Assembly type single-flange beam column bolt joint connecting device provided with cover plates

A single-bolt joint technology with a cover plate, which is applied in the direction of architecture and building construction, can solve the problems affecting the mechanical performance of joints, large residual stress, poor joint ductility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

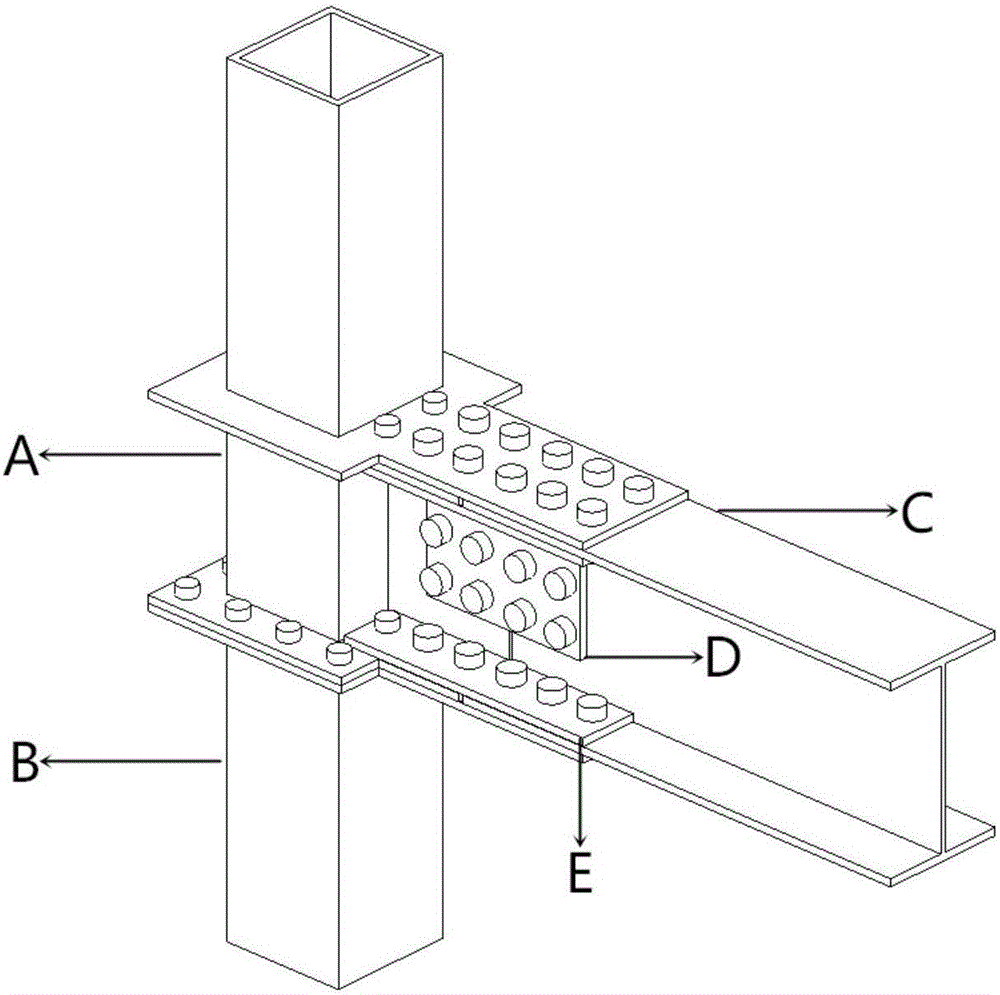

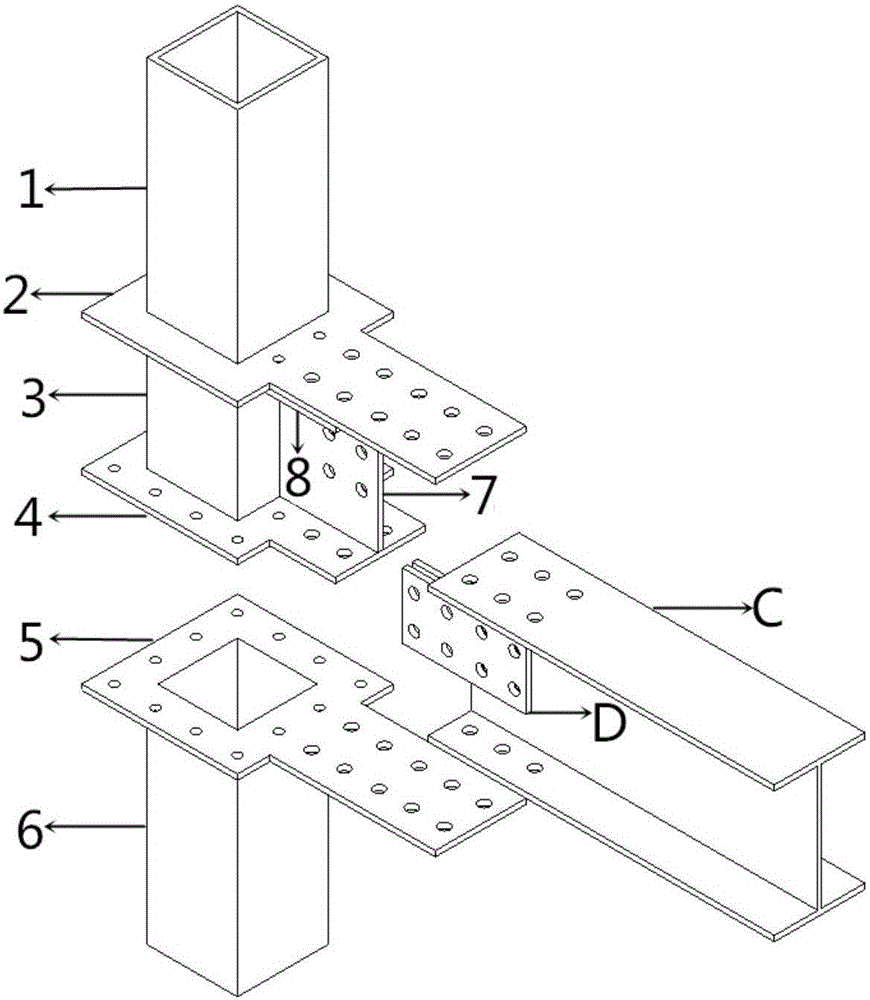

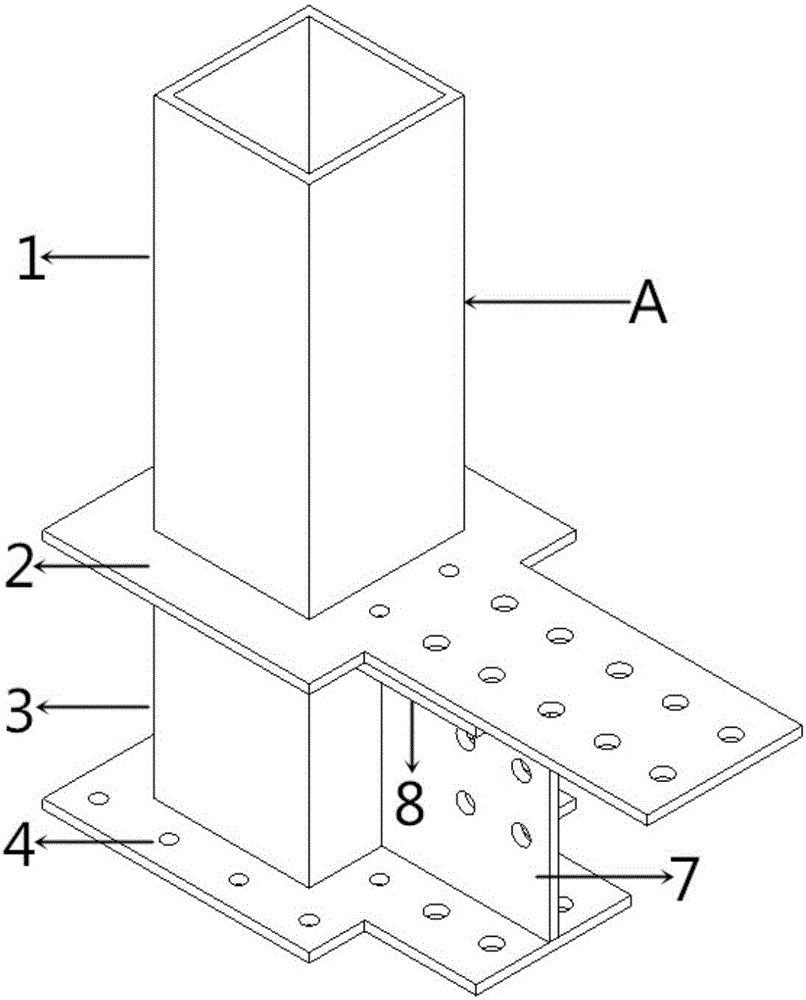

[0025] The specific connection mode of the beam-column node of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] as attached Figure 1-7 As shown, the outer ribs (2) and the first flange (4) of the short column of the node are respectively welded to the lower ends of the first square steel pipe column (1) and the second square steel pipe column (3) of the node, forming the upper column A The second flange plate (5) of the node short column is welded on the upper end of the third-party steel pipe column (6) to form the lower column B; the H-shaped steel beam C, the pasting plate D, the splint E and the upper and lower column flanges The holes are prefabricated in the factory. The structures B and A, B and C are connected by splint E and single or multiple rows of bolts, and A and C are connected by pasting plate D and single or multiple rows of bolts. The size of the bolts is based on It depends.

[0027] The above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com