Denitrification catalyst capable of oxidizing simple substance mercury

A denitration catalyst and single oxidation technology, which is applied in the field of denitration and can solve problems such as high technology transfer fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

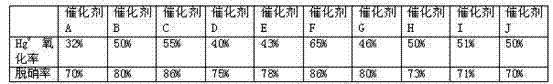

Image

Examples

Embodiment 1

[0018] Honeycomb type denitrification catalyst A (referred to as catalyst A) with the ability to oxidize elemental mercury was obtained by mixing, extruding, drying, and calcining according to conventional methods. Its composition was 0.3% by mass of vanadium pentoxide, Tungsten trioxide and 0.3% manganese oxide, the rest is titanium dioxide.

Embodiment 2

[0020] Honeycomb-type denitrification catalyst B (referred to as catalyst B) with the ability to oxidize elemental mercury was prepared by mixing, extruding, drying, and calcining according to conventional methods. Its composition was 0.8% by mass of vanadium pentoxide, Tungsten trioxide and 1% chromium oxide, the rest is titanium dioxide.

Embodiment 3

[0022] Honeycomb-type denitrification catalyst C (referred to as catalyst C) with the ability to oxidize elemental mercury was obtained by mixing, extruding, drying, and calcining according to conventional methods. Its composition is 1.2% by mass percentage of vanadium pentoxide, Tungsten trioxide and 0.5% copper oxide, the rest is titanium dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com