Metal sulfide/carbon composite material, preparation method and application thereof in battery negative electrode material

A technology of metal sulfide and carbon composite materials, applied in battery electrodes, active material electrodes, nanotechnology for materials and surface science, etc., can solve the problems of not being able to take into account low cost at the same time, achieve excellent structural stability, improve Cycle life, simple and unique effect of preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

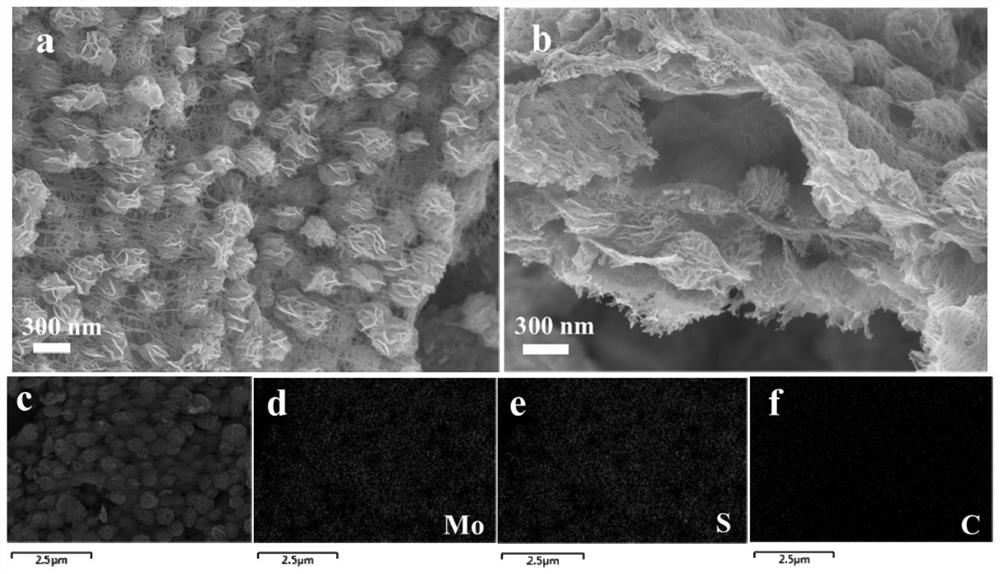

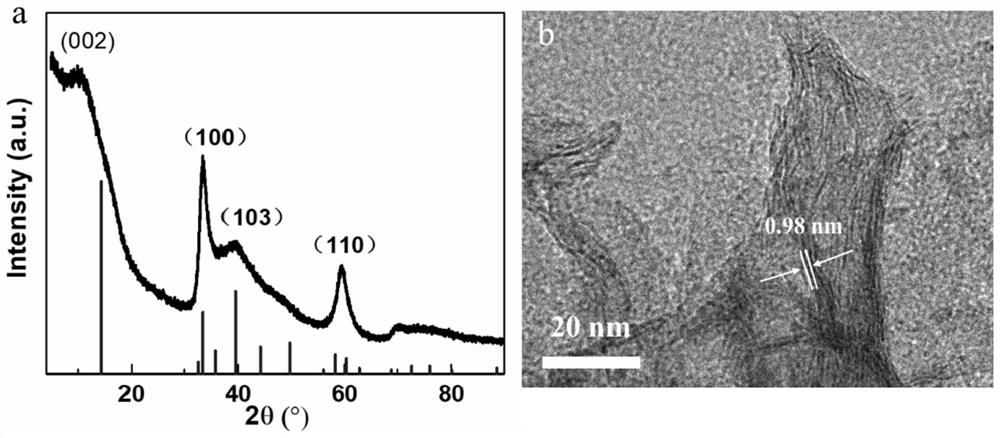

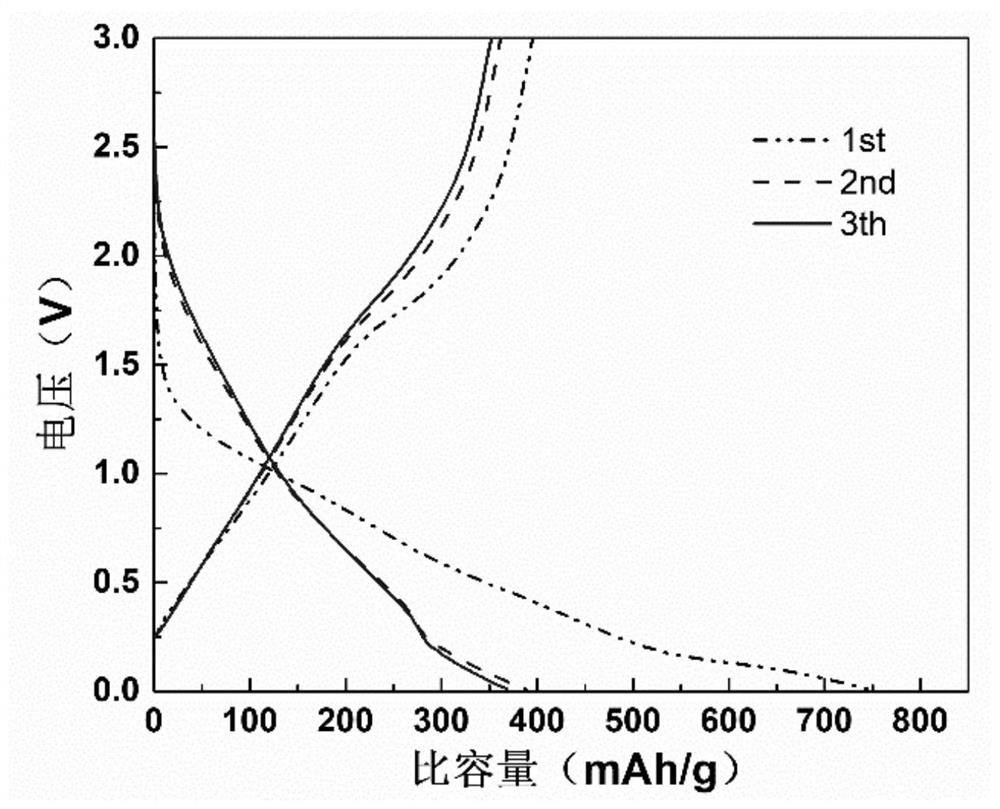

[0039] A kind of preparation method of molybdenum disulfide / carbon composite material, comprises steps as follows:

[0040] (1) Pretreatment of bagasse: crush 5 g of bagasse raw material, add 250 mL of sulfuric acid with a concentration of 1 mol / L to wash away impurities, heat at 80°C for 2 hours, wash with water, filter, and then add 250 mL of sulfuric acid with a concentration of In 10wt% sodium hydroxide solution, mix evenly and then heat, the heating temperature is 90°C, and the heating time is 3h, then wash with water, wash with alcohol, filter and dry to obtain the bagasse precursor.

[0041] (2) Take 1 g of the bagasse precursor prepared in step (1) and add it to 60 mL of water to disperse, add 2 mmol of sodium molybdate and 8 mmol of thiourea, adjust the pH to 7, stir and mix well, then carry out hydrothermal reaction, and the reaction temperature is 200 °C, the reaction time is 24h, the product is washed with water, washed with alcohol, filtered and dried.

[0042] (...

Embodiment 2

[0053] A kind of preparation method of molybdenum disulfide / carbon composite material, comprises steps as follows:

