Nitrogen-doped graphene and Co3O4 hollow nanosphere composite material as well as preparation method and application of composite material

A technology of nitrogen-doped graphene and composite materials, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high cost, difficult preparation of oxygen reduction electrocatalyst, low activity, etc., and achieve multiple active sites , Improve the physical and chemical properties, the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

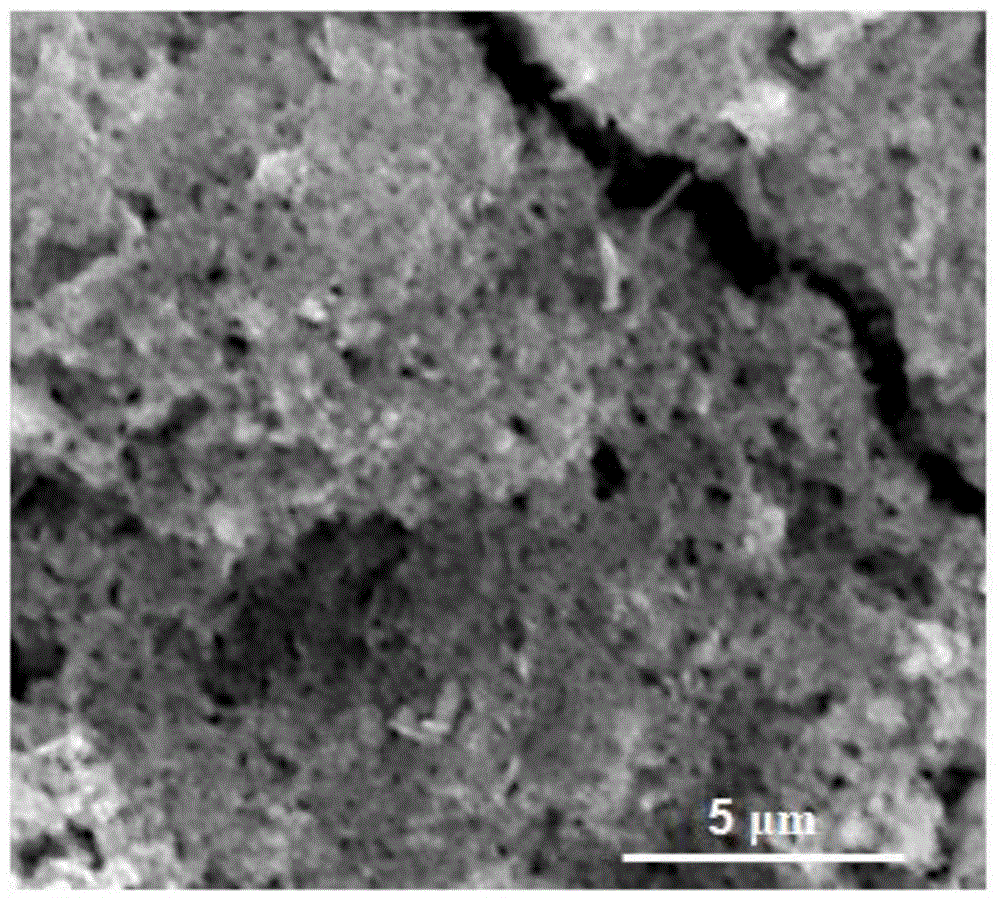

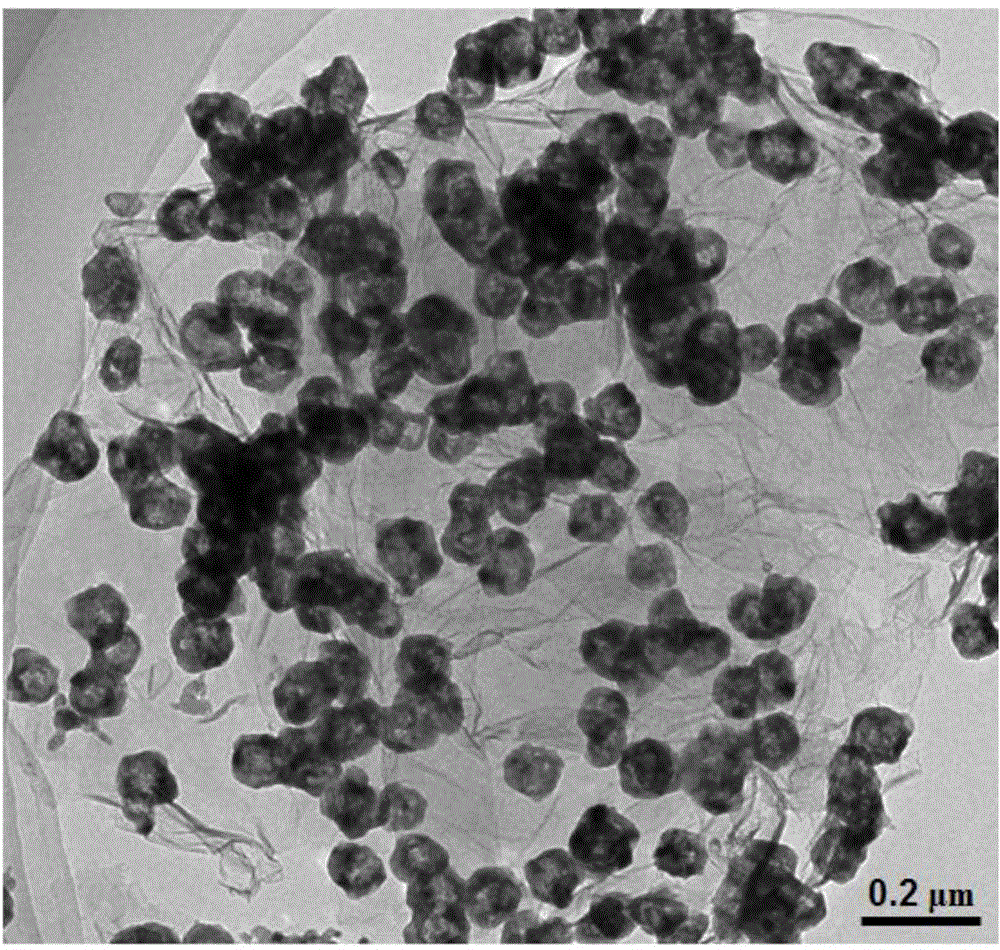

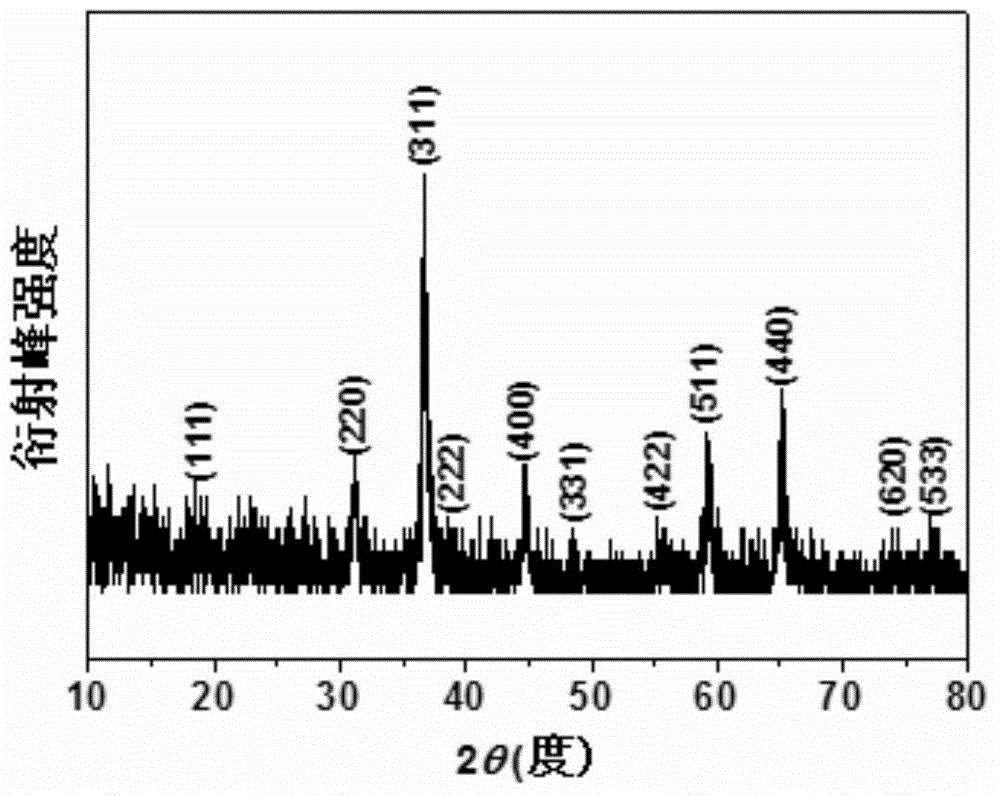

[0040] Preparation of nitrogen-doped graphene / Co 3 o 4 Hollow Nanosphere Composite

[0041] 1) Preparation of graphite oxide (GO) dispersion: Add 2g of colloidal graphite and 1g of sodium nitrate into 46mL of concentrated sulfuric acid cooled in an ice bath, slowly add 6g of potassium permanganate in portions, and keep stirring to keep the temperature of the reaction system below 20°C. Then the temperature was raised to about 35 °C and stirring was continued for 20 h. Add 92mL of deionized water, and the temperature of the reaction system rises rapidly. After stirring for 30 min, 142 mL of deionized