Negative electrode for nonaqueous electrolyte secondary battery, and nonaqueous electrolyte secondary battery

A non-aqueous electrolyte, secondary battery technology, applied in non-aqueous electrolyte battery electrodes, battery electrodes, circuits, etc., can solve problems such as battery capacity reduction, and achieve the effect of high capacity and good fast charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

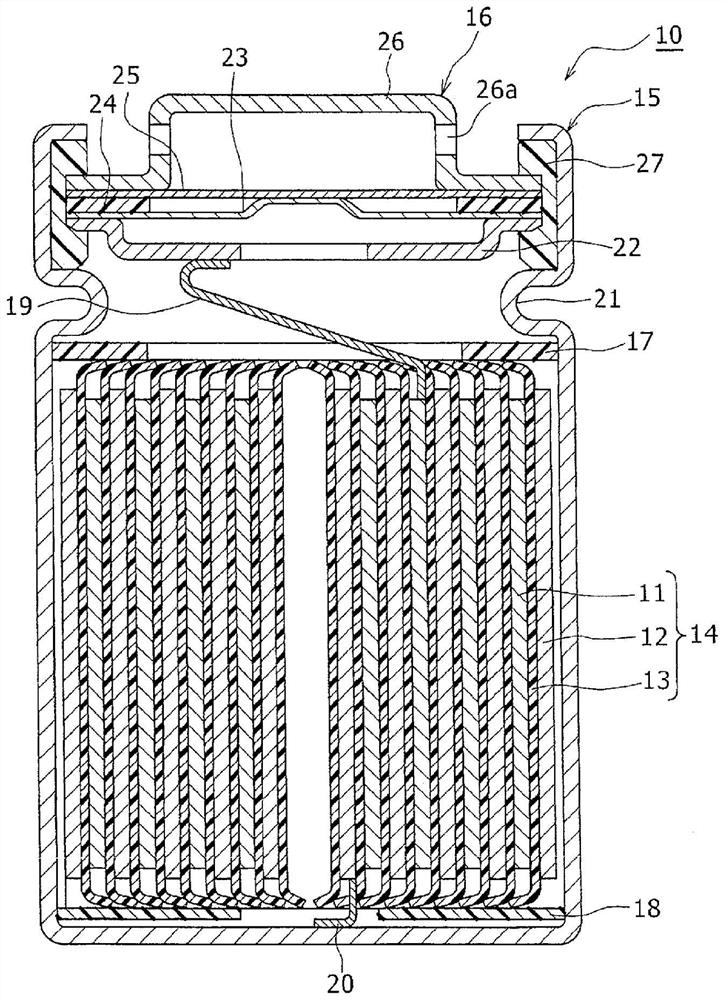

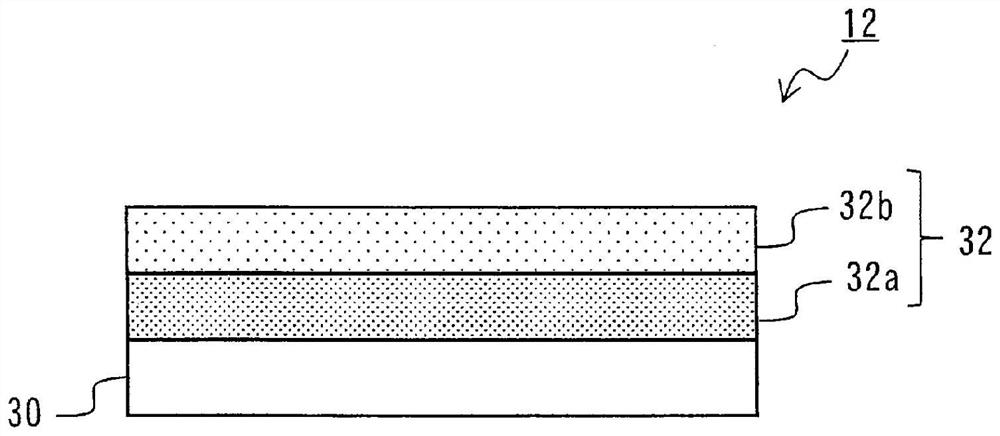

Embodiment 1

[0060] [Production of positive electrode]

