Quickly chargeable lithium ion battery and its making method

A lithium-ion battery, fast charging technology, applied in battery electrodes, secondary batteries, sustainable manufacturing/processing, etc. The effect of discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

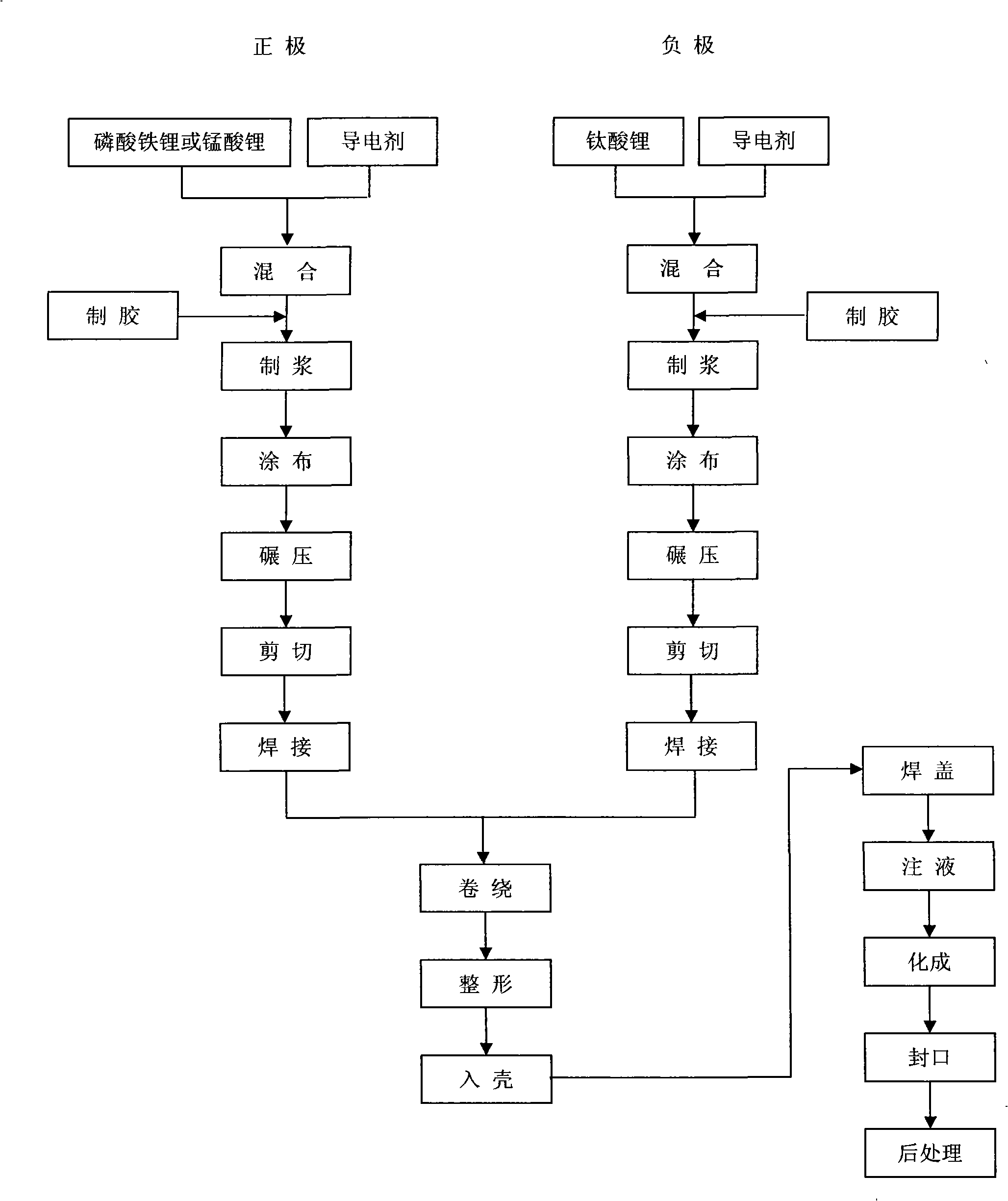

[0031] The preparation method of the rapidly chargeable lithium ion battery of the present invention comprises the following steps:

[0032] 1) Dissolve 70%-98% by weight of submicron lithium titanate, 1%-15% by weight of conductive agent and 1%-10% by weight of binder in a solvent to make a negative electrode slurry, with a thickness of 10 μm The copper foil is the current collector, and the negative electrode slurry is applied to the copper foil and dried to make a pole piece, and then the pole piece is rolled and sheared to make a negative electrode;

[0033] 2) Dissolve 70%-98% by weight of lithium manganate, 1%-10% conductive agent and 1%-10% binder in a solvent to make positive electrode slurry, and use 15μm thick aluminum foil as current collector , the positive electrode slurry is coated on the aluminum foil and dried to make a pole piece, and then the pole piece is rolled and sheared to make a negative electrode;

[0034] 3) The special polypropylene resin separator ...