water was added for dilution, and 6 mL of hydrogen peroxide (30%) was added to obtain a yellow dispersion. Suction filtration, washed with dilute hydrochloric acid (3.5%) until no SO 4 2- , and then washed with deionized water until neutral, and the resulting precipitate was vacuum-dried at 45°C for 24 hours to obtain graphite oxide. Ultrasonic disperse the prepared graphite...

Embodiment 2

[0050] Nitrogen-doped graphene / Co of the present invention 3 o 4 Lithium battery performance test of hollow nanosphere composites.

[0051] 1) Preparation of electrode sheet

[0052] Nitrogen-doped graphene / Co 3 o 4 Hollow nanosphere composite material, conductive carbon black and polyvinylidene fluoride (PVDF) are mixed at a mass ratio of 80:10:10, N-methylpyrrolidone is added to make a slurry, evenly coated on copper foil, and dried , made of electrode sheet.

[0053] 2) Battery assembly

[0054] The above-mentioned electrode sheet is used as the positive electrode of the half-cell, the lithium sheet is used as the negative electrode, and the Celgard-2400 porous membrane is used as the diaphragm, 1mol L -1 LiPF 6 Ethylene carbonate: dimethyl carbonate (volume ratio 1:1) was used as the electrolyte, and assembled into a CR2032 button cell in a glove box filled with argon.

[0055] 3) Battery performance test

[0056] Use Neware BTS battery tester for constant current...

Embodiment 3

[0058] Nitrogen-doped graphene / Co of the present invention 3 o 4 Electrocatalytic performance test of hollow nanosphere composites.

[0059] 1) Preparation of working electrode

[0060] A glassy carbon electrode with a diameter of 3 mm was polished to the mirror surface with aluminum oxide powder on the suede, ultrasonically cleaned with ethanol and deionized water for 5 min in turn, and dried naturally for use. The nitrogen-doped graphene / Co described in 1mg embodiment 2 3 o 4 Hollow nanosphere composites or commercial Pt / C catalysts were ultrasonically dispersed in 0.5mL Nafion ethanol solution (Nafion concentration was 0.05%). 5 μL of the catalyst dispersion was drop-coated on the surface of the prepared glassy carbon electrode, and dried naturally to prepare the working electrode with a catalyst loading of 141.6 μg cm -2 .

[0061] 2) Oxygen reduction electrocatalytic performance test

[0062] The catalyst-modified glassy carbon electrode is used as the working elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com