High-adhesion dip-coating water-based color matching finish paint and preparation method thereof

A high-adhesion, water-based technology, used in the field of wood paint, can solve the problem of high VOC emissions, reduce VOC emissions, improve construction safety, and achieve good leveling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

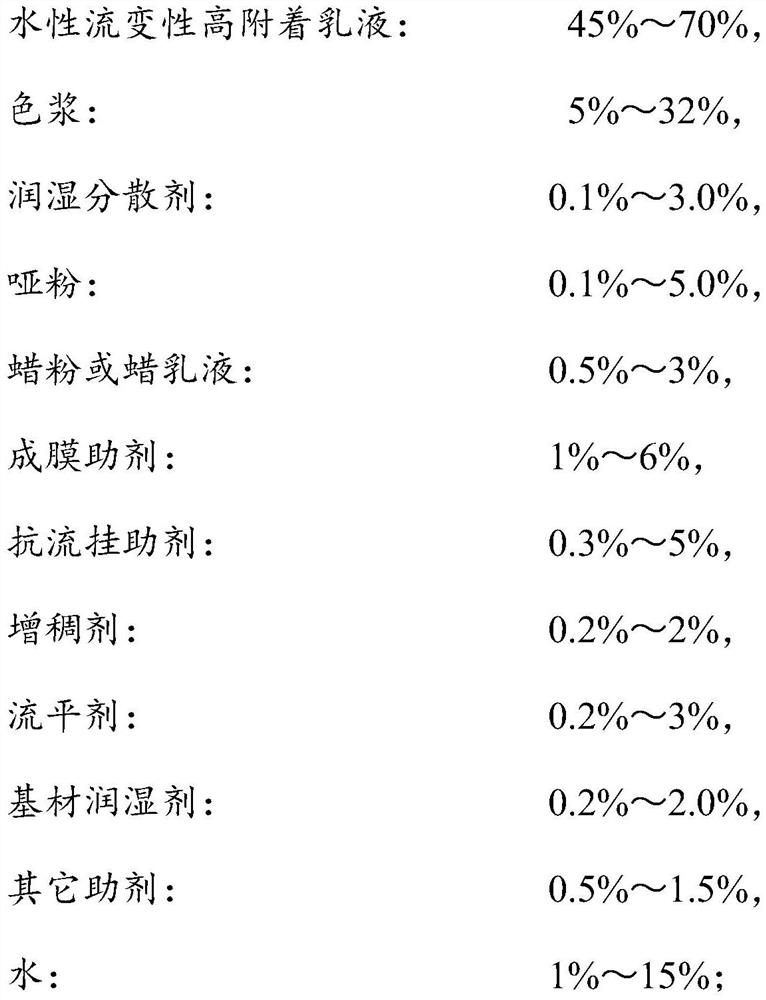

Method used

Image

Examples

Embodiment 1

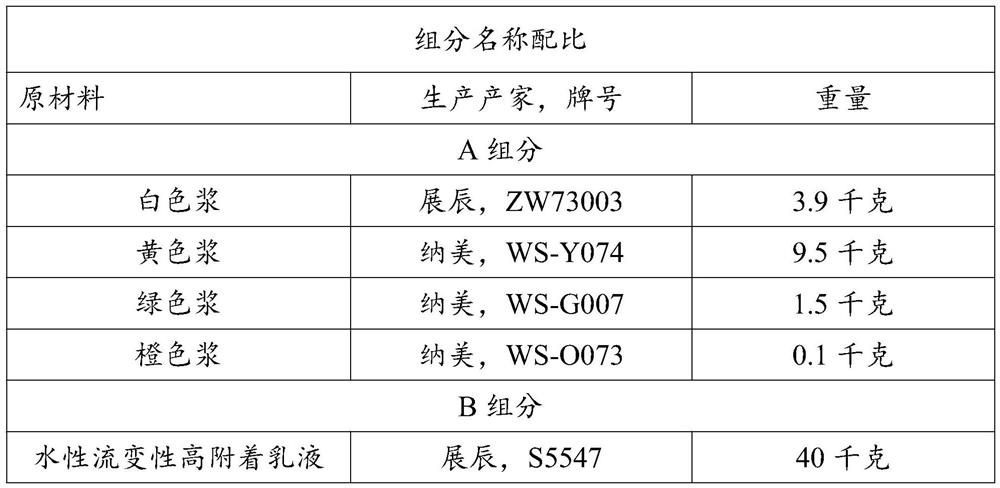

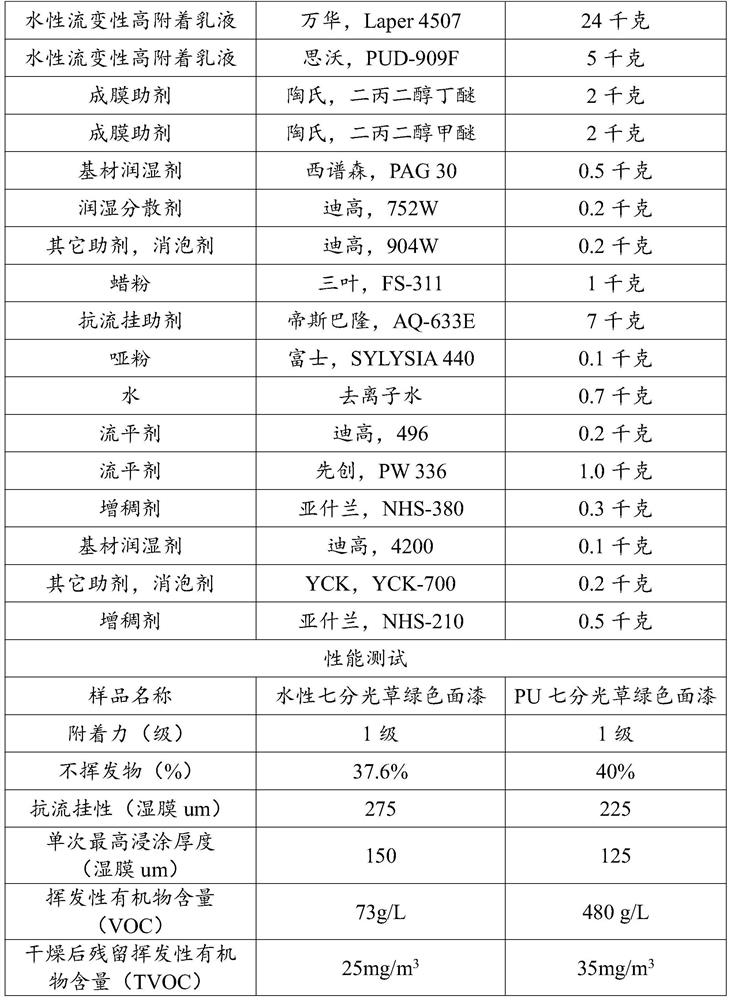

[0027] Component name proportioning and performance test of table 1 embodiment 1

[0028]

[0029]

[0030] The raw material components of the water-based seven-point light grass green finish paint of embodiment 1 are shown in Table 1, and its preparation method is:

[0031] (1) Disperse and add various types of color pastes of component A at 400 rpm, and disperse for 20 minutes until uniform for later use; (2) Disperse the water-based rheological High adhesion emulsion, wetting and dispersing agent, matte powder, wax powder or wax emulsion, film-forming aid, anti-sagging aid, thickener, leveling agent, substrate wetting agent and other additives mentioned above are added to the reaction In the container; (3) adjust the stirring rate to 1000 rpm and disperse for 30 minutes until uniform, the fineness is qualified and there is no oil shrinkage, adjust the viscosity with the water; (3) adjust the stirring rate to 500 rpm Next, add the color paste to the mixture in step (2...

Embodiment 2

[0034] Component name proportioning and performance test of table 2 embodiment 2

[0035]

[0036]

