Magnesium alloy automobile hub casting spinning compound molding method

A technology for composite forming of automobile wheels, which is applied in the field of casting and spinning composite forming of magnesium alloy automobile wheels, can solve the problems of poor strength and toughness of the wheels, and achieve the effects of low production cost, high material utilization rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

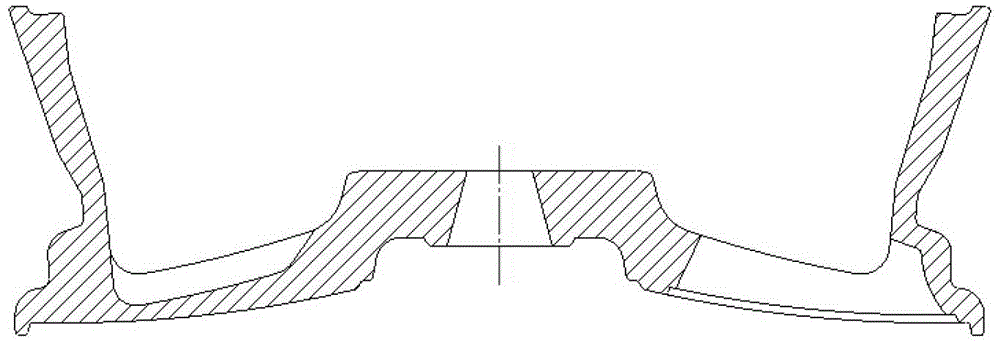

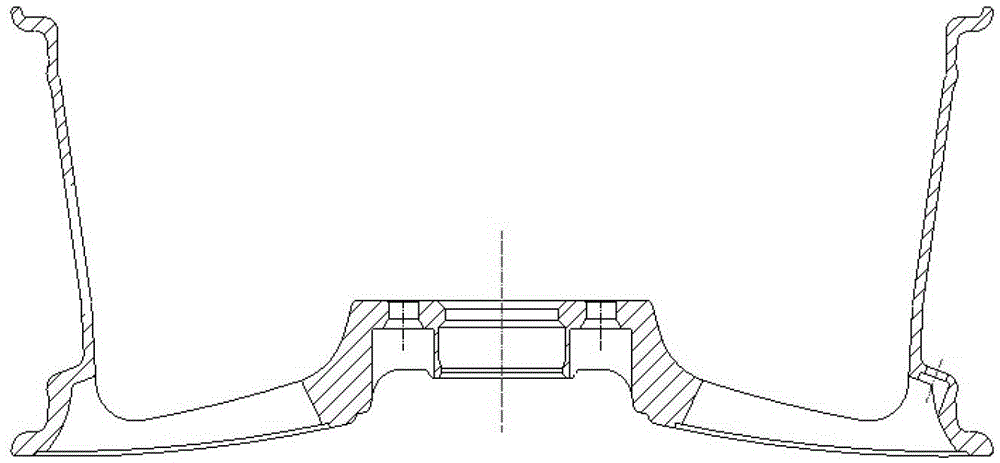

Image

Examples

Embodiment 1

[0036] In this embodiment, the magnesium alloy used is Mg-Zn-Al-Mn series magnesium alloy, and its alloy composition and weight content are as follows: Zn: 6.2; Al: 1.2; Mn: 0.3; Mg balance.

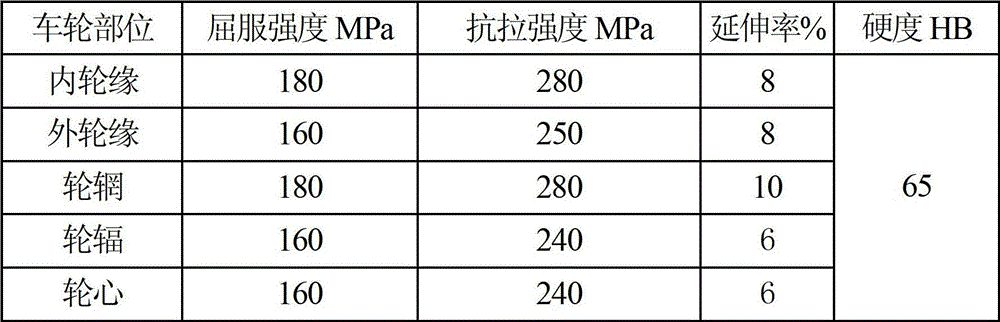

[0037] The average mechanical properties of the as-cast alloy of the Mg-Zn-Al-Mn series magnesium alloy are as follows:

[0038] Tensile strength σ b 300MPa, yield strength σ 0.2 180MPa, elongation δ11%, the performance of spokes and rims can fully meet the application requirements of automobile wheels.

[0039] The magnesium alloy automobile wheel hub casting spinning composite forming method that the present invention adopts, concrete steps are as follows:

[0040] 1) Put a certain amount of magnesium alloy ingots for automobile wheels into the preheating furnace for preheating, the temperature of the preheating furnace is 370°C, and the preheating time is 1.5h, and then put the preheated magnesium alloy ingots into the crucible of the melting furnace , heating and melting, refining a...

Embodiment 2

[0048] In this embodiment, the magnesium alloy used is Mg-Zn-Al-Mn series magnesium alloy, and its alloy composition and weight content are as follows: Zn: 6.0; Al: 1.5; Mn: 0.2; Mg balance.

[0049] The average mechanical properties of the as-cast alloy of the Mg-Zn-Al-Mn series magnesium alloy are as follows:

[0050] Tensile strength σ b 290MPa, yield strength σ 0.2 190MPa, elongation δ8%, the performance of spokes and rims can fully meet the application requirements of automobile wheels.

[0051] The magnesium alloy automobile wheel hub casting spinning composite forming method that the present invention adopts, concrete steps are as follows:

[0052] 1) Put a certain amount of magnesium alloy ingots for automobile wheels into the preheating furnace for preheating. The temperature of the preheating furnace is 350°C and the preheating time is 2 hours. Then put the preheated magnesium alloy ingots into the crucible of the melting furnace. Heating and melting, refining and...

Embodiment 3

[0060] In this embodiment, the magnesium alloy used is Mg-Zn-Al-Mn series magnesium alloy, and its alloy composition and weight content are as follows: Zn: 6.5; Al: 1.0; Mn: 0.4; Mg balance.

[0061] The average mechanical properties of the as-cast alloy of the Mg-Zn-Al-Mn series magnesium alloy are as follows:

[0062] Tensile strength σ b 280MPa, yield strength σ 0.2 175MPa, elongation δ10%, the performance of spokes and rims can fully meet the application requirements of automobile wheels.

[0063] The magnesium alloy automobile wheel hub casting spinning composite forming method that the present invention adopts, concrete steps are as follows:

[0064] 1) Put a certain amount of magnesium alloy ingots for automobile wheels into the preheating furnace for preheating. The temperature of the preheating furnace is 400°C and the preheating time is 1h. Then put the preheated magnesium alloy ingots into the crucible of the melting furnace. Heating and melting, refining and deg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com