[0061] As the positive electrode active material, lithium cobaltate (LiCoO) containing zirconium, magnesium, and aluminum was used. 0.979 Zr 0.001 Mg 0.01 Al 0.01 O 2 ). The above-mentioned positive electrode active material was mixed so that 95 parts by mass of the positive electrode active material, 2.5 parts by mass of the carbon powder as the conductive agent, and 2.5 parts by mass of the polyvinylidene fluoride powder as the binder were added, and an appropriate amount of N-methyl-2- Pyrrolidone (NMP) to prepare positive electrode mixture slurry. This slurry was applied to both sides of a positive electrode current collector made of aluminum foil (thickness: 15 μm) by a doctor blade method, the coating film was dried, and then the coating film was rolled with a calendering roll to produce a positive electrode current collector formed on both sides of the The positive electrode of the positive electrode mixture layer.

[0...

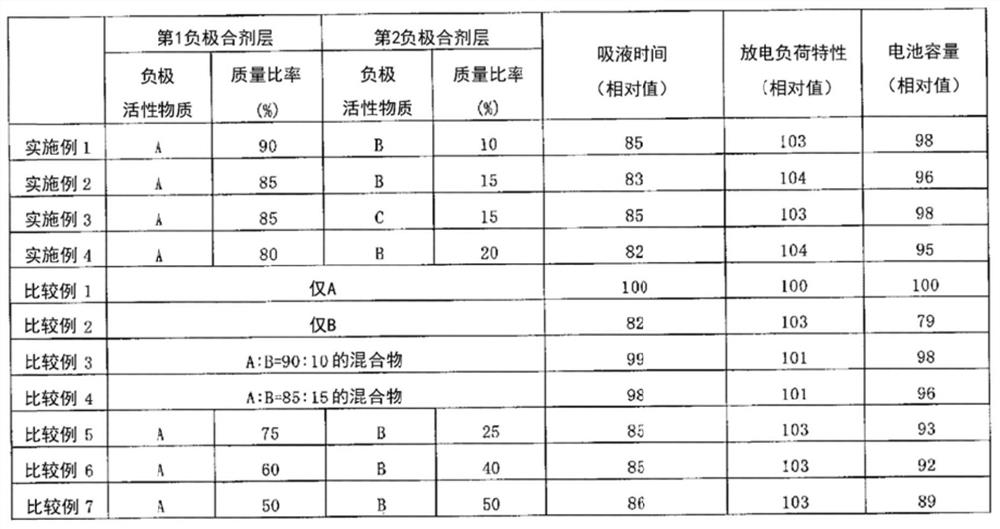

Embodiment 2、4

[0074]

[0075] As shown in Table 1, a non-aqueous electrolyte secondary battery was produced in the same manner as in Example 1, except that the mass ratio of the first negative electrode mixture layer and the second negative electrode mixture layer was changed.

Embodiment 3

[0077] A non-aqueous electrolyte secondary battery was produced in the same manner as in Example 2, except that the negative electrode active material C produced by mixing the carbon material C and SiO produced as follows was used instead of the negative electrode active material B.

[0078] [Production of carbon material C]

[0079] The coke was pulverized until the average particle diameter became 13 μm, and pitch as a binder was added to the pulverized coke to aggregate the coke until the average particle diameter became 18 μm. After firing the aggregate at a temperature of 1050°C, it was sieved using a 250-mesh sieve to obtain a carbon material C having an average particle diameter of 18 μm. The true density of the produced carbon material C was 1.9 g / cm as a result of measurement by the pycnometer method 3 .

[0080]

[0081] A nonaqueous electrolyte secondary battery was produced in the same manner as in Example 1, except that a single negative electrode mixture laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com