Stator for linear compressor

一种线性压缩机、定子的技术,应用在压缩机、制冷机、机械设备等方向,能够解决直线电机整体尺寸增加、线性压缩机尺寸增加、性能可靠性恶化等问题,达到防止组装变形、减小总尺寸、削减生产成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

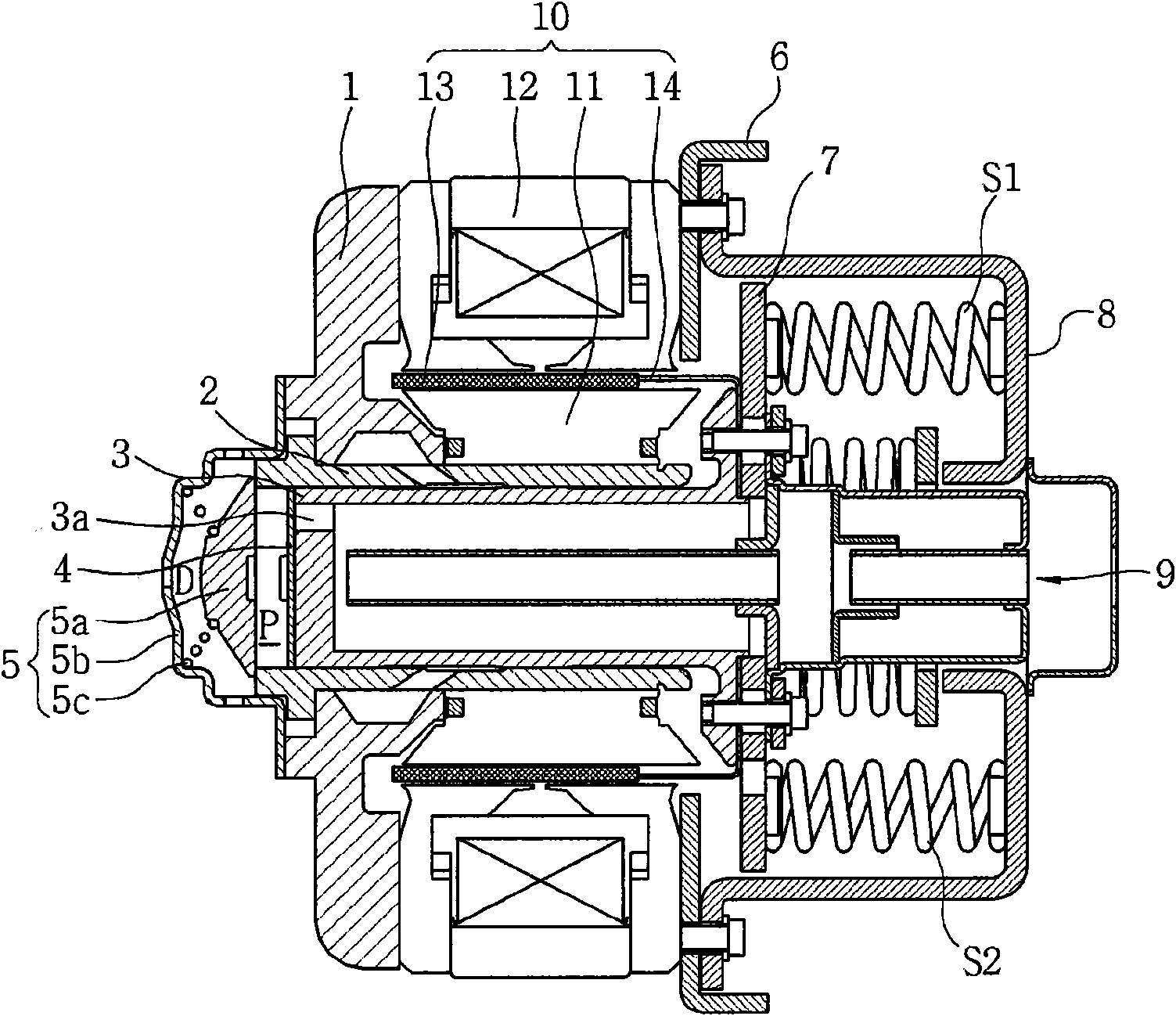

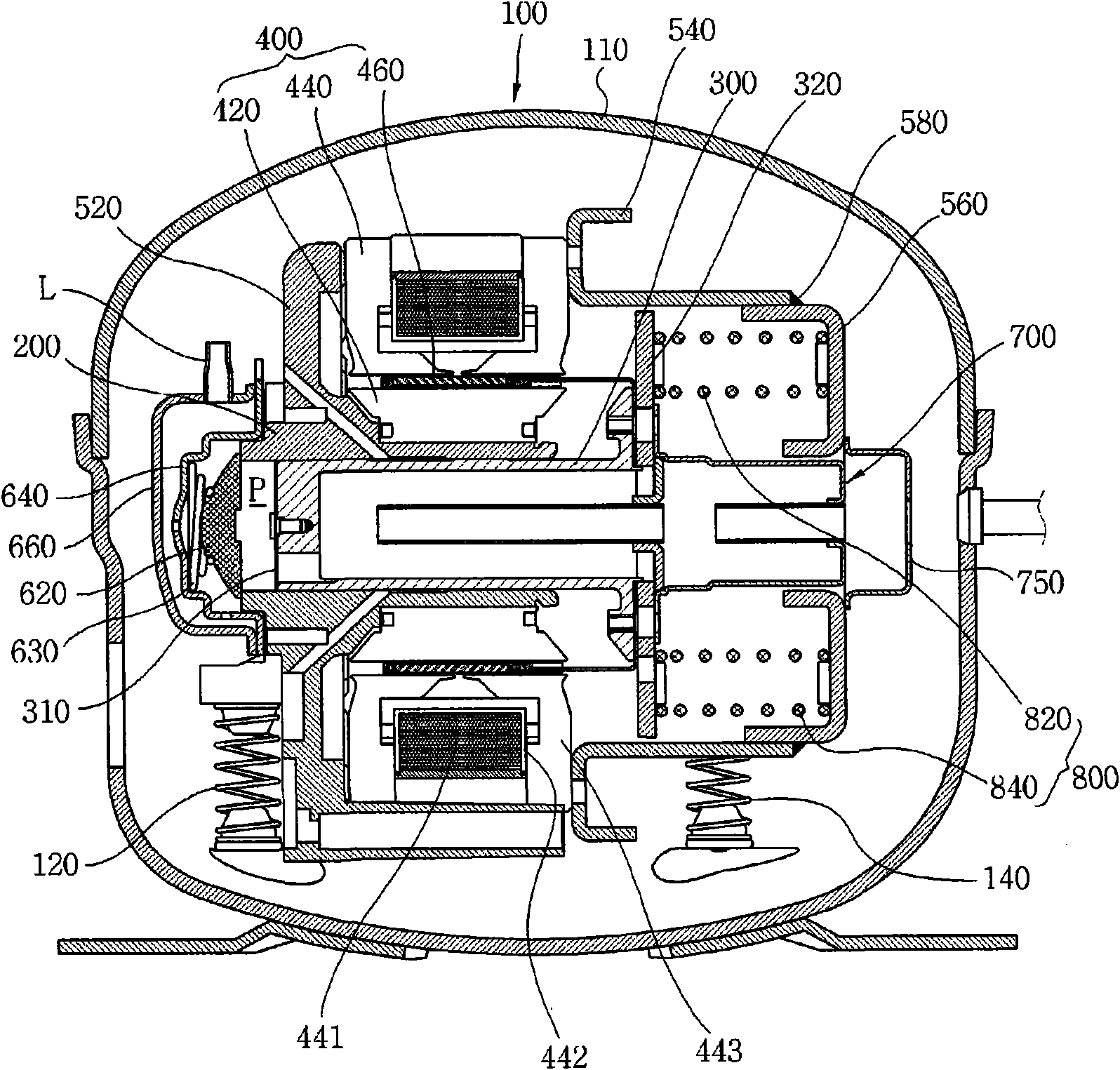

[0039] image 3 An example of a linear compressor according to the invention is shown. In one example, the linear compressor 100 of the present invention includes a cylinder 200, a piston 300, and a linear motor 400 having an inner stator 420, an outer stator 440, and a permanent magnet 460 within a casing 110 serving as a sealed container. . When the permanent magnet 460 starts to linearly reciprocate by the electromagnetic force of the interaction between the inner stator 420 and the outer stator 440 , the piston 300 operably coupled to the permanent magnet 460 also performs linear reciprocation.

[0040]The inner stator 420 is fixed to the outer contour of the cylinder 200 , and the outer stator 440 is axially fixed by the frame 520 and the motor cover 540 . The frame 520 and the motor cover 540 are coupled by fasteners such as bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com