Preparation method of nano-lithium titanate with particles uniformly dispersed in lithium-ion battery electrode material

A lithium-ion battery and nano-lithium titanate technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor discharge performance and shortening at high rates, shorten the transmission path, improve charge and discharge performance and cycle performance , the effect of good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

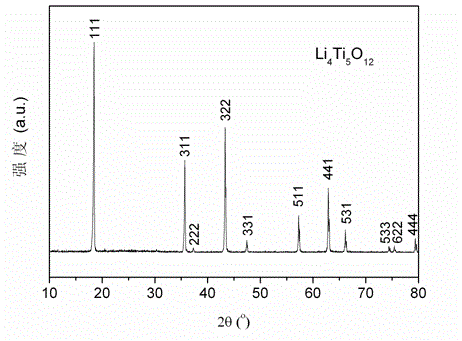

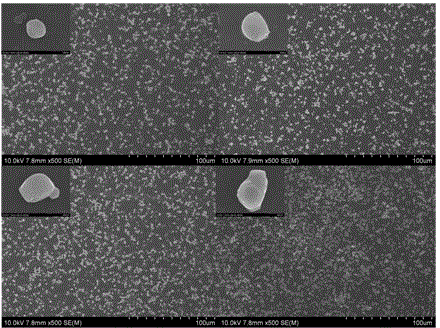

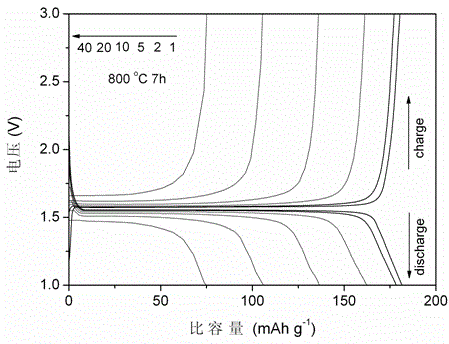

Embodiment 1

[0027] First, mix the slightly soluble or soluble compounds of lithium and titanium according to the molar ratio of Li:Ti=4.02:5, and weigh 19.97g of rutile TiO 2 , 7.426g of lithium lithium carbonate, and add agate balls as a ball milling medium, add 80mL of dehydrated alcohol as a solvent, then put into a planetary ball mill for ball milling for 10 hours, and the speed of ball milling is 400r / min; The material is taken out, put into the blast drying box and dry, the temperature is 80 ℃, then the gained Li 4 Ti 5 o 12 The precursor was calcined in a muffle furnace at 800 °C for 7 hours; then the prepared Li 4 Ti 5 o12 The powder is taken out and ground, and then 100g of powder is mixed with 200mL of water and put into an ultra-high-speed nano pulverizer for pulverization. The accelerated pulverized material collides, shears, and tears with the pulverizer in the pulverization chamber at a speed of 2000r / min, the pulverization time is 3 hours; Utilize peristaltic pump to ab...

Embodiment 2

[0030] First, mix the slightly soluble or soluble compounds of lithium and titanium according to the molar ratio of Li:Ti=4.04:5, and weigh 23.964g of rutile TiO 2 , the lithium lithium carbonate of 8.9111g, and add agate ball as ball milling medium, add the dehydrated alcohol of 100mL as solvent, put into planetary ball mill then and ball mill for 10 hours, the rotating speed of ball mill is 400r / min; The material is taken out, put into the blast drying box and dry, the temperature is 80 ℃, then the gained Li 4 Ti 5 o 12 The precursor was calcined in a muffle furnace at 800 °C for 7 hours; then the prepared Li 4 Ti 5 o 12 The powder is taken out and ground, and then 100g of powder is mixed with 200mL of water and put into an ultra-high-speed nano pulverizer for pulverization. The accelerated pulverized material collides, shears, and tears with the pulverizer in the pulverization chamber at a speed of 2000r / min, crushing time is 5 hours; Utilize peristaltic pump to above-...

Embodiment 3

[0032] Embodiment 3: First, the slightly soluble or soluble compounds of lithium and titanium are dosed according to the molar ratio of Li:Ti=4.04:5, and the anatase TiO of 19.97g is weighed 2 , 15.9167g of lithium acetate, and add agate balls as a ball milling medium, add 120mL of absolute ethanol as a solvent, then put it into a planetary ball mill and mill it for 10 hours at a speed of 500r / min; then mill the material in the jar Take it out, put it into a blast drying oven and dry it at a temperature of 80 ° C, and then the obtained Li 4 Ti 5 o 12 The precursor was put into a muffle furnace and calcined at 800°C for 12 hours; then the prepared Li 4 Ti 5 o 12 The powder is taken out and ground, and then 100g of powder is mixed with 200mL of water and put into an ultra-high-speed nano pulverizer for pulverization. The accelerated pulverized material collides, shears, and tears with the pulverizer in the pulverization chamber at a speed of 2500r / min, the pulverization tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com