[0054] (1) Pretreatment of bagasse: crush 5 g of bagasse raw material, add 250 mL of sulfuric acid with a concentration of 1 mol / L to wash away impurities, heat at 80°C for 2 hours, wash with water, filter, and then add 250 mL of sulfuric acid with a concentration of In 10wt% sodium hydroxide solution, mix evenly and then heat, the heating temperature is 90°C, and the heating time is 3h, then wash with water, wash with alcohol, filter and dry to obtain the bagasse precursor.

[0055] (2) Take 1 g of the bagasse precursor prepared in step (1) and add it to 60 mL of water to disperse, add 1 mmol of sodium molybdate and 4 mmol of thiourea, adjust the pH to 7, stir and mix well, then carry out hydrothermal reaction, and the reaction temperature is 200 °C, the reaction time is 24h, the product is washed with water, washed with alcohol, filtered and dried.

[0056] (...

Embodiment 3

[0059] A kind of preparation method of molybdenum disulfide / carbon composite material, comprises steps as follows:

[0060] (1) Pretreatment of corn cob: crush 5 g of corn cob raw material, add 300 mL of potassium hydroxide solution with a concentration of 5 wt %, mix well and heat, the heating temperature is 100 ° C, and the heating time is 2 h, then wash with water, alcohol washing, filtering and drying to obtain the corn cob precursor.

[0061] (2) Add 1.5 g of the corncob precursor prepared in step (1) into 60 mL of water to disperse, then add 2 mmol of sodium molybdate and 8 mmol of L-cysteine, adjust the pH to 6, stir and mix evenly, and conduct hydrothermal Reaction, the reaction temperature is 160°C, the reaction time is 24h, and the product is washed with water, washed with alcohol, filtered and dried.

[0062] (3) The mixture prepared in step (2) was placed in a tube furnace and heated under argon at a heating temperature of 500° C. for a heating time of 5 hours. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com