Method of synthesizing mesoporous nickel cobalt oxide nanowire using hydrothermal method and application thereof

A technology of nickel cobaltate and nanowires, which is applied in the field of electrochemical energy storage, can solve the problems of high energy consumption, long reaction time, and easy introduction of impurities, and achieve high specific surface area, simple operation, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) 0.64g CoCl 2 ·6H 2 O, 0.32g NiCl 2 ·6H 2 O with 1.20g CO(NH 2 ) 2 Dissolve in 50ml deionized water, stir thoroughly with a magnetic stirrer to make the solution evenly mixed.

[0027] (2) Transfer the mixed solution in step (1) to a polytetrafluoroethylene-lined autoclave, heat to 100 °C, and keep the temperature constant for 10 hours to obtain a precursor solution.

[0028] (3) After the reactor is cooled to room temperature, filter the precursor solution obtained in step (2) to collect the precursor. Wash thoroughly with deionized water and dry in an oven at 60 °C to prepare the precursor.

[0029] (4) The dry precursor prepared in step (3) was placed in a muffle furnace and annealed at 250°C for 2 hours in an air atmosphere to obtain nickel cobaltate nanowires.

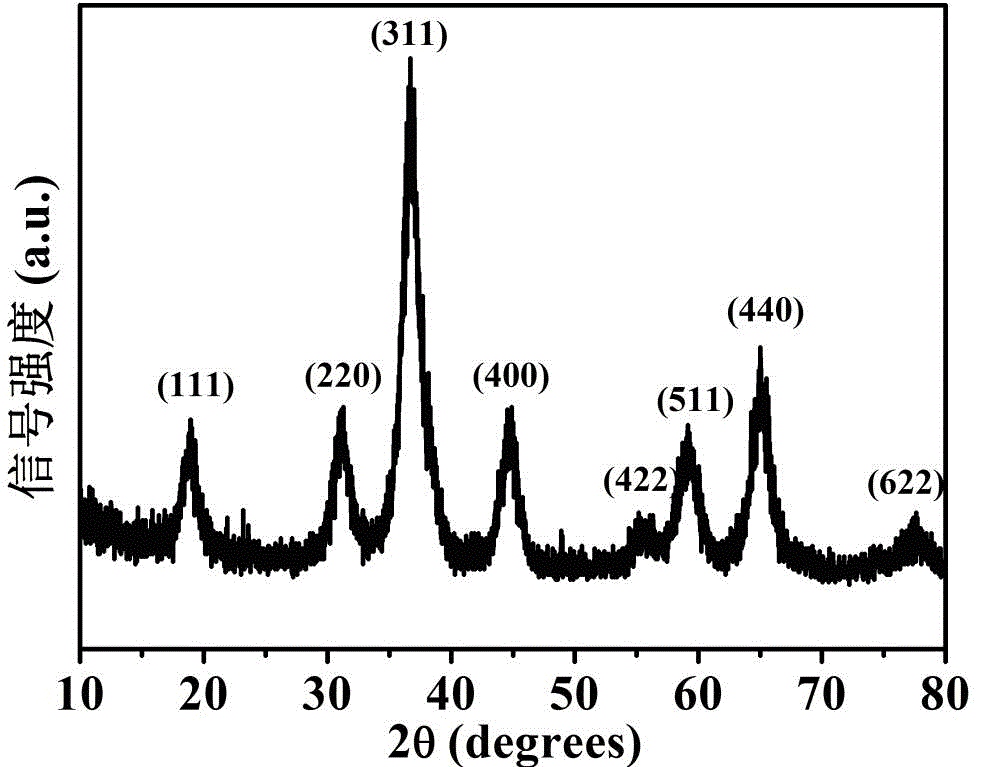

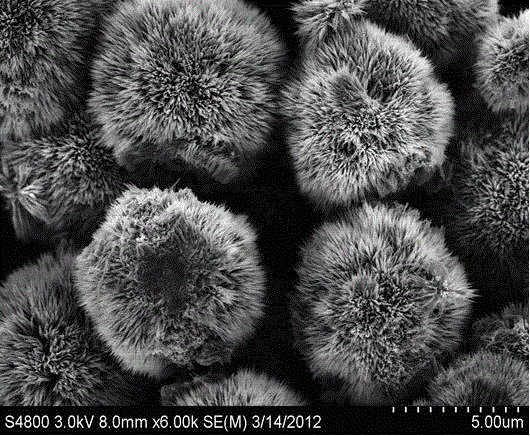

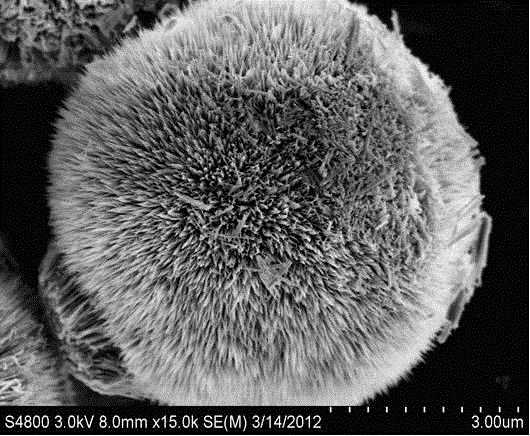

[0030] (5) The nickel cobaltate nanowires obtained in step (4) were characterized and tested for electrochemical properties. The results show that the nickel cobalt oxide nanowires synthesized by...

Embodiment 2

[0032] (1) 0.64g CoCl 2 ·6H 2 O, 0.32g NiCl 2 ·6H 2 O with 1.20g CO(NH 2 ) 2 Dissolve in 50ml deionized water, stir thoroughly with a magnetic stirrer to make the solution evenly mixed.

[0033] (2) Transfer the mixed solution in step (1) to a polytetrafluoroethylene-lined autoclave, heat to 100 °C, and keep the temperature constant for 10 hours to obtain a precursor solution.

[0034] (3) After the reactor is cooled to room temperature, filter the precursor solution obtained in step (2) to collect the precursor. Wash thoroughly with deionized water and dry in an oven at 60 °C to prepare the precursor.

[0035] (4) The dry precursor prepared in step (3) was placed in a muffle furnace and annealed at 200°C for 2 hours in an air atmosphere to obtain nickel cobaltate nanowires.

Embodiment 3

[0037] (1) 0.64g CoCl 2 ·6H 2 O, 0.32g NiCl 2 ·6H 2 O with 1.20g CO(NH 2 ) 2 Dissolve in 50ml deionized water, stir thoroughly with a magnetic stirrer to make the solution evenly mixed.

[0038] (2) Transfer the mixed solution in step (1) to a polytetrafluoroethylene-lined autoclave, heat to 100 °C, and keep the temperature constant for 10 hours to obtain a precursor solution.

[0039] (3) After the reactor is cooled to room temperature, filter the precursor solution obtained in step (2) to collect the precursor. Wash thoroughly with deionized water and dry in an oven at 60 °C to prepare the precursor.

[0040] (4) The dry precursor prepared in step (3) was placed in a muffle furnace and annealed at 300°C for 2 hours in an air atmosphere to obtain nickel cobalt oxide nanowires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com