Crank-link mechanism for refrigeration compressor

A technology of refrigeration compressor and connecting rod mechanism, which is applied in the direction of machine/engine, mechanical equipment, liquid variable capacity type machinery, etc., can solve the problems of high manufacturing cost and complex structure, and achieve low manufacturing cost, simple and reliable structure, and avoid Effects of machining and assembly deformations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

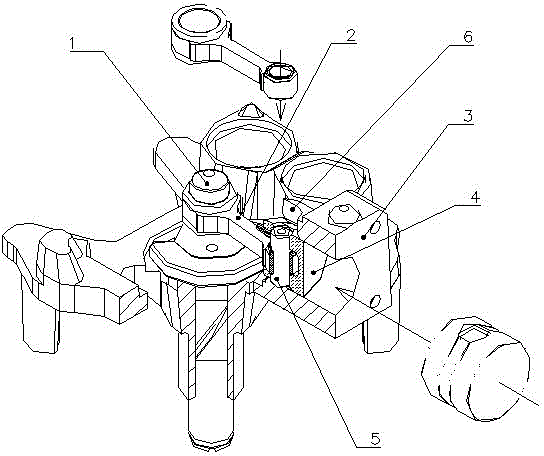

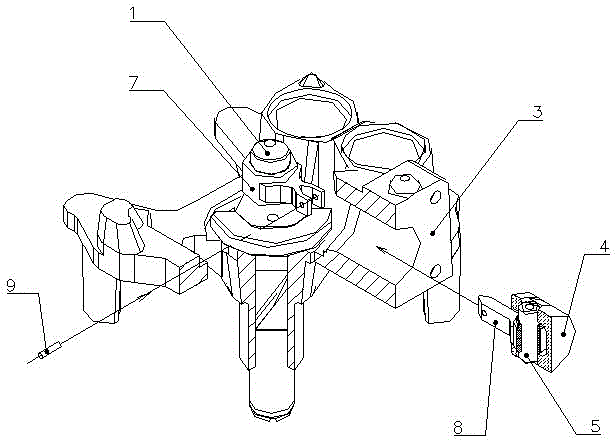

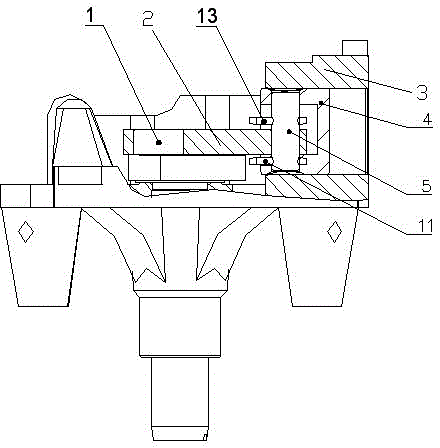

[0015] Such as image 3 As shown, the crank-connecting rod mechanism for refrigeration compressors of the present invention includes crankshaft 1, integral connecting rod 2, crankcase 3, piston 4, piston pin 5, positioning pin 11 and connecting rod retaining pin 13, the thickness of integral connecting rod 2 Less than the height of the inner cavity of the piston 4, the left end of the integral connecting rod 2 is sleeved on the upper end of the crankshaft, the right end of the integral connecting rod 2 is placed in the inner cavity of the piston 4, and the piston pin 5 is arranged on the right end of the integral connecting rod 2 and on the piston 4. In the provided opening, the positioning pin 11 is located at the lower end of the piston 4 and the piston 4 and the piston pin 5 are positioned and connected, and the connecting rod stop pin 13 is inserted into the pin hole of the piston pin 5 located above the right end of the integral connecting rod 2 to limit The range of moti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com