Olivine carbon bobbles composite material and use thereof

A composite material, olivine technology, applied in the direction of peroxide/peroxy hydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, non-metallic elements, etc., can solve the properties of difficult dispersion and interfacial ion transport Poor, the secondary lithium battery can not always maintain electronic contact and other problems, to achieve the effect of high power density, high safety, increased rate and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

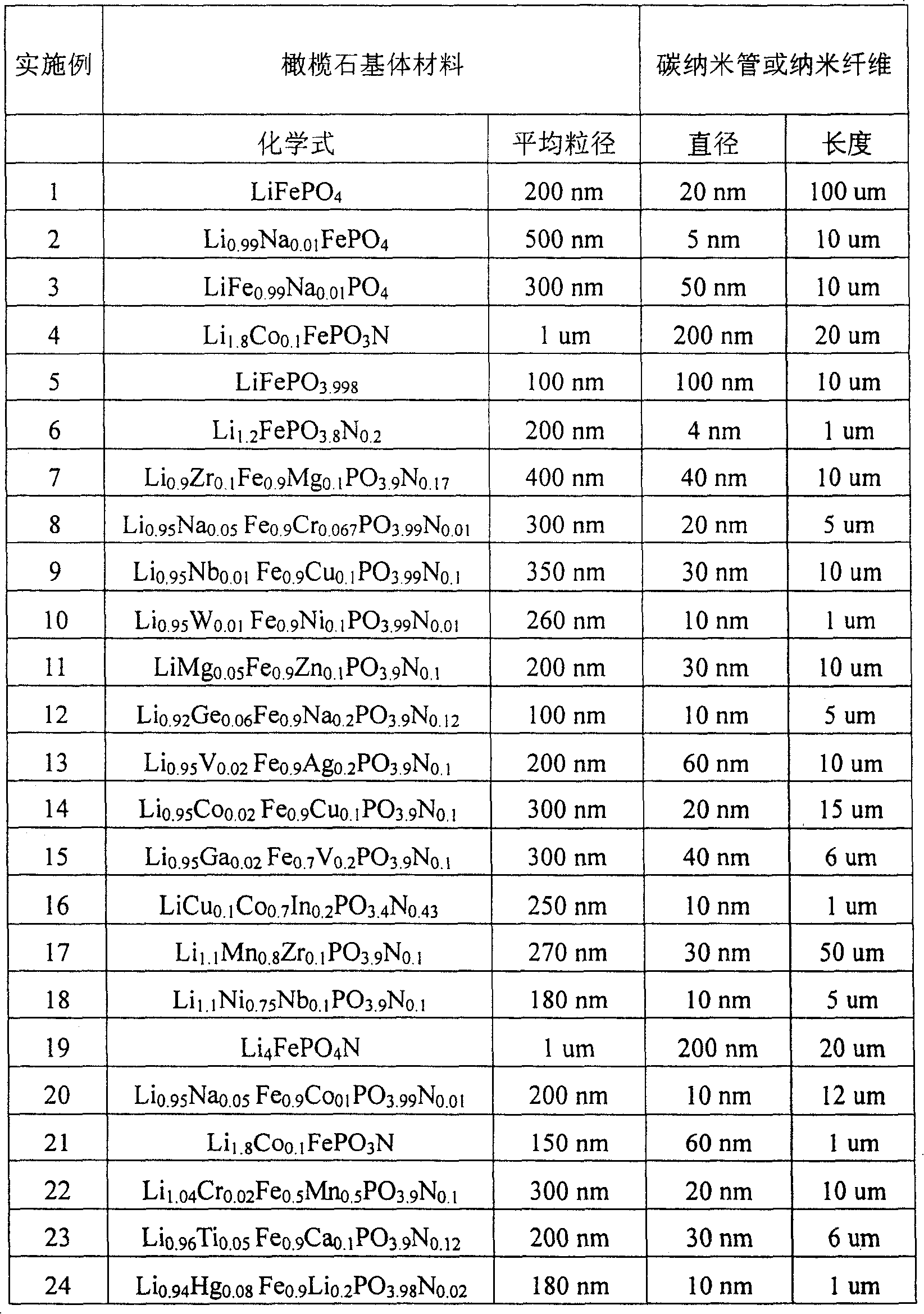

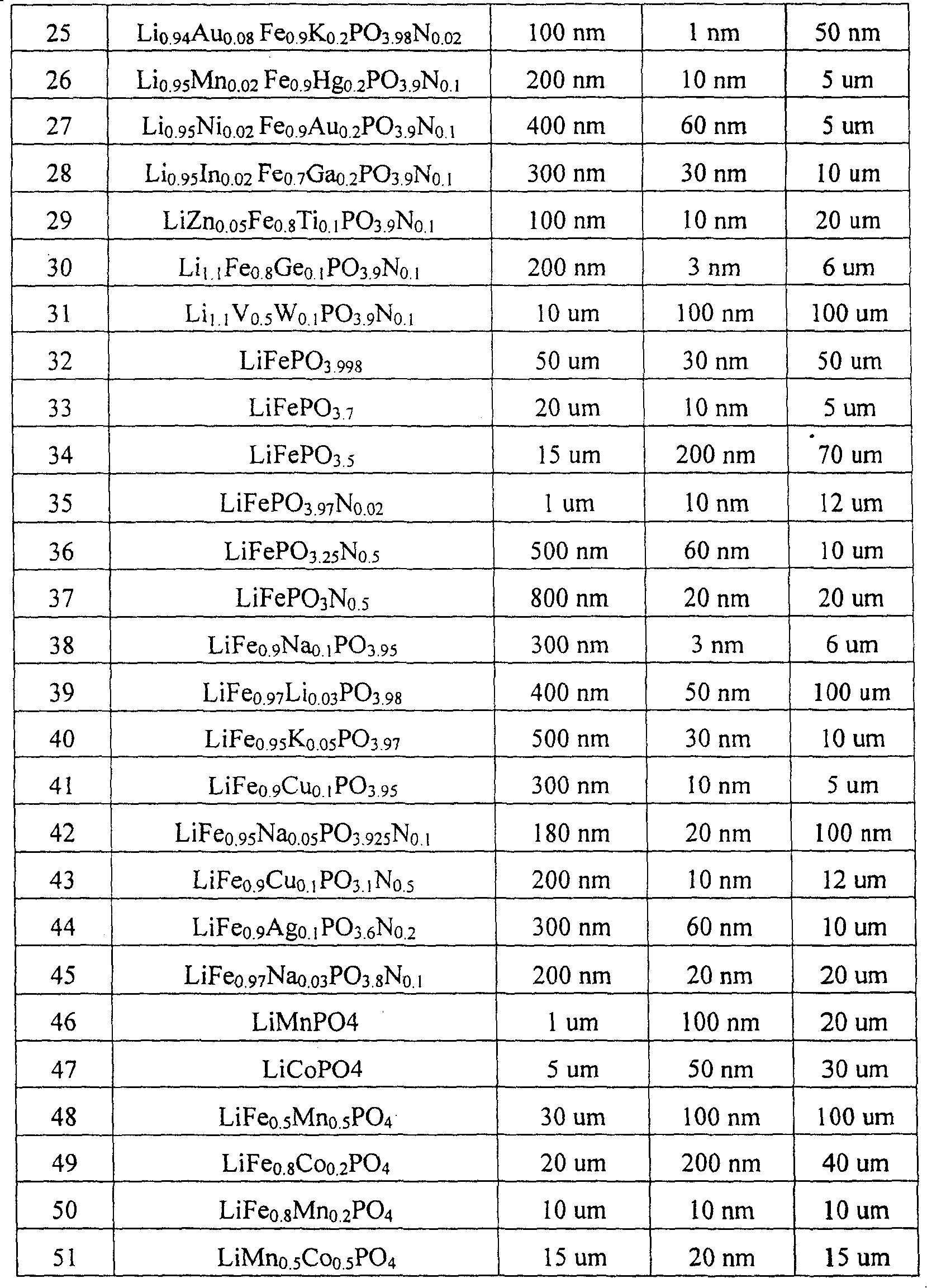

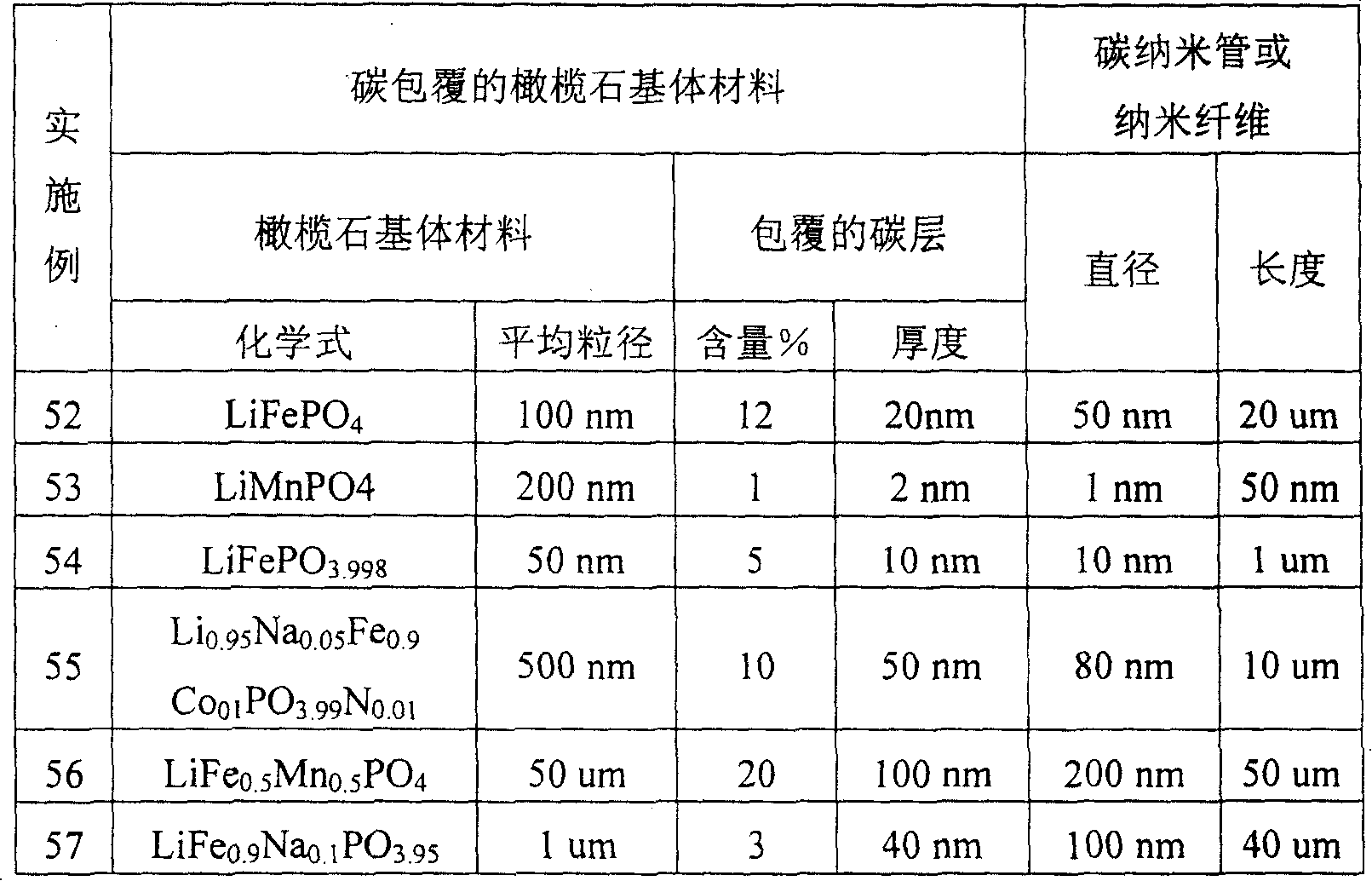

Examples

Embodiment 1

[0045] Embodiment 1, pure phase lithium iron phosphate carbon pompom composite material 1

[0046] Pure phase LiFePO 4 It can be prepared by a two-step solid-phase synthesis method by the following steps. First, weigh LiF, FeC according to the molar ratio 2 o 4 2H 2 O and NH 4 h 2 PO 4 (molar ratio is 1:1:1), after mechanical mixing (ball milling, rotating speed is 500 rev / min, 3 hours), this mixture is in high-purity Ar gas / H 2 Gas mixture (H 2 Gas volume ratio accounts for 8%) heat treatment under protection (the step of heat treatment is: