Organic silicon pouring sealant and preparation method thereof

A technology of silicone potting glue and base glue, applied in adhesives, photovoltaic power generation, adhesive additives, etc., can solve the problems of silicone potting glue, poor mechanical properties, poor thermal conductivity, etc., and improve the outdoor service life , good protection, high anti-UV effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

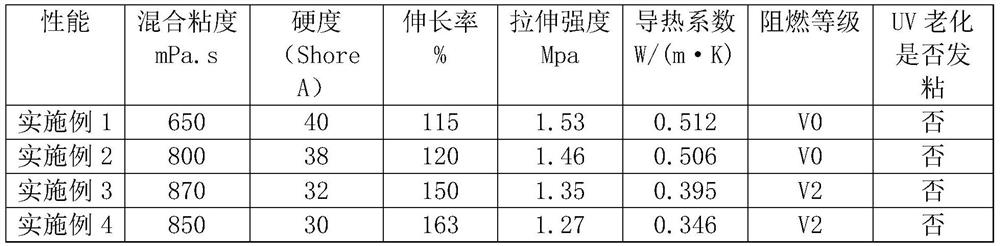

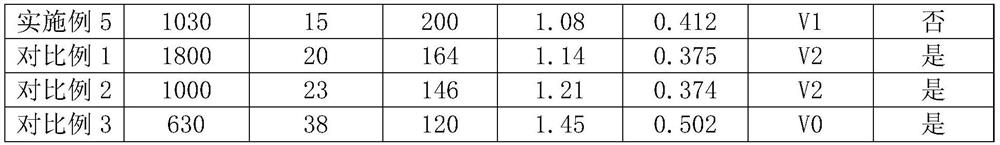

Examples

preparation example Construction

[0033] The preparation method of the above-mentioned silicone potting compound comprises the following steps:

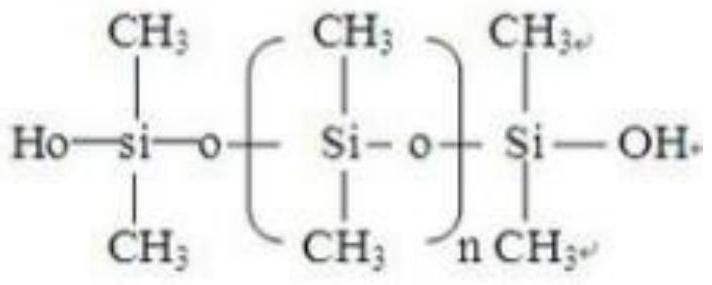

[0034] (1) Add double-terminated hydroxyl polydisiloxane B and semi-reinforcing filler into the dispersion container, raise the temperature to 110-125°C and blend for 30-90 minutes, after the blending, let stand and cool to below 50°C, grind , to obtain base glue;

[0035] (2) Add the base glue obtained in step (1), double-terminated hydroxyl polydisiloxane A, liquid MQ resin, plasticizer A, pigment and deep curing agent into the high-speed dispersion kettle, stir evenly, evacuate, cool, Component A can be obtained;

[0036] (3) Add crosslinking agent, coupling agent, organotin catalyst and plasticizer B into the kettle, stir evenly, after aging, filter out the precipitate to obtain component B;

[0037] (4) Mix component A and component B evenly, and obtain the silicone potting glue after defoaming.

[0038] Preferably, the mass ratio of base gum to double-terminat...

Embodiment 1

[0045] A silicone potting glue, its preparation raw materials include component A and component B, the preparation raw materials of said component A include in parts by mass: base glue 100 parts by mass, double-terminated hydroxyl polydisiloxane A 28.6 Parts by mass, 12.8 parts by mass of liquid MQ resin, 9.6 parts by mass of dimethyl silicone oil (viscosity 100mPa.s), 1.3 parts by mass of carbon black slurry and 1.2 parts by mass of deep curing agent; the raw materials for the preparation of component B are in parts by mass Including: 40 parts by mass of phenyltrimethoxysilane, 20 parts by mass of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, 0.5 parts by mass of dibutyltin dilaurate, 100 parts by mass of dimethyl Silicone oil (viscosity 100mPa.s); the raw materials for the preparation of the base rubber include: double-terminated hydroxyl polydisiloxane B and aluminum hydroxide, and the mass ratio of the two is 100:180. The viscosities of the double-terminated hydroxyl pol...

Embodiment 2

[0052] A silicone potting glue, its preparation raw materials include component A and component B, the preparation raw materials of said component A include in parts by mass: base glue 100 parts by mass, double-terminated hydroxyl polydisiloxane A 28.6 Parts by mass, 12.8 parts by mass of liquid MQ resin, 9.6 parts by mass of dimethyl silicone oil (viscosity 100mPa.s), 1.3 parts by mass of carbon black slurry and 1.2 parts by mass of deep curing agent; the raw materials for the preparation of component B are in parts by mass Including: 35 parts by mass of phenyltrimethoxysilane, 20 parts by mass of N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane, 0.5 parts by mass of dibutyltin dilaurate, 100 parts by mass of dimethyl Silicone oil (viscosity: 100 mPa.s); the raw materials for the preparation of the gum base include: double-terminated hydroxyl polydisiloxane B and aluminum hydroxide, and the mass ratio of the two is 100:180. The viscosities of the double-terminated hydroxyl poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com