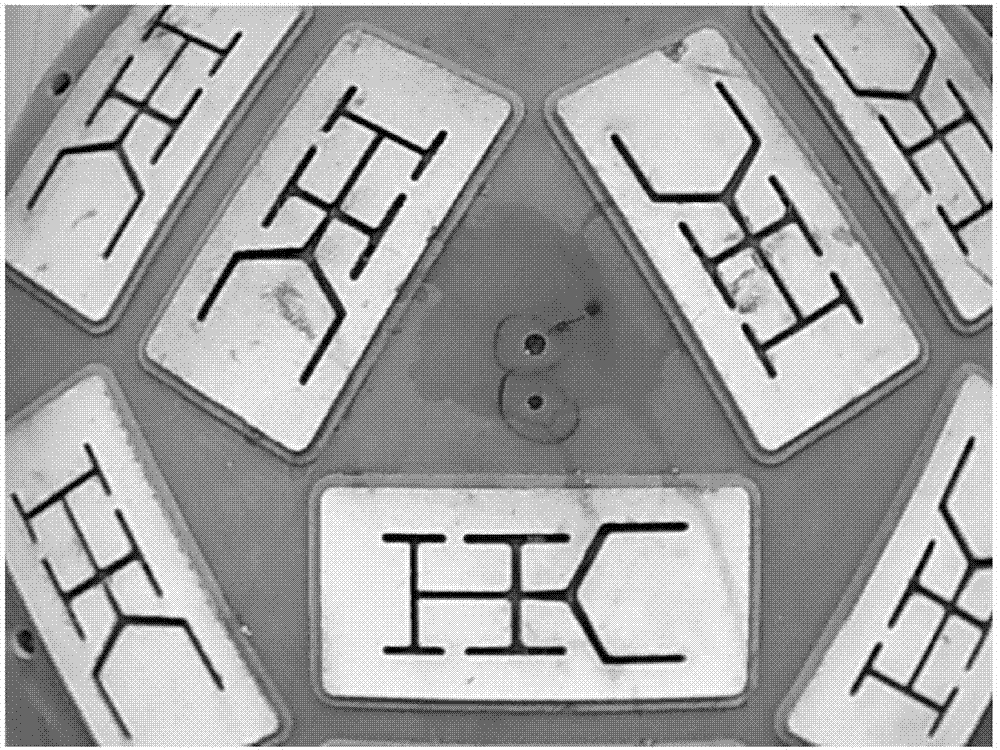

[0072] as attached figure 1 As shown, a machine vision-based high-precision online measurement system for turntable angle. In order to complete the angle measurement function, the hardware used in the present invention includes a 3,000,000-pixel high-definition CMOS industrial camera, a 6mm fixed-focus lens, an LED backlight light source, a computer, and a turntable to be measured (see attached image 3 ), two reference circles are marked on the turntable by punching holes, one of which is the circle where the center of the turntable is located, with a diameter of 8mm, and its center is point P1, and the other reference circle is 5mm in diameter, and its center is marked as P2. The LED ring light source can help improve the image quality collected by the industrial camera. The industrial camera collects the image of the turntable to be tested...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com