take 1 hour to be warmed up to 400 ℃ from room temperature, after 4 hours at 400 ℃ constant temperature, drop to room temperature with two hours), again ball milling (rotating speed is 500 rev / minutes, 1 hour), the mixture was sintered again (the sintering step is: take 2 hours to raise the temperature from room temperature to 600 ° C, keep the temperature at 600 ° C for 8 hours, and use 3 hours to drop to room temperature. The pu...

Embodiment 2

[0051] Embodiment 2, doped lithium iron phosphate carbon pompom composite material 2

[0052] Doped lithium iron phosphate Li 0.99 Na 0.01 FePO 4 It can be prepared by the following steps (refer to Chinese patent 200410031151.x). First, weigh Li according to the molar ratio 2 CO 3 、Na 2 CO 3 , FeC 2 o 4 2H 2 O and NH 4 h 2 PO 4 , after mechanical ball milling (rotating speed is 500 rev / min, 3 hours), this mixture is in Ar-H 2 Mixed gas (Ar:H 2 =92:8, v / v) heat treatment under protection (the steps of heat treatment are: take 1 hour to heat up from room temperature to 500 ° C, after keeping the temperature at 500 ° C for 8 hours, use two hours to drop to room temperature), ball milling again (rotating speed is 500 rpm, 1 hour), the mixture is sintered again (the sintering step is: take 2 hours to raise the temperature from room temperature to 700 ° C, keep the temperature at 700 ° C for 24 hours, and use 3 hours to drop to room temperature). Obtained doped lithiu...

Embodiment 3

[0057] Embodiment 3, doped lithium iron phosphate carbon pompom composite material 3

[0058] Doped lithium iron phosphate LiFe 0.99 Na 0.01 PO 4 It can be prepared by the following steps (refer to Chinese patent 200410031151.x). First, weigh Li according to the molar ratio 2 CO 3 、Na 2 CO 3 , FeC 2 o 4 2H 2 O and NH 4 h 2 PO 4 , after mechanical ball milling (rotating speed is 500 rev / min, 3 hours), this mixture is in Ar-H 2 Mixed gas (Ar:H 2 =92:8, v / v) heat treatment under protection (the steps of heat treatment are: take 1 hour to raise the temperature from room temperature to 450 ° C, after keeping the temperature at 450 ° C for 8 hours, use 5 hours to drop to room temperature), ball milling again (rotating speed is 500 rpm, 1 hour), the mixture is sintered again (the sintering step is: take 2 hours to raise the temperature from room temperature to 800° C., keep the temperature at 800° C. for 24 hours, and then use 3 hours to cool down to room temperature). ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com