105 DEG C thermoplastic, halogen-free, low-smoke, fire-retardant and ultraviolet-resistant covering material capable of preventing mice and ants and resisting cracking and preparation method thereof

A low-smoke, flame-retardant, UV-resistant technology, which is applied in the direction of plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve the problems of easy cracking of halogen-free flame-retardant sheaths, and achieve good high-temperature cracking resistance. Advanced technology, scientific and reasonable proportioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

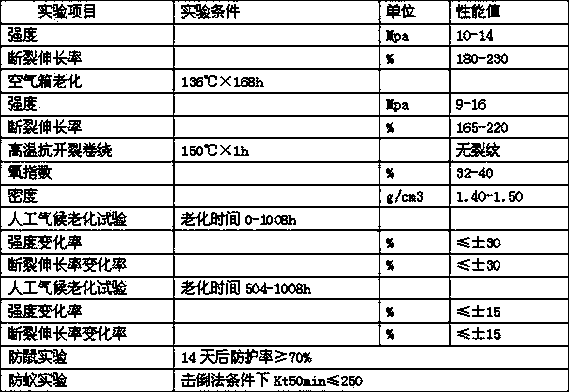

Image

Examples

Embodiment 1

[0059] 105℃ thermoplastic halogen-free, low-smoke, flame-retardant, UV-resistant, rodent-proof, anti-cracking type sheathing material, the raw materials include the following components by weight:

[0060] 30 parts of ethylene vinyl acetate copolymer (EVA) (the VA content of ethylene vinyl acetate copolymer is more than 28% and less than 50%),

[0061] Linear low density polyethylene (LLDPE) 15 parts,

[0062] 10 parts of high-density polyethylene (HDPE),

[0063] 25 parts of ethylene-octene copolymerized elastomer,

[0064] 20 parts of maleic anhydride grafting material,

[0065] 3 parts of silicone masterbatch,

[0066] 100 parts of aluminum hydroxide,

[0067] 20 parts of magnesium hydroxide,

[0068] Zinc borate 5 parts,

[0069] Nitrogen, phosphorus, intumescent type, flame retardant, 5 parts,

[0070] 1 part silicone oil,

[0072] Polyethylene wax 1.5 parts,

[0073] 2 parts of compound antioxidant,

[0074] 2.5 parts of light st...

Embodiment 2

[0081] 105℃ thermoplastic halogen-free, low-smoke, flame-retardant, UV-resistant, rodent-proof, anti-cracking type sheathing material, the raw materials include the following components by weight:

[0082] 60 parts of ethylene vinyl acetate copolymer (EVA) (the VA content of ethylene vinyl acetate copolymer is more than 28% and less than 50%),

[0083] Linear low density polyethylene (LLDPE) 50 parts,

[0084] 30 parts of high-density polyethylene (HDPE),

[0085] 30 parts of ethylene-octene copolymerized elastomer,

[0086] 30 parts of maleic anhydride grafting material,

[0087] 5 parts of silicone masterbatch,

[0088] 40 parts of aluminum hydroxide,

[0089] 60 parts of magnesium hydroxide,

[0090] 30 parts of zinc borate,

[0091] Nitrogen-phosphorus-expandable flame retardant 30 parts,

[0092] 1 part silicone oil,

[0093] Zinc stearate 1.5 parts,

[0094] Polyethylene wax 1.5 parts,

[0095] Composite antioxidant 4 parts,

[0096] 4 parts of light stabilize...

Embodiment 3

[0103] 105℃ thermoplastic halogen-free, low-smoke, flame-retardant, UV-resistant, rodent-proof, anti-cracking type sheathing material, the raw materials include the following components by weight:

[0104] 25 parts of ethylene vinyl acetate copolymer (EVA) (the VA content of ethylene vinyl acetate copolymer is greater than 28% and less than 50%),

[0105] Linear low density polyethylene (LLDPE) 20 parts,

[0106] 20 parts of high-density polyethylene (HDPE),

[0107] 15 parts of ethylene-octene copolymerized elastomer,

[0108] 20 parts of maleic anhydride grafting material,

[0109] 3 parts of silicone masterbatch,

[0110] 90 parts of aluminum hydroxide,

[0111] 25 parts of magnesium hydroxide,

[0112] Zinc borate 5 parts,

[0113] Nitrogen, phosphorus, intumescent type, flame retardant, 10 parts,

[0114] 1 part silicone oil,

[0115] 1 part zinc stearate,

[0116] Polyethylene wax 1.5 parts,

[0117] 2 parts of compound antioxidant,

[0118] 1.5 parts of light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com