Preparation of doped cobaltic-cobaltous oxide

A technology of tricobalt tetroxide and cobalt hydroxide, which is applied in the field of preparation of doped tricobalt tetroxide to achieve good fluidity, stability and electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

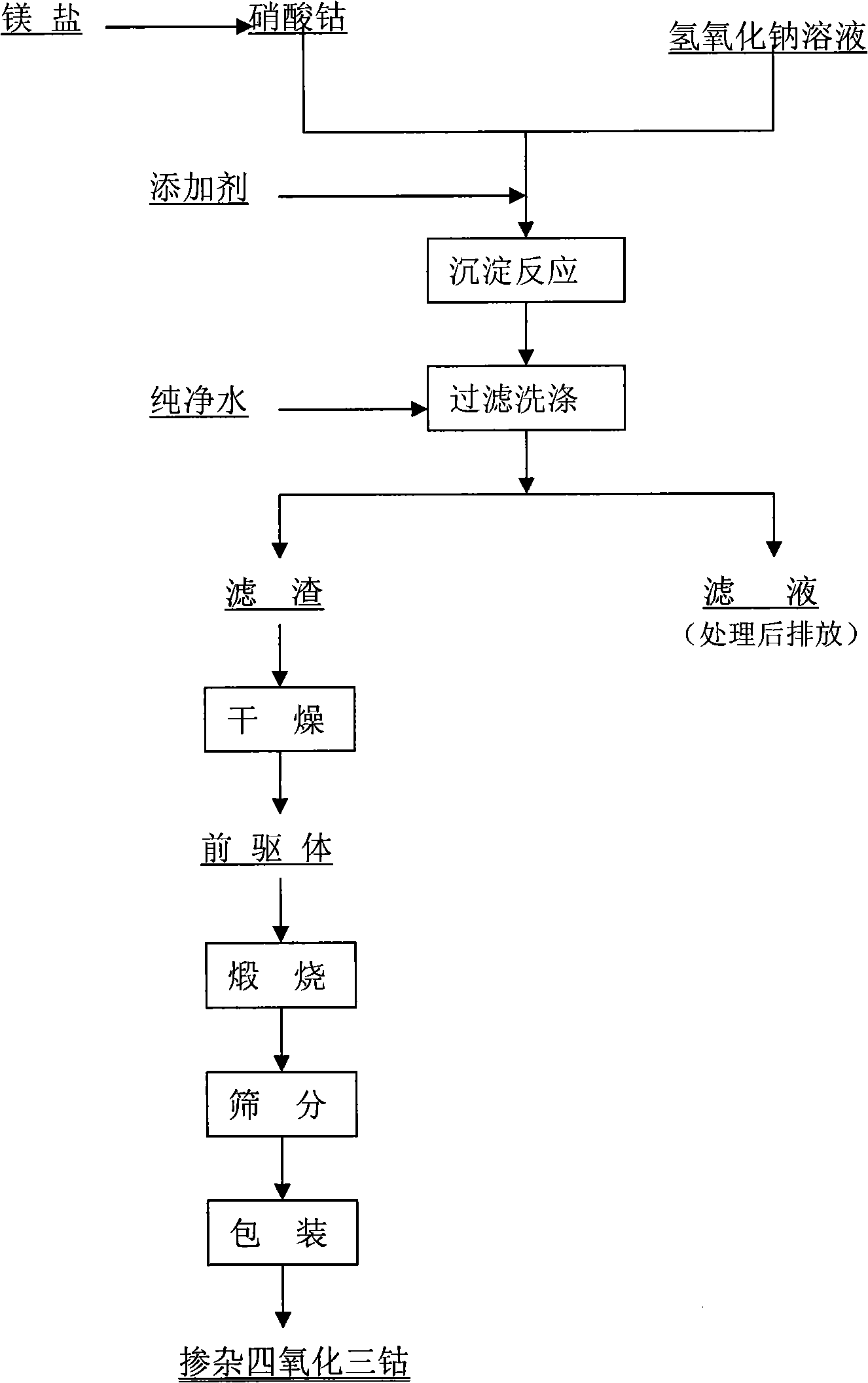

Method used

Image

Examples

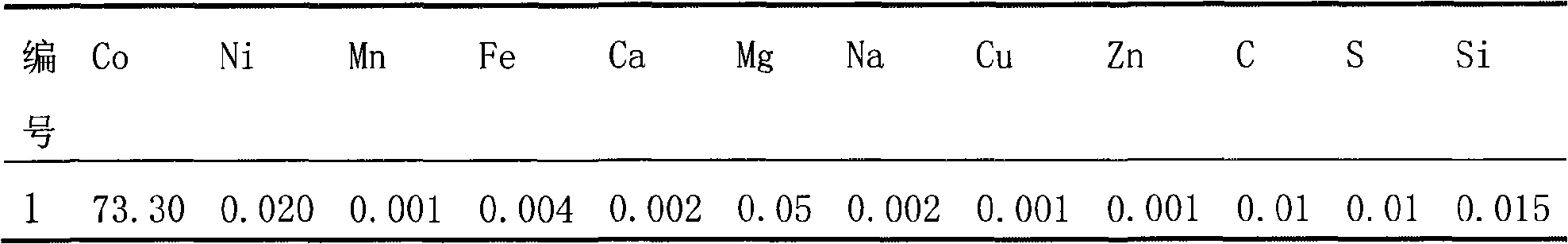

Embodiment 1

[0015] 1) preparation contains the cobalt nitrate solution of doping element ion, and the cobalt concentration in the solution is 80g / L, and the content of doping element magnesium is 0.06g / L; Ammonia is added in sodium hydroxide solution to make precipitant solution, and its precipitant Sodium hydroxide content is 100g / L in the solution, and ammoniacal liquor content is 20g / L.

[0016] 2) The cobalt nitrate solution containing the doping element ions and the precipitating agent solution are added to the reactor in a co-current manner to react, and the co-current volume ratio of the cobalt nitrate solution containing the doping element ions and the precipitating agent solution is 1: (1.1-1.3), the reaction pH value is 8.0-10.0, the reaction temperature is 60°C, and the reaction time is 10h.

[0017] 3) The reactant cobalt hydroxide was washed with pure water and then dried at 80°C; calcined at 650°C for three hours in an air atmosphere, and cooled in a furnace to obtain black ...

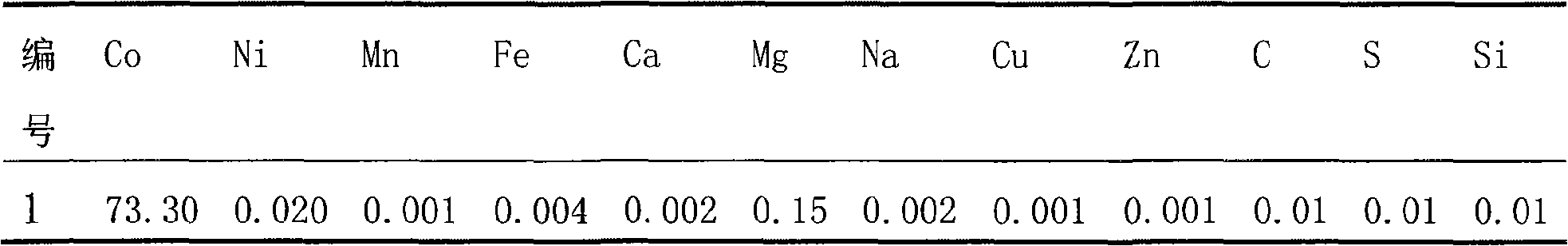

Embodiment 2

[0027] 1) preparation contains the cobalt nitrate solution of doping element ion, and in the solution, cobalt concentration is 80g / L, and doping element magnesium content is 0.17g / L; Ammonia is added in sodium hydroxide solution to make precipitant solution, and its precipitant Sodium hydroxide content is 100g / L in the solution, and ammoniacal liquor content is 20g / L.