Embodiment 1

[0042] By mass percentage (the same below), 85% of the positive active material lithium manganate, 5% of the super conductive carbon black, 10% of the binder polyvinylidene fluoride, with N-methylpyrrolidone as the solvent, to prepare a paste Using 15 μm thick aluminum foil as the current collector, the paste was applied to the aluminum foil and dried.

[0043] The pole piece is rolled, sheared and welded to make a positive pole piece, and the electrode density is 2.9g / cm 3 .

[0044] 80% of the anode material submicron lithium titanate (D 50 is 0.185μm, and the specific surface area is 5.2m 2 / g) mixed with 8% super conductive carbon black and 12% binder polyvinylidene fluoride, using N-methylpyrrolidone as a solvent to make a paste, and using a 10 μm thick copper foil as a current collector, the paste was coated onto copper foil and dry.

[0045] The pole piece is rolled, sheared and welded to make a negative pole piece, and the electrode density is 3.8g / cm 3 .

[0046...

Embodiment 2

[0052] Different from Example 1, the proportions of the positive electrode material lithium manganate, superconducting carbon black and the binder are respectively: 90%, 3% and 7%; the negative electrode material in the negative electrode is submicron lithium titanate. The proportions of , super conductive carbon black and binder are: 87%, 5% and 8% respectively.

