Preparation method for spherical cobalt oxyhydroxide

A cobalt oxyhydroxide and spherical technology, which is applied in the field of preparation of spherical cobalt oxyhydroxide, can solve problems such as complicated process, modification and doping, and equipment addition, and achieve the effects of high density, good sphericity, and smooth design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

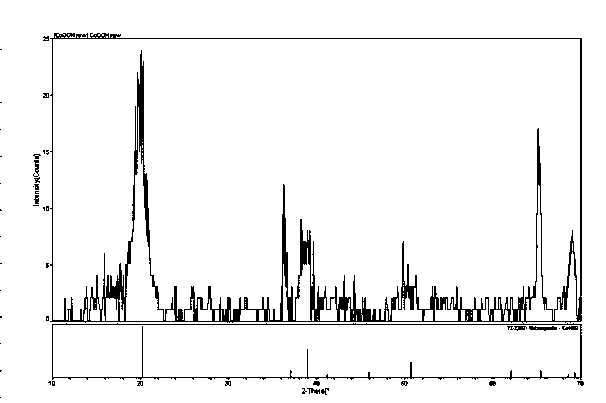

Image

Examples

Embodiment 1

[0029] A kind of preparation method of spherical cobalt oxyhydroxide, by CoSO 4 : MgCl 2 :Al 2 (SO 4- ) 3 The molar ratio is 0.97:0.02:0.005, prepare 1.5mol / L mixed salt solution; mix the mixed salt solution with 3mol / L KOH and NaOH (molar ratio 2:1) mixed solution, 4mol / L H 2 o -2 The aqueous solution was added to the reaction kettle in parallel at a certain flow rate, and stirred and reacted at 50°C and pH=9.2; then centrifuged, washed with pure water, and dried to obtain Co 0.97 Mg 0.02 Al 0.01 OOH. Measured D 50 =15.9 um, AD=1.97 g / cm 3 .

Embodiment 2

[0031] A kind of preparation method of spherical cobalt oxyhydroxide, by CoSO 4 : Fe 2 (SO 4 ) 3 The molar ratio is 0.95:0.025, prepare 1mol / L mixed salt solution; mix the mixed salt solution with 2mol / L NH 4 Add OH solution and high-purity oxygen into the reactor at a certain flow rate, stir and react at 40°C and pH=11.5; then filter, wash with pure water, and dry to obtain Co 0.95 Fe 0.05 OOH, measured D 50 =21.2um, AD=2.16g / cm 3 .

Embodiment 3

[0033] A kind of preparation method of spherical cobalt oxyhydroxide, by Co (NO 3 )- 2 : Mn (NO 3 ) 2 The molar ratio is 0.98:0.02, prepare 2mol / L mixed salt solution; add the mixed salt solution, 6mol / L NaOH solution, and compressed air into the reactor at a certain flow rate, and stir at 65°C and pH=8.3 reaction; then centrifuged, washed with pure water, and dried to obtain Co 0.98 mn 0.02 OOH, measured D 50 =6.7um, AD=1.38g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com