[0037] The raw material components of the water-based six-spectrum Chinese red finish paint of embodiment 2 are shown in Table 2, and its preparation method is: (1) the various types of colorants of A component are dispersed and added successively at 500 rpm, and dispersed for 15 minutes to (2) under stirring and dispersing at a rotating speed of 900 rpm, the aqueous rheological high-adhesion emulsion, wetting and dispersing agent, matte powder, wax powder or wax emulsion, film-forming aid, anti-sagging Auxiliaries, thickeners, leveling agents, substrate wetting agents and other auxiliaries are added to the reaction vessel; (2) the stirring rate is adjusted to 1200 rpm and dispersed for 15 minutes until uniform, the fineness is qualified and there is no Oil shrinkage, adjusted to a suitable viscosity with the water; (3) adjust the stirring rate to 600 rpm, add the color p...

Embodiment 3

[0040] Component name proportioning and performance test of table 3 embodiment 3

[0041]

[0042]

[0043] The raw material components of the water-based seven-split black finish paint of Example 3 are shown in Table 3, and its preparation method is: (1) disperse and add various types of colorants of component A at 600 rpm, and disperse for 10 minutes until uniform Standby; (2) Under stirring and dispersing at a rotating speed of 600 rpm, the water-based rheological high adhesion emulsion, wetting and dispersing agent, matte powder, wax powder or wax emulsion, film-forming aid, anti-sagging aid, etc. Add additives, thickeners, leveling agents, substrate wetting agents and other additives into the reaction vessel; (2) adjust the stirring speed to 900 rpm and disperse for 20 minutes until uniform, fineness is acceptable and oil-free shrink, use the water to adjust to a suitable viscosity; (3) adjust the stirring rate to 4000 rpm, add the color paste to the mixture in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com