Positioning jig used for press fitting of core shaft of cast-aluminum rotor

A technology of casting aluminum rotors and positioning fixtures, which is applied in the manufacture of stator/rotor bodies, etc., can solve problems such as not being fully utilized, and achieve the effects of avoiding rotor temperature drop, saving energy, and avoiding assembly deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

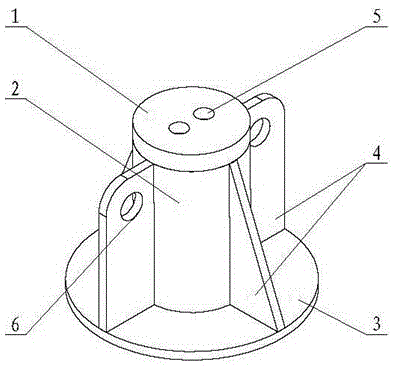

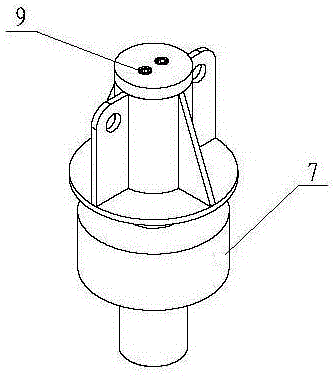

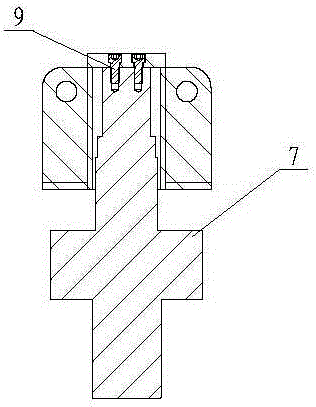

[0016] Such as figure 1 , 2 A positioning fixture for press-fitting the mandrel of a cast aluminum rotor is shown, including a positioning plate 3, a connecting plate 1, and a sleeve 2. The upper end of the sleeve is fixed with a connecting plate by welding, and the lower end is welded The positioning plate is fixed by welding, and the middle part of the positioning plate 3 is provided with an opening communicating with the casing 2. The diameter of the positioning plate is larger than the diameter of the shaft hole of the cast aluminum rotor 8, and the connecting plate is provided with a screw counterbore 5 , which is connected with the mandrel 7 by screws 9, four auxiliary plates 4 are uniformly arranged on the outside of the casing, and a lifting hole 6 is also prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com