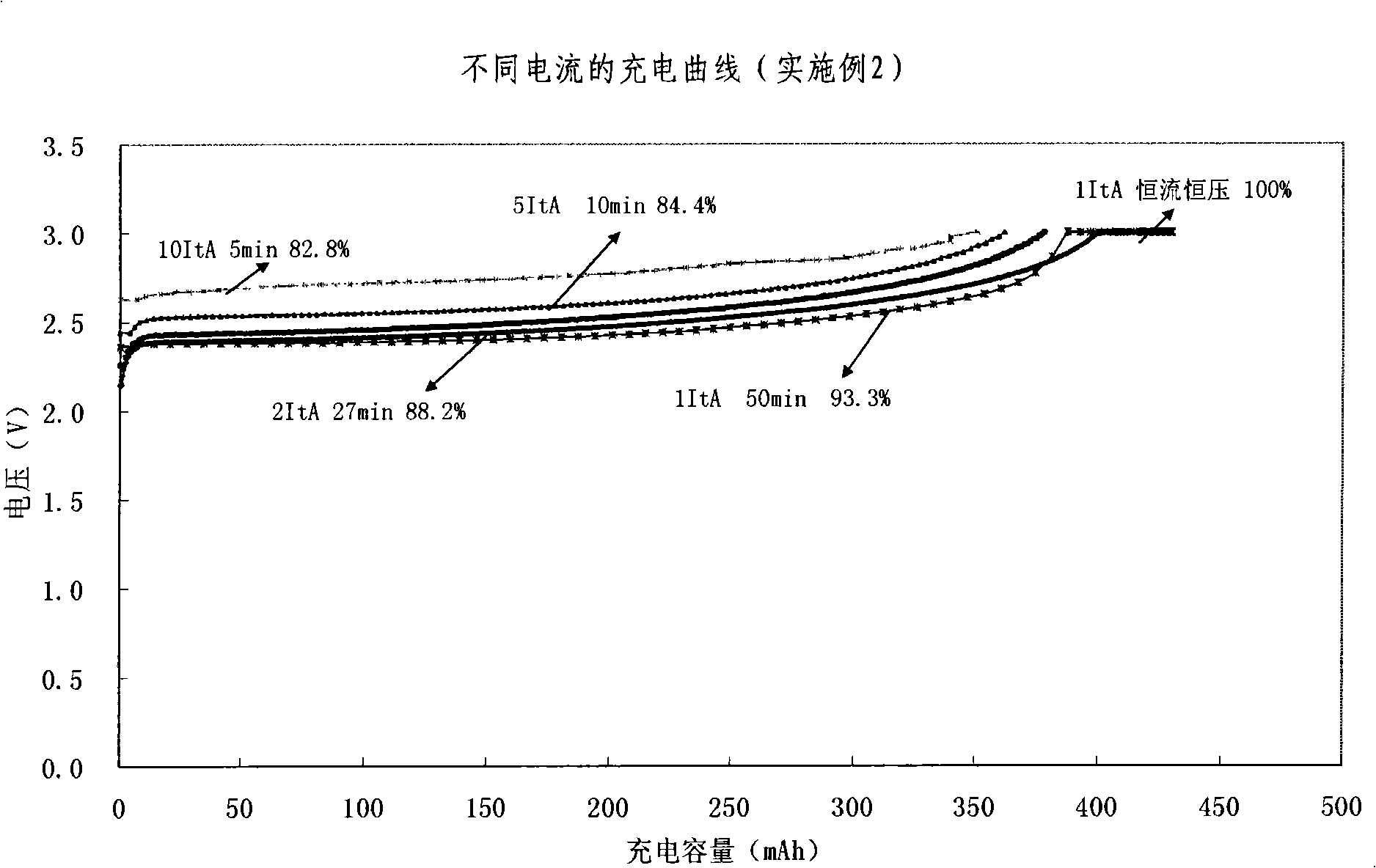

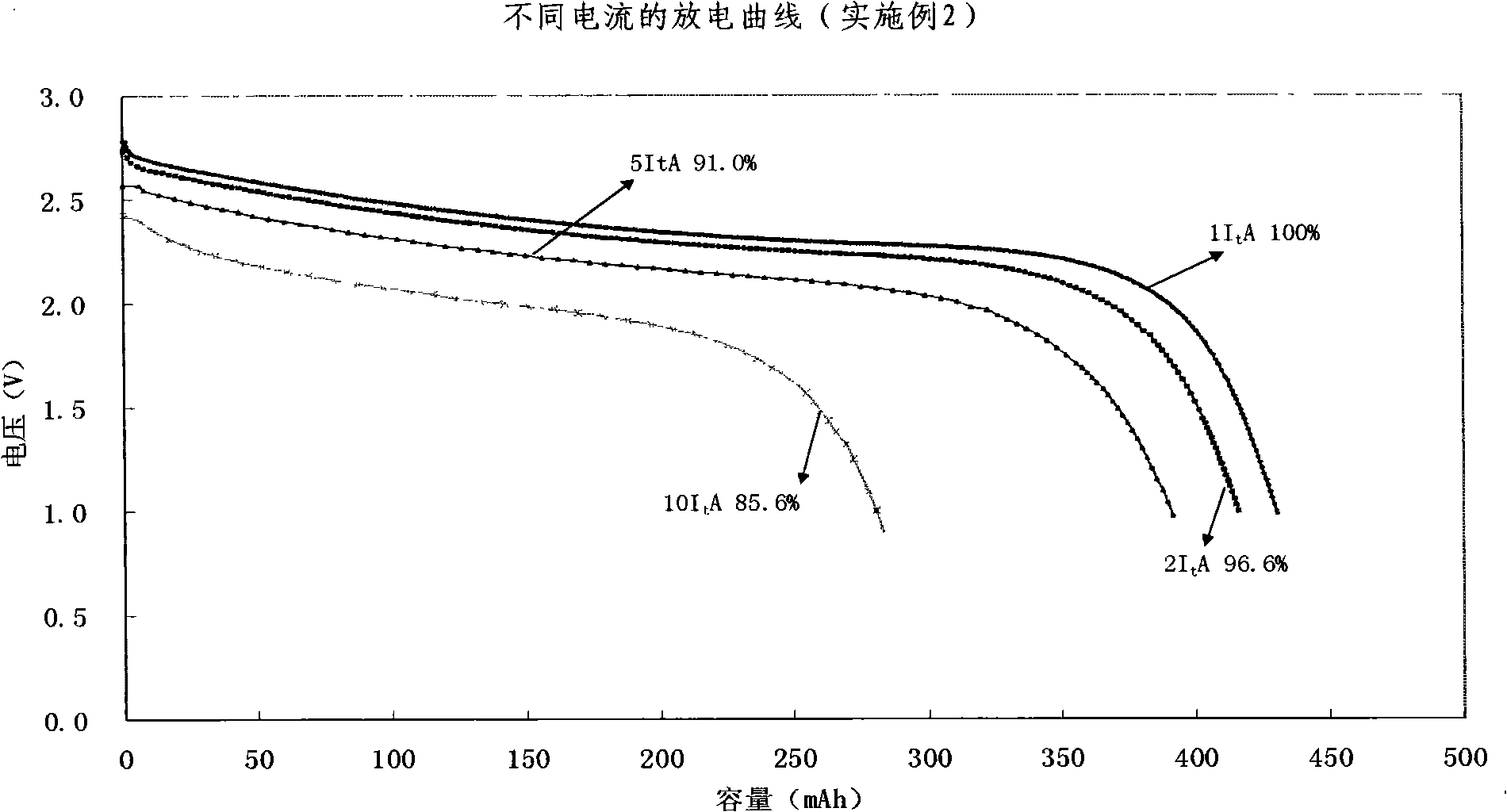

[0053] The square lithium-ion battery prepared as ICP053048 is charged with a current of 10ItA and can be charged to 82.8% in 5 minutes.

[0054] The charge and discharge curves and cycle curves of the fabricated batteries at different currents are shown in Figure 2 to Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Coating amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com