[0028] 2) The cobalt nitrate solution containing the doping element ions and the precipitating agent solution are added to the reactor in a co-current manner to react, and the co-current volume ratio of the cobalt nitrate solution containing the doping element ions and the precipitating agent solution is 1: (1.1~1.3), the reaction pH value is 8.0-10.0, the reaction temperature is 60°C, and the reaction time is 10h.

[0029] 3) The reactant cobalt hydroxide was washed with pure water and dried at 80°C; calcined at 650°C for three hours in an air atmosphere, and cooled in a furnace to obtain black doped tricobalt...

Embodiment 3

[0039] 1) preparation contains the cobalt nitrate solution of doping element ion, and in the solution, cobalt concentration is 80g / L, and doping element aluminum content is 0.05g / L; Ammonia is added in sodium hydroxide solution to make precipitant solution, and its precipitant Sodium hydroxide content is 100g / L in the solution, and ammoniacal liquor content is 20g / L.

[0040] 2) The cobalt nitrate solution containing the doping element ions and the precipitating agent solution are added to the reactor in a co-current manner to react, and the co-current volume ratio of the cobalt nitrate solution containing the doping element ions and the precipitating agent solution is 1: (1.1~1.3), the reaction pH value is 8.0-10.0, the reaction temperature is 60°C, and the reaction time is 10h.

[0041] 3) The reactant cobalt hydroxide was washed with pure water and then dried at 80°C; calcined at 650°C for three hours in an air atmosphere, and cooled in a furnace to obtain black doped trico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Loose specific gravity | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com